Steel for heavy-duty loader tire protecting chain and production method thereof

A production method and loader technology, applied in the direction of temperature control, etc., can solve the problems that cannot fully fit the working environment of heavy loaders, the tires of heavy loaders are expensive, and the working environment of heavy loaders is harsh, so as to improve the corrosion resistance and Oxidation resistance, increased temperature, effect of good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

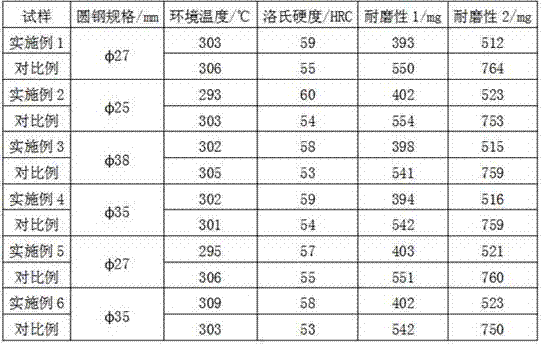

[0022] Embodiments 1-6: The steel for the tire protection chain of the heavy-duty loader is produced by the following specific process.

[0023] (1) Smelting and refining according to the above process, tapping and casting into 165mm 2 See Table 1 for the composition ratio of the refining tapping in each embodiment.

[0024] Table 1: Composition ratio (wt%) of refining tapping in each embodiment

[0025] Example C Si Mn P S Cr TAl 1 0.38 0.92 1.06 0.014 0.021 0.55 0.012 2 0.40 1.10 0.92 0.018 0.016 0.40 0.009 3 0.35 1.03 1.14 0.035 0.031 0.44 0.015 4 0.37 0.78 0.85 0.029 0.018 0.60 0.014 5 0.42 0.85 1.20 0.017 0.024 0.48 0.008 6 0.39 0.70 0.99 0.022 0.035 0.52 0.010

[0026] In Table 1, the balance is Fe and inevitable impurities.

[0027] (2) The above-mentioned billets are heated and rolled to make round steel, and the round steel is then cooled and forged to make steel chains, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com