Treatment method of Si-Si bonded surface stains

A technology for surface contamination and treatment methods, which is applied in the direction of processing microstructure devices, photolithography on patterned surfaces, precision positioning equipment, etc., can solve problems such as ion contamination, and achieve the purpose of avoiding contamination, improving integrity, and processing The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A method for treating contamination of a silicon-silicon bonding surface provided by the present invention will be further described below in conjunction with the accompanying drawings.

[0023] 1. Silicon gasket structure and production:

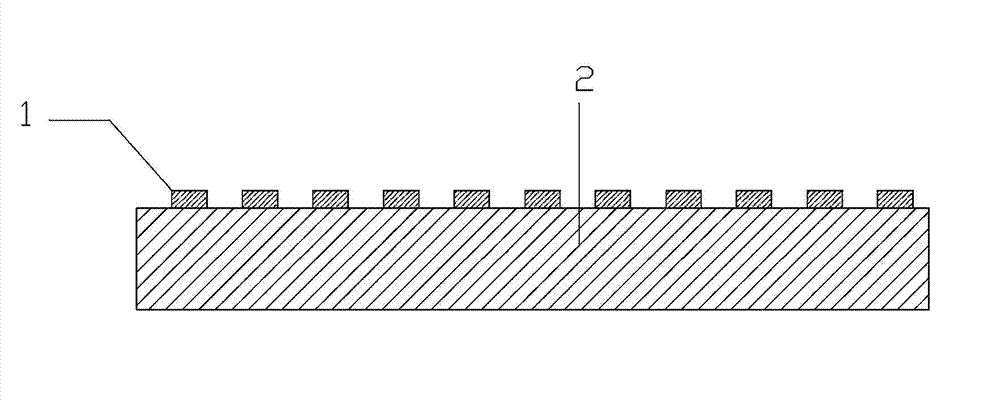

[0024] like figure 1 As shown, the silicon spacer among the present invention comprises: making silicon nitride 1 thin film on the surface of monocrystalline silicon wafer 2, the manufacturing process of silicon nitride thin film is known technology, mainly contains the following several steps:

[0025] (a) Routine cleaning of silicon wafers;

[0026] (b) PECVD deposits a layer of 1500? silicon nitride film;

[0027] (c) LC100A photoresist photolithographic pattern;

[0028] (d) Dry etching silicon nitride to form silicon nitride bumps 2 in an array on the single crystal silicon wafer 2 .

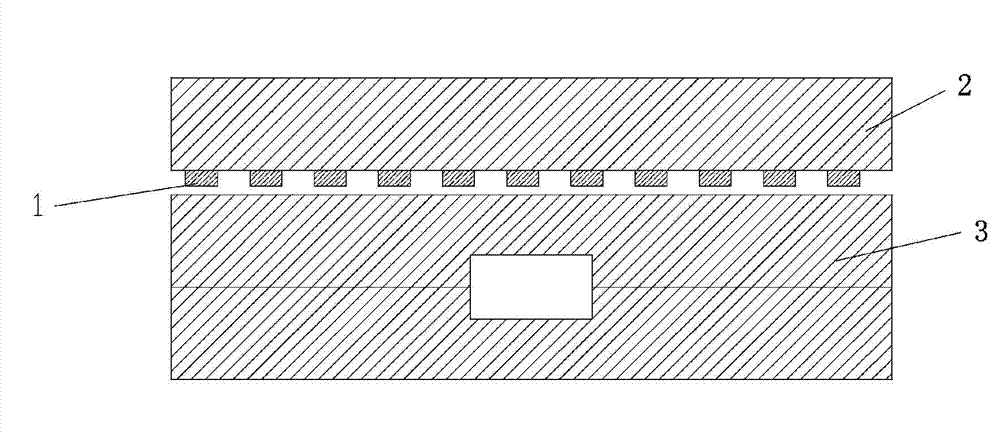

[0029] 2. Cut the silicon gasket with a dicing machine so that the silicon gasket is adapted to the shape of the silicon wafer to be bonded; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com