Patents

Literature

62results about How to "Applicable processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

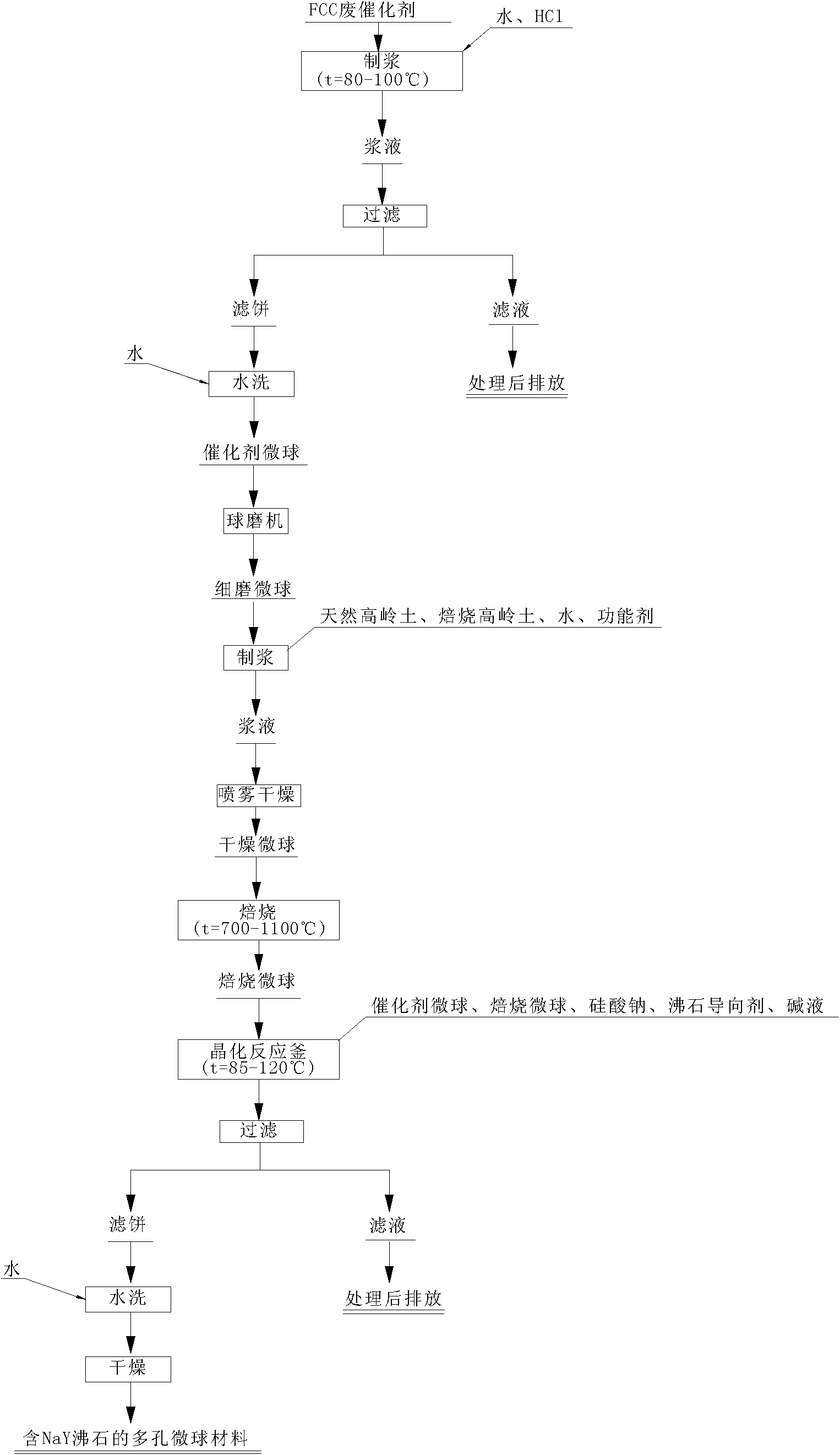

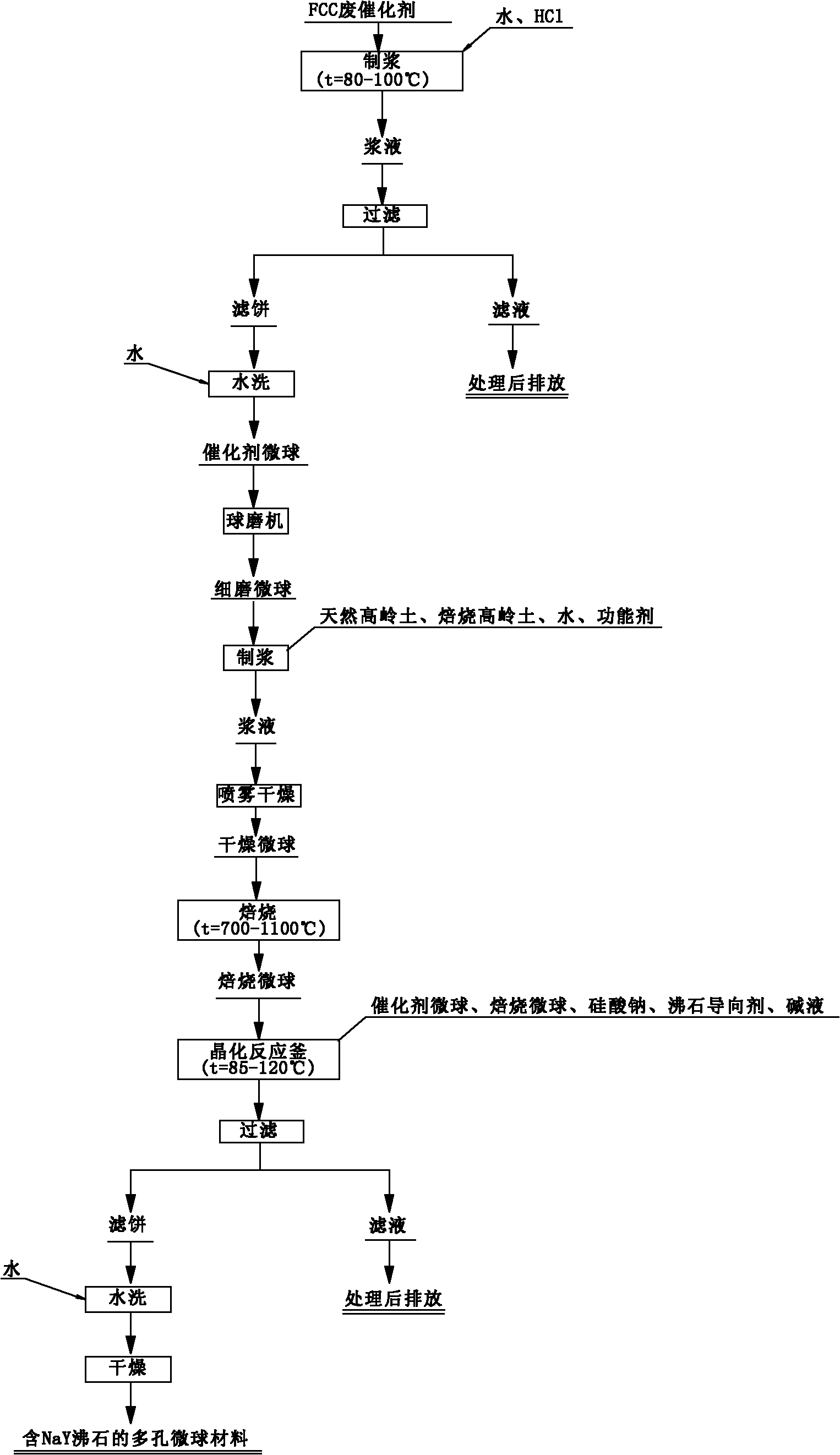

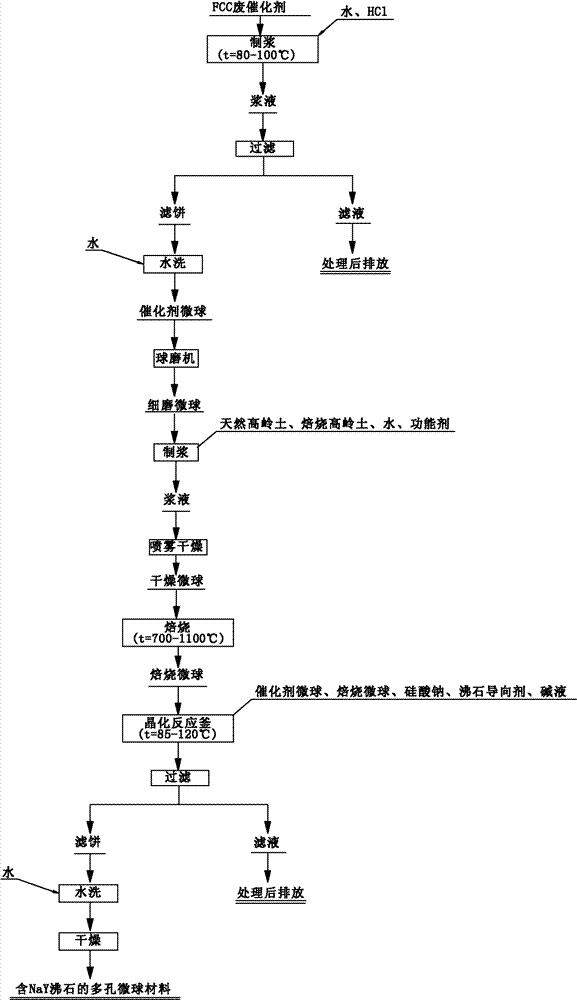

Method for synthesizing porous microsphere material containing NaY zeolite by waste FCC (fluid catalytic cracking) catalyst

ActiveCN102125872AReduce pollutionImprove performanceCatalytic crackingMolecular sieve catalystsSlurrySodium silicate

The invention discloses a method for synthesizing a porous microsphere material containing NaY zeolite by a waste FCC (fluid catalytic cracking) catalyst, which is a catalytic cracking process. The method is characterized by comprising the following steps: A. adding water and hydrochloric acid to the waste FCC catalyst for mixing slurry and acidizing to obtain catalyst microspheres; B. mixing thecatalyst microspheres with one or a combination of natural kaolin and roasted kaolin, adding water to obtain slurry containing 30-50% of solid, adding a functional agent to the slurry and then forming dried microspheres through spray drying, and roasting the dried microspheres at the temperature of 700-1100 DEG C for 0.5-10 hours to obtain roasted microspheres; and C. adding sodium silicate, a zeolite directing agent and alkali liquor to the catalyst microspheres and / or the roasted microspheres, adding the obtained mixed solution to a crystallization reaction kettle, performing hydrothermal crystallization at the temperature of 85-120 DEG C for 10-30 hours, filtering out a mother liquid, washing the obtained filter cake with deionized water, and then drying to finally obtain the finished product. The method is mainly used for synthesizing the porous microsphere material containing the NaY zeolite.

Owner:HUNAN JULI CATALYST

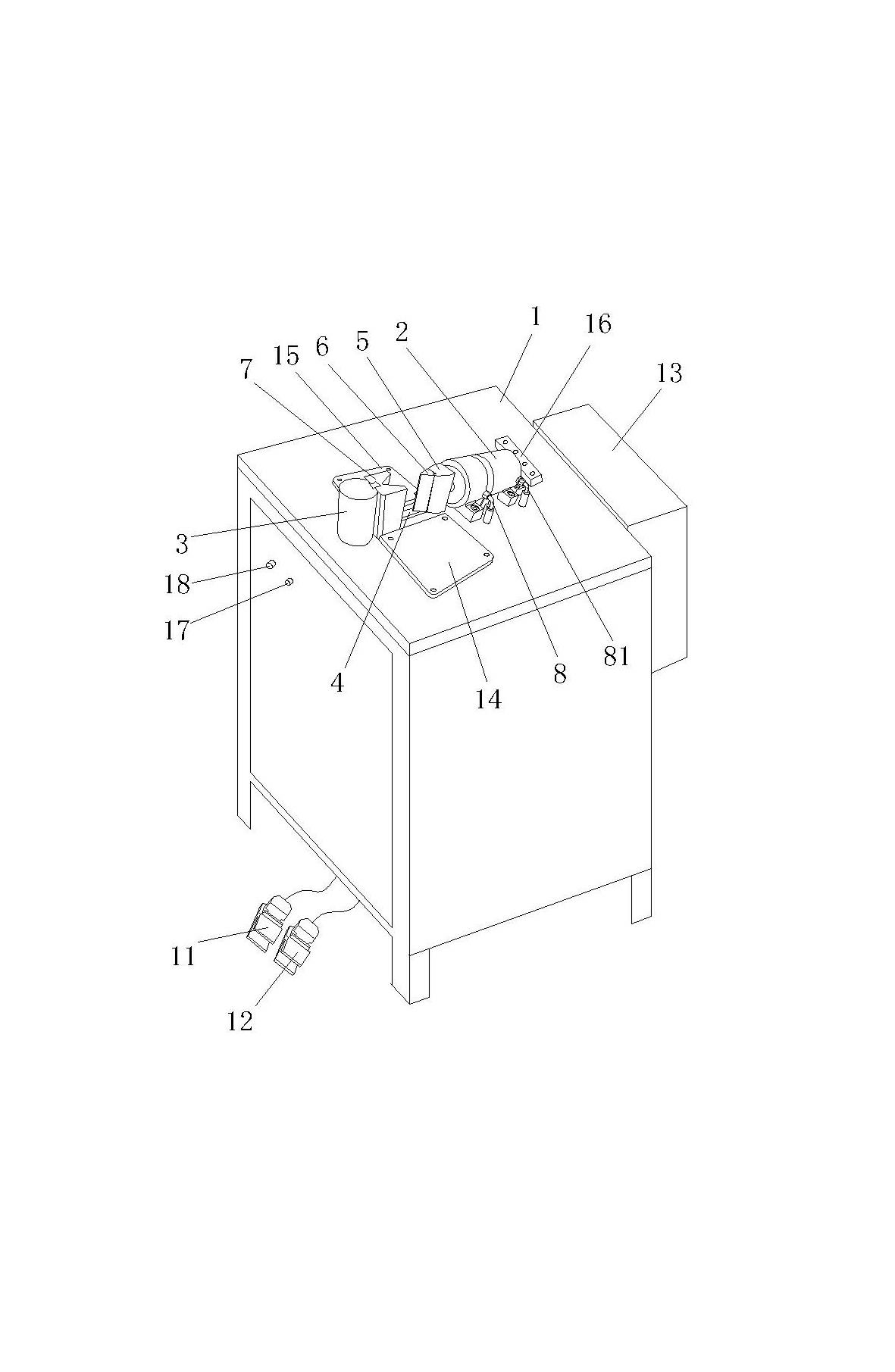

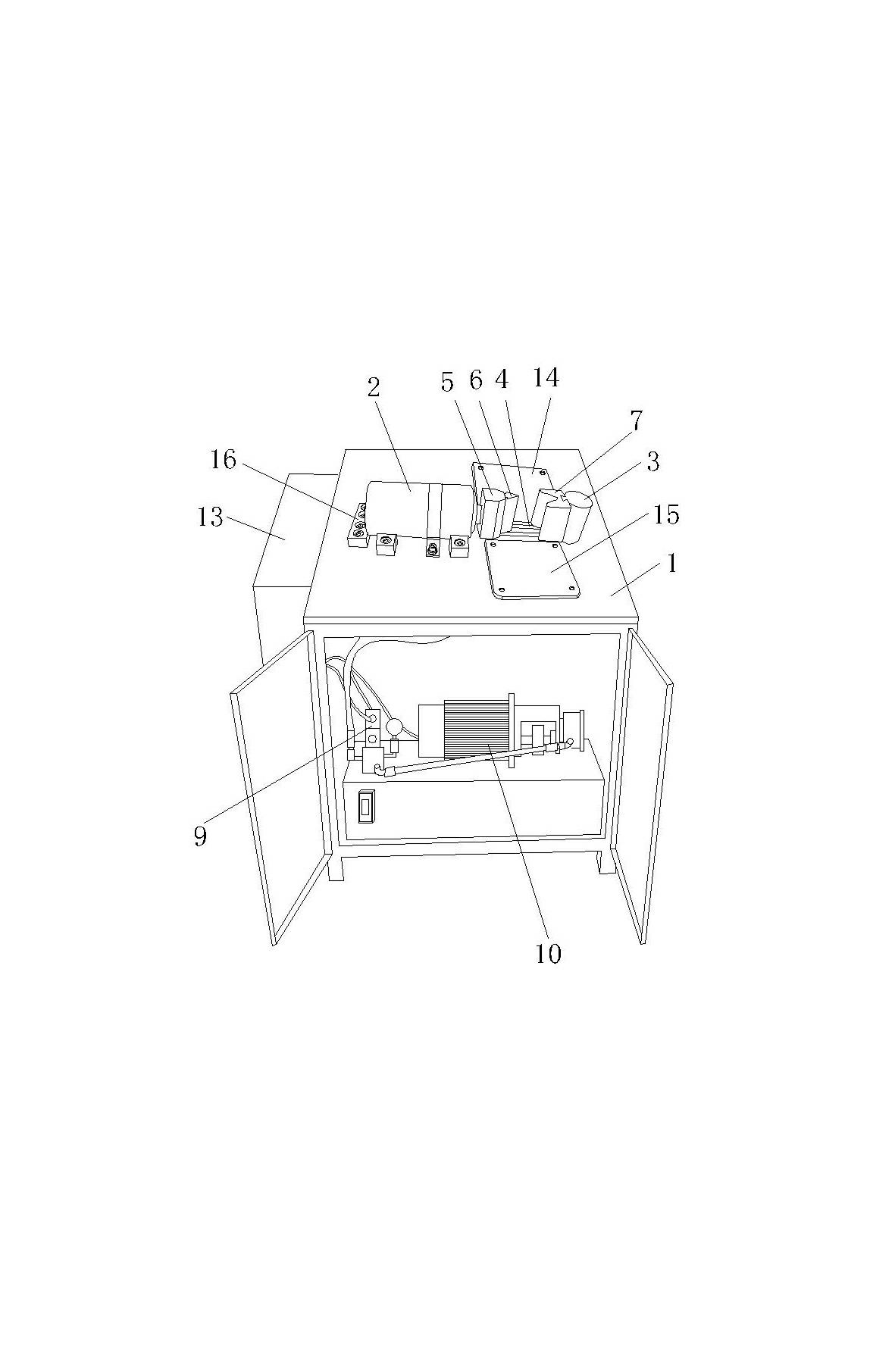

Small horizontal bending machine

The invention discloses a small horizontal bending machine, which comprises a working table and an oil cylinder. A vertical column is longitudinally arranged along one side of the working table, the oil cylinder is fixed on the other side of the working table, and the lower portion of the vertical column penetrates through the working table and is fixed to the working table. A longitudinal rail is fixed on the working table between the vertical column and the oil cylinder, a slider is fixed on a piston rod of the oil cylinder, opposite sides of the slider and the vertical column are respectively provided with a vertical dovetail groove, a male die is mounted on the dovetail groove of the slider, a female die is mounted on the dovetail groove of the vertical column, the lower portion of the slider is provided with a groove matched with the longitudinal rail, and the slider can move front and back along the longitudinal rail. The lateral face of the oil cylinder is connected with a hydraulic station by electromagnetic reversing valves through two oil pipes, two pedal switches are connected with electromagnetic coils of the electromagnetic reversing valves through an electric control box, and the piston rod of the oil cylinder moves ahead or back when the two pedal switches are respectively switched on. The small horizontal bending machine is simple in structure, low in manufacturing cost, convenient in disassembly and assembly and suitable for bending elongated plates.

Owner:SUCTRN TECH

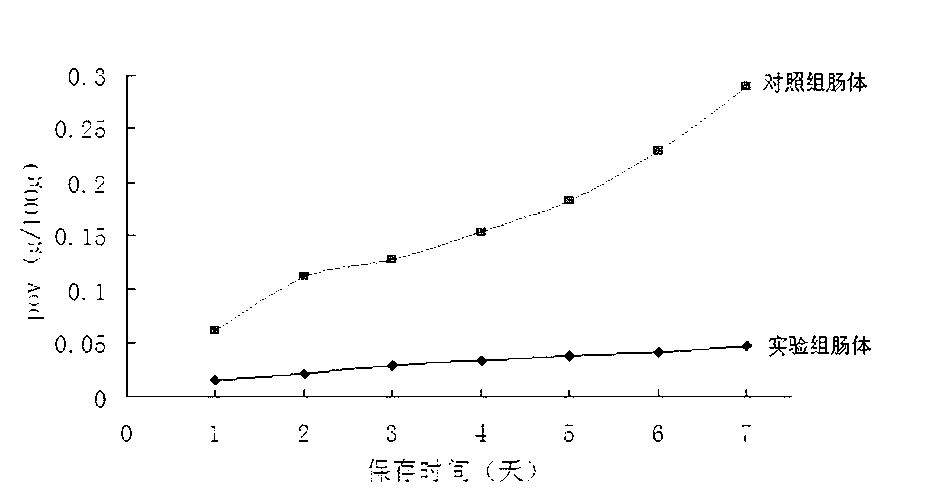

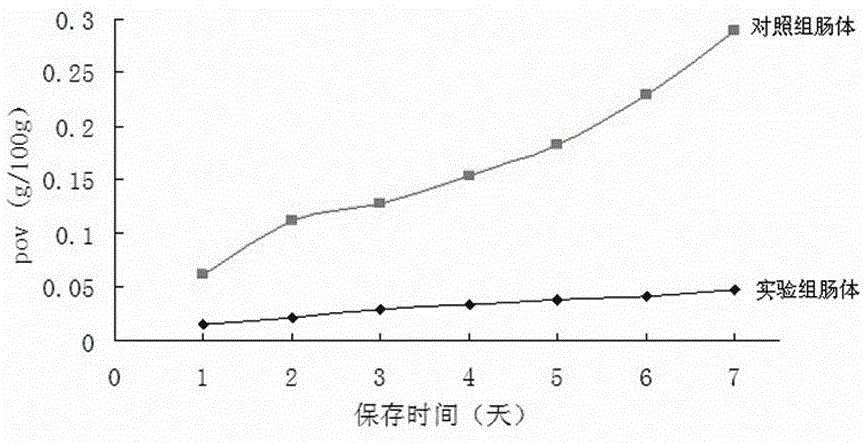

Composite antioxidant for sausage products and preparation method thereof

ActiveCN103211000AReasonable ratioSynergisticMeat/fish preservation using chemicalsFood additiveMaterial type

The invention belongs to the field of food additives, and in particular relates to a composite antioxidant for sausage products and a preparation method thereof. The antioxidant comprises the following materials: a glycyrrhiza antioxidant, sodium phytate, a rosemary extract, D-sodium isoascorbate, tea polyphenols and an emulsifier. The materials are reasonable in proportion, contain various antioxidant compounds, have synergy effect, and are good in antioxidant effect; the shelf-life of sausage products can be prolonged under the precondition of hardly increasing the cost; the composite antioxidant is wide in application range, and is suitable for processing sausage products under the conditions of high temperature and low temperature; the composite antioxidant is simple in formula, convenient to use, high in applicability, simple and convenient to prepare; the quality of material type and using amount is safe and efficient; and the composite antioxidant has an important meaning for solving fat and grease oxidation problem in cooked meat products.

Owner:北京美添阳光科技有限公司

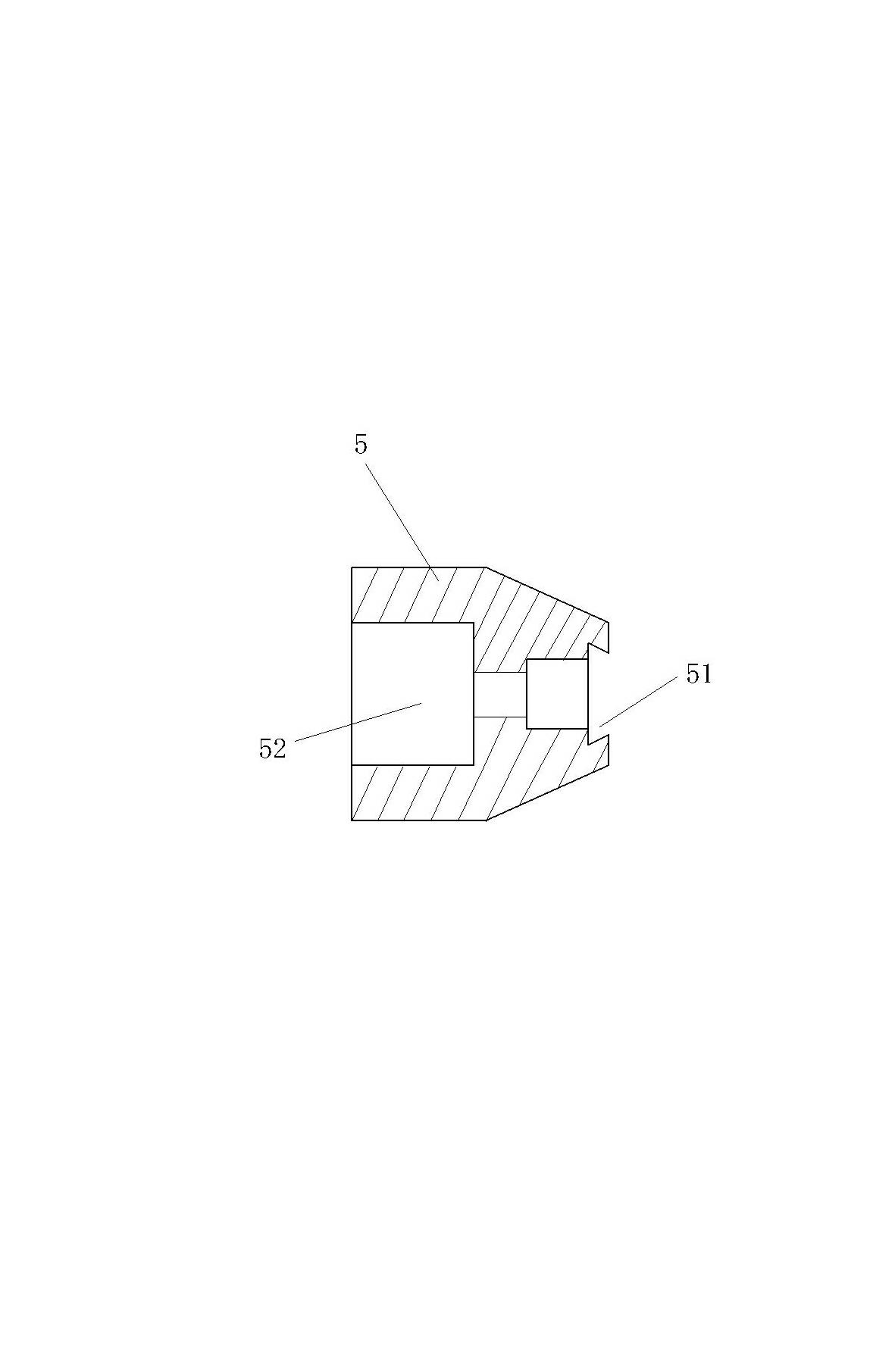

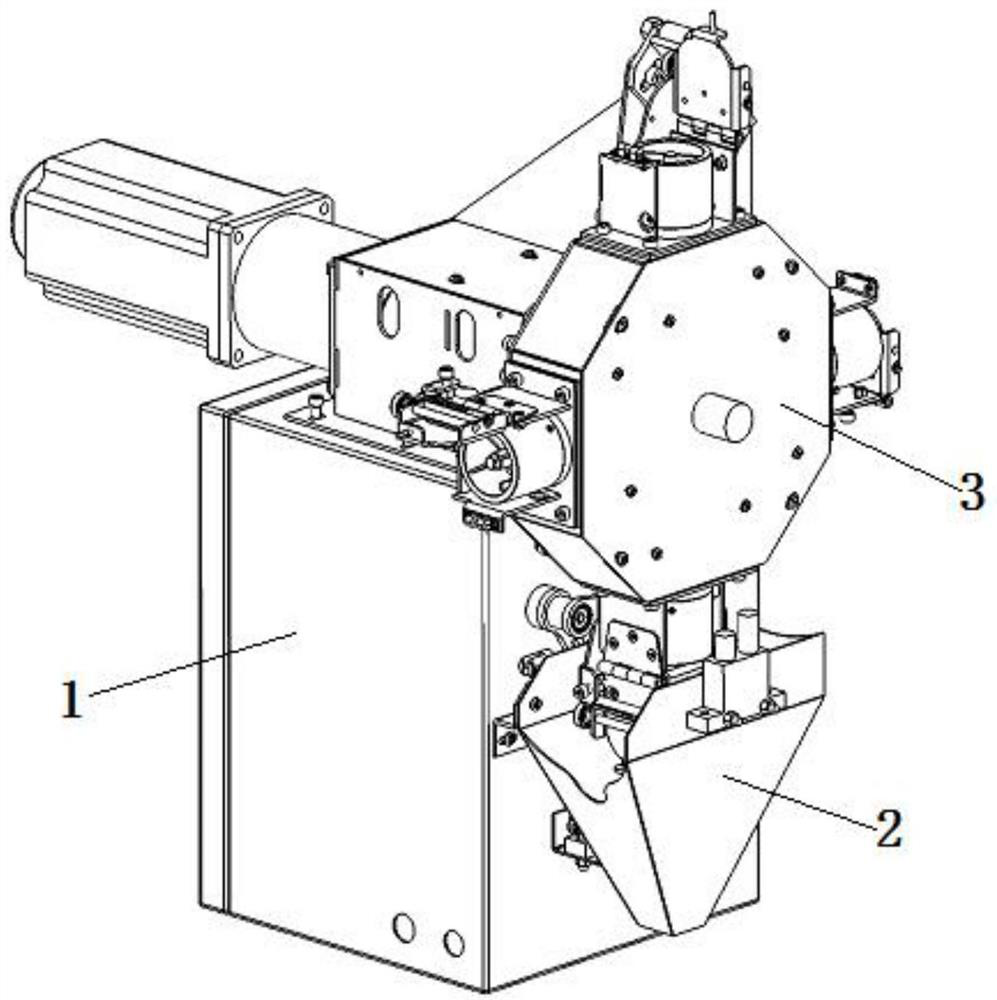

Perforating machine

PendingCN109175074ALow costImprove mobile stabilityMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention discloses a perforating machine comprising a workbench. A stand column is vertically and fixedly connected with one side of the upper end of the workbench; the upper end of the stand column is fixedly connected with a cross arm; a punching device is fixedly arranged at the lower end of the cross arm; a first supporting board is fixedly arranged at the position, under the punching device, of the upper end of the workbench; a second supporting board is movably arranged at the upper end of the first supporting board; a clamping table is movably arranged at the upper end of the second supporting board; a cavity is transversely arranged inside the clamping table; a bidirectional screw rod is transversely arranged inside the cavity; the two ends of the bidirectional screw rod are rotationally connected with the two sides of the cavity through first rolling bearings separately; and one end of the bidirectional screw rod extends out of the clamping table and is fixedly connectedwith a first rotary wheel. Clamped workpieces are driven to move in a comprehensive mode, different positions of the workpieces are punched through the punching device conveniently, needed cost is low, and the perforating machine is suitable for machining mechanical parts of small enterprises.

Owner:TIANJIN LONGCHI MACHINERY MFG CO LTD

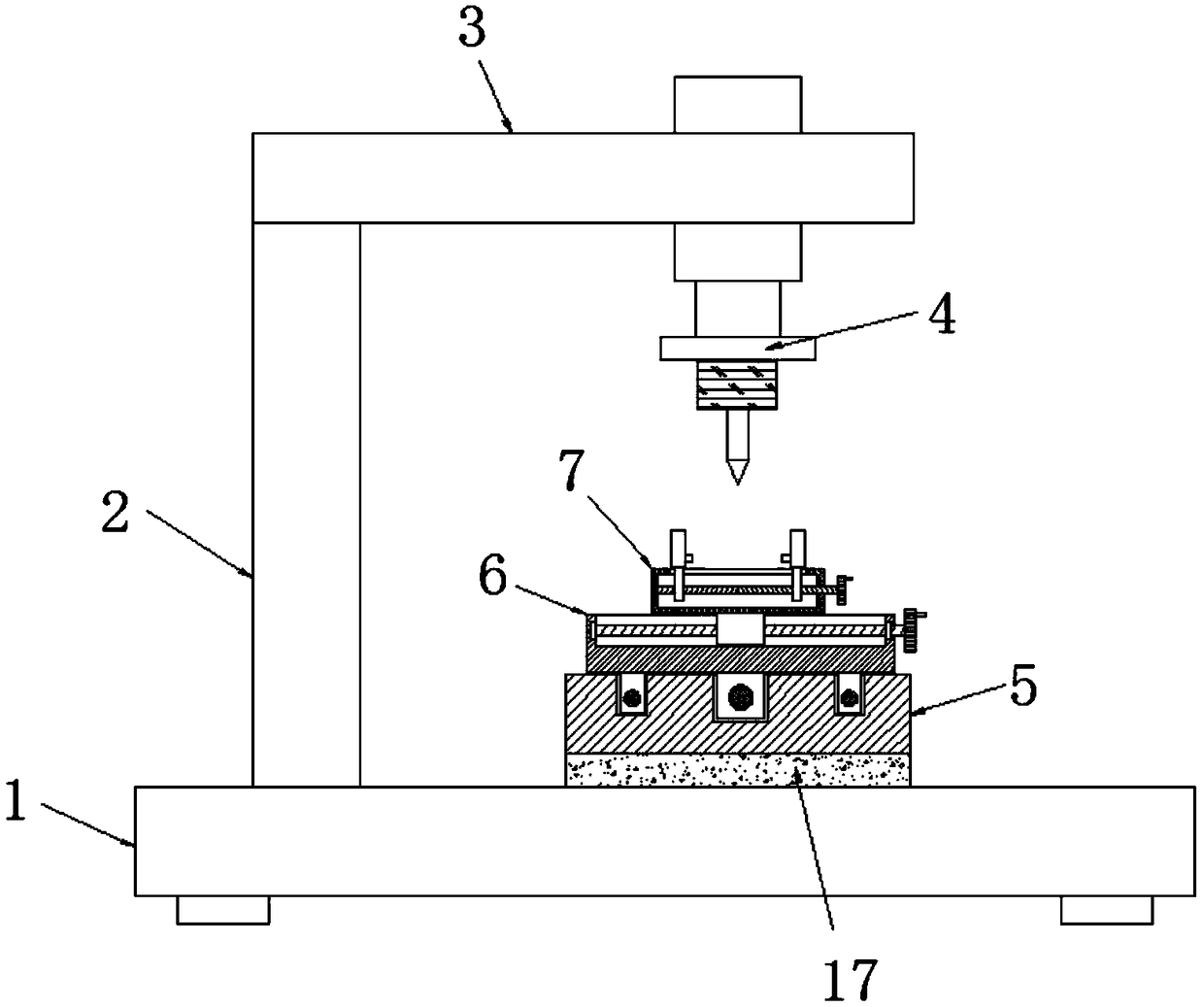

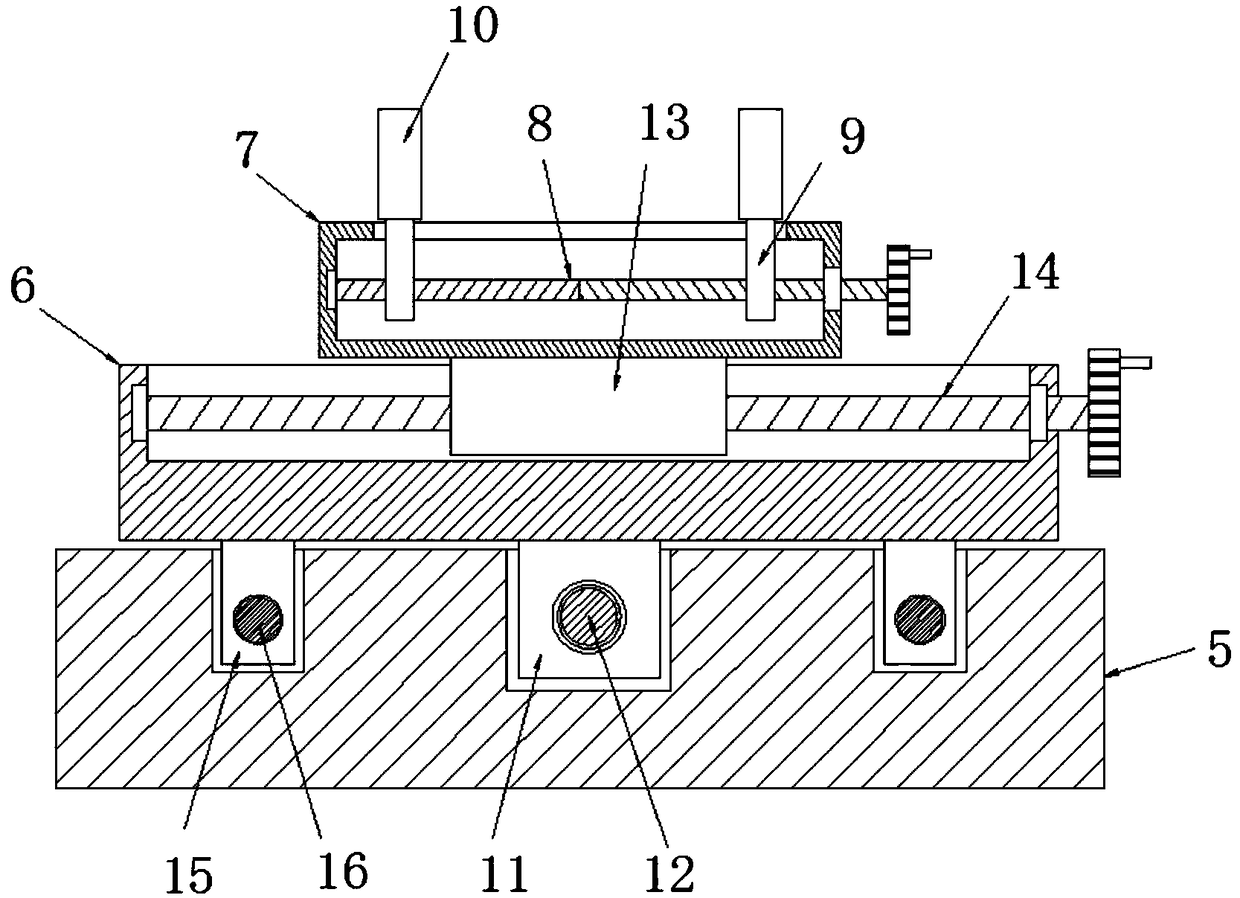

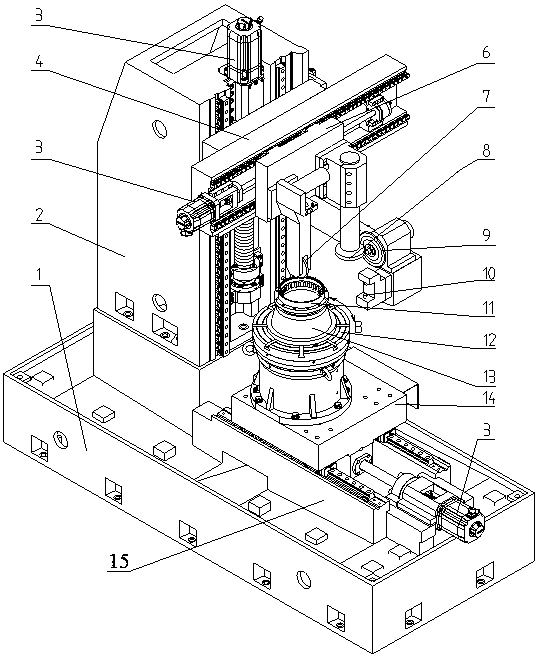

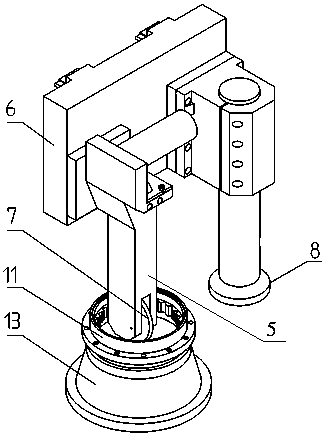

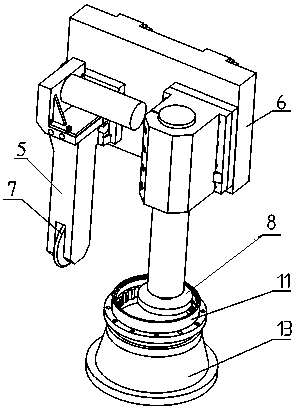

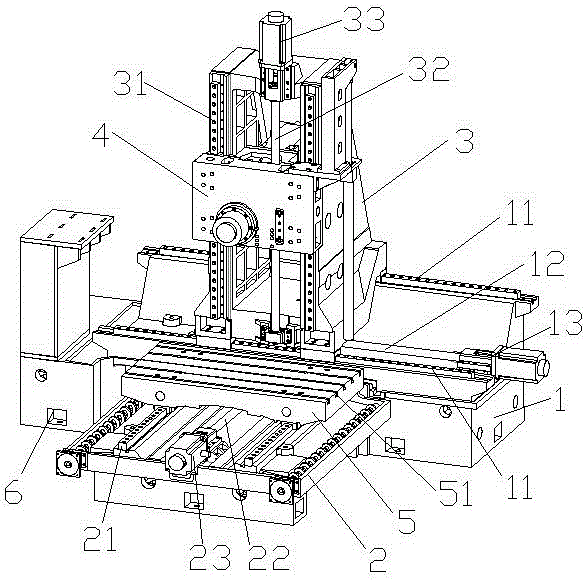

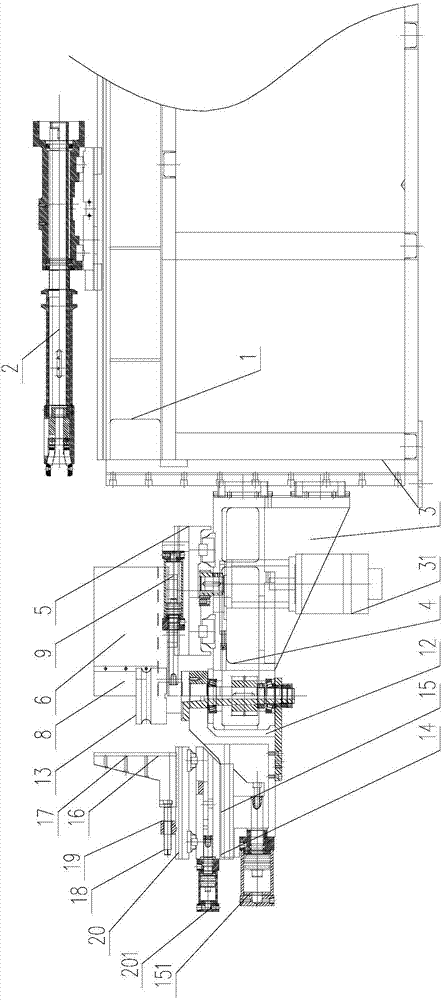

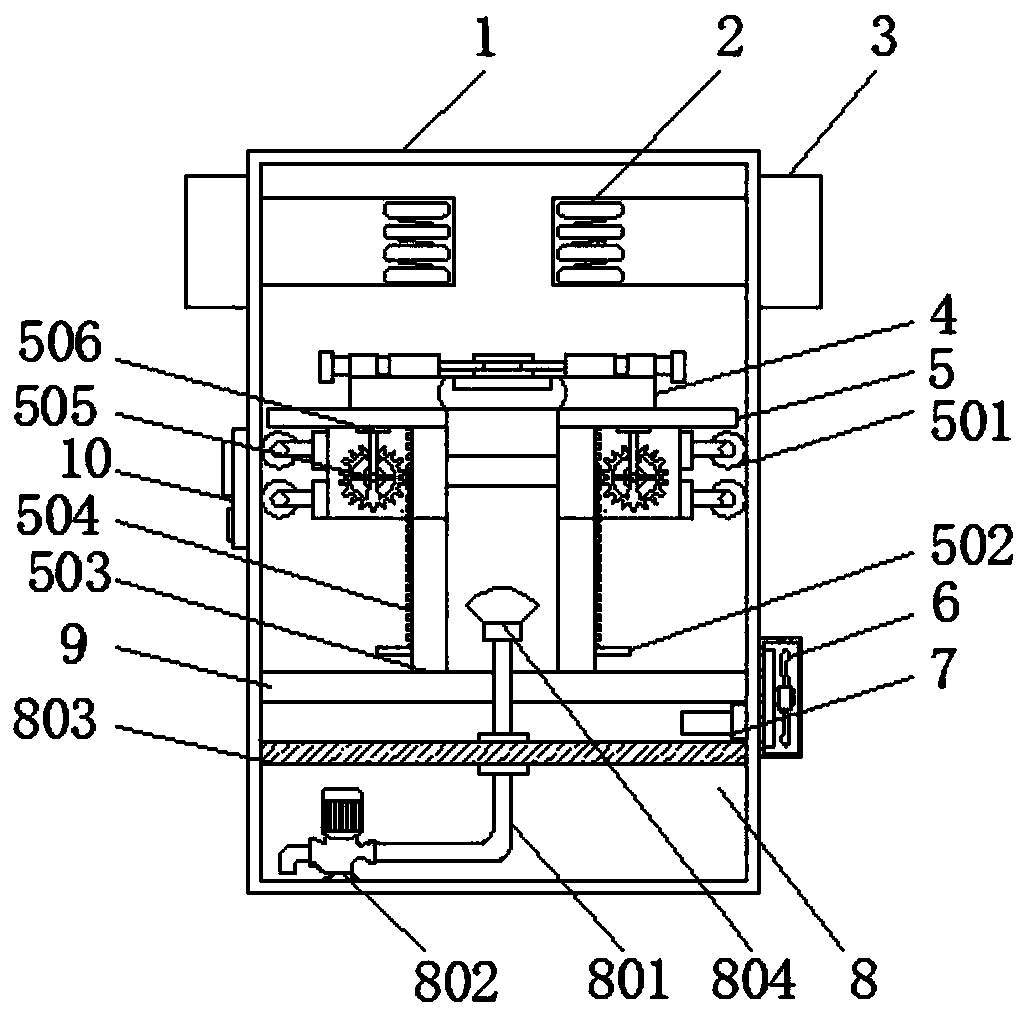

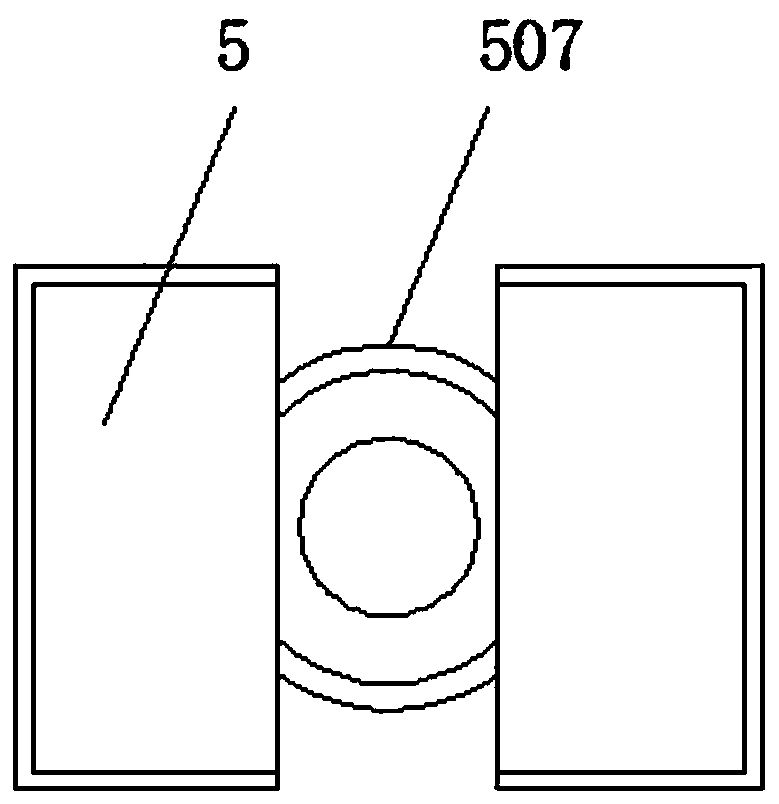

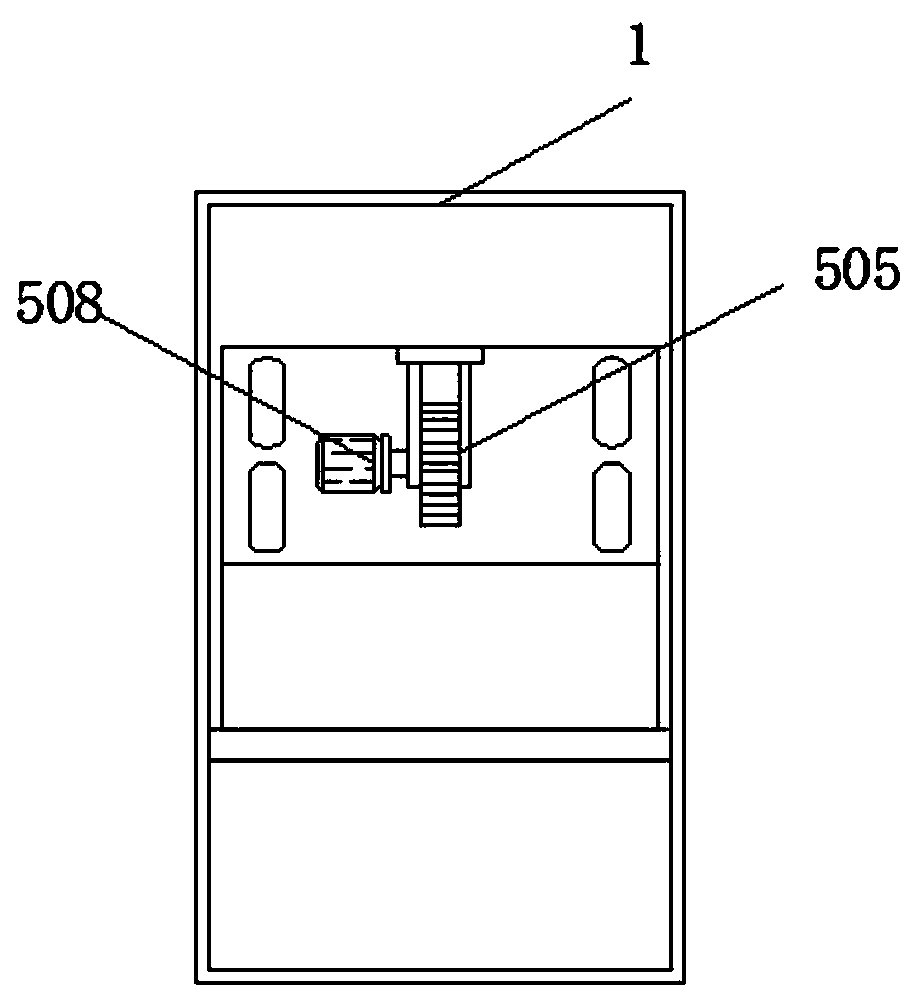

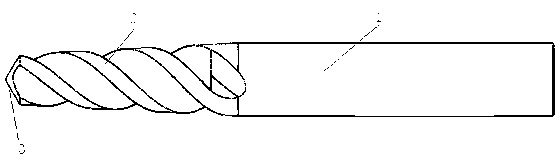

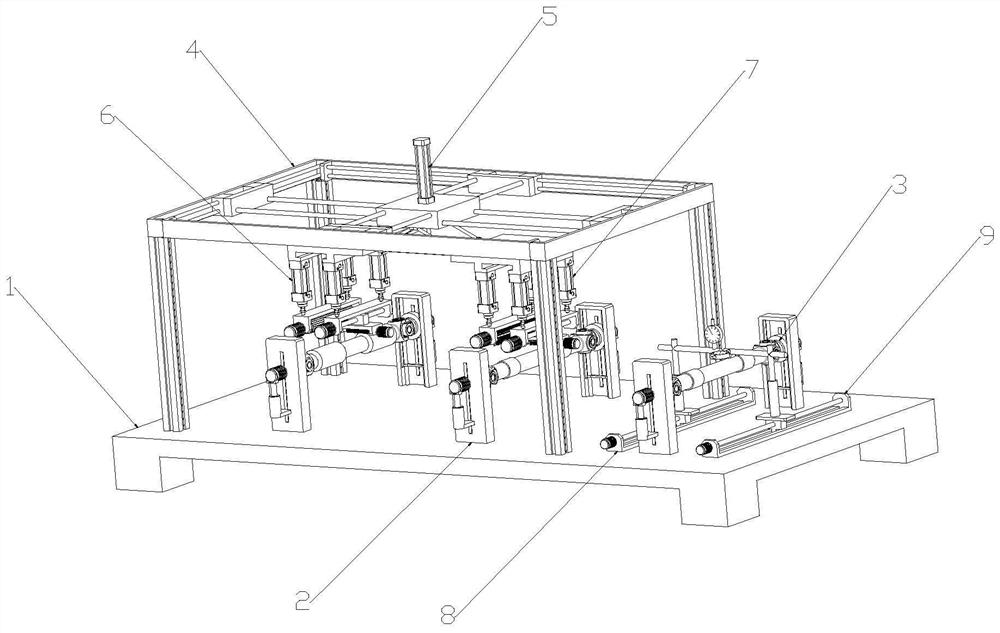

Combined machining grinder for robot RV speed reducer pin wheel housing

ActiveCN108098475AImprove production efficiencyGuaranteed machining accuracyRevolution surface grinding machinesGrinding work supportsReduction driveEngineering

The invention relates to a combined machining grinder for a robot RV speed reducer pin wheel housing. The combined machining grinder comprises a grinder body, an inner hole grinding wheel and a turntable are arranged on the grinder body, the inner hole grinding wheel is used for grinding an inner hole of the pin wheel housing, the turntable is used for mounting the pin wheel housing, the inner hole grinding wheel is provided with an inner hole grinding surface for grinding the inner hole of the pin wheel housing, a pin wheel grinding wheel for grinding a pin wheel hole of the pin wheel housingis arranged on the grinder body, the pin wheel grinding wheel is provided with a pin wheel grinding surface for grinding a pin wheel hole of the pin wheel housing, and end grinding surfaces for grinding two axial end surfaces of the inner hole of the pin wheel housing are arranged on two axial end surfaces of the inner hole grinding wheel. The combined machining grinder can be clamped once, so that the pin wheel hole, the inner hole and the two axial end surfaces of the inner hole of the pin wheel housing are grinded, machining accuracy is ensured, and the manufacturing efficiency of the pinwheel housing is improved.

Owner:HENAN UNIV OF SCI & TECH

Aluminium ware special-purpose noctilucence paint and application

InactiveCN104893492AGood dispersionImprove adhesionLuminescent paintsSpecial surfacesAdditive ingredientLight extinction

The invention discloses an aluminium ware special-purpose noctilucence paint and application, the aluminium ware special-purpose noctilucence paint is characterized by including the following ingredients by weight: 20-80% of resin, 5-60% of a curing agent, 0.1-20% of a levelling agent, 0.01-20% of a gloss enhancer, 1-40% of a pigment, 0.1-10% of a spice, 1-50% of barium sulfate, 0-50% of a light extinction curing agent, and 1-50% of noctilucent powder. Compared with the existing technology, th aluminium ware special-purpose noctilucence paint has low manufacturing cost, strong adhesion, good pigment dispersion and other characteristics, the prepared coating has the characteristics that the surface is smooth, and may not be too bright and blinkering, and is especially suitable for processing of aluminum curtain walls, aluminum doors, aluminum windows and sun room frames.

Owner:何炳贵

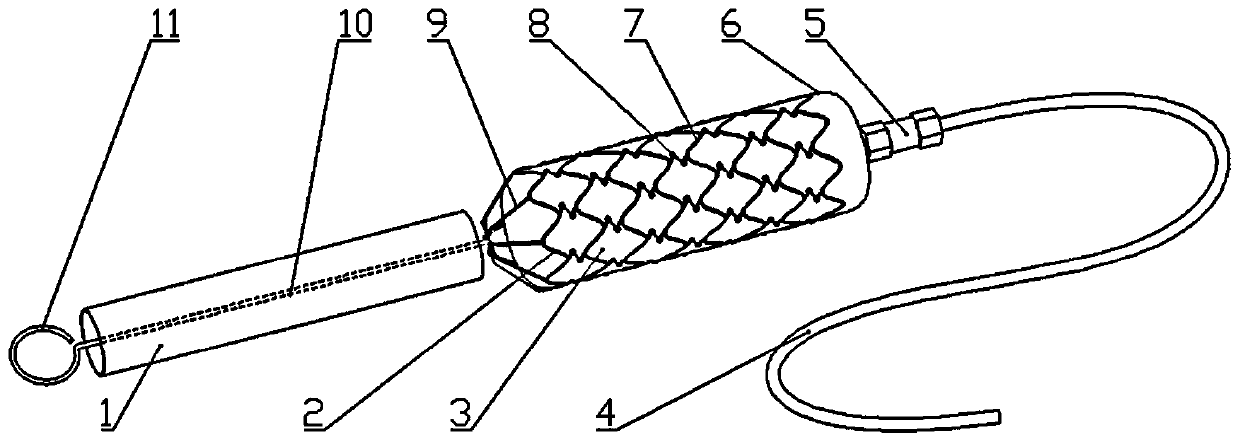

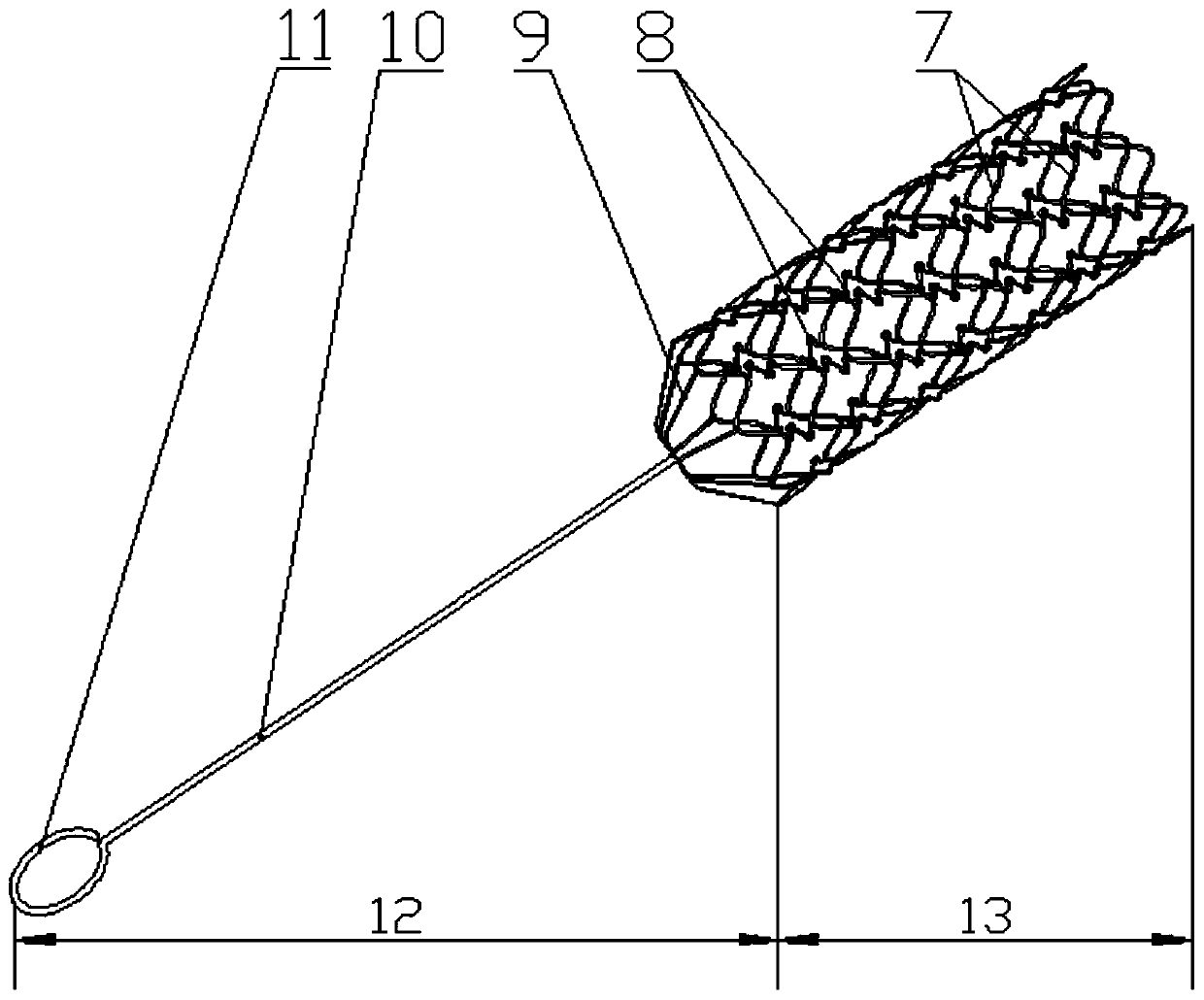

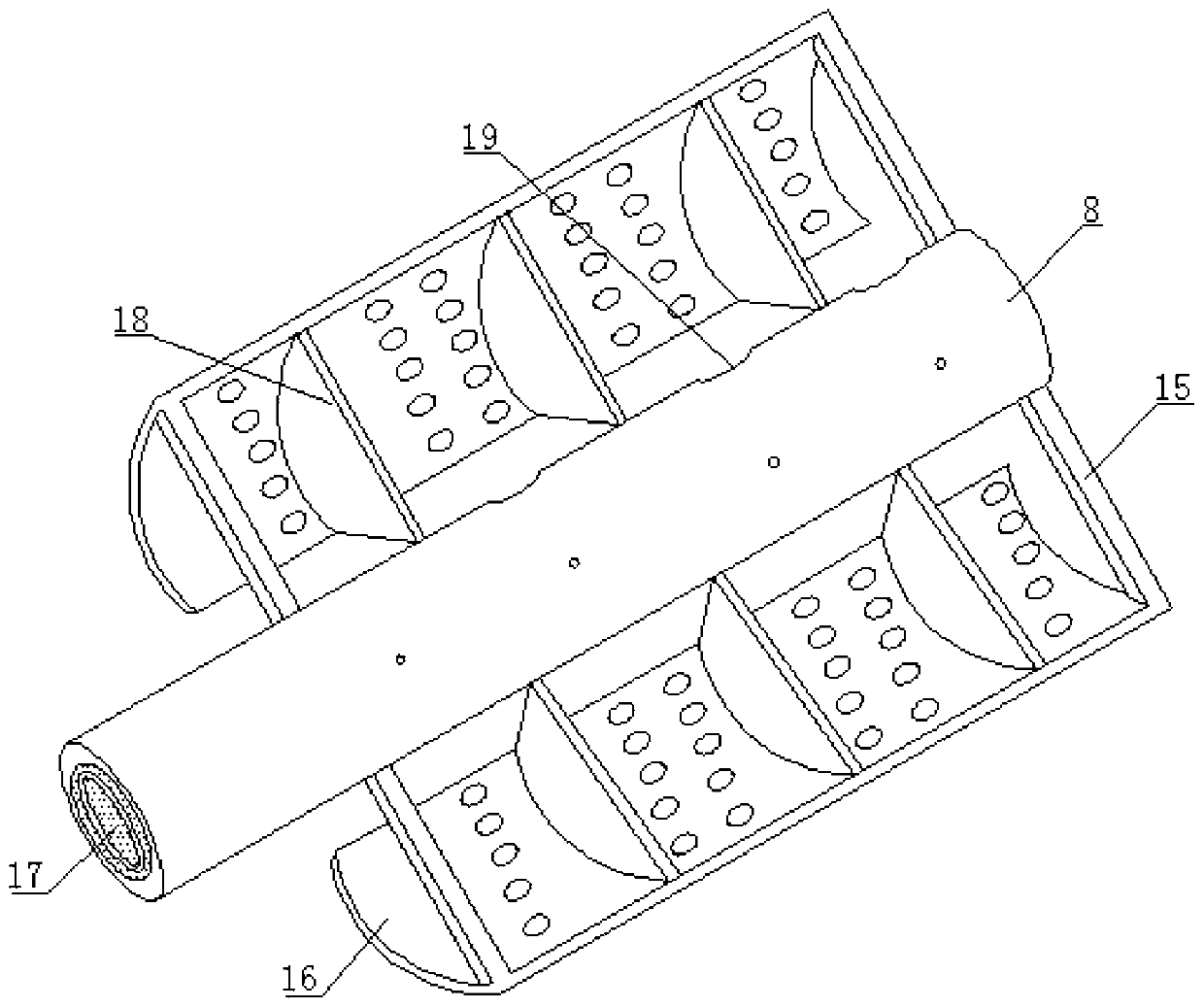

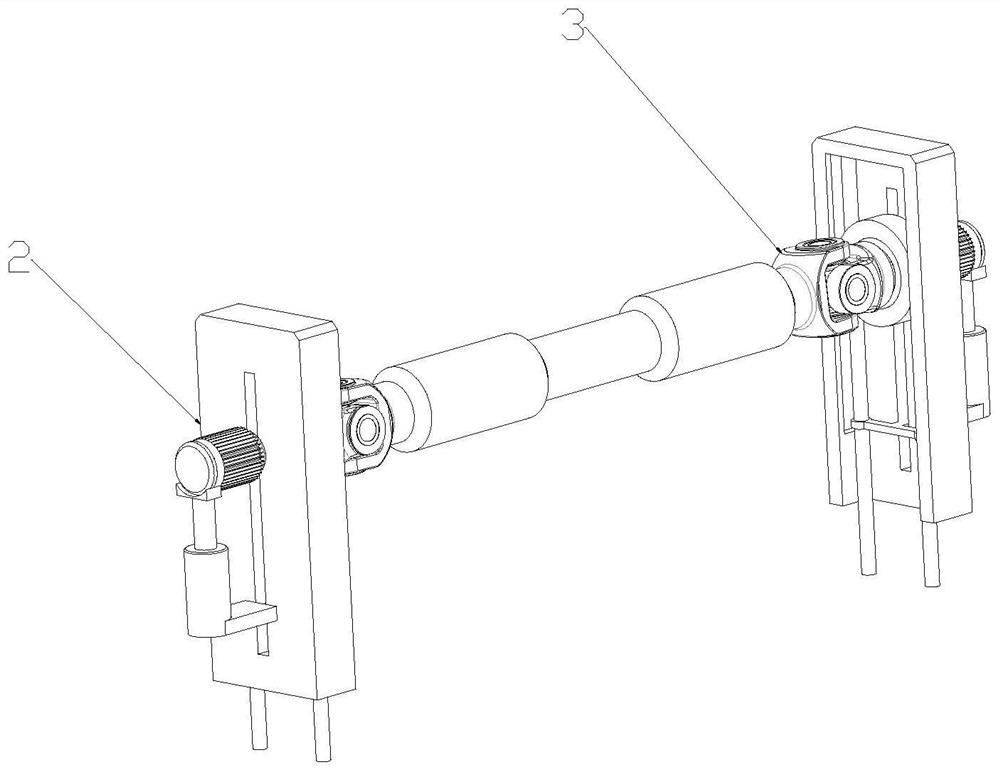

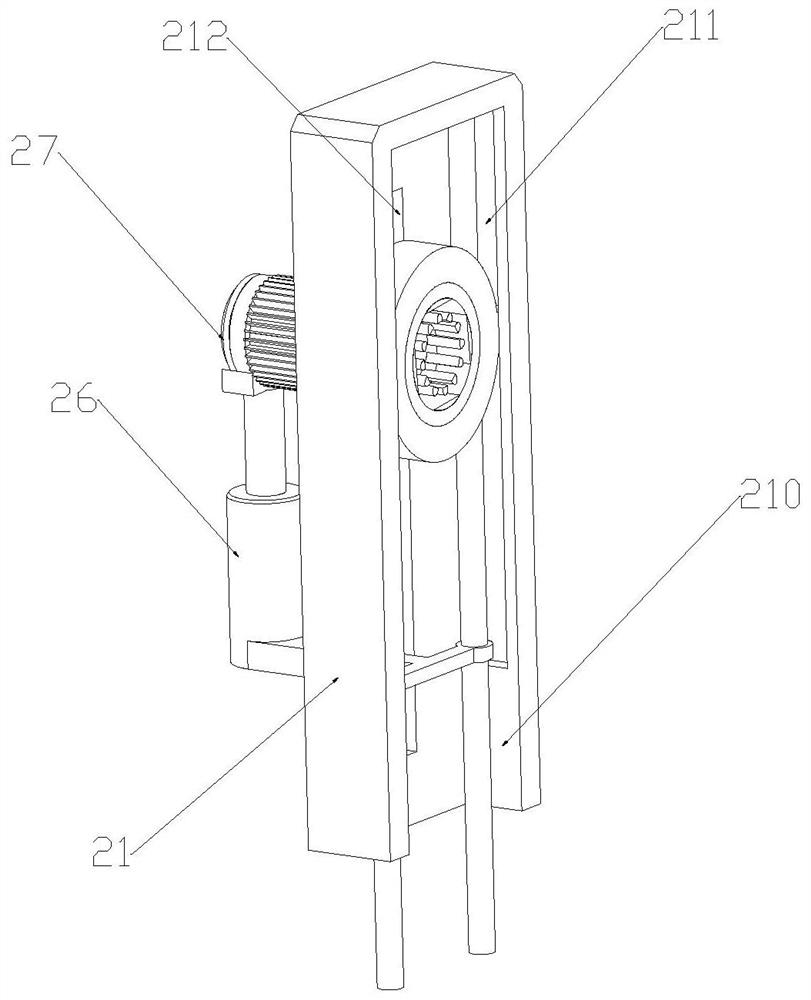

Elastic double-support variable-diameter core rod for bending aircraft engine metal conduit

The invention discloses an elastic double-support variable-diameter core rod for bending an aircraft engine metal conduit. The elastic double-support variable-diameter core rod comprises a support storage tube, an elastic outer support and an inner hydraulic part, in the inner hydraulic part, an inner cavity of an elastic membrane is filled with liquid, the tail end of the elastic membrane is provided with an opening, the opening is connected and communicates with a liquid conveying tube through a connector, the other end of the liquid tube is externally connected with a hydraulic system, theelastic outer support is a flexible whole composed of a pull rod and an elastic net-shaped structure, the pull rod is divided into three parts, namely an elastic traction section, a straight section and a pull ring which are sequentially connected, the elastic net-shaped structure is mainly formed by connecting a plurality of layers of wave-shaped metal strip circumferences and a plurality of anti-fatigue elastic connecting pieces in a net-shaped manner, and the support storage tube is arranged outside the elastic outer support / inner hydraulic part in a sleeving mode. The elastic double-support variable-diameter core rod is variable in diameter and can adapt to machining requirements of aircraft engine metal bent tubes with different sizes, so that the production cost is reduced, and the defects of wrinkling and section flattening forming in the bending process are effectively overcome.

Owner:ZHEJIANG UNIV

Adhesive for textiles and preparation method thereof

InactiveCN106221590AApplicable processingImprove adhesionMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesCarvacryl acetateTributyl citrate

The invention discloses adhesive for textiles and a preparation method thereof. The adhesive comprises the following components in parts by weight: 120-300 parts of vinyl acetate, 60-150 parts of vinyl versatate, 30-120 parts of butyl acrylate, 5-20 parts of acrylic acid, 400-500 parts of deionized water, 50-150 parts of a non-ortho-benzene plasticizer, and 1-5 parts of an antiseptic. The non-ortho-benzene plasticizer is one of tributyl citrate and diisooctyl sebacate. The adhesive for textiles has bonding strength which is better than the bonding strength of other adhesives, and has the advantages of usage convenience and wide applicability. The adhesive for textiles has the advantages of easily available raw materials, low cost, and simple preparation technology. The adhesive for textiles does not have toxicity, bad smell, pollution corrosion, inflammability, and the like, and gluing of the adhesive does not have wire drawing.

Owner:FOSHAN CITY YONGHENGDA NEW MATERIAL TECH CO LTD

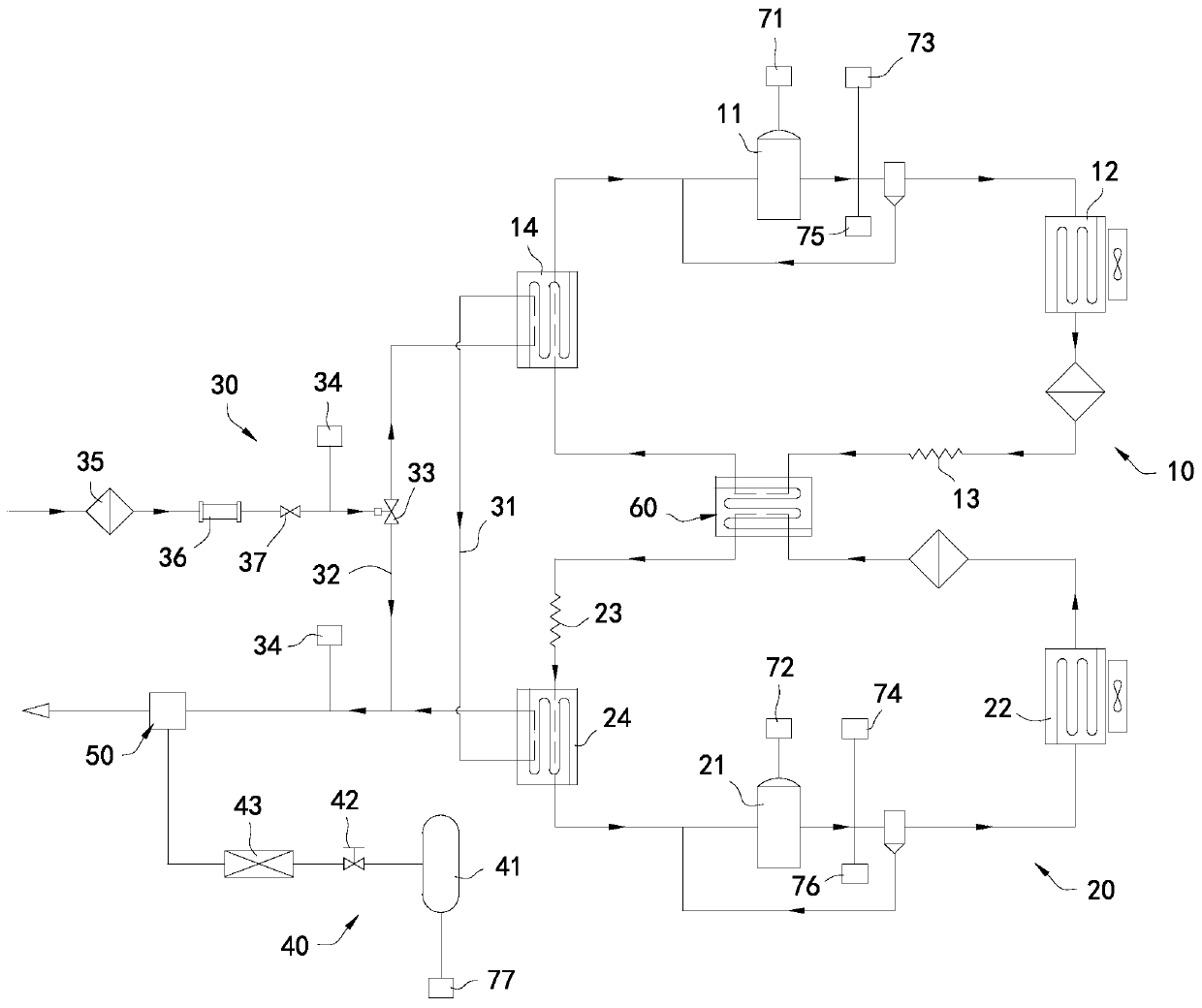

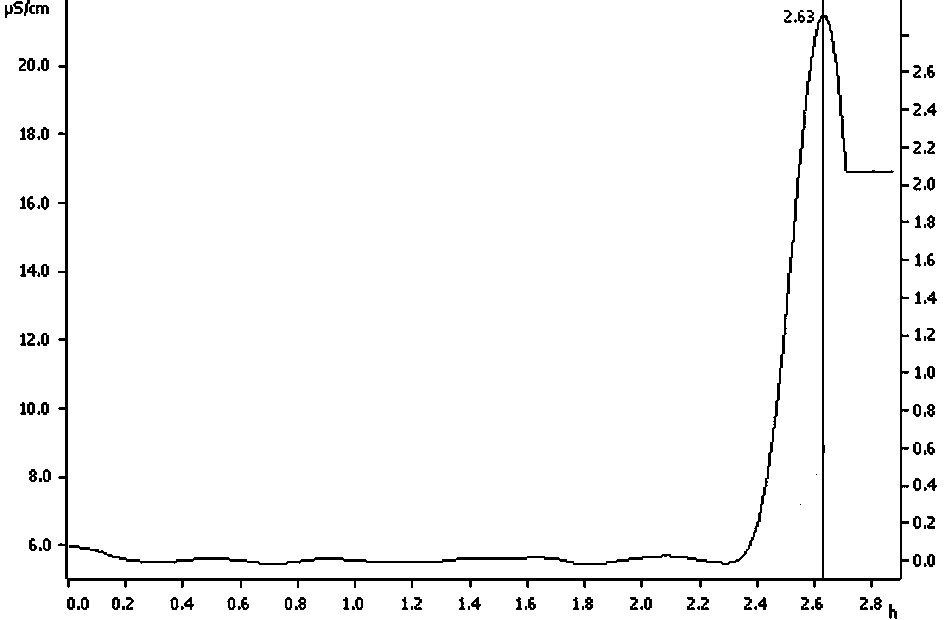

Low-temperature cold air refrigeration system and control method thereof as well as minimal quantity lubrication cooing system

InactiveCN110375452AStable controlRegulation stabilityMechanical apparatusCompression machines with cascade operationCold airEngineering

The invention discloses a low-temperature cold air refrigeration system and a control method thereof as well as a minimal quantity lubrication cooing system. The low-temperature cold air refrigerationsystem comprises a first refrigeration pipeline, a second refrigeration pipeline and a gas conveying pipeline, the gas conveying pipeline is sequentially connected with a first evaporator of the first refrigeration pipeline and a second evaporator of the second refrigeration pipeline in the flowing direction of compressed gas, so that heat exchange is carried out between the compressed gas and arefrigerant, the gas conveying pipeline is used for conveying the compressed gas to sequentially undergo heat exchange with the first refrigeration pipeline and the second refrigeration pipeline, thecompressed gas is subjected to two times ofheat release in sequence so that the temperature can be effectively reduced, and low-temperature cold air at 60 DEG C below zero at the minimum can be formed. Moreover, two times ofheat exchange is carried out so that full heat exchange can be carried out between the compressed gas and the refrigerant under the condition that the flow velocity of the compressed gas is not reduced.

Owner:CONPROFE TECH GRP CO LTD +1

Compound thickening agent for improving texture and emulsifying property of meat product and preparation method and application thereof

The invention provides a compound thickening agent for improving the texture and emulsifying property of a meat product and a preparation method and application thereof. The compound thickening agentis prepared from Sanzan gum, sodium hyaluronate, xanthan gum, konjac glucomannan, flaxseed gum and curdlan gum, the Sanzan gum, the sodium hyaluronate, the xanthan gum, the konjac glucomannan, the flaxseed gum and the curdlan gum are weighed according to the specified weight part ratio, added in sequence and mixed, and after uniform mixing, the compound thickening agent is obtained. On the premisethat the cost is little increased, the texture property, the water binding capacity, the gel strength and the yield of the meat product can be improved by using the compound thickening agent; the compound thickening agent is used in the production process of the meat product, materials can be significantly emulsified and evenly mixed, fat separation is prevented, the water-retaining property andthe hardness of the product are improved, the tissue form of the product is improved, the elasticity of the meat product is increased, the machining operability is improved, adhesion is reduced, demoulding and slicing are facilitated, and the quality of the meat product is improved.

Owner:北京美添前景科技有限公司

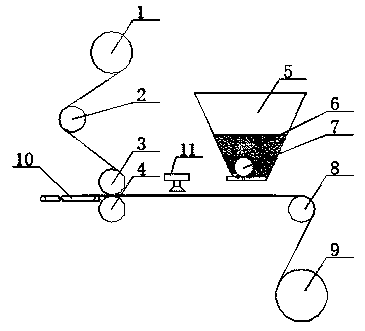

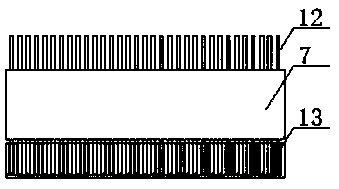

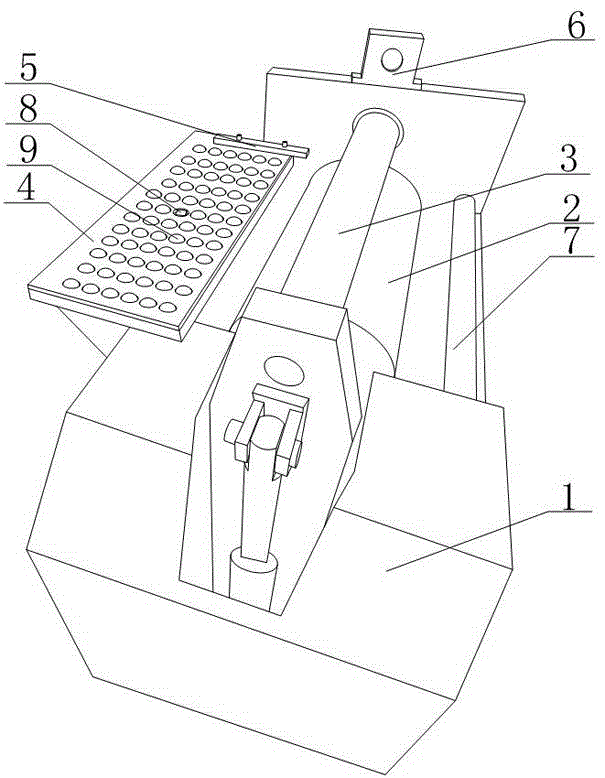

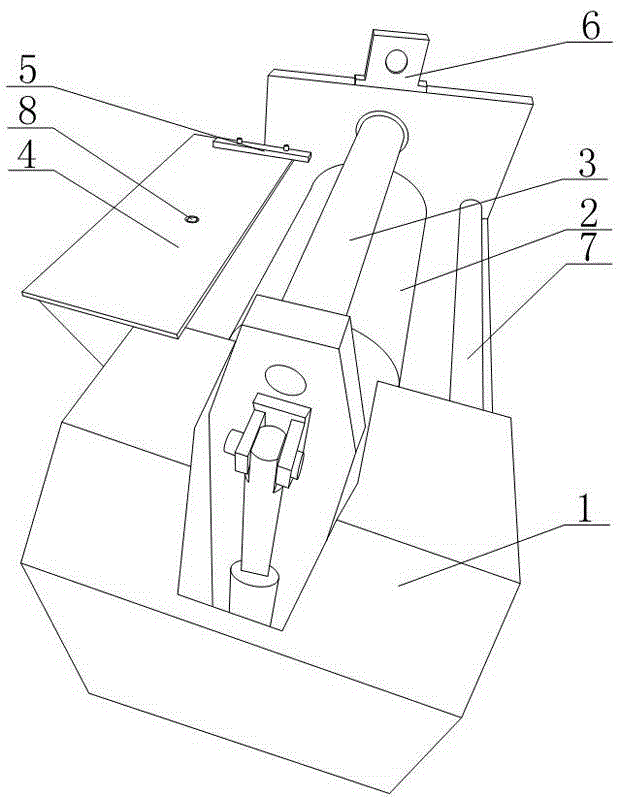

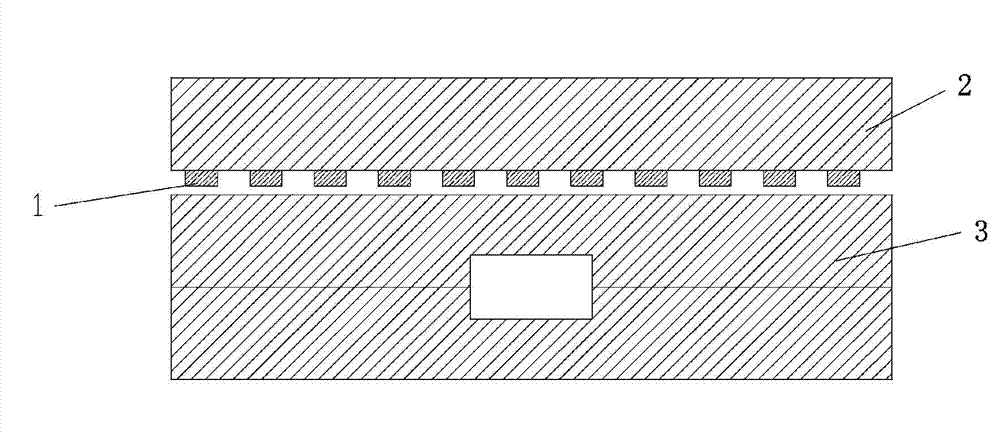

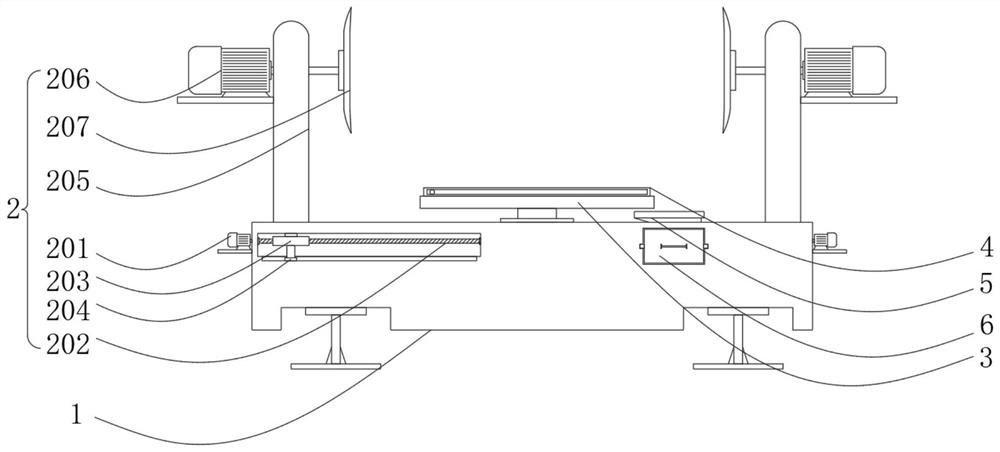

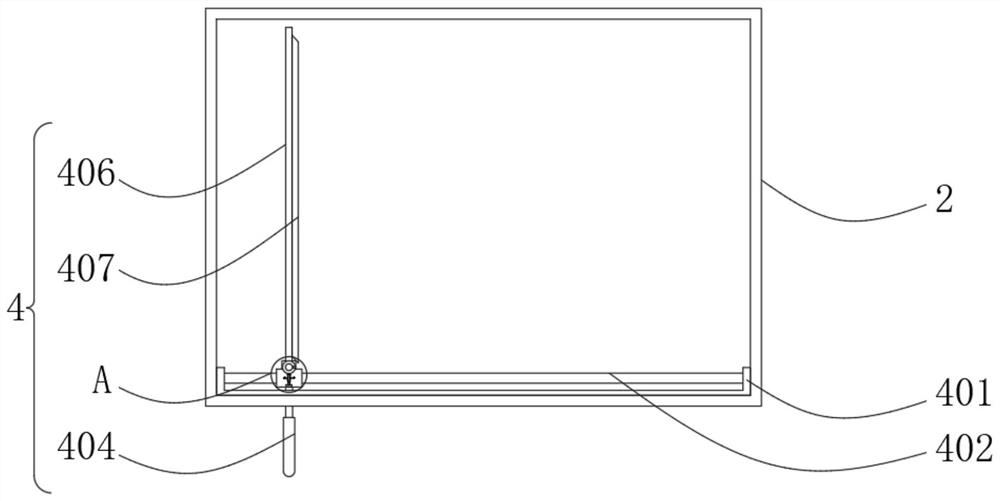

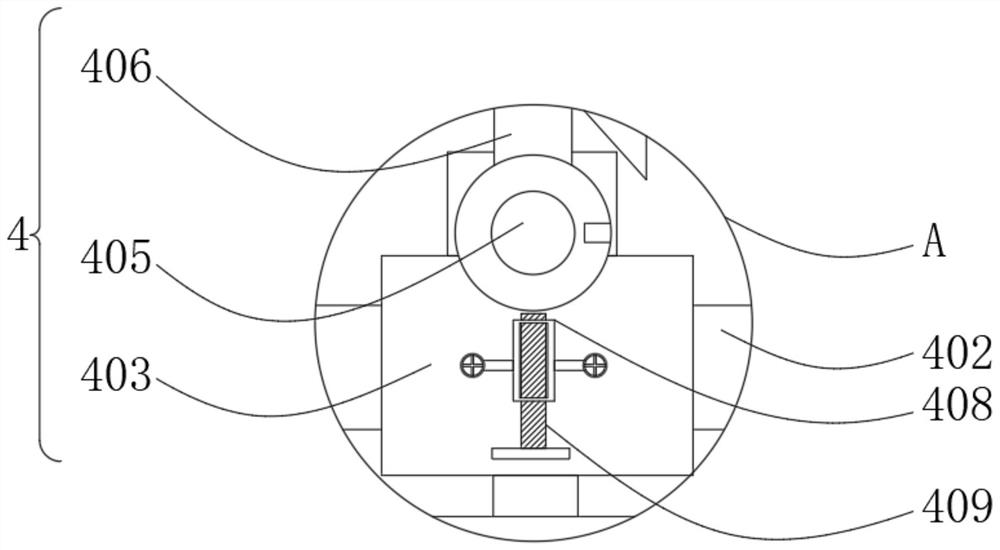

Forming device of layered biomass composite material

The invention discloses a forming device of a layered biomass composite material. The forming device comprises an upper layer discharge module, a lower layer discharge module, a fiber laying module and a pressing module. By means of the forming device, a biomass fiber material can be wrapped in thermoplastic resin sheets on the upper layer and the lower layer, and then the layered composite material can be obtained after pressing. The forming device is reasonable in design, biomass fiber does not need to be refined, and continuous production can be achieved; and the manufactured layered composite material is uniform in texture, smooth in surface and good in mechanical property.

Owner:湖南科维智能科技有限公司

High-precision machining machine tool

The invention discloses a high-precision machining machine tool. The high-precision machining machine tool comprises a base, a supporting platform is arranged on one side of the base, and a workbench which can move back and forth relative to the supporting platform is arranged on the supporting platform. The base is provided with a saddle which can move left and right relative to the base, and the saddle is provided with a main shaft which can move up and down relative to the saddle. A control cabinet is arranged at one end of the base. The base is in a step shape, and the height of the workbench is consistent with the height of a low step face of the base. Due to the fact that the saddle is designed to move left and right relative to the base, the main shaft is designed to move up and down relative to the saddle, and the workbench is designed to move back and forth relative to the base, the main shaft can be adjusted to corresponding positions according to positions of a workpiece, and the machine tool is suitable for machining any position on the surface of the workpiece.

Owner:ZHENJIANG FUDE NC MACHINE TOOL TECH CO LTD

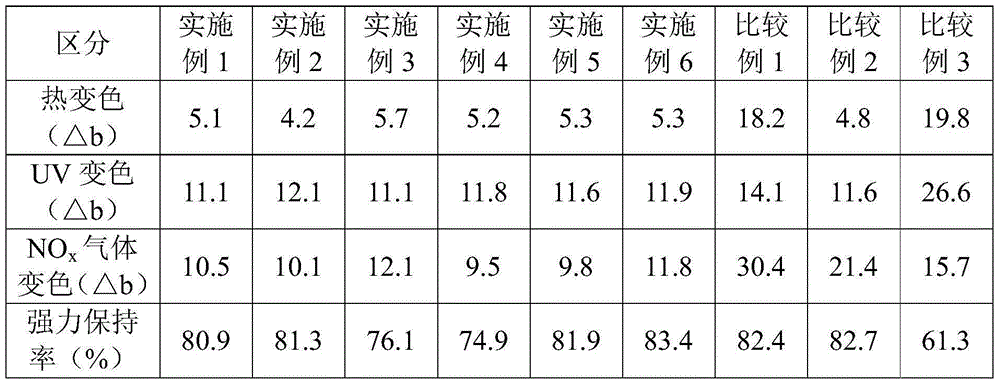

Spandex fiber having excellent chlorine resistance and discoloration resistance and method for preparing same

ActiveCN105051271AApplicable processingGood discoloration effectMonocomponent polyurethanes artificial filamentDry spinning methodsFiberScavenger

The purpose of the present invention is to solve problems of easy discoloration of a chlorine-resistant spandex fiber employing an inorganic chlorine resistant agent when left in the air, a short-term or temporary chlorine resistant effect, and the loss of a unique trait of a spandex fiber, and to provide a spandex fiber having excellent chlorine resistance and discoloration resistance and a method for preparing the same, wherein the spandex fiber is prepared by adding and mixing, as organic additives for improving chlorine resistance added in the preparation of a normal chlorine-resistant spandex fiber, at least one compound among symmetric di-hindered hydroxyphenyl-based compounds and mono-hindered hydroxyphenyl-based compounds, an additive containing a semicarbazide-based compound having heat resistance and a radical scavenger function, and an urethane-based additive containing a tertiary butyl group serving as a secondary antioxidant, into a slurry of a polyurethane solution, thereby preparing a spinning solution, followed by defoamation, dry spinning, and winding.

Owner:HYOSUNG CORP

Method for synthesizing porous microsphere material containing NaY zeolite by waste FCC (fluid catalytic cracking) catalyst

ActiveCN102125872BPromote growthReduce pollutionCatalytic crackingMolecular sieve catalystsSlurrySodium silicate

Owner:HUNAN JULI CATALYST

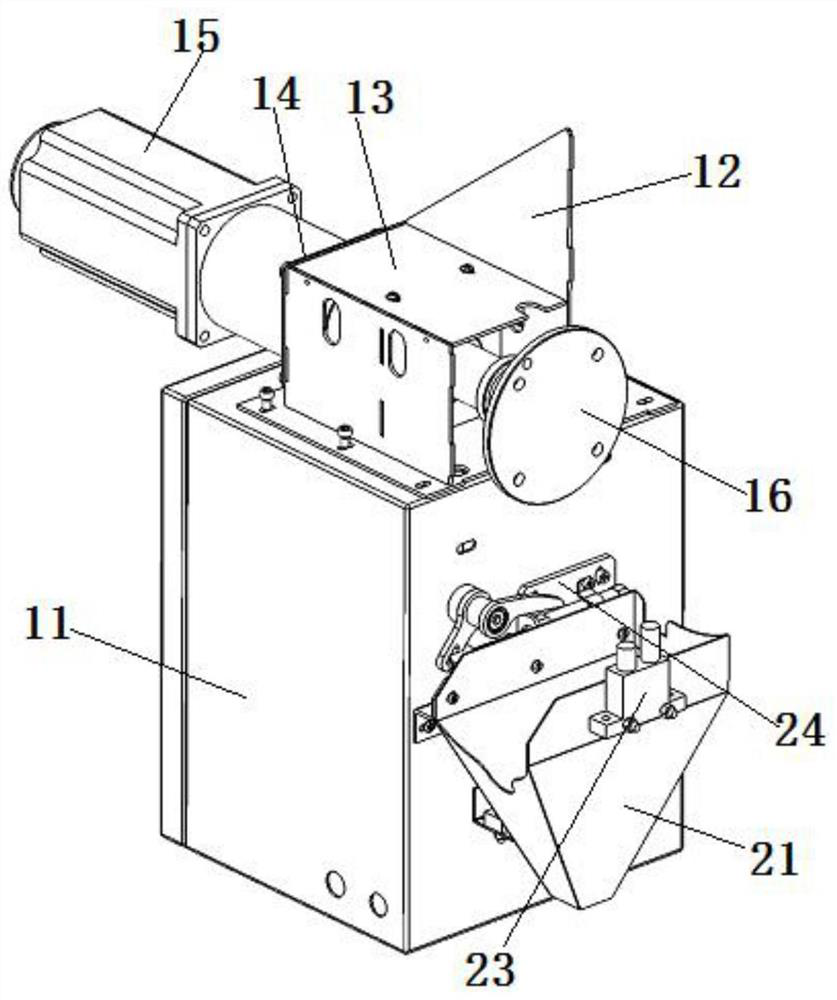

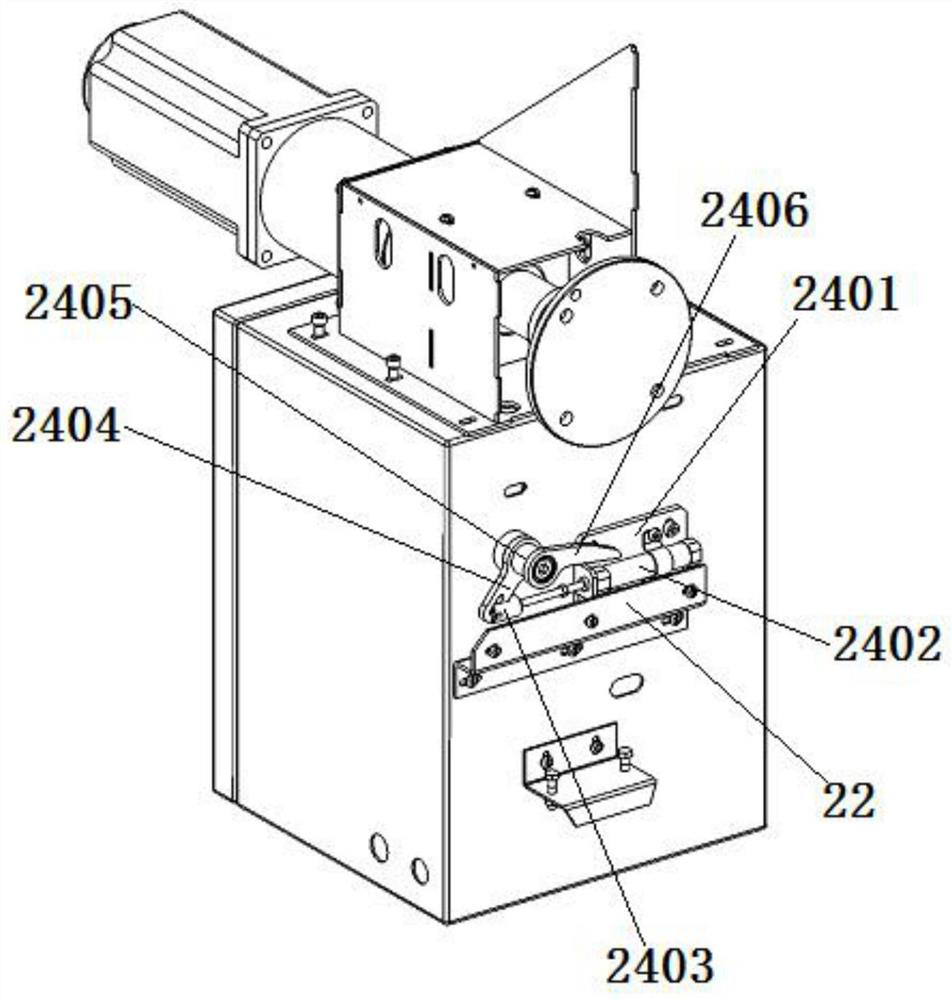

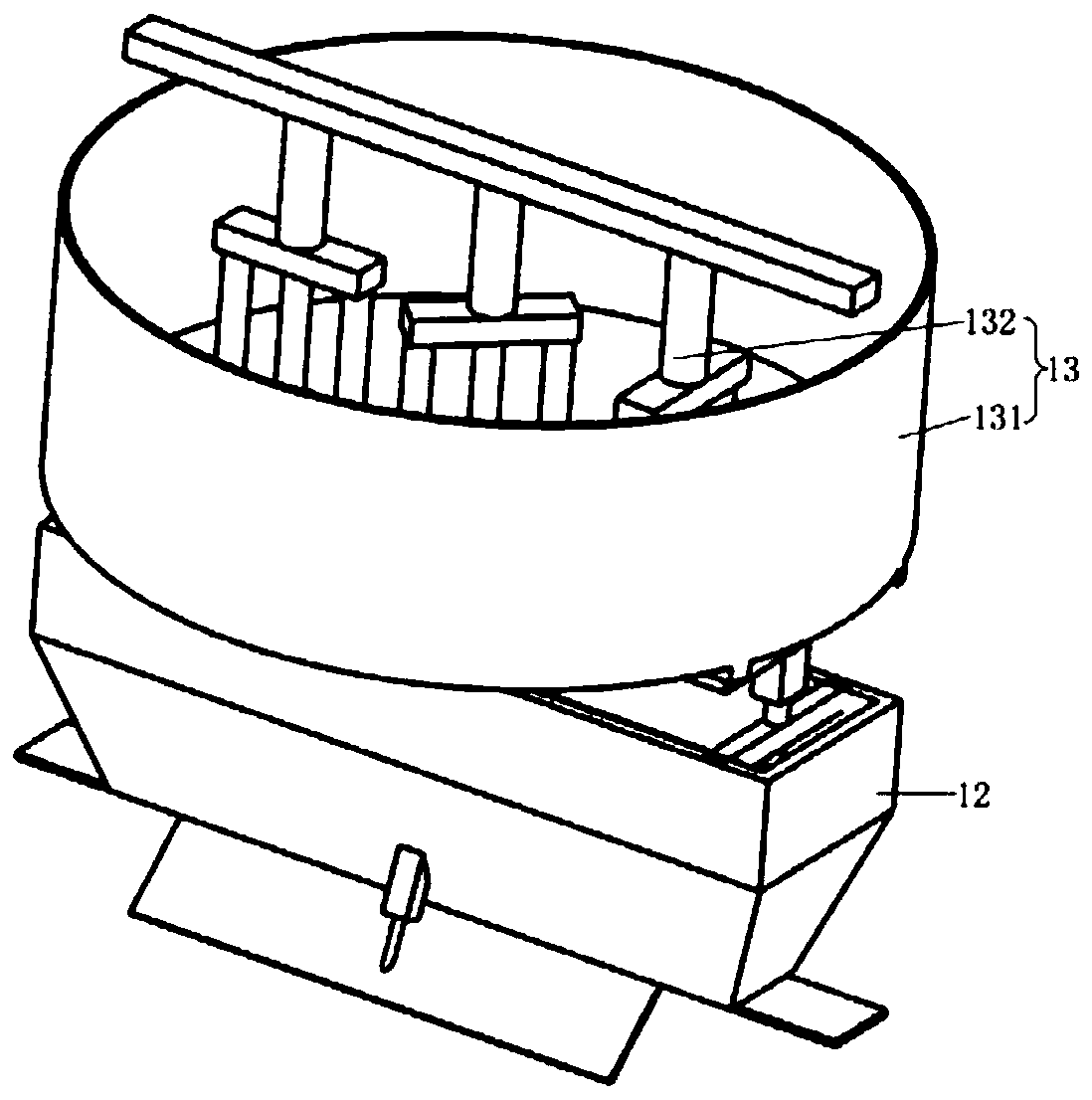

Mixing device with quantitative discharging function for traditional Chinese medicine decoction pieces

InactiveCN111617687AEasy to controlEasy to operateShaking/oscillating/vibrating mixersTransportation and packagingProcess engineeringChinese herbology

The invention discloses a mixing device with a quantitative discharging function for traditional Chinese medicine decoction pieces, the mixing device with the quantitative discharging function for thetraditional Chinese medicine decoction pieces comprises a bearing device, a discharging device and a mixing device, and the discharging device and the mixing device are both mounted on the bearing device; the bearing device comprises a bearing box body, and a triangular supporting vertical plate and a first L-shaped plate are fixed to the upper surface of the bearing box body; the discharging device comprises a hopper, the hopper is fixed to the surface of the bearing box body through a Z-shaped plate, the discharging device further comprises an adjusting mechanism, and the adjusting mechanism is installed on the bearing box body; the mixing device comprises a bearing frame, a mixing mechanism and a feeding mechanism, the bearing frame is fixed to a rotary disc, the mixing mechanism is installed on the bearing frame, and the feeding mechanism is installed on the triangular supporting vertical plate. According to the invention, not only can the crushing process be realized, but also the quantitative discharging function can be realized, traditional Chinese medicinal materials subjected to quantitative discharging can be directly subjected to the next process operation, and the process flow of a traditional Chinese medicinal beverage is simplified; and the device is simple in structure, easy to operate and suitable for processing of traditional Chinese medicine beverages.

Owner:临泉县朦顺中药材有限公司

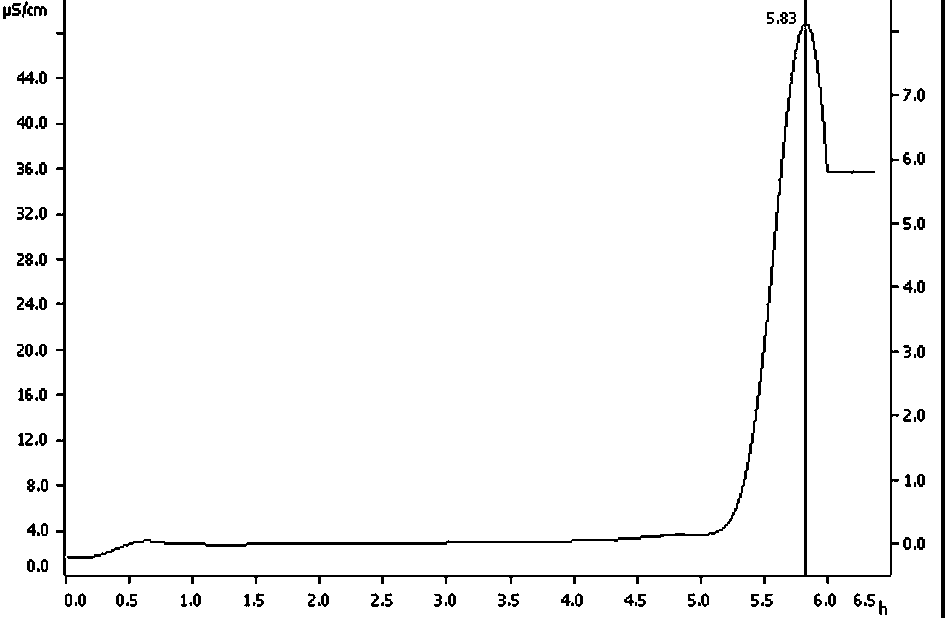

Modified plate pipe manufacturing reeling machine

InactiveCN104148459AApplicable processingImprove product qualityMetal working apparatusRolling resistanceEngineering

The invention discloses a modified plate pipe manufacturing reeling machine. The modified plate pipe manufacturing reeling machine comprises a machine frame, a driving roller, a driven roller and a feeding platform, wherein a concaved hole is formed in the feeding platform, and an optoelectronic switch is arranged in the concaved hole and connected with a driving mechanism of the driving roller; the feeding platform comprises a base plate and a surface plate, wherein a concaved pit is formed in the base plate, a through hole is formed in the surface plate, the concaved pit and the through hole are matched to form an incomplete round cavity, and balls are installed in the cavity and protrude out of the upper surface of the feeding platform. According to the modified plate pipe manufacturing reeling machine, in-place preparation of a plate is a condition of starting the driving mechanism, so that the movement rule of the driving mechanism is matched with in-place preparation of the plate. The multiple balls are arranged on the feeding platform, sliding frictional force is changed into rolling frictional force, the action of external force is reduced, the possibility that plates are manually pushed to be aligned with one another is improved, the defective rate of products is lowered, and production quality is improved.

Owner:CHENGDU LINGCHUAN CHANGYOU AUTOMOBILE PART MFG

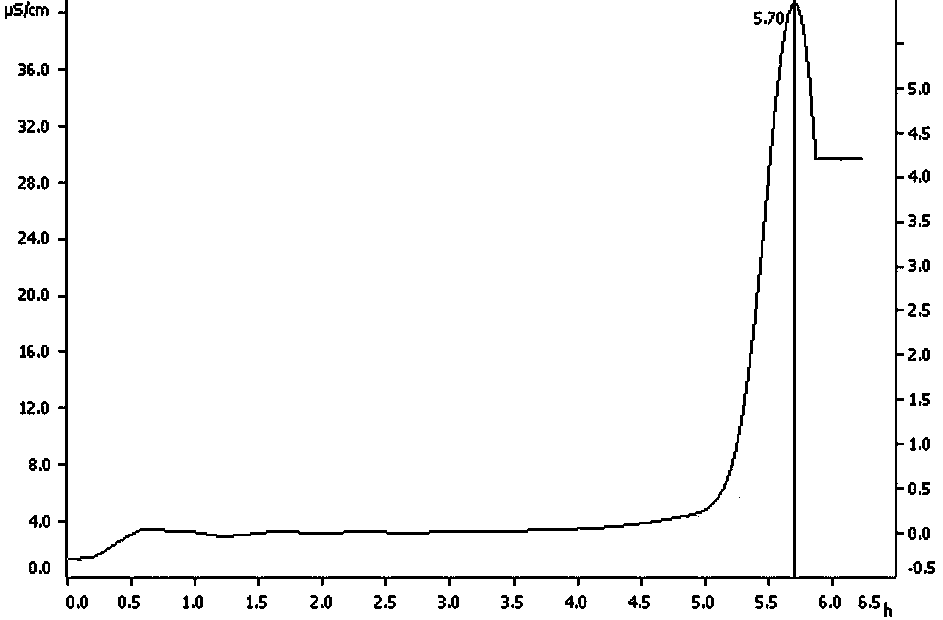

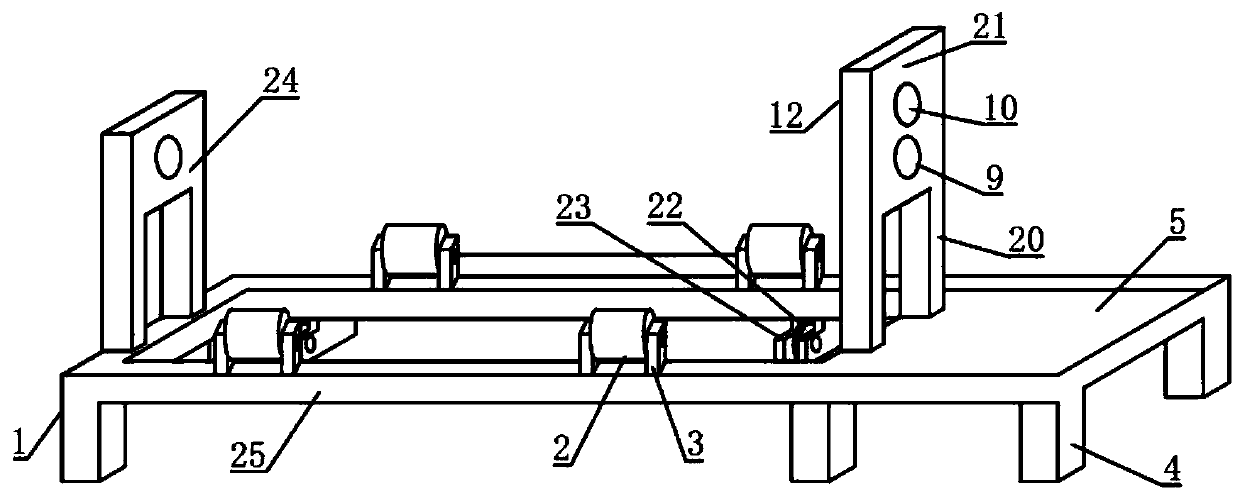

Improved plate pipe-manufacturing rolling machine structure

InactiveCN104148456AApplicable processingAccurate timeMetal-working feeding devicesPositioning devicesTime delaysStop time

The invention discloses an improved plate pipe-manufacturing rolling machine structure. The improved plate pipe-manufacturing rolling machine structure comprises a machine frame. A driving roller is installed on the machine frame. A driven roller is arranged above the driving roller. A feeding platform is also installed on the machine frame and is right opposite to the interval between the driving roller and the driven roller. The feeding platform is provided with a concave hole. An optoelectronic switch is arranged in the concave hole and connected with a drive mechanism of the driving roller. An output signal of the optoelectronic switch serves as a driving and switchover signal of the drive mechanism. The drive mechanism will be started as long as a plate is put in place accurately, so that the operating law of the drive mechanism is matched with arrival of the plate, a time delay switch and other components can be arranged to set the starting and stopping time of the drive mechanism so that time can be more accurate, and the improved plate pipe-manufacturing rolling machine structure is applicable to most part machining.

Owner:CHENGDU LINGCHUAN CHANGYOU AUTOMOBILE PART MFG

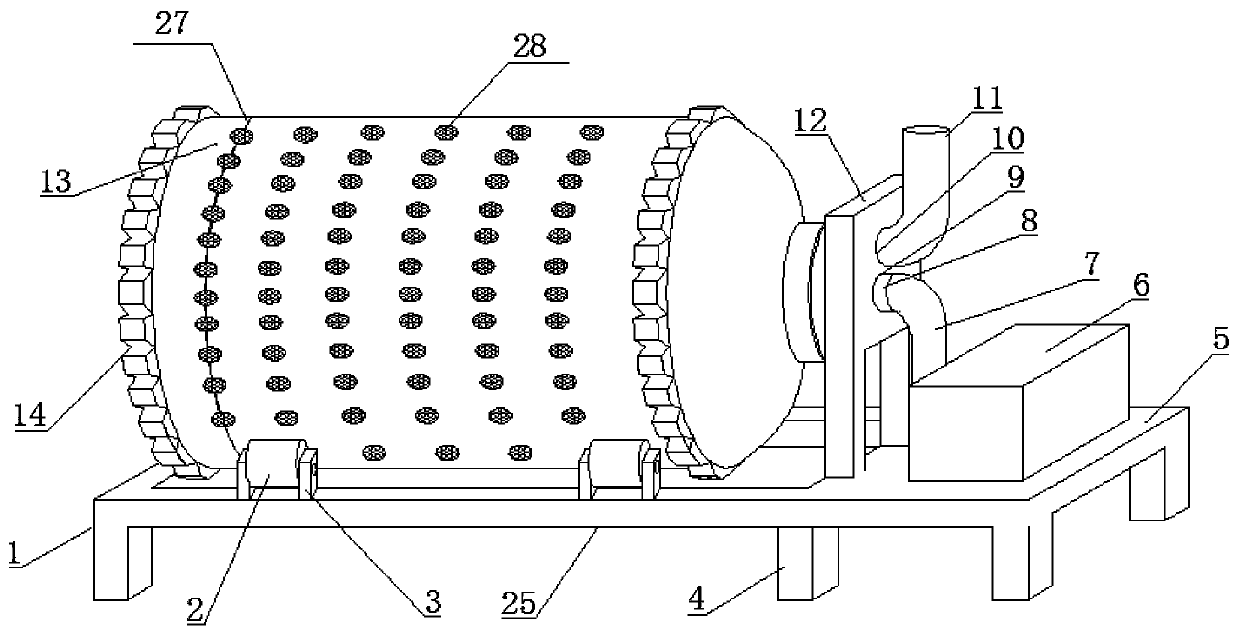

Material drying device for processing aquatic animal concentrated feed

ActiveCN109900085AImprove uniformityImprove drying efficiency and uniformityDrying gas arrangementsDrying chambers/containersEngineeringAquatic animal

The invention discloses a material drying device for processing aquatic animal concentrated feed. When the material drying device is used for processing and drying the aquatic animal concentrated feed, a rotating drum is driven by a rotating drive assembly to rotate, high-pressure hot air and low-pressure hot air are respectively led into an inner air pipe and an outer air pipe by a hot air blower, the high-pressure hot air sprayed through a high-pressure spray pipe is used for blowing and spreading the aquatic animal concentrated feed, at least part of the aquatic animal concentrated feed overcomes the gravity and is blown away from the inner surface of the rotary drum, the high-pressure hot air is used for drying the aquatic animal concentrated feed, so that the drying uniformity is improved. The drying efficiency and the uniformity can be improved by adopting a high-pressure hot air flow raising method; the material is lifted to a certain height in a spiral rotating manner and thennaturally falls down, the hot air dries the material in the falling process of the material, so that all the material is uniformly dried; and the spiral rotating drum enables the material to be turnedwhen the material enters different spiral grooves, the material can be dried in all directions, so that the device is suitable for processing a large amount of material.

Owner:陈青

Treatment method of Si-Si bonded surface stains

ActiveCN102963865AAvoid contaminationImprove integrityPrecision positioning equipmentSoldering apparatusSilicon siliconSilicone

The invention relates to a treatment method of Si-Si bonded surface stains. The method comprises the steps of: a. making a silicon gasket matching a to-be-bonded silicon wafer in shape, and depositing a layer of silicon nitride film on the silicone gasket surface; b. aligning the silicon nitride deposited side of the silicon gasket with the to-be-bonded silicon wafer to stick them tightly, and putting them in a bonding jig for fixation; c. pre-bonding the silicon gasket and the to-be-bonded silicon wafer, and then tearing off the silicon gasket; and d. subjecting the pre-bonded silicon wafer to sintering bonding . The invention has the advantages that: (1) no chemical and physical removal means is needed, the integrity of the movable structure of an MEMS device can be improved; and (2) being simple and practicable, the method is easy to operate, and is suitable for wide application in production and processing.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

Double-sided milling machine cutting machine convenient to maintain

PendingCN114309735AEasy maintenanceEasy to adjustMilling machinesCleaning using toolsElectric machineryStructural engineering

The double-sided milling machine cutting machine comprises a rack, a cutting device, a machining table, a cleaning device, a feeding port and an ash storage box, the cutting device is arranged in the rack and at the upper end of the rack, the machining table is fixedly installed at the position, close to the middle, of the upper end of the rack, and the cleaning device is fixedly installed at the upper end of the machining table; the feeding port is formed in one side of the machining table, the ash storage box communicates with the lower end of the feeding port, the cutting device comprises a first motor, the first motor is fixedly installed on one side of the rack, the output end of the first motor is rotationally connected with a lead screw, and the outer surface of the lead screw is sleeved with a movable sleeve. By arranging the cutting device, adjustment can be conveniently carried out according to alloy plates of different sizes, so that the alloy plate machining device is suitable for machining the alloy plates of different sizes, by arranging the cleaning device, chippings generated in the machining process can be conveniently cleaned, meanwhile, folding is convenient and rapid, and the occupied space is small.

Owner:宝方轴瓦材料(江苏)有限公司

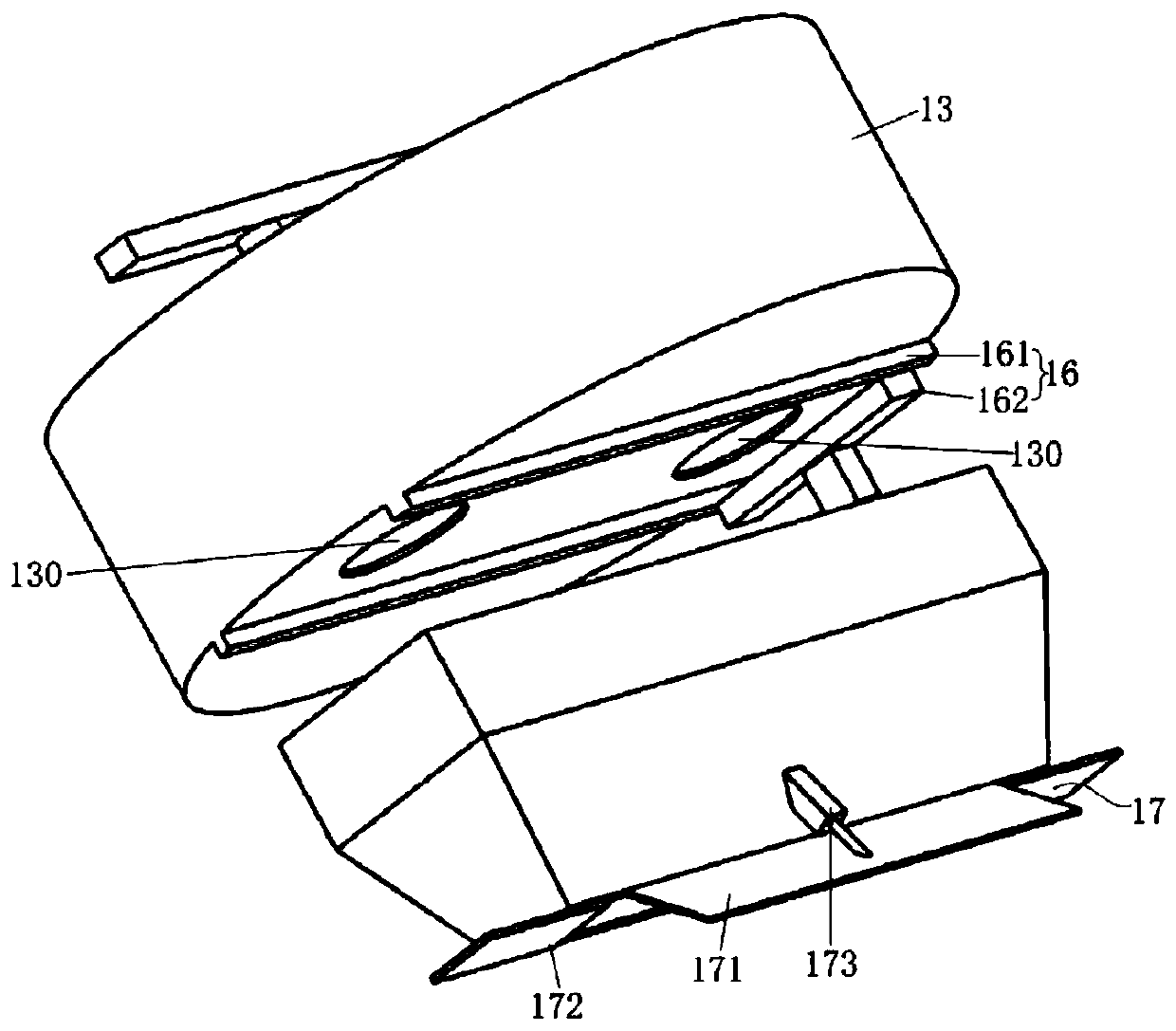

Automatic quartz stone plate production line

ActiveCN109760193AEvenly distributedRealize automatic clothCeramic shaping plantsFeeding arrangmentsProduction lineAutomatic quartz

The invention discloses an automatic quartz stone plate production line. The production line comprises a mixing and material distribution device, an automatic paper spreading device, a vacuum air compressor, a drying device and a surface treatment device which are sequentially arranged, wherein the mixing and material distribution device comprises a first conveying line used for conveying formingmolds, a material distribution bin arranged right above the first conveying line and a mixing and stirring mechanism arranged right above the material distribution bin, the mixing and stirring mechanism is used for mixing and uniformly stirring a raw material, the lower end of the mixing and stirring mechanism is provided with discharging ports corresponding to the material distribution bin, the material distribution bin is of a long-strip-shaped structure matched with the width of the first conveying line, a horizontal push plate is installed in the material distribution bin, the horizontal push plate is driven to move up and down through a lifting driving mechanism, the horizontal push plate is driven by a horizontal driving mechanism to horizontally reciprocate along the length direction of the material distribution bin, and the lower end of the material distribution bin is provided with a long-strip-shaped lower opening and a switch mechanism used for opening and closing the loweropening. According to the automatic quartz stone plate production line, automatic material distribution of plates can be realized, and the material distribution efficiency is improved.

Owner:YUNFU OPALY NEW MATERIALS TECH CO LTD

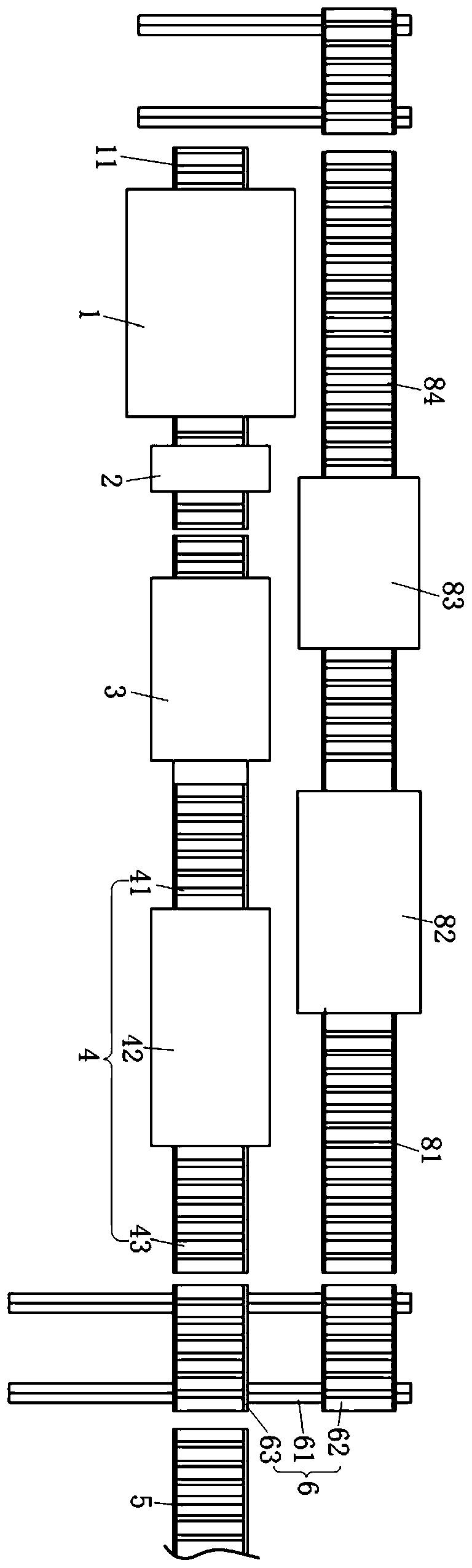

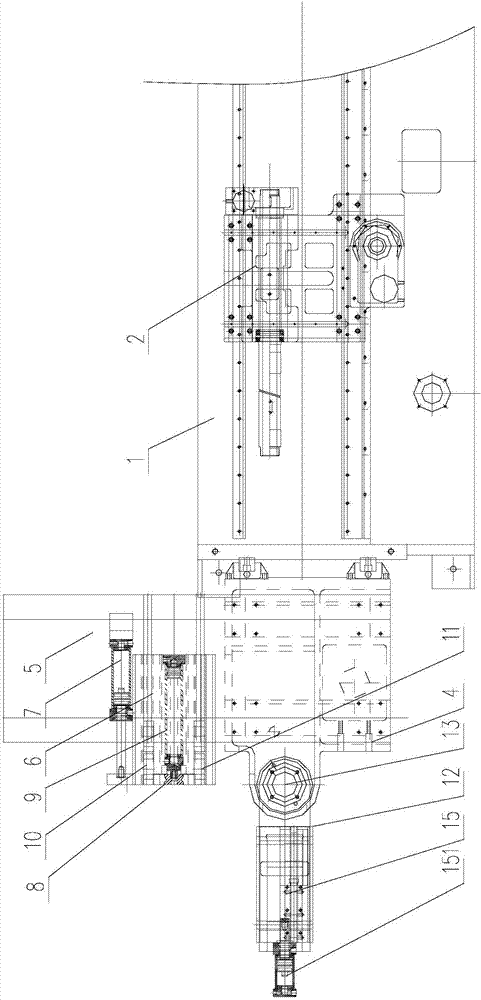

Two-way pipe bending machine

ActiveCN107030154AEasy to processSolve the situation that there is interference in the operation and cannot be processedMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses a two-way pipe bending machine. The machine comprises a stand; a pipe feeding device is movably arranged on the stand; a lifting base and a lifting power device are arranged at the end part of the stand; the lifting base is provided with a lower slide base and a lower driving device; the lower slide base is provided with an upper slide base and an upper driving device; the upper slide base is provided with an auxiliary push basic table and a positioning oil cylinder; the auxiliary push basic table is provided with an auxiliary push mold base and an auxiliary push oil cylinder; a left auxiliary push module and a right auxiliary push module are respectively arranged on two sides of the auxiliary push mold base; the lower slide base is provided with a rotating table and a rotating power device; the rotating table is provided with a pipe bending wheel mold module in the rotating center; the rotating table is provided with an end slide base aligned to the direction of a pipe bending wheel mold; a pipe bending movable mold module is arranged on the end slide base; the rotating table is provided with a slide oil cylinder for driving the end slide base to slide; the end slide base is provided with an adjusting base for sliding in a pipe feeding direction when the end slide base leans against the upper slide base; and the end slide base is further provided with a deviation oil cylinder for driving the adjusting base on the end slide base to slide.

Owner:张家港和升数控机床制造有限公司

Surface heat treatment device for producing electromechanical device

InactiveCN110468261AEasy to fixConducive to sustainable useFurnace typesIncreasing energy efficiencyAlloyEngineering

The invention discloses a surface heat treatment device for producing an electromechanical device. The surface heat treatment device comprises a housing, induction coils, a supporting plate and a heatresistant plate; high frequency AC (alternating current) generators are correspondingly mounted on two sides of the top end of the top of the outer part of the housing; the induction coils are correspondingly mounted on two sides of the top end of the inner part of the housing; a control panel is mounted in the middle position on one side of the outer part of the housing; an air cooler is mountedat the bottom end of the outer part of the housing; a guide pipe is connected with the bottom end of one side of the air cooler; the heat resistant plate is connected with the middle position of thetop end of a baffle; the supporting plate is mounted in the middle position of the top end of the heat resistant plate; and the supporting plate is of a hollow structure. Screw rods are mounted on thesupporting plate, and enable push blocks to move on sliding grooves, the push blocks move to drive connected telescopic rods to move inwards and expand and retract, a workpiece on a bearing plate isfixed by clamping blocks on the telescopic rods, the fixation of the workpiece to be subjected to heat treatment is facilitated, a fixing device is made of high temperature resistant alloy, and the continuous utilization of the fixing device is facilitated.

Owner:深圳市嘉扬科技有限公司

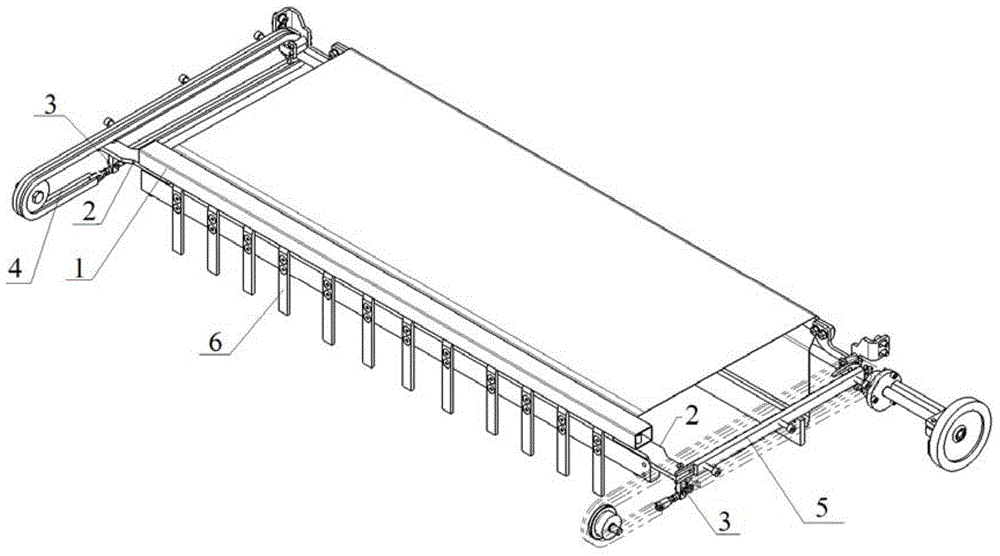

Movable rear paper-neatening device adapted to various types of paper sizes

ActiveCN104925569AApplicable processingMeet processing requirementsPile receiversDevice formEngineering

The invention relates to a movable rear paper-neatening device adapted to various types of paper sizes. The rear paper-neatening device, a front paper-neatening device, a left paper-neatening device and a right paper-neatening device form a paper-receiving part of a die-cutting machine, and the paper-receiving part is used for the stacking and neatening of paper after die-cutting receiving. The rear paper-neatening device comprises a longitudinal beam, supporting plates, moving blocks, chains, cross beams, and a paper-neatening fence. The number of the chains is two, and the two chains are respectively disposed at two sides of the longitudinal beam. The number of the cross beams is two, and the two cross beams are disposed above the two chains in a parallel manner. The number of the moving blocks is two, and the two moving blocks are respectively connected to the central segments of the two chains and move along with the chains. The number of the supporting plates is two, wherein the internal ends of the supporting rods are connected with an end part of the longitudinal beam, and the external ends of the supporting rods are connected with the moving blocks. The paper-neatening fence is vertically connected to the longitudinal beam. Compared with the prior art, the structure of the supporting plates meets requirements that the vertical distance from the longitudinal beam to a connection line between the two moving blocks is 10 mm, the structure enables the distance between the rear paper-neatening device and the front paper-neatening device to be increased by 10 mm on the original basis, and the rear paper-neatening device can be suitable for paper in large sizes.

Owner:BOBST SHANGHAI

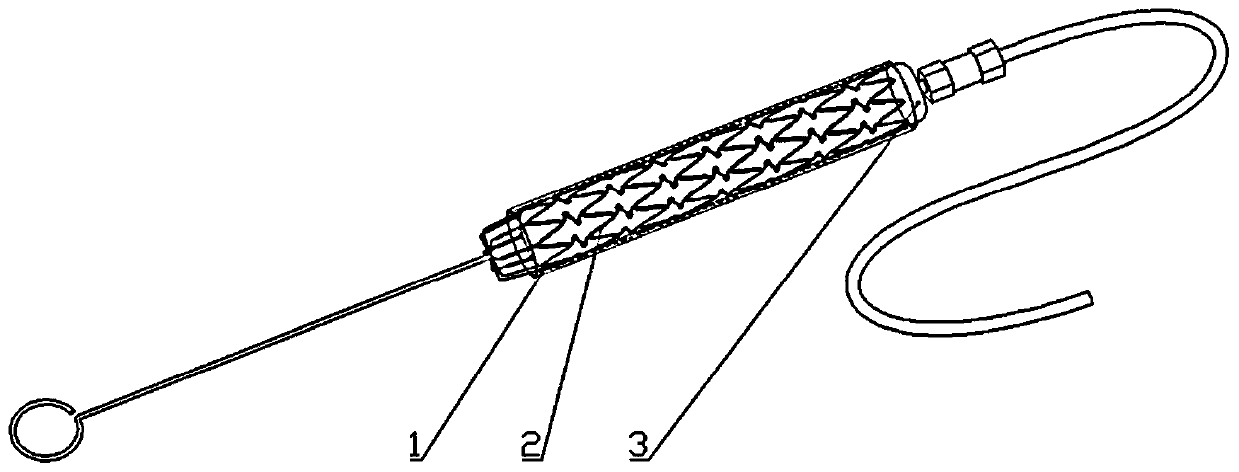

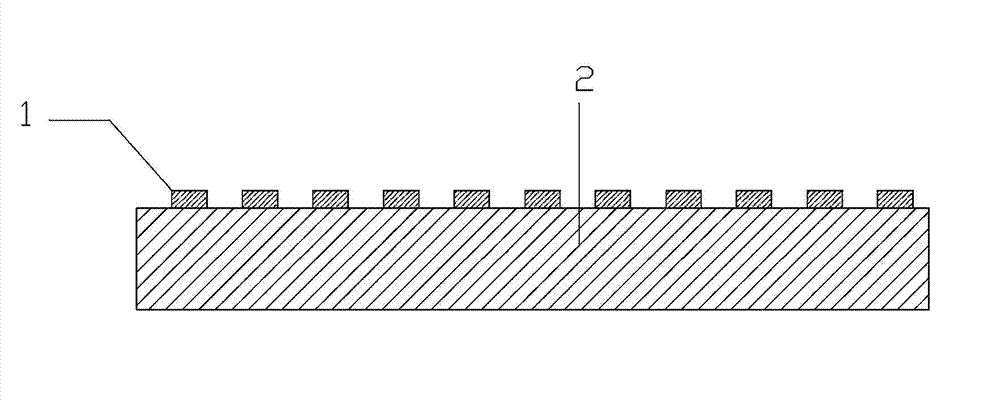

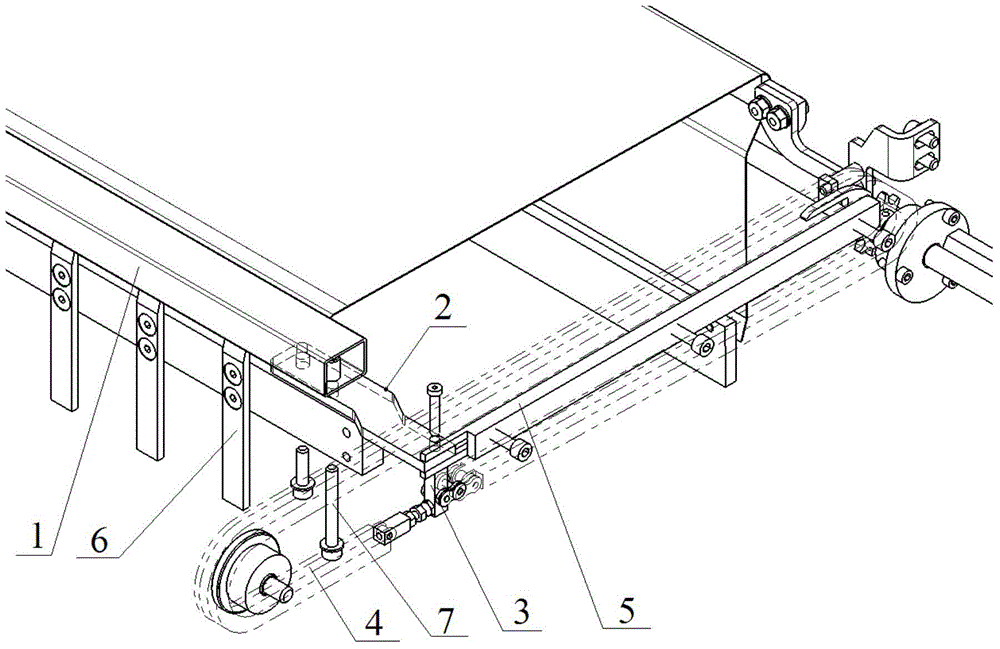

Three-edge taper twist drill

The invention relates to a three-edge taper twist drill. The three-edge taper twist drill is characterized in that the three-edge taper twist drill is in an integral structure provided with a cylindrical drill shank (1), a twist drill rod (2) is connected to the front end of the drill shank, three cutting edges (3) are evenly arranged on the drill rod, and the twist drill shank is a taper drill rod with 5-degree taper. The drill rod of the three-edge taper twist drill has 5-degree taper, and the three-edge taper twist drill is applicable to machining of tapered holes and is especially applicable to machining of tapered threaded bottom holes.

Owner:WUXI YUTIAN PRECISION TOOL

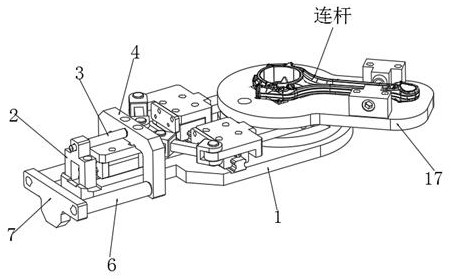

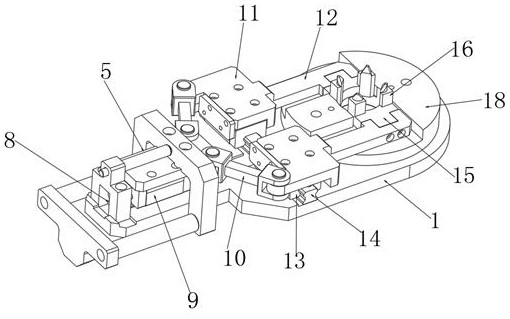

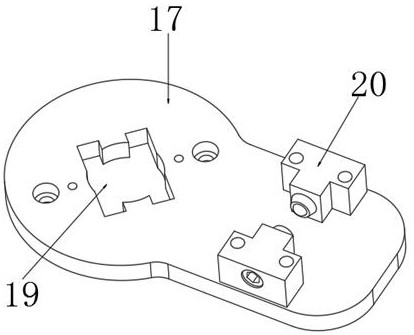

Automatic clamping and positioning mechanism suitable for multiple types of connecting rods

PendingCN114055220AApplicable processingHigh positioning accuracyPositioning apparatusMetal-working holdersClassical mechanicsSlide plate

The invention relates to an automatic clamping and positioning mechanism suitable for multiple types of connecting rods. The automatic clamping and positioning mechanism comprises a bottom plate, wherein a first sliding plate is slidably mounted at one end of the top side of the bottom plate, a U-shaped base is mounted on the top side of the first sliding plate, the first sliding plate and one ends of two linkage rods are rotatably mounted, the two linkage rods are symmetrically arranged, the other ends of the two linkage rods are rotationally installed with two symmetrically-arranged second sliding plates correspondingly, a fixing base is installed at the other end of the top side of the bottom plate, a workpiece positioning plate used for fixing a connecting rod workpiece is installed on the fixing base, and a positioning groove is formed in the workpiece positioning plate. Inner hole positioning is adopted for the connecting rod workpiece, the maximum stroke amount is adjusted according to different hole diameters, namely the moving stroke amount of a stretching claw is adjusted, and the automatic clamping and positioning mechanism is suitable for machining of multiple types of connecting rod workpieces; an inner hole four-claw centering tensioning structure is adopted, and a centering pressing structure is additionally arranged at the small end of the connecting rod workpiece, so that the product positioning precision is greatly improved; and when a rotary table rotates at a high speed in the machining process, the positioning precision can be guaranteed.

Owner:FOSHAN PRATIC CNC SCI & TECH

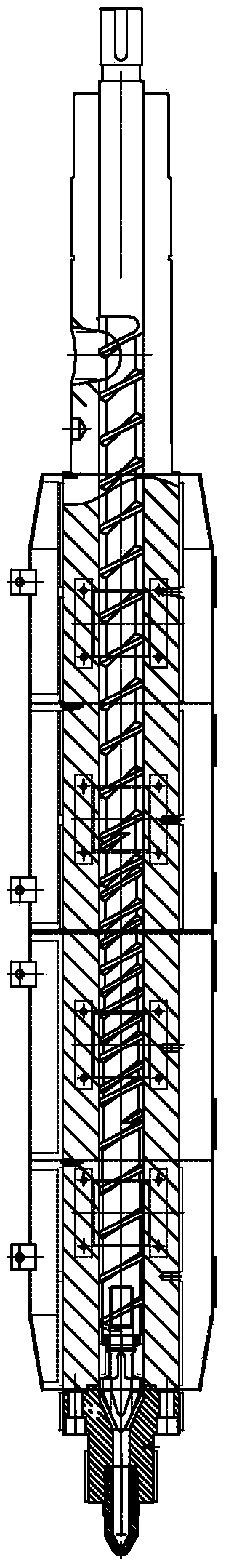

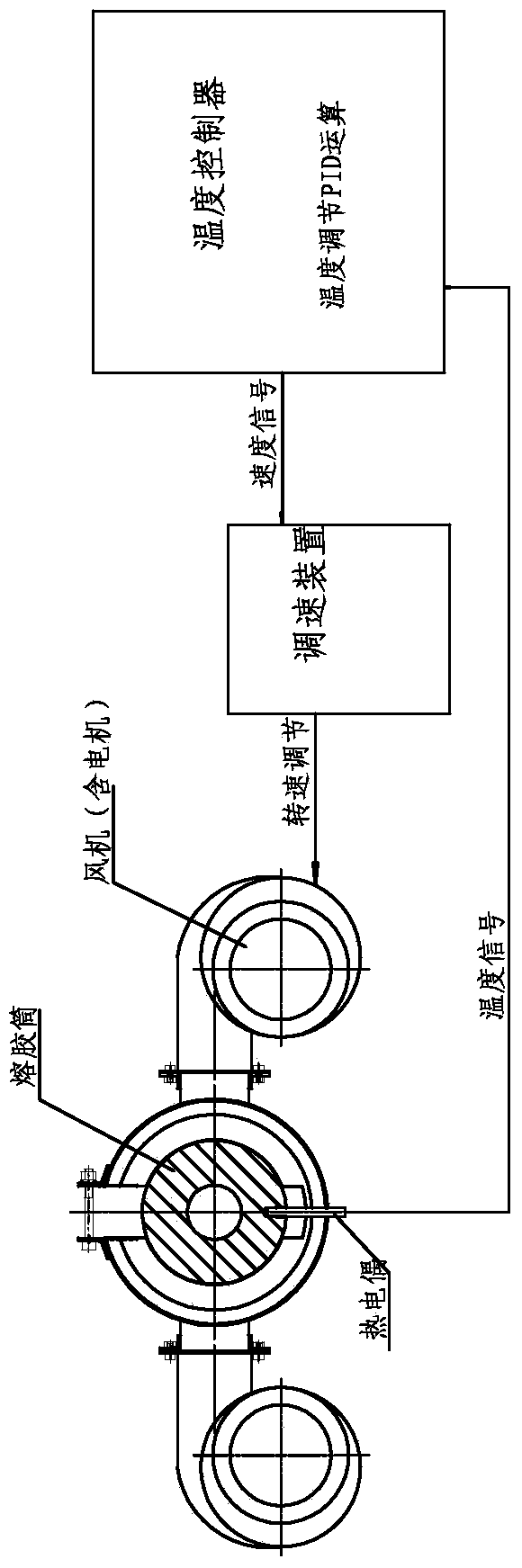

Device and method for controlling temperature of plastic melting barrel of injection molding machine or extruder

The invention discloses a device and a method for controlling the temperature of a plastic melting barrel of an injection molding machine or an extruder. The controlling device comprises the plastic melting barrel and a housing body outside the plastic melting barrel, wherein a cavity is jointly defined by the plastic melting barrel and the housing body; an air outlet or an air inlet of a fan is communicated with the cavity. A driving motor of the fan is a common alternating-current motor or a servo motor, wherein the common alternating-current motor is connected with a frequency converter which is connected with a central controller, or the servo motor is connected with a servo driver which is connected with the central controller. The plastic melting barrel is provided with a temperature sensor which is connected with the central controller. In work, the work temperature of the plastic melting barrel is acquired by the temperature sensor; when the work temperature exceeds preset temperature, the central controller gives out a control instruction, the rotation speed of the common alternating-current motor is controlled by virtue of the frequency converter, or the rotation speed of the servo motor is controlled by virtue of the servo driver, so that the flow of the fan is controlled. The controlling device is simple and reasonable in structure, flexible in operation, high in accuracy of injection molding or extrusion molding, and especially applicable to processing of precise products.

Owner:GUANGDONG YIZUMI PRECISION MACHINERY

Polyester chip for producing automotive interior fiber and preparation method thereof

The invention discloses a polyester chip for producing automobile interior decoration fibers and a preparation method thereof. Firstly, the polyester chip that meets the technical requirements is synthesized: using a two-pot process semi-continuous polymerization reaction device, by introducing isocyanate in the esterification reaction Construct and replace carboxylic acid to reduce the melting point of the product to the target range, and then add reactive catalyst, stabilizer, auxiliary materials, etc. in the polycondensation reaction to control the reaction temperature and vacuum degree, and the final synthetic intrinsic viscosity is 0.730‑0.740dl / g The target polyester chip base material; the synthesized product is passed through the solid phase drum device water steam crystallization process to complete the pre-crystallization of the polyester chip; the pre-crystallized polyester chip is obtained by temperature control without cooling down. The continuous negative pressure processing technology completes the drying of polyester chips. After drying, the water content of polyester chips is not higher than 0.05%, and the intrinsic viscosity is not lower than 0.715dl / g. Through the above three steps, the special polyester chips for automotive interior fibers that meet the requirements of industrial production can be prepared.

Owner:TIANJIN HUAXIN YINGJU POLYESTER MATERIAL SCI & TECH

An automobile rear axle drive shaft processing device

ActiveCN113927310BImprove cutting efficiencyImprove work efficiencyOther manufacturing equipments/toolsMechanical measuring arrangementsDrive shaftControl theory

The invention relates to the field of shaft parts processing, in particular to an automobile rear axle transmission shaft processing device. The upper end is provided with a horizontal driving mechanism, the horizontal driving mechanism includes a horizontal driving block, an expansion mechanism is installed on the horizontal driving block, a cutting mechanism is provided on one side of the bottom end of the expansion mechanism, and a polishing mechanism is provided on the other side of the bottom end of the expansion mechanism; A first detection mechanism and a second detection mechanism are respectively provided on both sides of the transmission shaft at the sidemost end. When in use, cutting, polishing and inspection can be carried out at the same time. During cutting, the cutting roller and the drive shaft rotate at the same time to improve the cutting efficiency. The vertical setting of the cutting roller can simultaneously cut the shaft wall and the raised side wall. The same is true for polishing. During detection, the eccentricity of the transmission shaft and the verticality of the raised sidewall can be simultaneously detected, thereby improving the work efficiency.

Owner:ANHUI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com