White synchronization railway

A white, railway technology, applied in the direction of roads, tracks, ballast layers, etc., can solve the problems of limited rail length, limited time saving, complex railway structure, etc., and achieve the effect of high effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

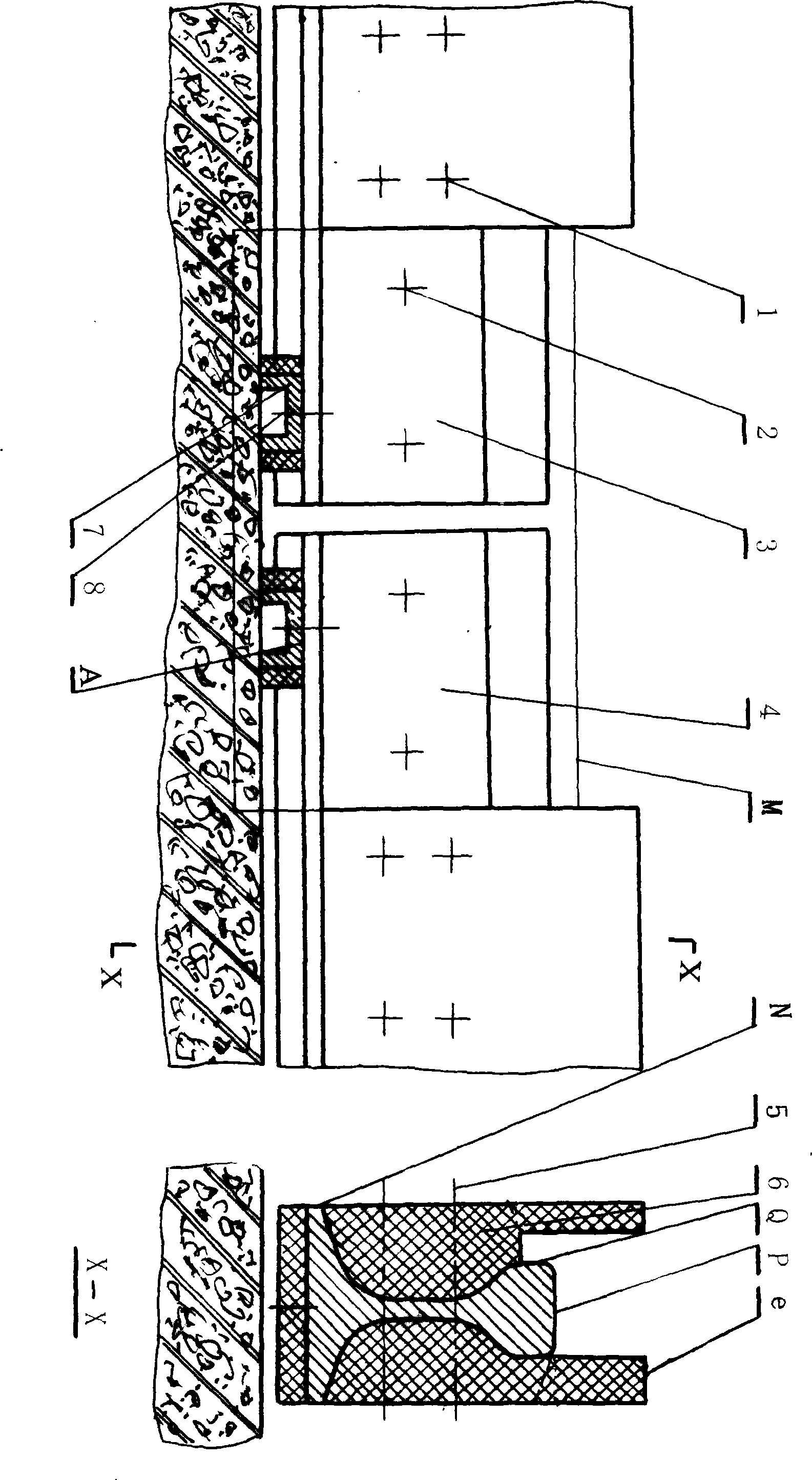

[0031] A white synchronous railway, every two adjacent rails (3) and (4) are connected together and laid on channel steel sleepers (7), the feature is: the rails (3) and (4) are painted smooth White heat insulation layer (6); the sunshade edge (e) is used to block the sun and cold wind, suitable for railways without scattered objects, for example, suitable for closed train lines; the design of this train will take into account the sunshade edge; safety The section (M) and the safety edge (N) are painted with clean white; the two ends of the channel steel sleeper (7) are closed and painted with a clean white heat insulation layer; the contact surface (A) between the rail and the steel sleeper is derusted Fit to facilitate heat conduction between rail and sleeper.

[0032] When the whiteness of the railway surface is high and the finish is also high, both of them have a high anti-radiant heat effect. Although one of them is far from enough to reflect all the radiant heat, the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com