Method for improving friction reduction and wear resistance of matrix

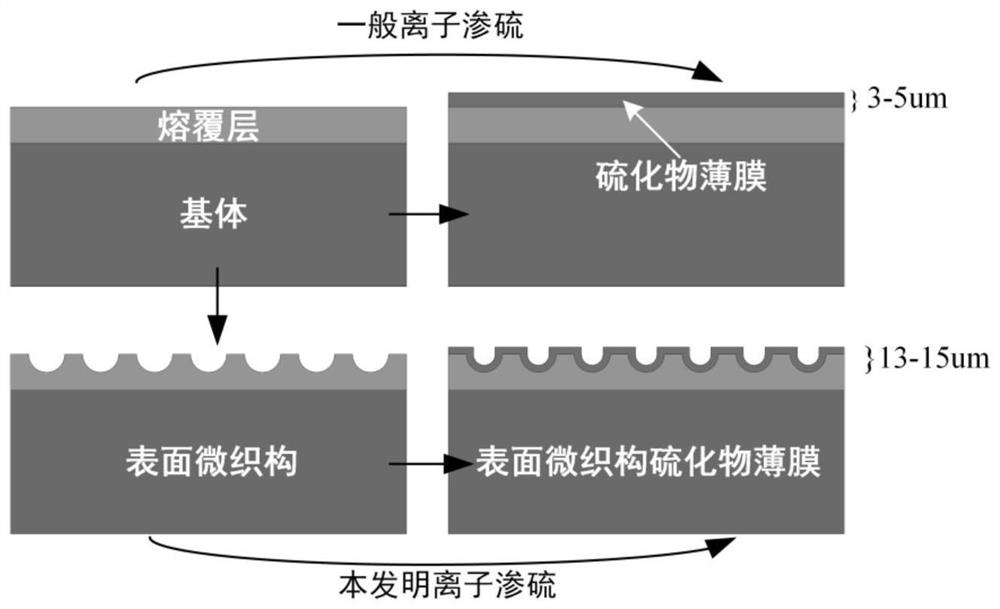

A technology of wear resistance and matrix, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of difficult diffusion and easy wear, achieve low friction coefficient, improve bonding force, and improve work efficiency The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The CoCrFeNiMo high-entropy alloy powder used in the present invention is prepared by the following method: mix the gas-atomized powder CoCrFeNi and the elemental powder Mo evenly at a molar ratio of 1:1, dry and dehumidify at 120°C to obtain CoCrFeNiMo High entropy alloy powder.

[0040] The SD-Ni45 cermet powder that the present invention adopts, its diameter is 48~100 μ m, and powder chemical composition is as shown in table 1:

[0041] Table 1 Chemical composition of SD-Ni45 alloy powder (mass fraction, %)

[0042]

[0043] The substrate used in the present invention is Q235 steel (about 100mm×50mm×10mm in size), and the surface needs to be polished with a grinder to remove scale before laser cladding.

[0044] The laser cladding of the present invention is carried out in a HWF60 composite welding robot workstation under argon protection. The laser output from the IPG YLS-6000 fiber laser is transmitted through the optical fiber to the rectangular spot cladding...

Embodiment 1

[0052] The preparation of micro-textured ion sulfurized CoCrFeNiMo high-entropy alloy cladding layer, the steps are as follows:

[0053] (1) Laser cladding

[0054] The CoCrFeNiMo high-entropy alloy powder is evenly laid on the surface of Q235 steel with a thickness of 2mm for laser cladding. The laser cladding conditions are: laser power 1800W, cladding speed 300mm / min, lap rate 30%, spot size 10mm×1mm , Shielding gas 4L / min, every cladding layer, spread another layer of powder on the overlapping part, and finally form a cladding layer with a thickness of about 1mm. After the cladding layer sample is air-cooled to room temperature, use a grinder to remove impurities such as surface oxide slag.

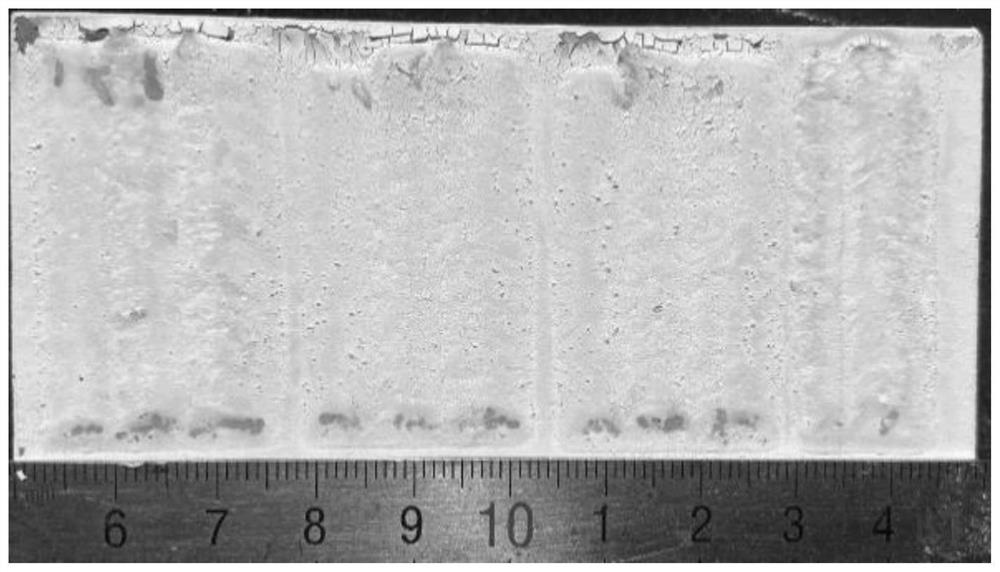

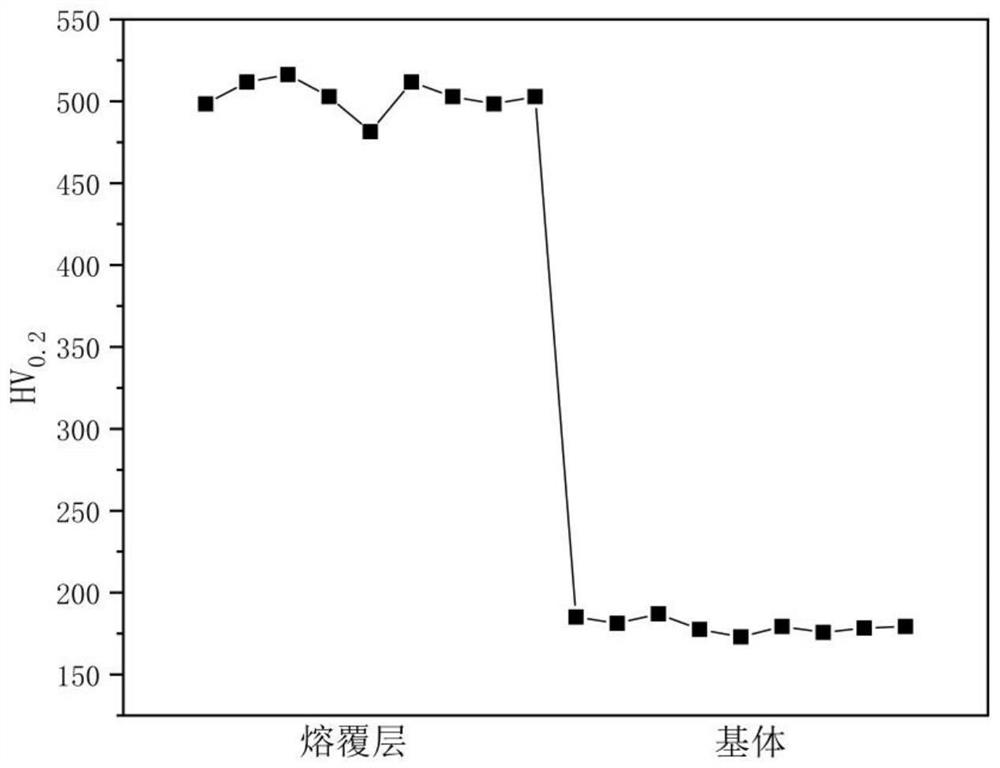

[0055] Carry out colored penetrant inspection on cladding layer samples, such as figure 2 As shown, the CoCrFeNiMo high-entropy alloy powder is formed well after cladding, and it is detected by a flaw detector, and there is no red color reaction, indicating that the cladding layer ...

Embodiment 2

[0065] The preparation of micro-textured ion sulfurized SD-Ni45 cermet cladding layer, the steps are as follows:

[0066] (1) Laser cladding

[0067] Put the dried SD-Ni45 cermet powder in the powder feeder, and evenly send it to the surface of Q235 steel through the front powder feed nozzle for laser cladding. The laser cladding conditions are: laser power 2500W, cladding speed 200mm / min, overlapping rate 30%, spot size 10mm×1mm, shielding gas 5L / min, powder feeding rate 20g / min, powder feeding gas 11L / min, and finally form a cladding layer with a thickness of about 1mm. After the cladding layer sample is air-cooled to room temperature, use a grinder to remove impurities such as surface oxide slag.

[0068] Carry out colored penetrant inspection on cladding layer samples, such as Figure 10 As shown, the SD-Ni45 cermet cladding layer is well formed, and it is detected by a flaw detector, and there is no red color reaction, indicating that the cladding layer has no cracks a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com