Combined machining grinder for robot RV speed reducer pin wheel housing

A composite machining, pin-tooth shell technology, applied in grinding machines, components with teeth, metal processing equipment, etc., to achieve the effect of reducing weight, uniform overall force, and improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be further described below in conjunction with the drawings.

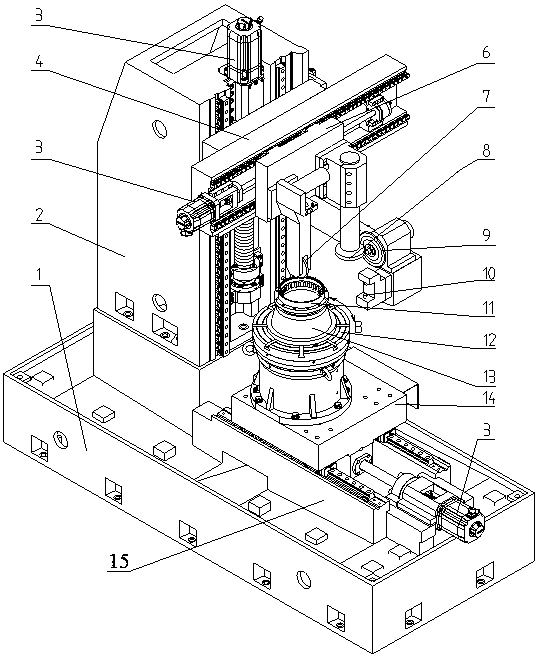

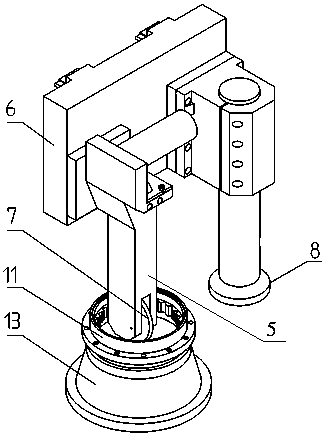

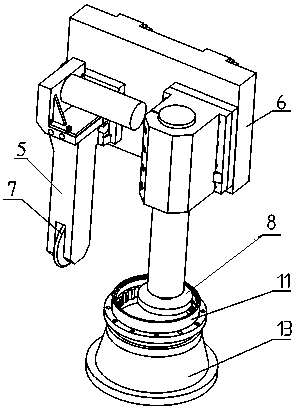

[0027] Embodiment 1 of the compound machining grinder for the needle gear shell of the robot RV reducer of the present invention, such as Figure 1 to Figure 3 As shown, the compound machining and grinding machine for the needle gear shell of the robot RV reducer includes a machine bed 1, on which a needle gear grinding wheel 7 for grinding the needle hole of the needle gear shell 11 is provided for grinding a workpiece The inner hole grinding wheel 8 of the inner hole and the turntable 12 for mounting the pin gear shell 11, the pin gear grinding wheel 7 has a pin gear hole grinding surface for grinding the pin gear holes of the pin gear shell 11, and the inner hole grinding wheel 8 has Grinding the inner hole grinding surface of the inner hole of the pin gear housing 11, the axial ends of the inner hole grinding wheel 8 are respectively provided with end surface gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com