Positive electrode of lithium sulfur secondary battery

A lithium-sulfur secondary battery, cathode technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of reducing battery mass specific energy and volume energy density, large volume and mass, and not providing capacity, etc. Achieve the effects of suppressing the shuttle effect, simple cathode structure, and compatible coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

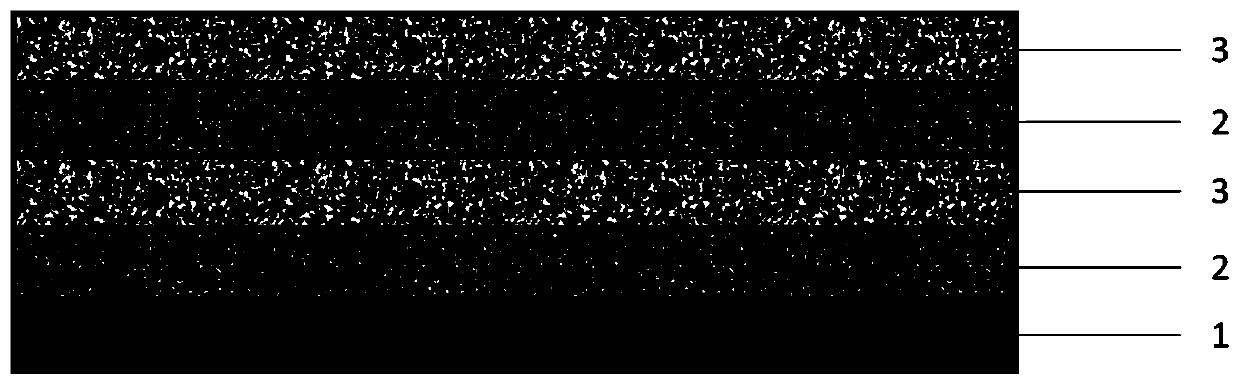

[0029](1) After grinding and mixing elemental sulfur with a mass ratio of 70:30 and activated carbon, heat to 165°C to melt the sulfur and infiltrate into the activated carbon to obtain a sulfur / carbon composite material. Mix the obtained sulfur / carbon composite material with acetylene black and carboxymethyl cellulose at a ratio of 70:20:10, add an appropriate amount of water to make a slurry, coat it on the aluminum foil fluid, and dry it naturally at 100°C and dried under vacuum for 24 hours to obtain a sulfur-containing cathode material layer with a thickness of 100 microns.

[0030] (2) Grind and mix lithium vanadate with acetylene black and polyvinylidene fluoride at a ratio of 85:10:5, add an appropriate amount of N-methylpyrrolidone as a solvent to make a slurry, and coat it on the sulfur-containing cathode material layer , dried in a vacuum at 100°C for 24 hours after natural drying, and the thickness was 50 microns.

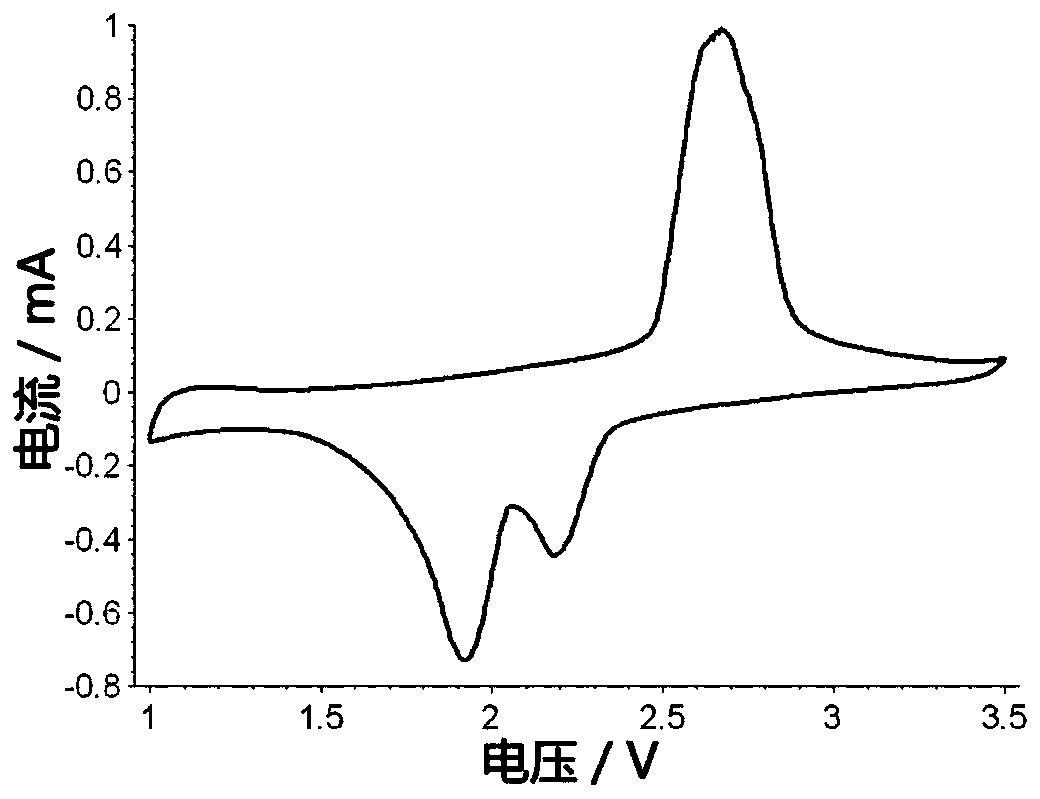

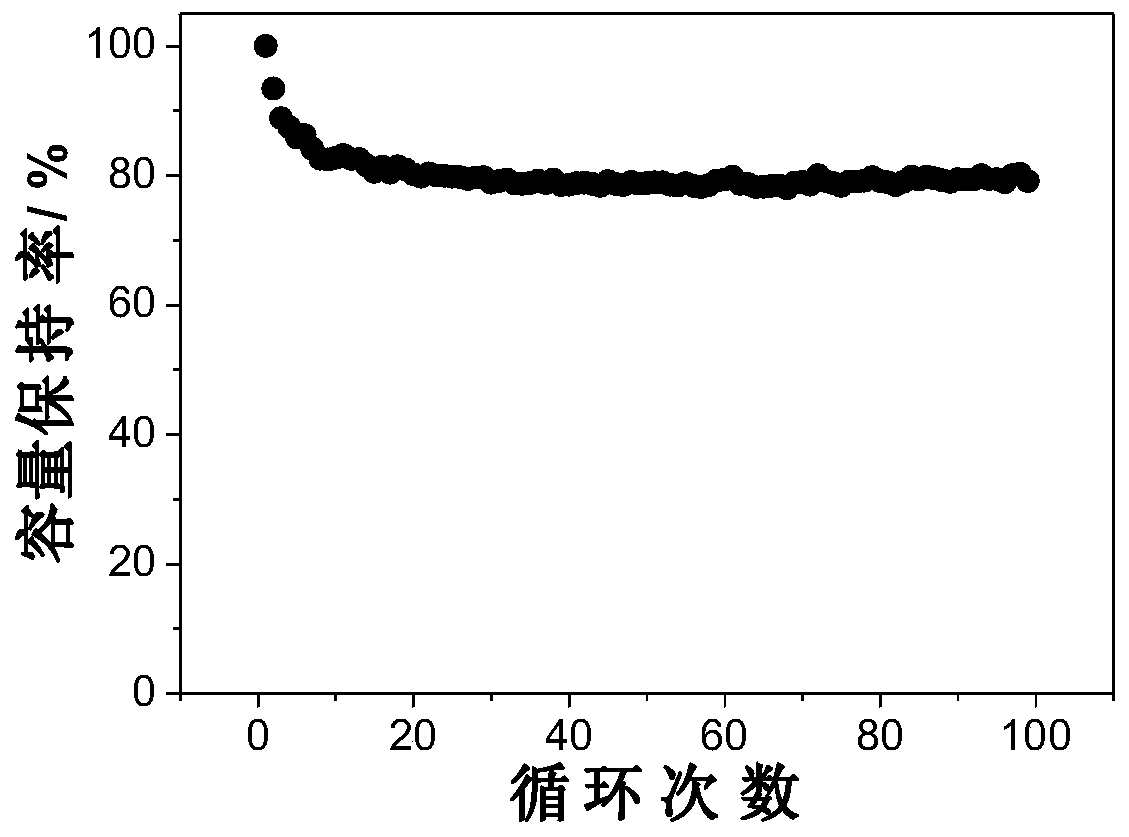

[0031] The obtained double-layer structure lithi...

Embodiment 2

[0033] (1) After grinding and mixing elemental sulfur with a mass ratio of 70:30 and activated carbon, heat to 165°C to melt the sulfur and infiltrate into the activated carbon to obtain a sulfur / carbon composite material. Mix the obtained sulfur / carbon composite material with acetylene black and carboxymethyl cellulose at a ratio of 70:20:10, add an appropriate amount of water to make a slurry, coat it on the aluminum foil fluid, and dry it naturally at 100°C and dried under vacuum for 24 hours to obtain a sulfur-containing cathode material layer with a thickness of 60 microns.

[0034] (2) Grind and mix ferrous disulfide with acetylene black and polyvinylidene fluoride at a ratio of 80:15:5, add an appropriate amount of N-methylpyrrolidone as a solvent to make a slurry, and coat it on the sulfur-containing cathode material layer After air drying, vacuum drying at 100°C for 24 hours, the thickness is 20 microns.

[0035] (3) After grinding and mixing elemental sulfur with a ...

Embodiment 3

[0039] (1) After grinding and mixing elemental sulfur with a mass ratio of 50:50 and activated carbon, heat to 165°C to melt the sulfur and infiltrate into the activated carbon to obtain a sulfur / carbon composite material. Mix the obtained sulfur / carbon composite material with acetylene black and styrene-butadiene rubber emulsion to make slurry, the mass ratio of sulfur / carbon composite material to acetylene black and styrene-butadiene rubber is 70:20:10, and coat it on the aluminum foil fluid , dried naturally and then vacuum-dried at 100°C for 24 hours to obtain a sulfur-containing cathode material layer with a thickness of 100 microns.

[0040] (2) Grind and mix lithium iron phosphate with acetylene black and polyvinylidene fluoride at a ratio of 80:15:5, add an appropriate amount of N-methylpyrrolidone as a solvent to make a slurry, and coat it on the sulfur-containing cathode material layer , dried in a vacuum at 100°C for 24 hours after natural drying, and the thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com