Forming device of layered biomass composite material

A composite material and molding device technology, applied in the field of layered biomass composite material molding device, can solve the problems of difficult processing, low aspect ratio, low strength, etc., achieve physical and mechanical strength improvement, improve production efficiency, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

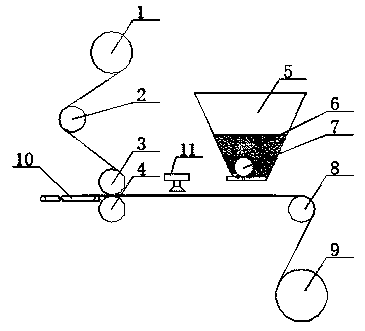

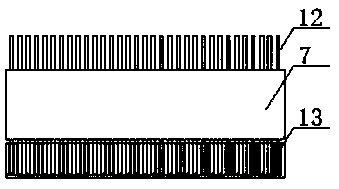

[0033] Such as figure 1 As shown, the layered biomass composite material forming device provided in this embodiment includes an upper layer discharging module, a lower layer discharging module, a fiber laying module and a pressing module. The upper layer discharge module includes the upper layer discharge 1 roller and the preheating roller 1 2; the lower layer discharge module includes the lower layer discharge roller 9 and the preheating roller 2 8; the fiber laying module is the fiber prelaying device 5; the pressing module includes the upper pressing roller 3. Lower pressure roller 4. The surface of the upper discharge roller 1, the preheating roller 2 and the upper pressure roller 3 forms the upper material delivery channel; the lower discharge roller 9, the preheating roller 2 8 and the lower pressure roller 4 form the lower material delivery channel. There is a gap between the upper pressure roller 3 and the lower pressure roller 4, the positions of the upper pressure r...

Embodiment 2

[0039] This embodiment provides a layered biomass composite material forming device for preparing layered biomass composite materials, and its working process is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com