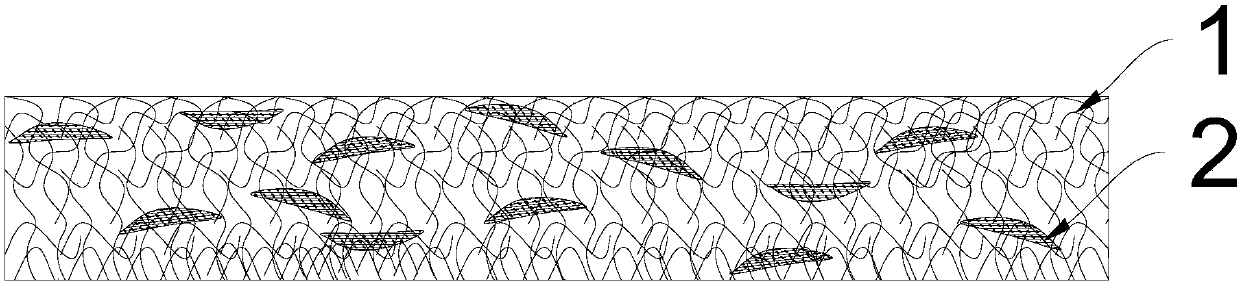

Non-woven fabric containing flaky natural flowers and production technology of non-woven fabric

A non-woven, flower and grass technology, applied in textiles and papermaking, non-woven fabrics, fiber processing, etc., can solve the problem that natural flowers and grasses in sheet or block cannot be uniformly dispersed into non-woven fabrics, etc., to achieve enhanced aesthetics, The effect of improving strength properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

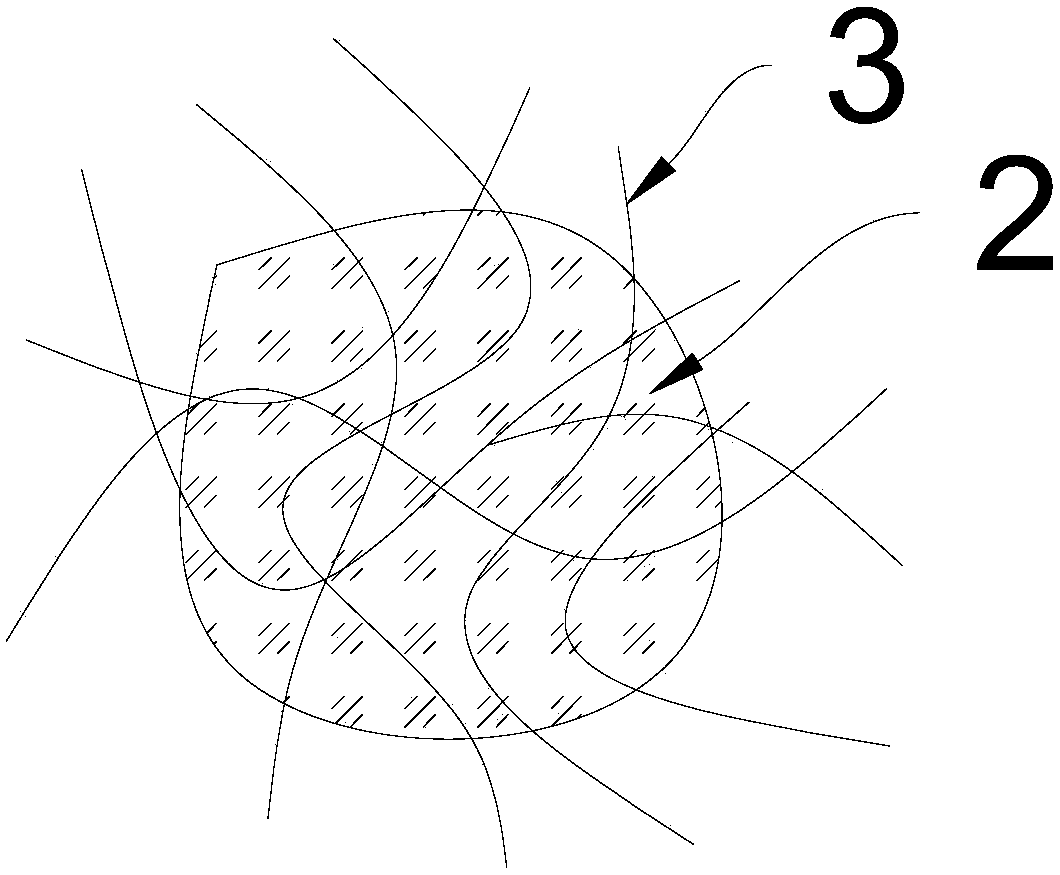

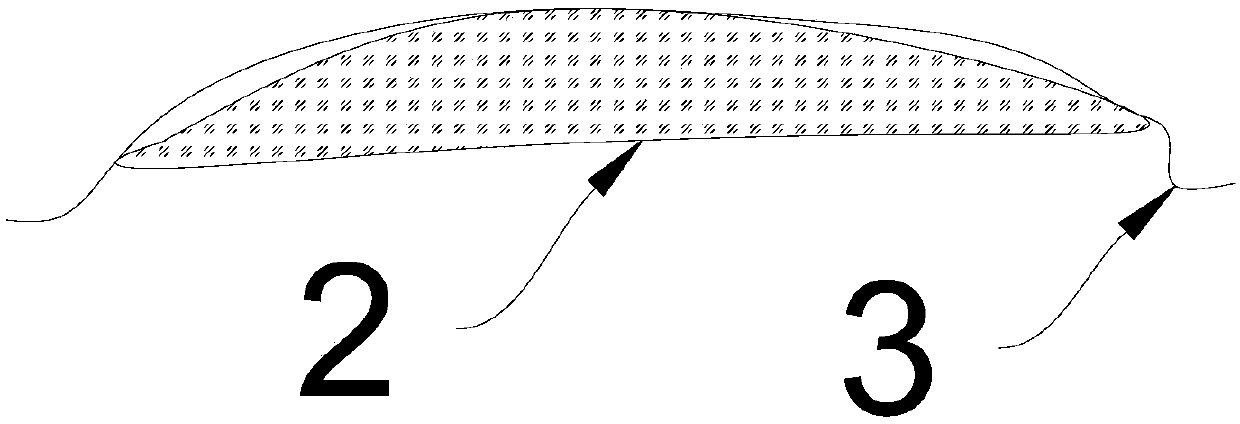

[0044] Fresh roses were cut into small petals of 3mm×3mm with a knife, soaked in water to soften, and mixed with 10% (mass concentration, the same below) mixture 1. After soaking, the petals had some settling properties in mix 1. The white viscose fiber of 1.7d * 12mm is dispersed in water and then mixed to form 2% mixture 2. Mixture 1 and mixture 2 were formulated into mixture 3 with a fiber mass concentration of about 2% by volume ratio of 1:100. The mixture 3 is stored in the storage tank, and stirred with a stirring device in the storage tank, and the stirring rate is controlled at 40r / min. At this time, the petals can be evenly dispersed in the mixed solution and the viscose fiber can still maintain a dispersed state. It will be tangled into clusters. The mixture 3 is then diluted with water to 1‰, and the diluted liquid is sent to the wet former in a turbulent flow with a pump, and the water of the mixture 3 is removed to form a mixed fiber web with a dryness of 20%. ...

Embodiment 2

[0046] Compared with Example 1, this embodiment differs only in that the fiber mass concentration of mixture 2 and mixture 3 is 1%, and the stirring rate of the stirring device in the storage tank is controlled at 50r / min, and the mixture sent to the wet former Mixture 3 was diluted with water to 5‰, and the rest were the same. Finally, the non-woven fabric material with complete rose petal shape and evenly dispersed in the surface layer can also be obtained.

Embodiment 3

[0063] Cut fresh roses into small petals of 3mm×3mm with a knife, soak them in water to soften, and make a mixture 1 of 10% (mass concentration); : 50% of the ratio is dispersed with water and mixed to form a 5% mixture 2; the mixture 1 and the mixture 2 are formulated into a 2% mixture 3 at a volume ratio of 1:100, and the mixture 3 is stored in a storage tank and stored in the storage tank Stir with a stirring device, and the stirring rate is controlled at 180r / min. The mixture 3 is then diluted to 2‰ with water, and the diluted liquid is sent to the wet former in a turbulent flow with a pump, and the water of the mixture 3 is removed to form a mixed fiber web with a dryness of 20%. The mixed fiber net is entangled with 2 kpa 3 lanes, 3 kpa 4 lanes, and 5 kpa 2 lanes in the hydroentanglement machine to make a fiber net with a certain strength, and then dehydrated and dried to make a gram weight of 50g / m 2 wet-laid spunlace nonwovens. The non-woven fabric uses wood pulp f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com