Method for preparing Fe3O4/polypyrrole/polyaniline/TiO2/ZnO composite material

A composite material, polypyrrole technology, applied in the field of photocatalysis, can solve the problems of affecting the separation efficiency of electron and empty electron pairs, reducing the photocatalytic performance of composite materials, reducing the photocatalytic performance of composite materials, etc., to achieve strong photocatalytic degradation ability, Efficient photocatalytic performance and magnetic recycling performance, and the effect of improving magnetic recycling performance and catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] a kind of Fe 3 o 4 / polypyrrole / polyaniline / TiO 2 The preparation method of / ZnO composite material comprises the steps:

[0028] S1, Fe 3 o 4 Preparation: Dissolve ferrous chloride, potassium sulfite, polyvinylpyrrolidone and potassium hydroxide in deionized water at a mass ratio of 1.5:0.8:0.7:0.7, and react at a constant temperature under the protection of helium at a temperature of 170°C The reaction time is 8h, and Fe is prepared after separation, washing and drying. 3 o 4 ;

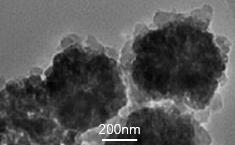

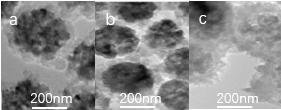

[0029] figure 1 For the Fe prepared in this embodiment 3 o 4 The TEM image of the prepared Fe 3 o 4 It can be seen from the TEM image that the prepared Fe 3 o 4 It is in the shape of microspheres, with relatively uniform size distribution and high roundness.

[0030] S2, Fe 3 o 4 / Preparation of polypyrrole: Fe prepared by step S1 3 o 4 Dispersed in deionized water, Fe 3 o 4 The solid-to-liquid ratio of the mass to the volume of deionized water is 1g:200mL, and then pyrrole...

Embodiment 2

[0042] In order to examine the Fe 3 o 4 / polypyrrole / polyaniline / TiO 2 The photocatalytic performance of / ZnO composite material, get the Fe that 5mg embodiment 1 prepares 3 o 4 / polypyrrole / polyaniline / TiO 2 / ZnO composite material was added to 100ml of methyl orange solution with a concentration of 1mg / L, stirred under dark conditions for the first 1h, and carried out photocatalytic reaction under visible light irradiation conditions for the next 1h, and the methyl orange solution was taken out every 15min. Measure the concentration of methyl orange at this time, Figure 6 For the Fe prepared in this embodiment 3 o 4 / polypyrrole / polyaniline / TiO 2 / ZnO composite photocatalytic performance line graph, by Figure 6 It can be seen that: stirring under dark conditions for the first 1h, the concentration of the methyl orange solution gradually decreases and at 60min the C / C 0 is 0.71, which is due to the fact that Fe 3 o 4 / polypyrrole / polyaniline / TiO 2 / ZnO composite m...

Embodiment 3

[0044] In order to examine the Fe 3 o 4 / polypyrrole / polyaniline / TiO 2 Magnetic recovery performance of / ZnO composites for Fe 3 o 4 / polypyrrole / polyaniline / TiO 2 / ZnO composite material, the hysteresis loop is measured at 25°C as Figure 7 shown by Figure 7 It can be seen that its saturation magnetization is 25.0emu / g, Fe 3 o 4 / polypyrrole / polyaniline / TiO 2 The remanence and coercivity of the / ZnO composite material are basically zero, and it can be magnetized and demagnetized quickly, which can ensure that Fe 3 o 4 / polypyrrole / polyaniline / TiO 2 The magnetism of the / ZnO composite material itself disappears rapidly, which can effectively prevent its agglomeration due to its magnetism and affect its photocatalytic effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com