Preparation method of layered cobalt-zinc double hydroxide-graphene compound supercapacitor electrode

A double hydroxide and supercapacitor technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, can solve the problems of low specific surface area and ion diffusion rate, high theoretical specific capacitance, and low cycle performance. Effects of high specific surface area, efficient ion diffusion channels, and high rate capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 4mg graphene oxide and 4mg sodium dodecylbenzene sulfonate are ultrasonically dispersed in 40mL molar concentration of 2mol / L aqueous urea solution to form a graphene oxide suspension, then add 1 × 10 to the graphene oxide suspension respectively -3 mol of cobalt nitrate hexahydrate and 3×10 -3 mol of zinc acetate dihydrate, stirred to form a uniform precursor solution, and then transferred the precursor solution to the hydrothermal reaction kettle, and at the same time, the foamed nickel current collector with a size of 1cm×1cm×0.1cm was immersed in the hydrothermal reaction kettle In the precursor solution, the hydrothermal reaction was carried out at 120°C for 5 hours, and the hydrotalcite-like layered cobalt-zinc double hydroxide-graphene composite was deposited on the surface of the nickel foam current collector, and the composite active electrode was obtained after ultrasonic washing and drying.

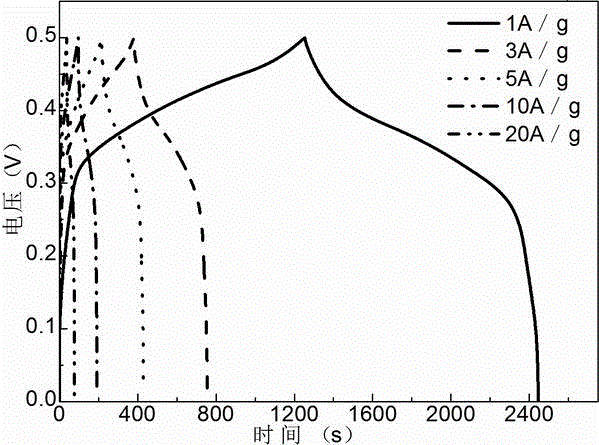

[0015] Two sheets of the prepared composite active electrodes were ...

Embodiment 2

[0017] 40mg graphene oxide and 40mg polyvinylpyrrolidone are ultrasonically dispersed in 40mL molar concentration of 2mol / L aqueous urea solution to form a graphene oxide suspension, then add 1 × 10 -3 mol of cobalt nitrate hexahydrate and 3×10 -3 mol of zinc acetate dihydrate, stirred to form a uniform precursor solution, and then transferred the precursor solution to the hydrothermal reaction kettle, and at the same time, the foamed nickel current collector with a size of 1cm×1cm×0.1cm was immersed in the hydrothermal reaction kettle In the precursor solution, the hydrothermal reaction was carried out at 150°C for 8 hours, and a hydrotalcite-like layered cobalt-zinc double hydroxide-graphene composite was deposited on the surface of the nickel foam current collector, and the composite active electrode was obtained after ultrasonic washing and drying.

[0018] Two sheets of the prepared composite active electrodes were separated by a hydrophilic glass fiber separator, immerse...

Embodiment 3

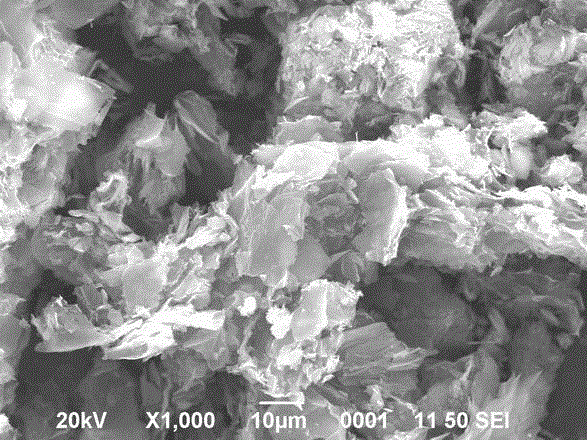

[0020] 40mg graphene oxide and 200mg P123 ultrasonic dispersion in 40mL molar concentration is the urea aqueous solution of 2mol / L to form graphene oxide suspension, add 2 * 10 respectively in this graphene oxide suspension -2 mol of cobalt nitrate hexahydrate and 2×10 -2 mol of zinc acetate dihydrate, stirred to form a uniform precursor solution, and then transferred the precursor solution to the hydrothermal reaction kettle, and at the same time, the foamed nickel current collector with a size of 1cm×1cm×0.1cm was immersed in the hydrothermal reaction kettle In the precursor solution, the hydrothermal reaction was carried out at 180°C for 5 hours, and a hydrotalcite-like layered cobalt-zinc double hydroxide-graphene composite was deposited on the surface of the nickel foam current collector. After ultrasonic washing and drying, the composite active electrode was obtained. The active electrode The complex on the surface presents a sheet-assembled structure (such as figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com