Device and method for controlling temperature of plastic melting barrel of injection molding machine or extruder

A technology of a control device and a glue-melting cylinder is applied in the field of the control device of the glue-melting cylinder of an injection molding machine or an extruder. , The effect of small temperature change range and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

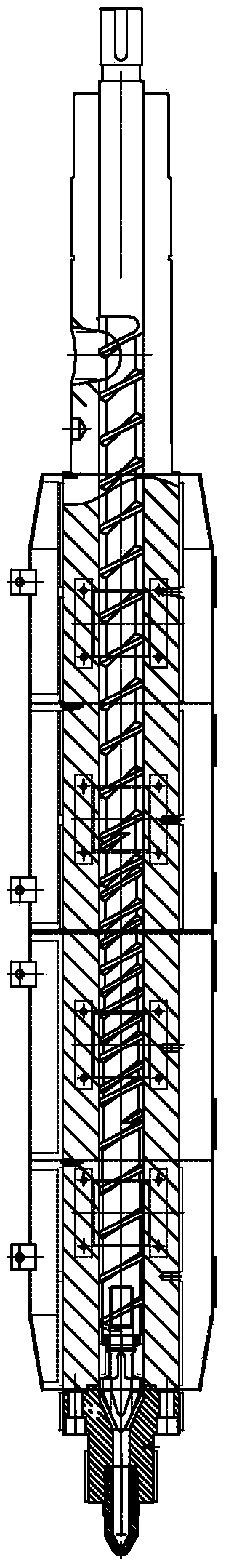

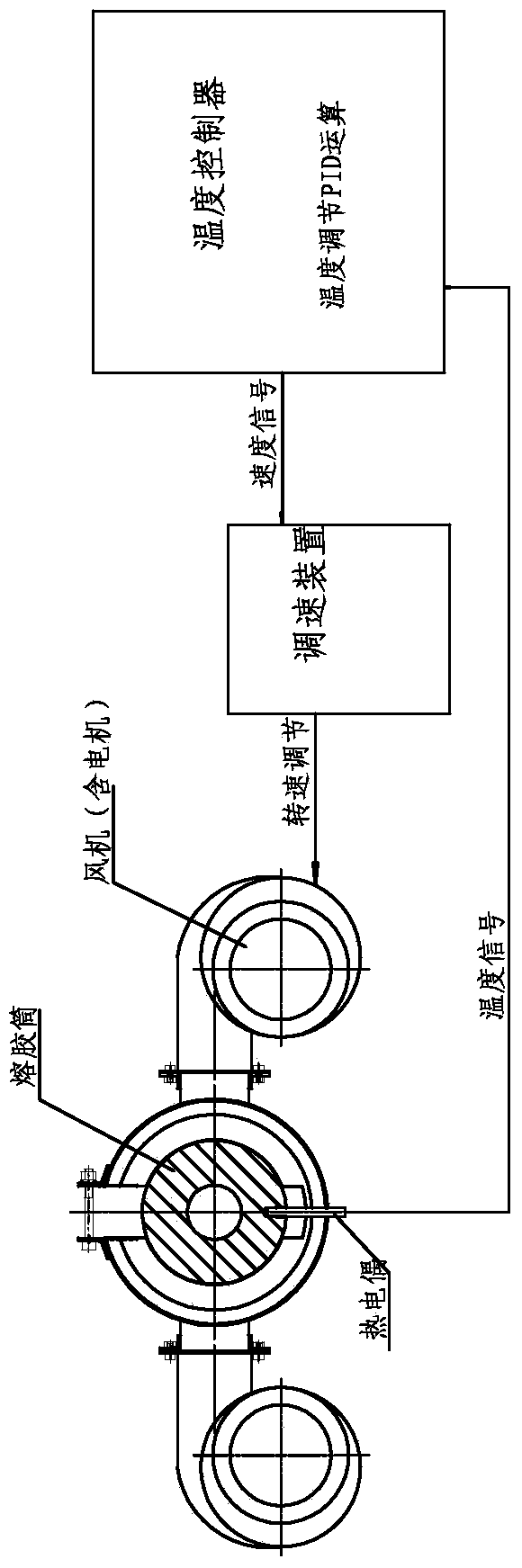

[0014] see Figure 1-Figure 2 , the method for controlling the temperature of the melt cylinder of the injection molding machine or the extruder comprises a melt cylinder 1, a cover 2 is installed outside the melt cylinder 1, the melt cylinder 1 and the cover 2 together form a chamber, and the blower 3 The air outlet or air inlet communicates with the chamber.

[0015] In this embodiment, the driving motor of the blower fan 3 is an ordinary AC motor or a servo motor; wherein, the ordinary AC motor is connected to the frequency converter, and the frequency converter is connected to the central controller 5; the servo motor is connected to the servo driver, and the servo driver Connect with the central controller 5.

[0016] A temperature sensor 4 is arranged on the melt glue cylinder 1 , and the central controller is connected with the temperature sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com