Semiconductor thermopile precise temperature control system for ship

A temperature control system, semiconductor technology, applied in lighting and heating equipment, machines using electrical/magnetic effects, cooling/ventilation/heating renovation, etc., can solve the problem of narrow working temperature area, long temperature stabilization time, and many wearing parts and other problems, to achieve the effect of good energy saving, reliable application and efficient work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

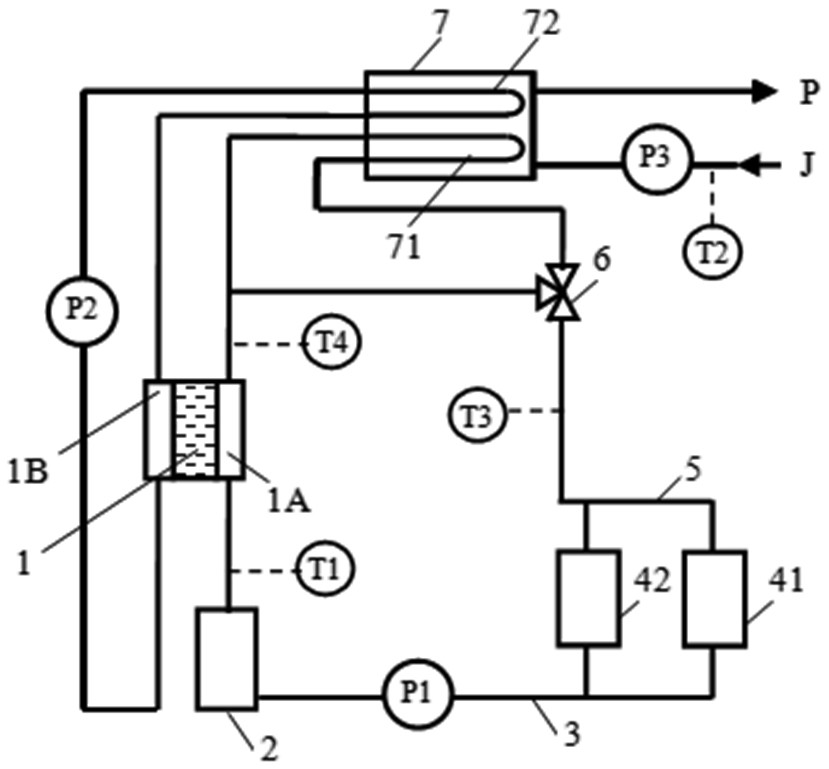

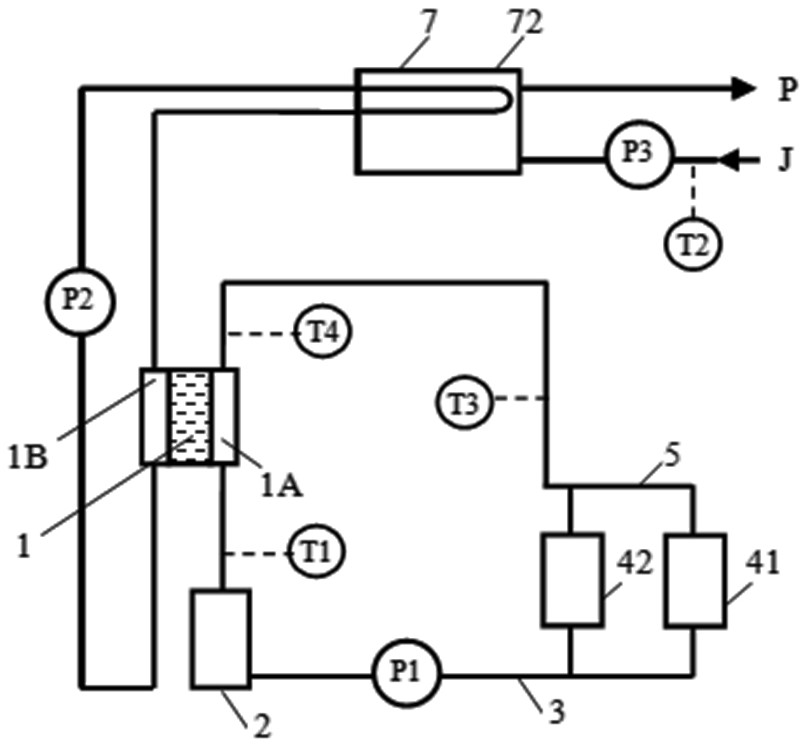

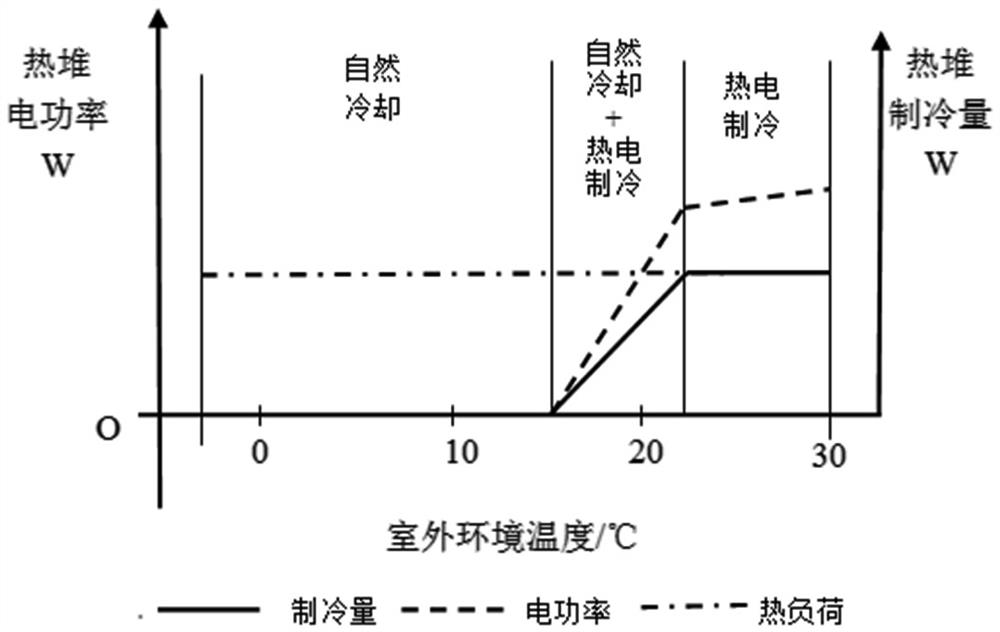

[0034] see figure 1 , the present embodiment is a kind of precise temperature control system of a semiconductor thermal pile for a ship, comprising: a semiconductor thermal pile 1, a liquid reservoir 2, a liquid supply pump P1, a three-way valve 6, a heat exchanger 7, a liquid supply pump P1, a circulation Pump P2, cooling water pump P3 and connecting pipelines and loads. The precise temperature control system uses the semiconductor thermal stack 1 as a cold and heat source, and sets a three-way valve 6. The second outlet of the three-way valve 6 and the first heat exchange tube cluster 71 of the heat exchanger 7 form a natural cooling branch. The natural temperature difference between the first circulating fluid and the low-temperature seawater realizes heat transfer. The cooling water pump P3 is a variable frequency pump.

[0035] The liquid cooling source system of this embodiment uses the semiconductor thermal pile 1 as the core device—the cold and heat source, and uses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com