Elastic double-support variable-diameter core rod for bending aircraft engine metal conduit

An aircraft engine and metal conduit technology, applied in the field of elastic double-support variable-diameter mandrels, can solve the problems of increasing the use and storage costs of mandrels, difficult support effects, mandrels that cannot be reused, etc., to prevent wrinkling and flat cross-section Eliminate forming defects, improve forming quality, and prevent bending and wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing description, the present invention is described in detail:

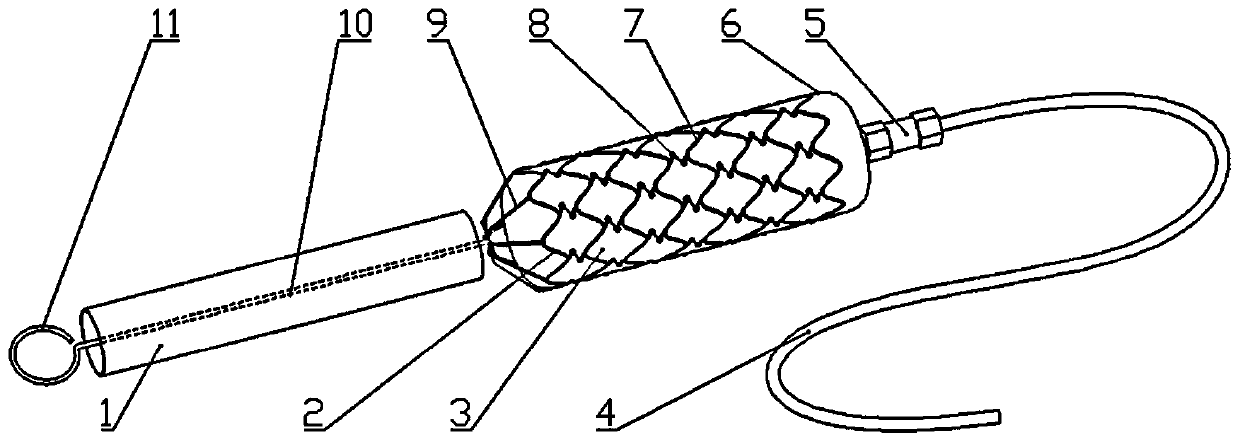

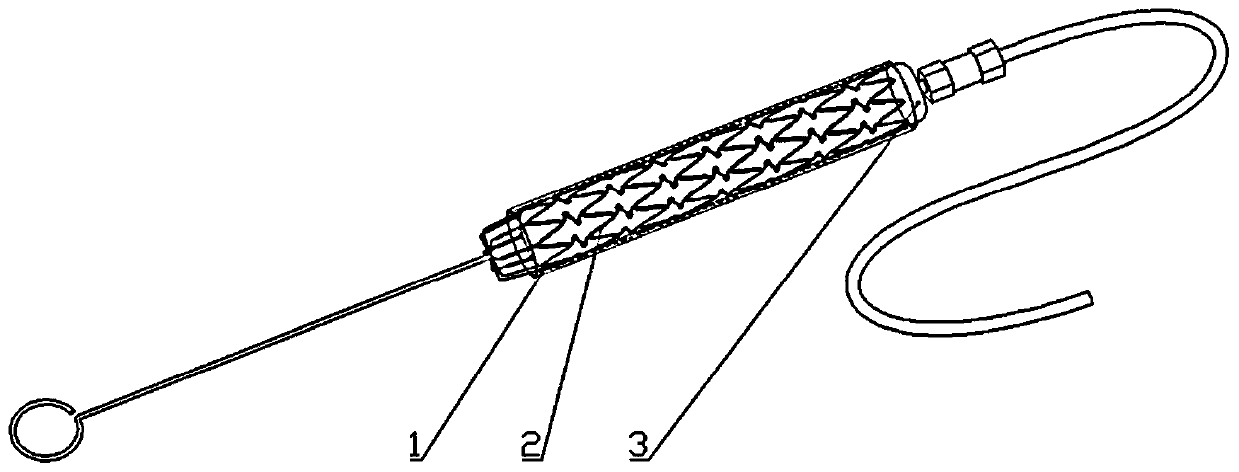

[0034] Such as Figure 1-Figure 3 As shown, the specific implementation includes a bracket receiving tube 1, an elastic outer bracket 2 and an inner hydraulic component 3; the inner hydraulic component 3 includes an infusion tube 4, a pipe joint 5 and an elastic membrane 6, and the inner cavity of the elastic membrane 6 is filled with liquid, and the elastic membrane 6 The tail end is open, the opening is connected to one end of the infusion tube 4 through the tube joint 5, the end of the elastic membrane 6 away from the tube joint 5 is closed, the other end of the infusion tube 4 is externally connected to the hydraulic system, and the infusion tube 4 is used to fill the inner cavity of the elastic membrane 6 .

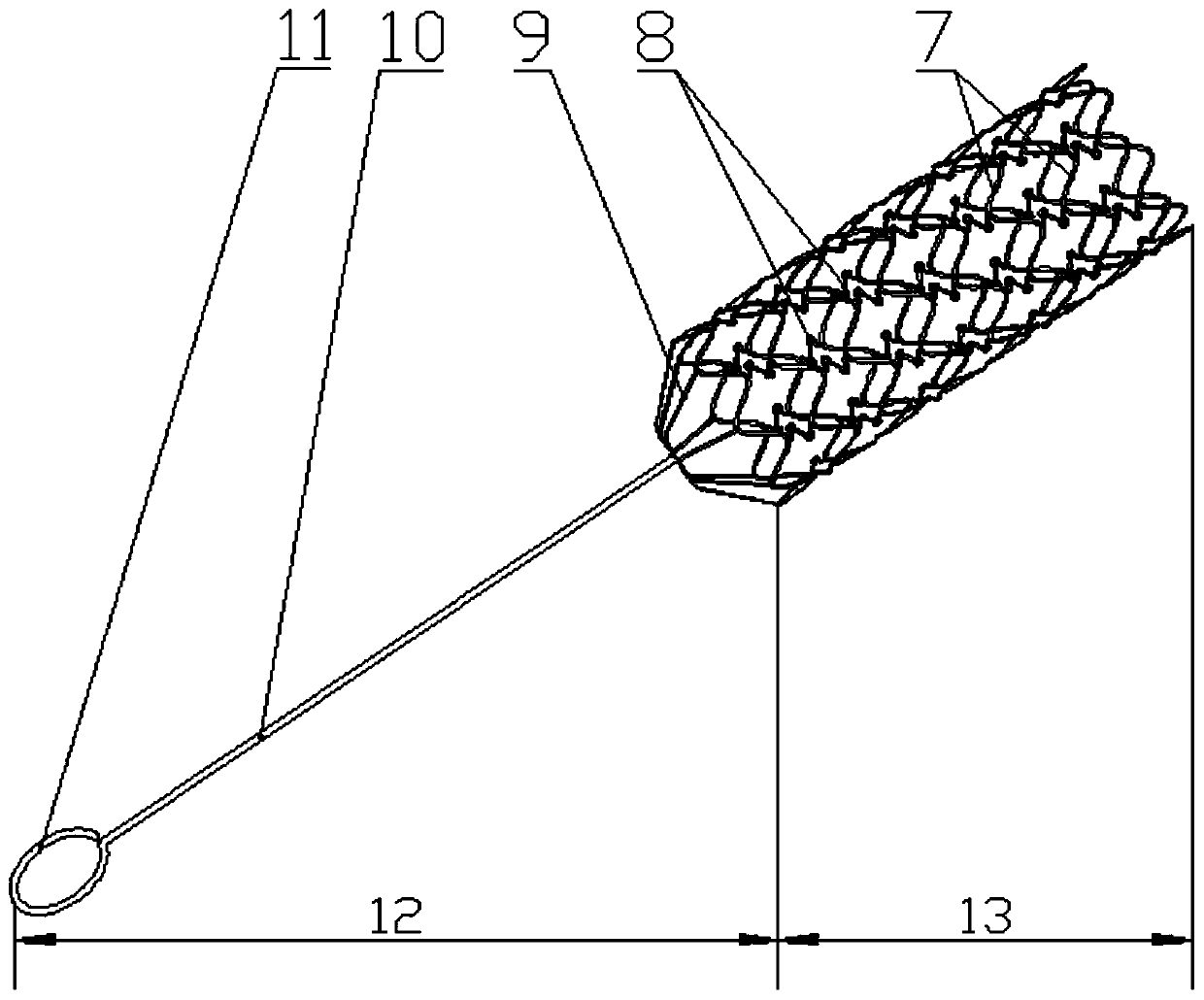

[0035]The elastic outer support 2 is a flexible whole mainly composed of a pull rod 12 and an elastic mesh structure 13. The pull rod 12 is divided int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com