Hexagonal boron nitride modified graphitized carbon nitride composite photocatalyst and its preparation method and application

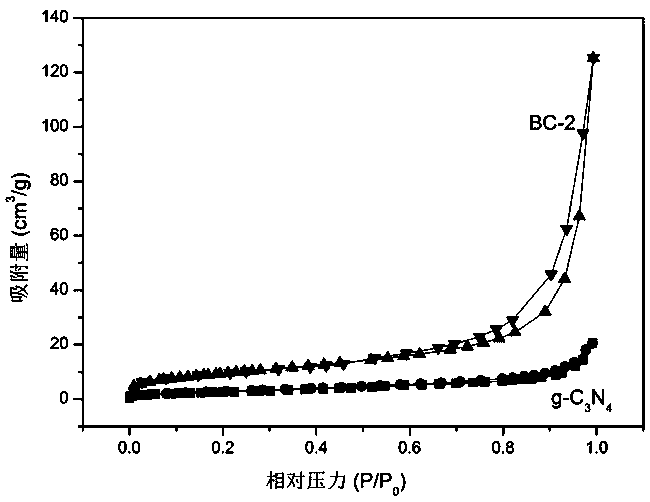

A hexagonal boron nitride and graphitization technology, applied in the field of photocatalysis, can solve the problems of poor photocatalytic activity, low specific surface area, and weak separation ability of photogenerated carriers, so as to improve the migration speed, increase the specific surface area, and quickly predict The effect of adsorbing pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

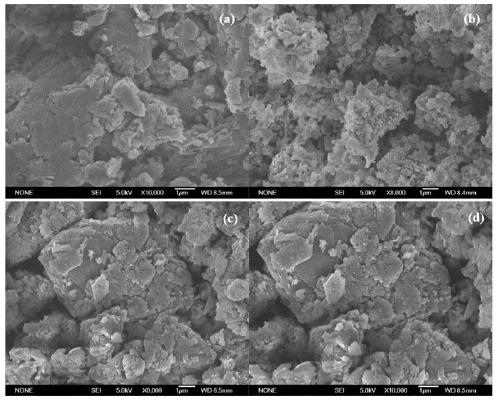

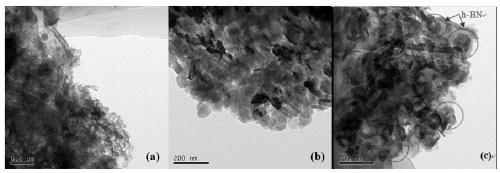

[0034] A hexagonal boron nitride modified graphitized carbon nitride composite photocatalyst of the present invention, the hexagonal boron nitride modified graphitized carbon nitride composite photocatalyst uses graphitized carbon nitride as a carrier, and the graphitized carbon nitride carrier is modified Layered hexagonal boron nitride.

[0035] In this embodiment, the mass percentage of hexagonal boron nitride in the hexagonal boron nitride-modified graphitized carbon nitride composite photocatalyst is 0.22%.

[0036] The preparation method of the hexagonal boron nitride modified graphitized carbon nitride composite photocatalyst of the above-mentioned present embodiment comprises the following steps:

[0037](1) Mix 1 mg hexagonal boron nitride and 1 g dicyandiamide in an agate mortar, and grind continuously for 30 min to obtain the precursor of the mixture.

[0038] (2) Put the mixture precursor of hexagonal boron nitride and graphitized carbon nitride precursor obtained...

Embodiment 2

[0042] A hexagonal boron nitride modified graphitized carbon nitride composite photocatalyst of the present invention, the hexagonal boron nitride modified graphitized carbon nitride composite photocatalyst uses graphitized carbon nitride as a carrier, and the graphitized carbon nitride carrier is modified Layered hexagonal boron nitride.

[0043] In this embodiment, the mass percentage of hexagonal boron nitride in the hexagonal boron nitride-modified graphitized carbon nitride composite photocatalyst is 0.44%.

[0044] The preparation method of the hexagonal boron nitride modified graphitized carbon nitride composite photocatalyst of the above-mentioned present embodiment comprises the following steps:

[0045] (1) Mix 2 mg of hexagonal boron nitride and 1 g of dicyandiamide in an agate mortar, and grind continuously for 30 min to obtain the precursor of the mixture.

[0046] (2) Put the mixture precursor of hexagonal boron nitride and graphitized carbon nitride precursor o...

Embodiment 3

[0053] A hexagonal boron nitride modified graphitized carbon nitride composite photocatalyst of the present invention, the hexagonal boron nitride modified graphitized carbon nitride composite photocatalyst uses graphitized carbon nitride as a carrier, and the graphitized carbon nitride carrier is modified Layered hexagonal boron nitride.

[0054] In this embodiment, the mass percentage of hexagonal boron nitride in the hexagonal boron nitride-modified graphitized carbon nitride composite photocatalyst is 0.88%.

[0055] The preparation method of the hexagonal boron nitride modified graphitized carbon nitride composite photocatalyst of the above-mentioned present embodiment comprises the following steps:

[0056] (1) Mix 4 mg hexagonal boron nitride and 1 g dicyandiamide in an agate mortar, and grind continuously for 30 min to obtain the precursor of the mixture.

[0057] (2) Put the mixture precursor of hexagonal boron nitride and graphitized carbon nitride precursor obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com