Stabilizer for trichloroethylene

A technology of trichloroethylene and stabilizer, which is used in the long-term storage field of electronic cleaning grade trichloroethylene, can solve the problems of damage and corrosion of components, and achieve the effect of reducing the decomposition speed, meeting the quality requirements and prolonging the use time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

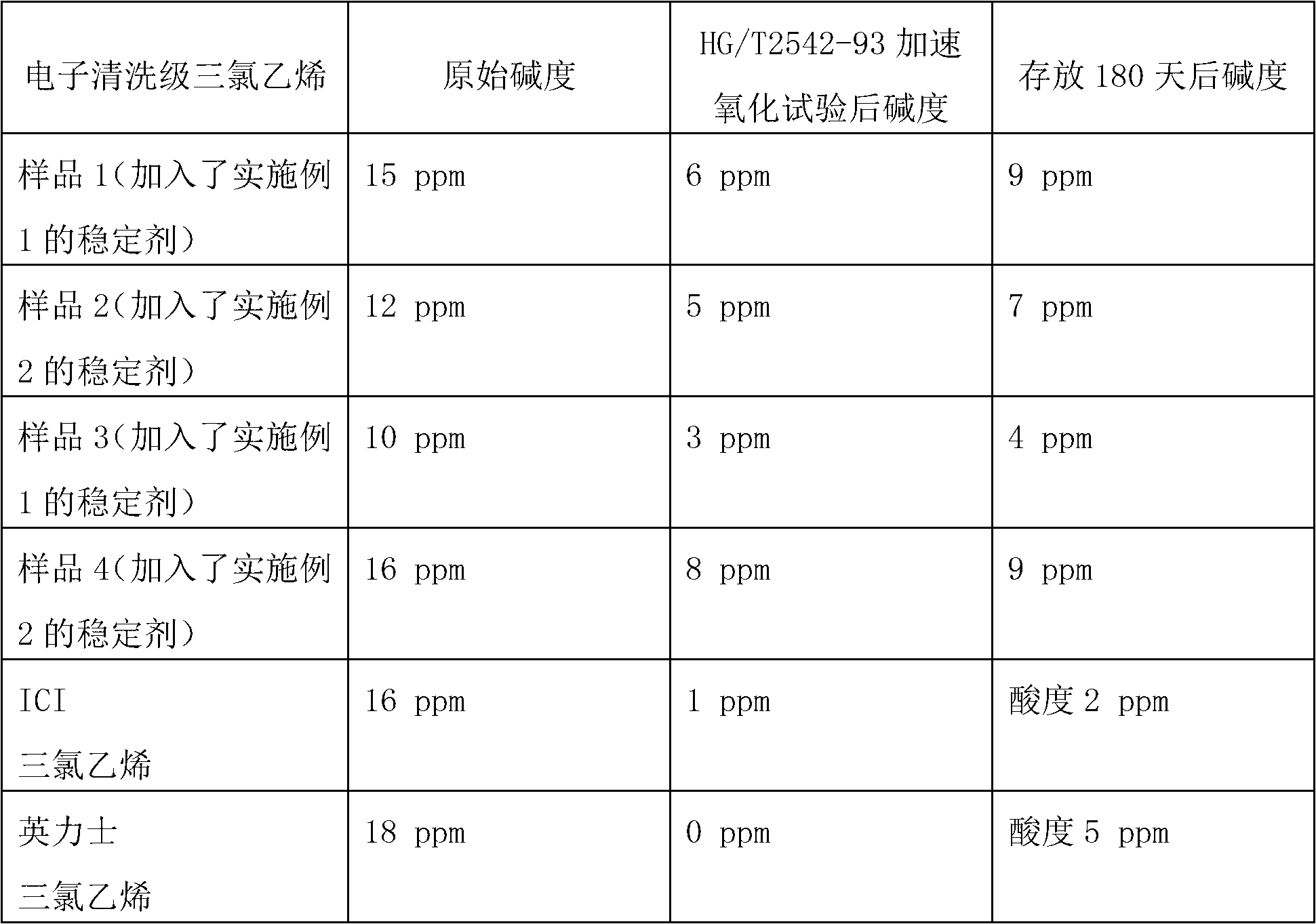

Examples

Embodiment 1

[0013] Embodiment 1: a stabilizer for trichlorethylene, its component content is: triethanolamine 80ml / t, diisopropane 100ml / t, thymol 90ml / t, epichlorohydrin 100ml / t, isobutanol 100ml / t, the above content is calculated based on the mass of trichlorethylene.

Embodiment 2

[0014] Embodiment 2: a stabilizer for trichlorethylene, its component content is: triethanolamine 90ml / t, diisopropane 90ml / t, isobutanol 110ml / t, diethylene glycol ether 80ml / t, the above content All are calculated based on the mass of trichlorethylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com