Magnetic ferroferric oxide nano particle and graphene composite, as well as preparation method and application thereof

A technology of ferric oxide and composite materials, applied in the field of magnetic ferric oxide nanoparticles-graphene composite materials and their preparation, can solve the problems of increased electrode cost, high price, limited reserves of precious metal Pt and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Magnetic Fe3O4 nanoparticle-graphene composite material (Fe 3 O 4 @RGO) Preparation

[0040] To 32.4g of ferric chloride hexahydrate, 24g of polyethylene glycol (PEG), 14.4g of sodium hydroxide, and 110.688g of graphene oxide were added 240ml of ethylene glycol (EG), and then magnetically The stirrer stirs to make it fully dissolved. Then mix these four solutions and stir evenly. Put it into a reaction kettle, heat it in an oven at 200 degrees Celsius and keep it for 24 hours to obtain a magnetic ferroferric oxide nanoparticle-graphene composite material.

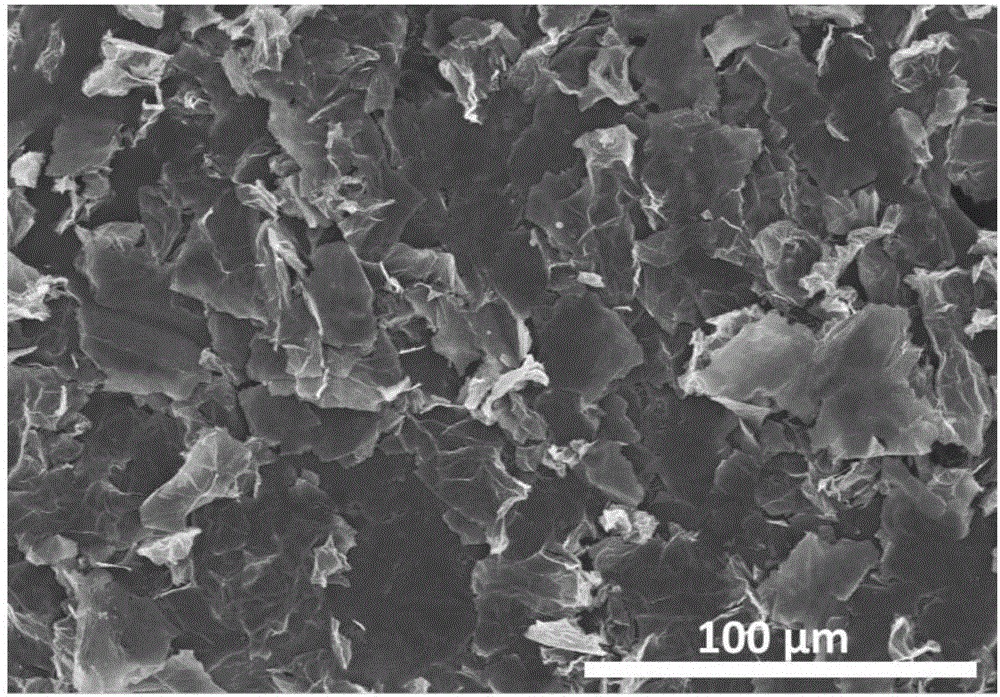

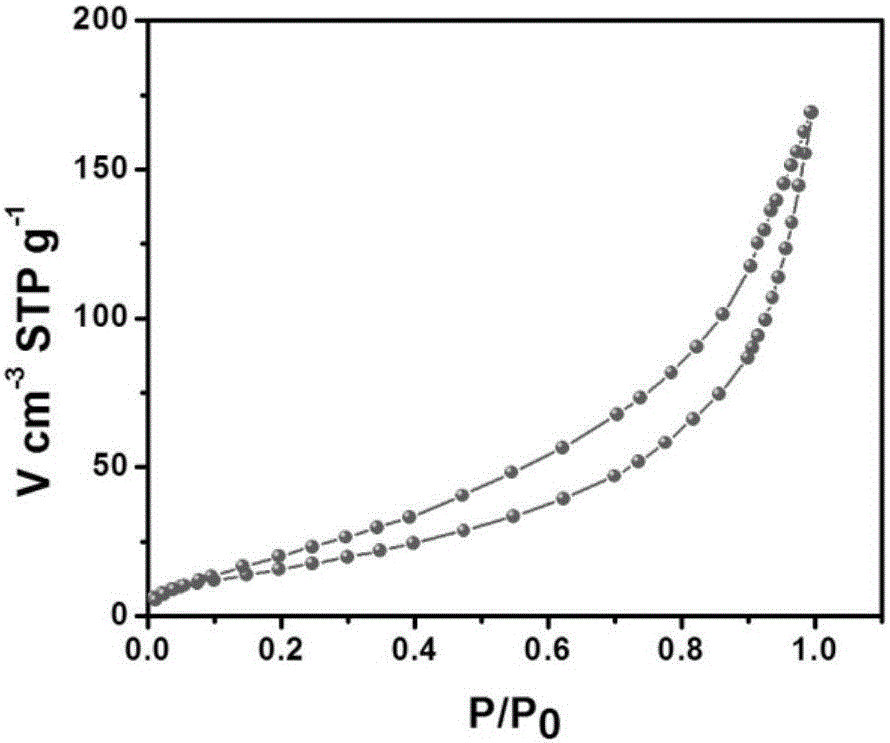

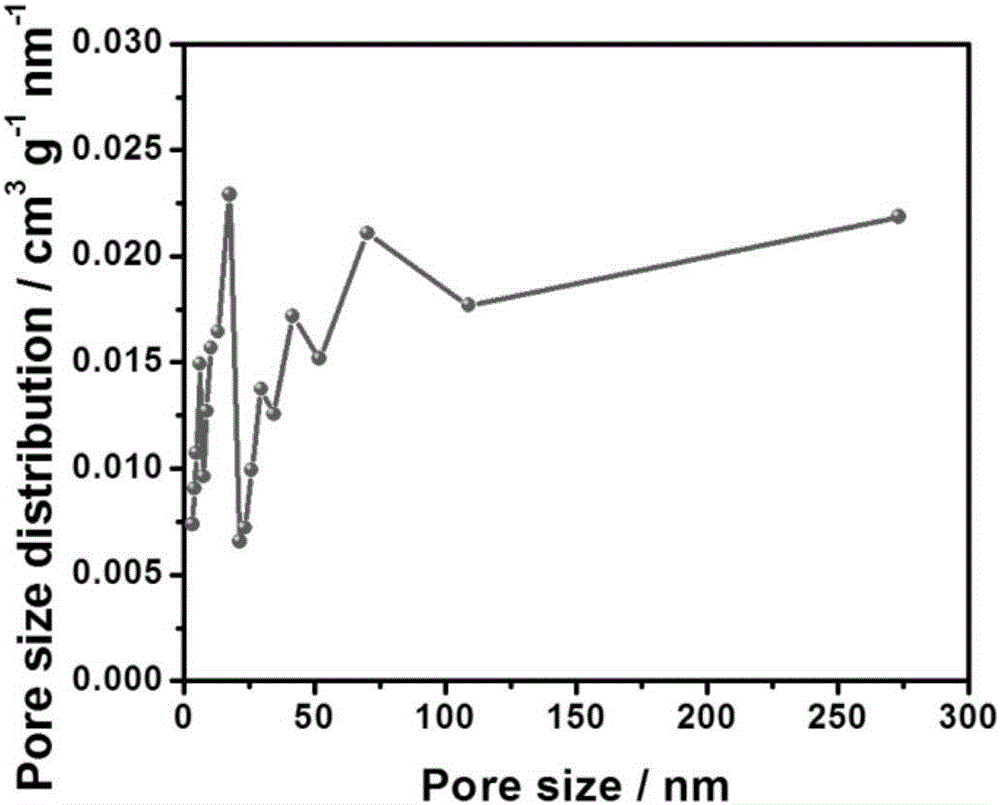

[0041] This embodiment uses micron-level graphene oxide materials (such as figure 1 ), this micron-sized graphene oxide can greatly increase the specific surface area of the composite material. BET test shows that its specific surface area is 64.3m 2 / g. The adsorption desorption curve can be seen ( figure 2 ), the shape of the hysteresis ring is H3, shaped like a crescent, and relatively long and narrow. ...

Embodiment 2

[0043] Example 2: Fe 3 O 4 @RGO composite material adsorption test for hexavalent chromium ions

[0044] 1. Preparation of hexavalent chromium standard solution:

[0045] Since the color of hexavalent chromium is not very obvious, we added the color developer diphenylcarbazide ethanol solution (DPCI) as Cr 6+ Ion concentration probe. The specific standard solution and standard curve are as follows: Take five 50ml colorimetric tubes, numbered 1-5. Take 0.10, 0.18, 0.35, 0.75, 1.50ml of 100mg / L potassium dichromate solution in the above 50ml colorimetric tube, and then add two drops of mixed acid to it, and then add 1.5ml of color developer diphenyl Carbohydrazide ethanol solution (DPCI). Shake the above solution, add water to dilute to 50ml, and make the volume constant, which is the standard color scale.

[0046] From Image 6 It can be seen that after adding DPCI, the standard solution showed a deep red ( Image 6 The upper middle image, from left to right, the colors darken in t...

Embodiment 3

[0049] Example 3: Fe 3 O 4 @RGO composite material adsorption test for CdS nanoparticles

[0050] Since the ultraviolet-visible absorption spectrum of CdS nanoparticles has no peak, only the macroscopic separation phenomenon can be observed. From Picture 8 It can be seen that the solution changes from orange to yellow ( Picture 8 Center left picture) becomes clear and transparent ( Picture 8 Middle right picture), which shows that nanoparticles in the dispersion can also be adsorbed, which shows that Fe 3 O 4 @RGO composite material has obvious adsorption effect on CdS nanoparticles. Finally we calculate 1 gram of Fe 3 O 4 @RGO composite material can adsorb 1.37g CdS nanoparticles. From this point of view, the substance can be used to effectively adsorb suspended nano-solid pollutants in sewage, so as to achieve the purpose of purifying sewage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com