Preparation and use methods of magnesium hydrate/reduced graphene oxide composite material

A magnesium hydroxide and composite material technology, applied in the field of materials, can solve the problems of toxicity, non-degradation, carcinogenicity, etc., and achieve the effects of reducing separation time, increasing adsorption effect, and rapid adsorption and degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1

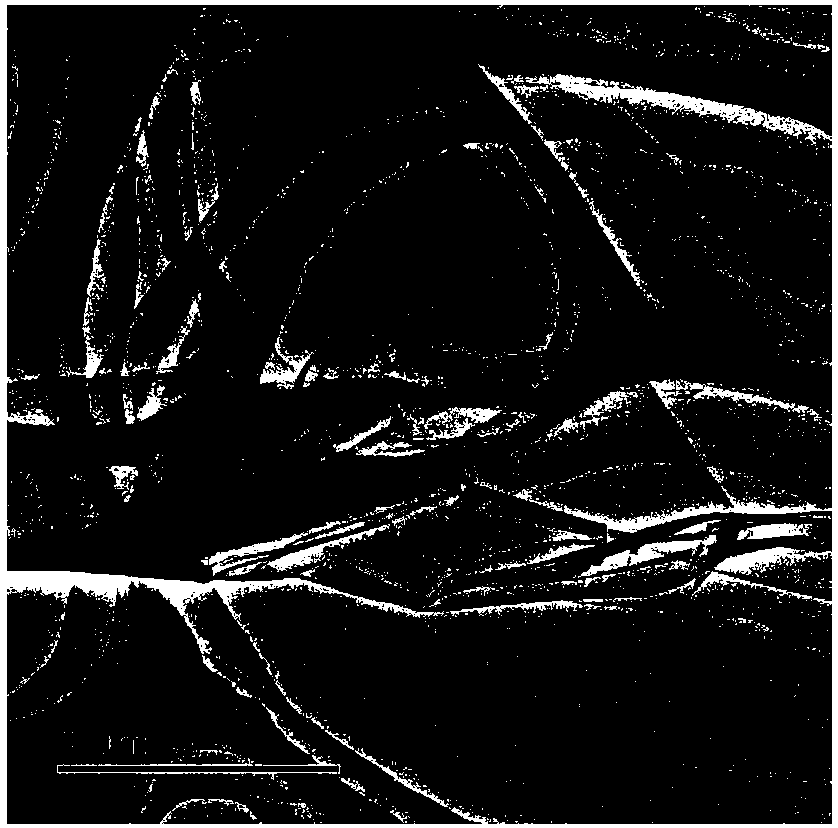

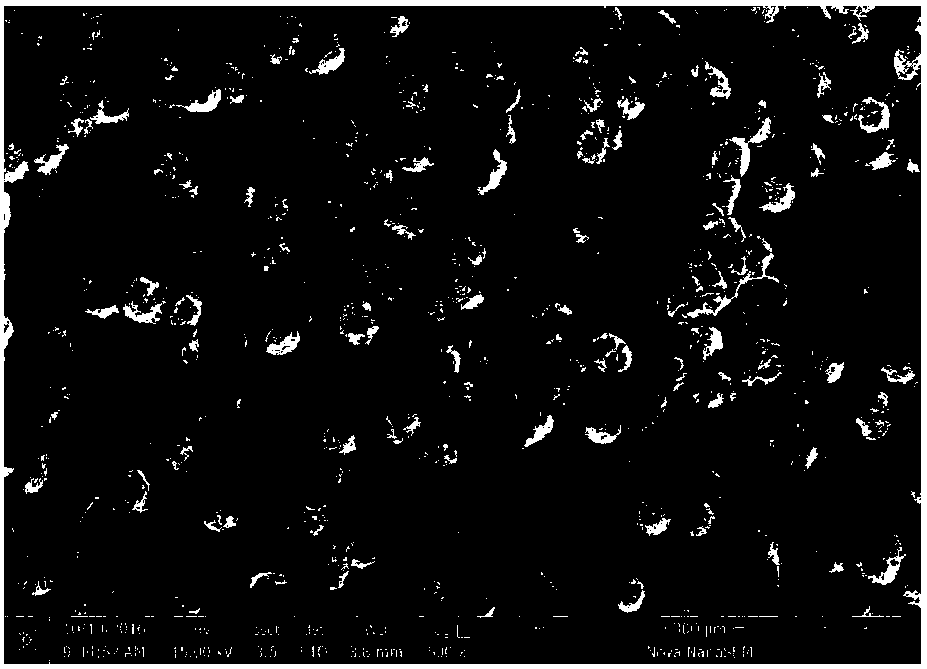

[0027] Preparation of High Efficiency Photocatalyst Magnesium Hydroxide / Reduced Graphene Oxide Composite

[0028] Step 1), prepare graphene oxide suspension: take 1-3 parts by mass of natural graphite, 50ml-150ml mass fraction of concentrated sulfuric acid with a mass fraction of 98%, and potassium permanganate of 7-21 parts by mass are added to the reactor in batches, Keep the reaction temperature at 0°C, stir vigorously for 2 hours, then raise the temperature to 50°C, and react for 10-12 hours; after cooling the reactant to room temperature, pour it into 30% mass fraction of H 2 o 2 In aqueous solution, the H 2 o 2 The aqueous solution is cooled with ice water; the reaction product is washed with 30% dilute hydrochloric acid, and then washed with ethanol and deionized water respectively, and the reaction product is centrifuged several times to obtain graphene oxide; directly disperse graphene oxide in water to obtain graphene oxide suspension Liquid, t...

Embodiment 2

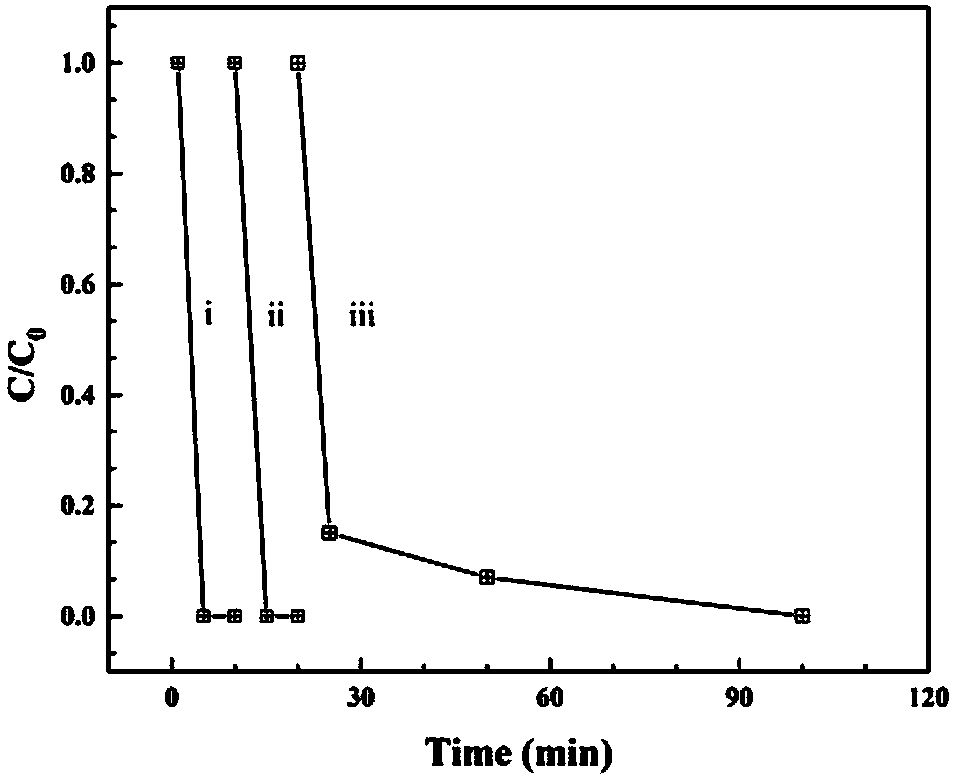

[0031] Photodegradation of Methylene Blue by Magnesium Hydroxide / Reduced Graphene Oxide Composite

[0032] First, configure 2.0*10 -5 For the methylene blue aqueous solution of M, take 20mg of composite material and add 50mL of methylene blue solution, and stir magnetically for 30min in a dark environment to completely absorb. After irradiating with 365nm ultraviolet light for 5min, the methylene blue was completely degraded and the solution became colorless. And after UV-Vis absorption spectrum test, the results show that the methylene blue is completely degraded. Secondly, in order to test the recyclability of the composite material, the black solid obtained after centrifugation of the suspension was soaked in 10 mL of absolute ethanol with magnetic stirring for 2 h, washed by centrifugation and dried, and the above photocatalytic steps were repeated. The results show (such as image 3 ), the second cycle process can still be completely degraded within 5min, and the third...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com