Photocatalytic material for degrading antibiotics as well as preparation method and application of photocatalytic material

A photocatalytic material and technology of catalytic material, applied in the field of photocatalytic material and its preparation, can solve the problems of high light absorption range and photogenerated electron-hole recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

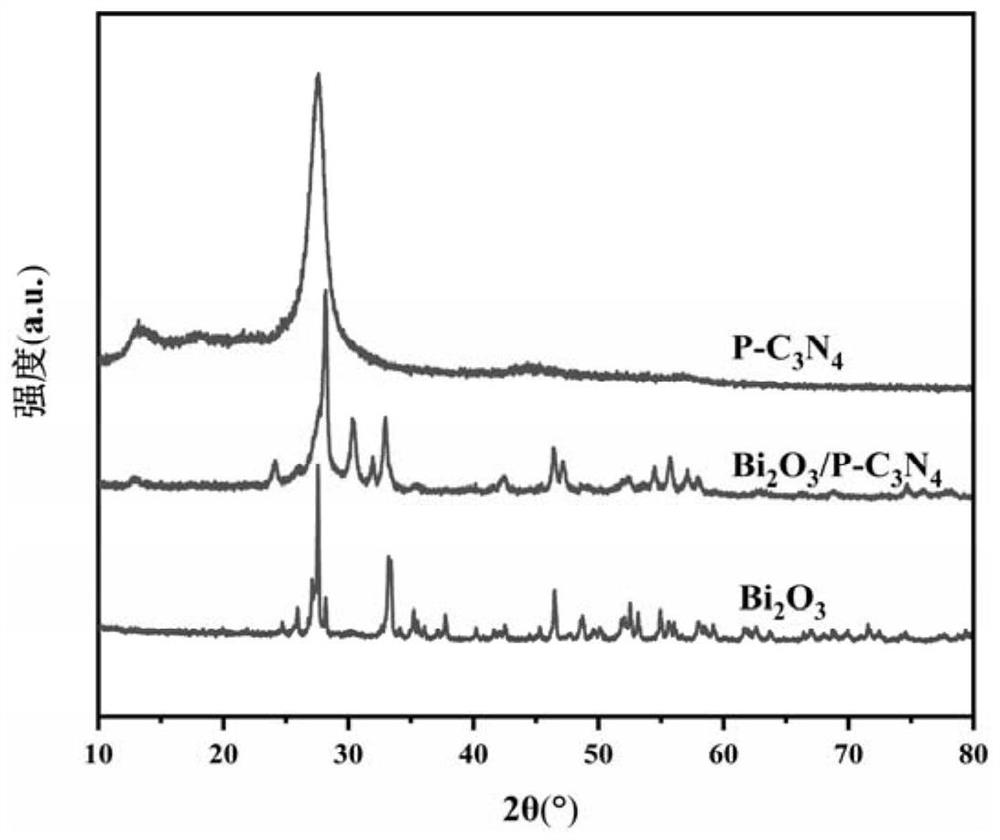

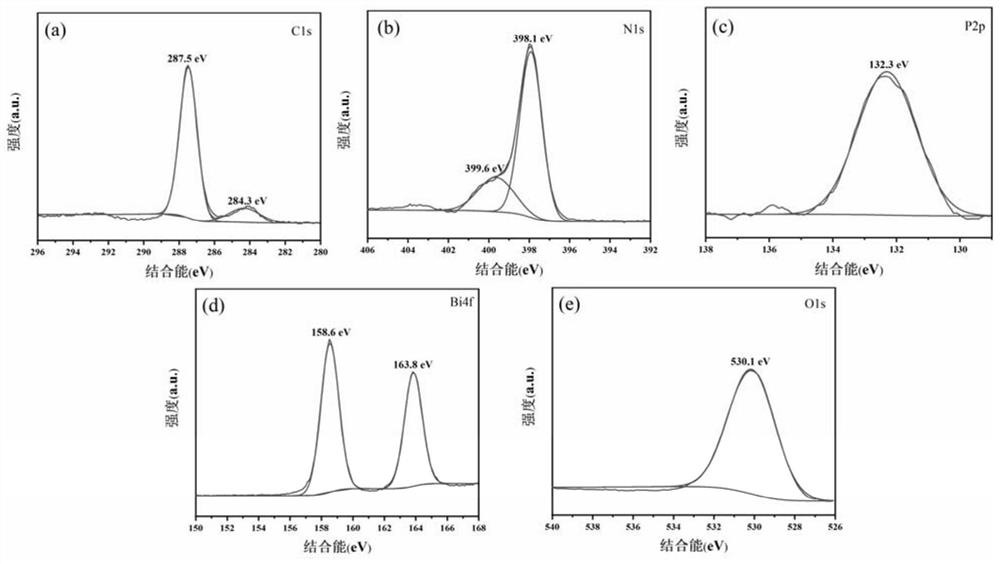

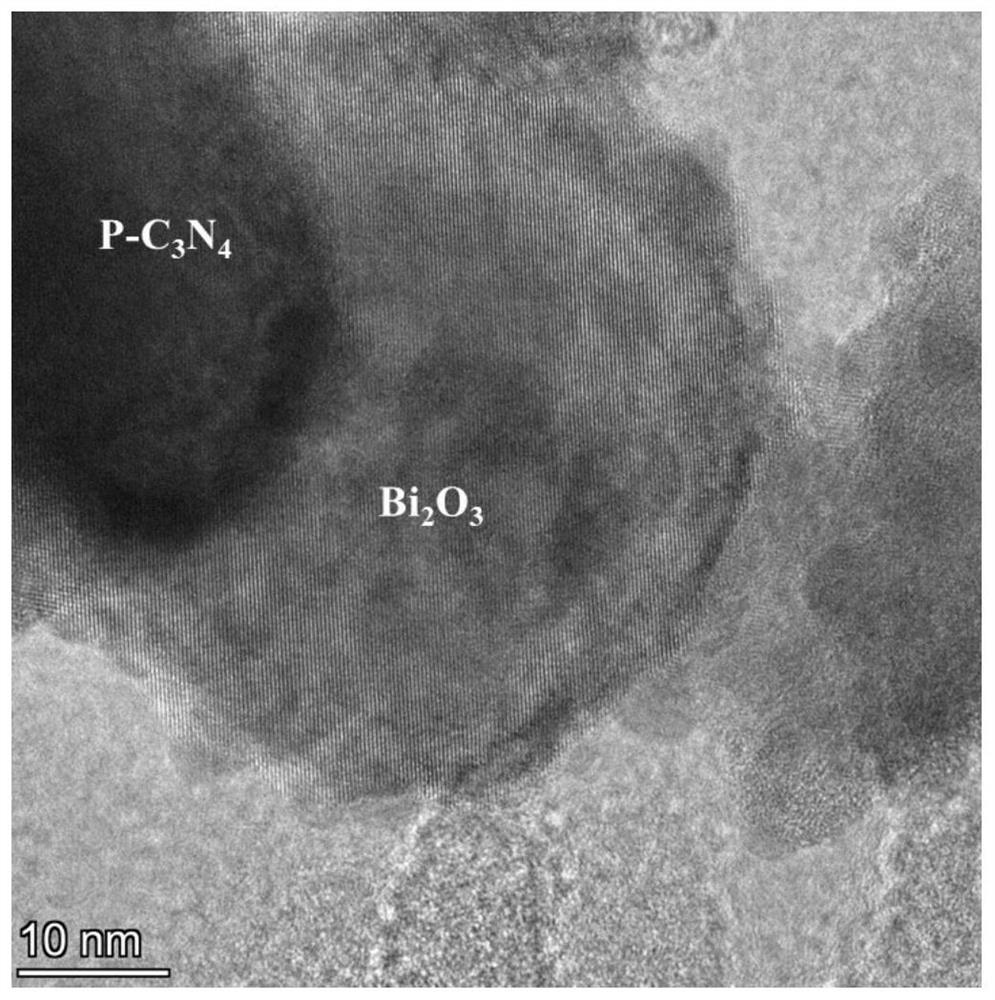

[0030] Embodiment 1 Photocatalytic material and preparation method thereof

[0031] 1) Put 5 g of melamine and 20 mg of phytic acid into an agate mortar for thorough grinding and mixing, then put them into a muffle furnace and heat at a constant temperature of 550° C. for 4 hours at a heating rate of 5° C. / min. After the heating is completed, it is cooled for later use, and the heated product P-C 3 N 4 Continue to grind for 20 minutes, grind it into a powder with uniform particles, and store it for future use;

[0032] 2) Heating bismuth nitrate pentahydrate at a constant temperature of 550°C for 4h at a heating rate of 5°C / min to prepare pure-phase Bi 2 o 3 ;

[0033] 3) Bi 2 o 3 / P-C 3 N 4 Preparation: Weigh 0.312g of Bi prepared in step 22 o 3 , 5g of melamine and 20mg of phytic acid were thoroughly mixed in an agate mortar, ground and transferred to a corundum crucible with a lid. Subsequently, it was placed in a muffle furnace and heated at 500° C. for 4 hours a...

Embodiment 2

[0035] Embodiment 2 Levofloxacin photocatalytic degradation experiment

[0036] Photocatalytic experiments were carried out in a photochemical reactor at room temperature:

[0037] 1) Get the P-C prepared in 50mg embodiment 1 3 N 4 、 Bi 2 o 3 or photocatalytic materials (Bi 2 o 3 / P-C 3 N 4 ) into the quartz test tube, adding 50mL concentration is the levofloxacin detection solution of 10mg / L, and the concentration at this moment is denoted as C 0 ; The detection solution without adding any catalyst was used as a blank control.

[0038] 2) Put the quartz test tube containing the detection system into the photoreaction instrument. After the instrument is adjusted, react according to the following process: first, carry out 30min dark reaction, so that the prepared photocatalytic material and levofloxacin reach the adsorption-desorption equilibrium; After the dark reaction, turn on the 500w xenon lamp (simulated sunlight), extract 1.5mL of the detection solution at inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com