Fire-resistant hydraulic fluid composition, preparation method of fire-resistant hydraulic fluid composition and hydraulic fluid prepared by using composition

A composition and hydraulic fluid technology, applied in the field of lubrication, can solve problems such as poor lubricity, increased power consumption, hydraulic medium leakage, etc., and achieve the effect of improving friction and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

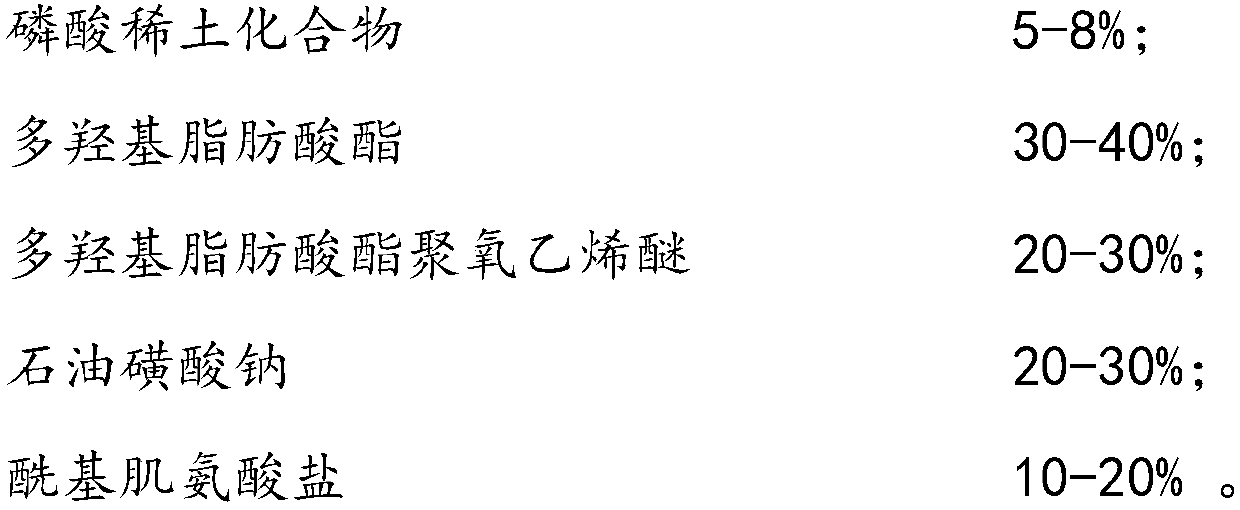

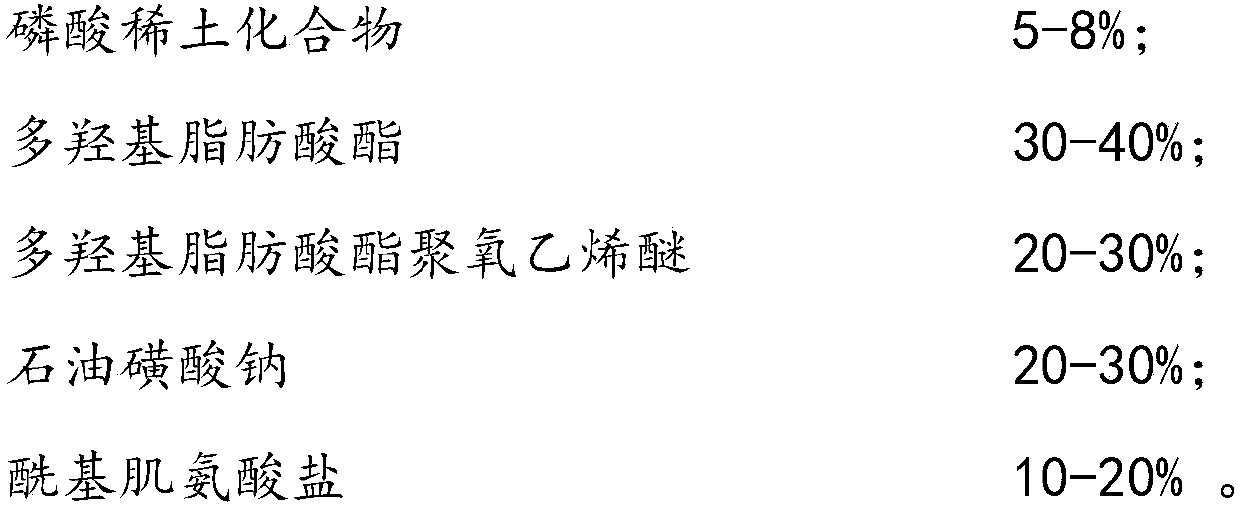

Embodiment 1

[0032] Weigh 80g of lanthanum phosphate hydrate, add it to 400g of mannitol monooleate and stir well until a uniform paste is formed, add 200g of Tween-80, 200g of sodium petroleum sulfonate, and 120g of sodium lauroyl sarcosinate and continue stirring until translucent , which is a fire-resistant hydraulic fluid composition.

[0033] The preparation method of above-mentioned sorbitol monooleate is: take by weighing 1821.7g (10mol) of sorbitol and 2824.7g (10mol) of oleic acid in proportion and add respectively in the reactor, add 40g (85%) phosphoric acid and stir and heat to 210 ℃, fully reacted for 10 hours, decompressed and drained the water, which was sorbitol monooleate.

[0034] After mixing 300 g of the fire-resistant hydraulic fluid composition prepared above and 9700 g of water-ethylene glycol base oil (water content 45%) evenly, a fire-resistant hydraulic fluid is obtained.

[0035] The above fire-resistant hydraulic fluid was applied to the TIMKEN test machine for...

Embodiment 2

[0038] Weigh 50g of lanthanum phosphate hydrate and add it into 300g of glycerol monooleate and stir until a uniform paste is obtained, add 300g of Tween-60, 200g of sodium petroleum sulfonate, and 150g of sodium oleoyl sarcosinate and continue stirring until translucent. That is, a fire-resistant hydraulic fluid composition.

[0039] After mixing 20 g of the fire-resistant hydraulic fluid composition prepared above and 980 g of water-ethylene glycol base oil (water content 40%) uniformly, a fire-resistant hydraulic fluid is obtained.

Embodiment 3

[0041] Weigh 60g of cerium phosphate hydrate and add it to 350g of pentaerythritol monooleic acid and stir well until a uniform paste is formed, add 250g of Tween-40, 210g of sodium petroleum sulfonate, 130g of sodium myristoyl sarcosinate and continue stirring until translucent , which is a fire-resistant hydraulic fluid composition.

[0042] After mixing 10 g of the fire-resistant hydraulic fluid composition prepared above and 990 g of water-ethylene glycol base oil (50% water content), a fire-resistant hydraulic fluid is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com