A metal-organic framework compound @ mesoporous material composite, a preparing method thereof and applications of the composite

A mesoporous material and organic framework technology, applied in the field of metal-organic framework compound@mesoporous material composite material and its preparation, can solve the problems of equipment corrosion, easy decomposition and deformation, high energy consumption of liquid ammonia adsorption method regeneration, and achieve excellent The effect of high temperature resistance and water resistance, simple preparation method and process, suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

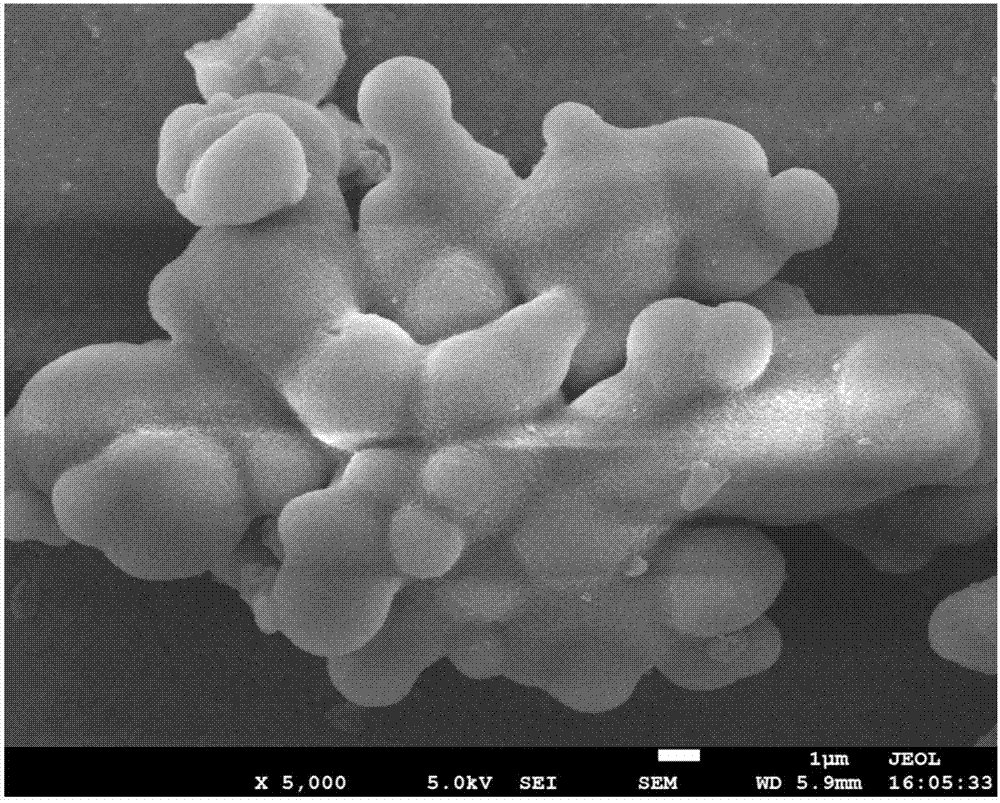

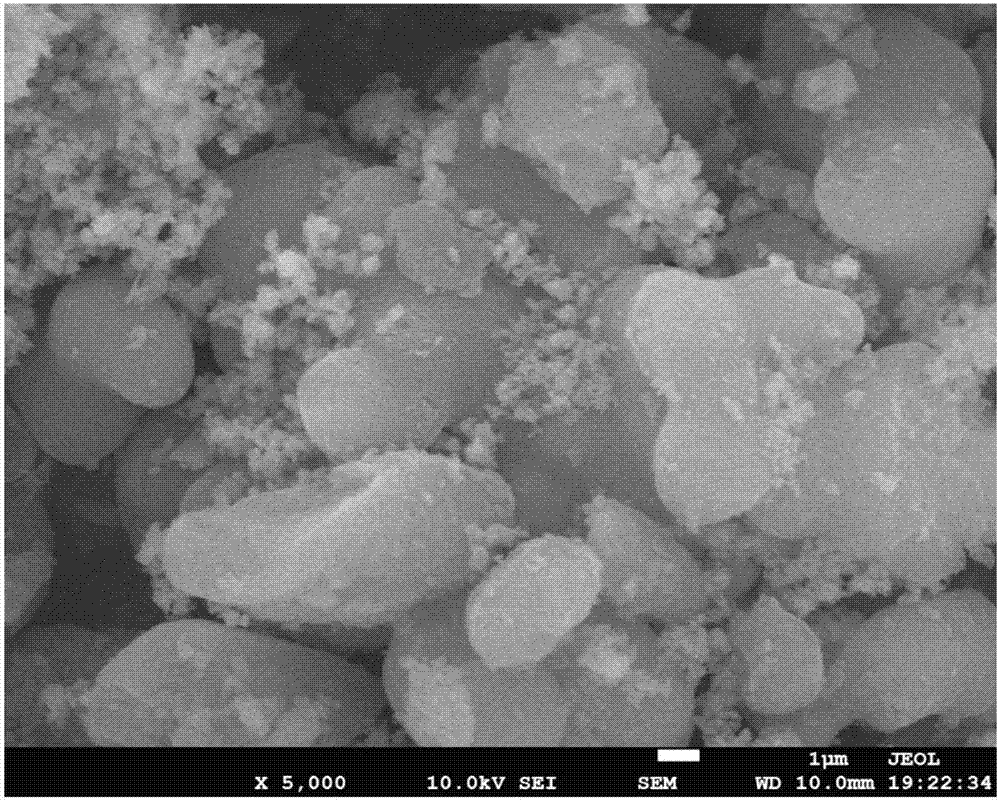

[0078] In a preferred embodiment of the present invention, the preparation method of the silica mesoporous foam material comprises:

[0079] Dissolve P123 in water, add concentrated hydrochloric acid, add mesitylene (TMB) after heating and stirring, add tetraethyl orthosilicate (TEOS) after stirring, and continue heating; collect and seal the obtained liquid product, heat and crystallize to obtain a mesoporous material .

[0080] In a preferred embodiment of the present invention, the mass ratio of P123, concentrated hydrochloric acid, mesitylene and ethyl orthosilicate is 8:40-50:2-12:10-20, preferably 8:45- 50:6-10:15-20, more preferably 8:50:6:17.

[0081] The use of specific raw materials and dosage is helpful to obtain mesoporous materials with fixed pore size and structure, which is conducive to the transmission of carbon dioxide, fully contacting the metal-organic framework compounds loaded inside the mesoporous materials, and the complex pore structure is also increas...

Embodiment 1

[0138] Dissolve 8g of P123 in 250mL of deionized water, add 45g of concentrated hydrochloric acid with a mass fraction of 36% to 38%, heat and stir in a water bath at 40°C for 3 hours, then add 12g of TMB, continue stirring for 3 hours, and then add 10g of TEOS produced a milky white colloidal solution, and continued stirring at 40°C for 48h, then filled the liquid into a polytetrafluoroethylene-lined white steel tank, and placed it in an oven at 80°C for crystallization for 48h. After filtering, washing and drying, MCF was obtained. Denoted as MCF-1, in a simulated flue gas environment, using a fixed bed, test its CO at 30°C and 60°C 2 Adsorption capacity. See Table 2 for the data.

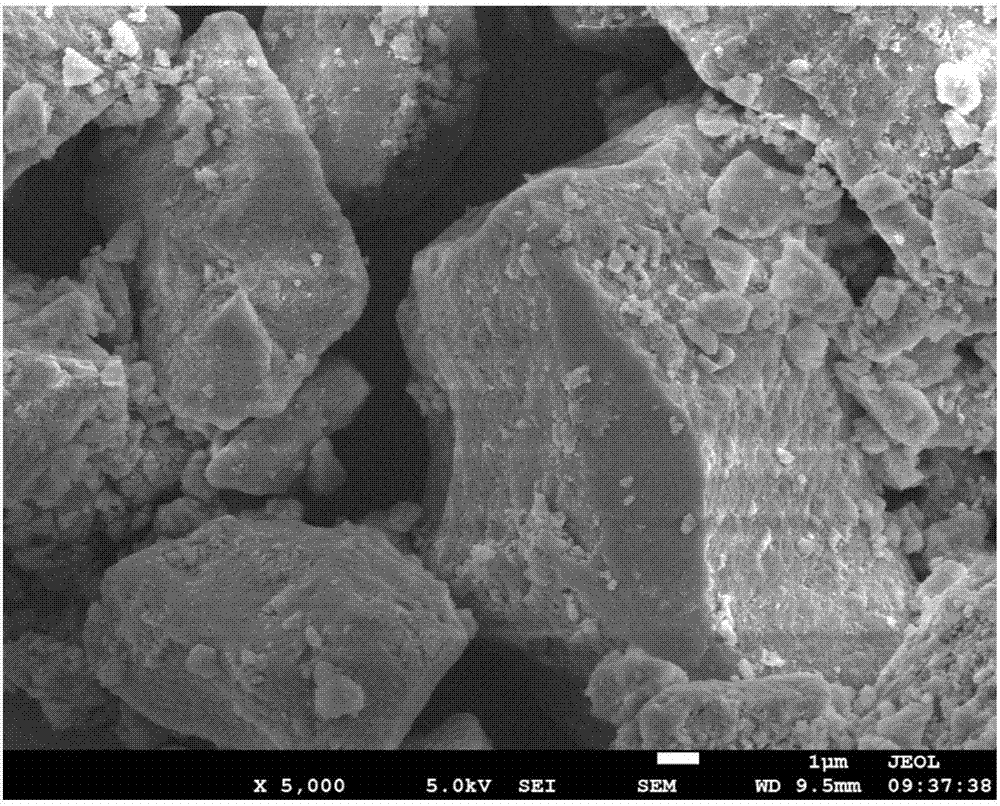

Embodiment 2

[0140] Dissolve 8g of P123 in 250mL of deionized water, add 40g of concentrated hydrochloric acid with a mass fraction of 36% to 38%, heat and stir in a water bath at 50°C for 2 hours, then add 2g of TMB, continue stirring for 2 hours, and then add 20g of TEOS produced a milky white colloidal solution, and continued stirring at 40°C for 36h, then filled the liquid into a polytetrafluoroethylene-lined white steel tank, and placed it in an oven at 100°C for crystallization for 36h. After filtering, washing and drying, MCF was obtained. Denoted as MCF-2, in a simulated flue gas environment, using a fixed bed, test its CO at 30°C and 60°C 2 Adsorption capacity. See Table 2 for the data.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com