Material drying device for processing aquatic animal concentrated feed

A technology for concentrated feed and aquatic products, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of slow drying speed, uneven drying and long drying time of aquatic feed, so as to improve drying efficiency and uniformity, improve the degree of automation, and reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

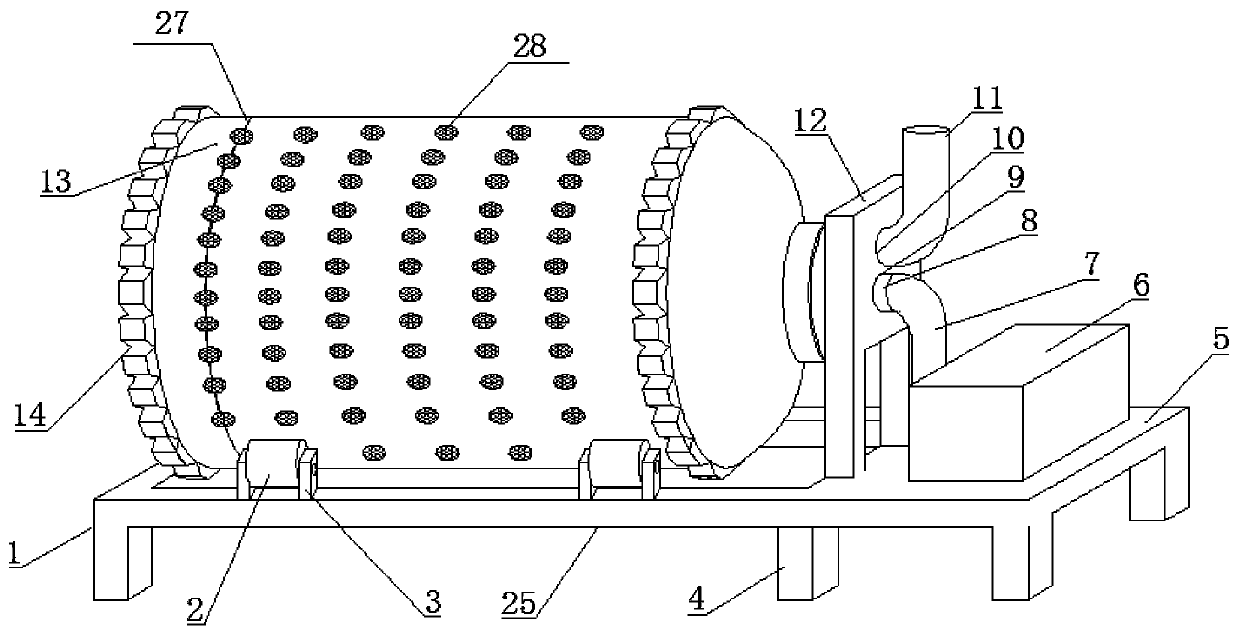

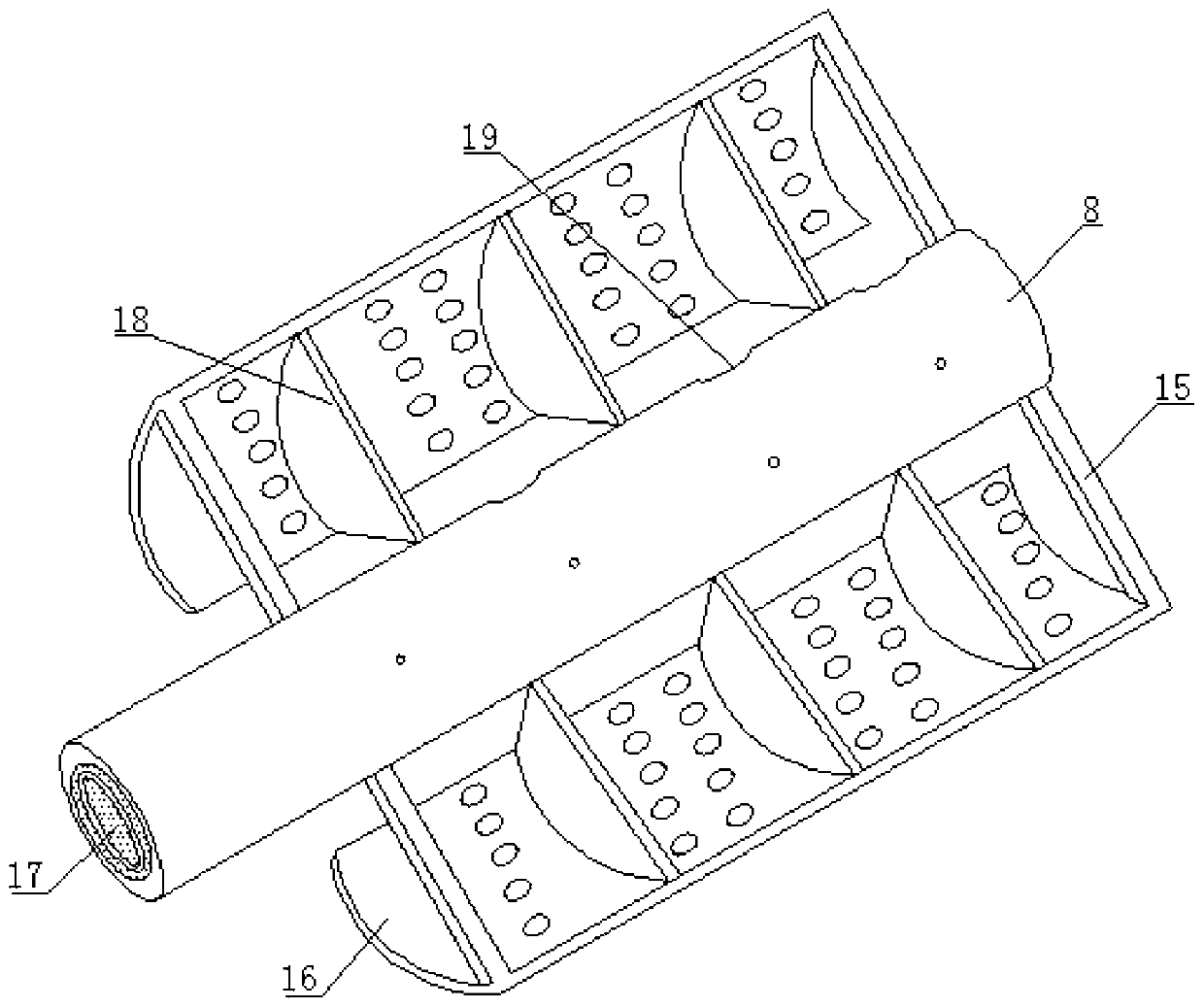

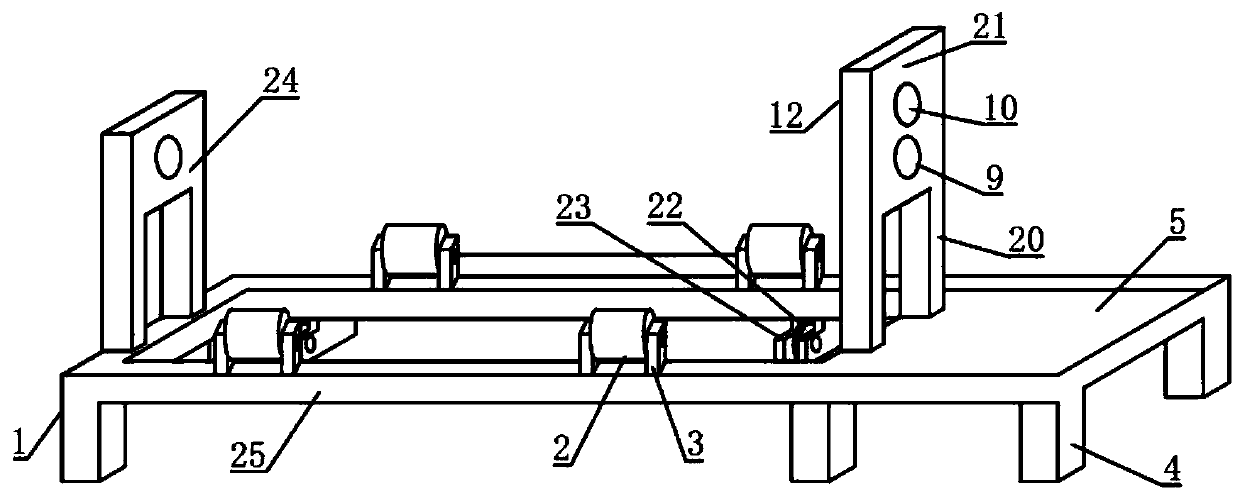

[0031] see Figure 1~6 , in an embodiment of the present invention, a drying device for processing concentrated aquatic feed, a drying device for processing concentrated aquatic feed, including a bracket 1, a drum 13, a hot air blower 6, an air duct assembly 17 and Rotation drive assembly, wherein, the rotatable support on the support 1 is provided with the drum 13, the central axis of the drum 13 is arranged horizontally, and the rotation of the drum 13 around its central axis is controlled by the rotating The drive assembly is driven to rotate, and the rotation drive assembly is arranged on the support 1, and it is characterized in that,

[0032] One end of the support 1 is connected with an organic platform 5, and the hot air blower 6 is supported on the machine platform 5. The hot air outlet of the hot air blower 6 is connected to the air duct assembly 17, and the air duct assembly 17 extends into the drum 13;

[0033] The circumference of the rotating drum 13 is provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com