Preparation of one-dimensional nanotubular Ag/AgCl/AgBr composite heterojunction visible light catalyst and application thereof

A composite heterojunction, photocatalyst technology, applied in catalyst activation/preparation, physical/chemical process catalyst, nanotechnology, etc., can solve the problem of less research on one-dimensional structure, and achieve easy and efficient photocatalytic performance of equipment and materials , improve the effect of photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 0.3g of copper nitrate trihydrate and dissolve it in 10mL of deionized water, and add it dropwise into a beaker containing 15mol / L 200mL sodium hydroxide solution, then slowly add 2mL of ethylenediamine and 0.5mL of hydrazine hydrate, and then place React in a water bath at 60°C for 2 hours, cool to room temperature, wash, centrifuge, collect, and dissolve the product in 100 mL of deionized water, and disperse it ultrasonically for 5 minutes. Finally, add 100mL of a solution containing 4g of PVP and 100mL of a solution containing 0.5g of silver nitrate, stir and react at room temperature for 2h, wash, centrifuge, collect, and dry in a vacuum oven at 60°C for 24h to obtain silver nanotubes.

Embodiment 2

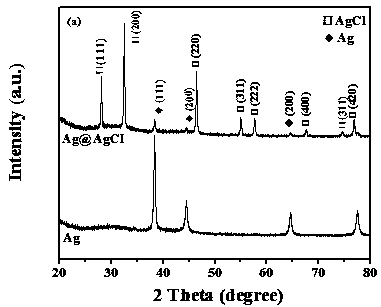

[0030] Example 2 Weigh 0.05 g of silver nanotubes and 0.03 mg of PVP prepared in Example 1, add them into 50 mL of deionized water, and disperse them ultrasonically for 5 minutes. Prepare 30mL of 15.4mmol / L ferric chloride solution, add it to the above suspension, stir at room temperature for 2h, wash, centrifuge, collect, and dry in a vacuum oven at 60°C for 24h to obtain nanotube Ag / AgCl.

Embodiment 3

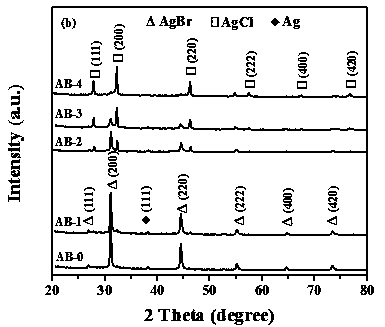

[0032] Weigh 0.05 g of Ag / AgCl and 0.03 g of PVP prepared in Example 2, add them into 50 mL of deionized water, and disperse by ultrasonic for 5 min. Weigh 41.5 mg of KBr and add it to the above solution, stir at room temperature for 2 hours, wash, centrifuge, collect, and dry in a vacuum oven at 60°C for 24 hours to obtain nanotube Ag / AgBr (by molar ratio, Br:Cl=10: 0,, the number is AB-0).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com