Variable-runner thermostat

A technology of variable flow passage and thermostat, which is applied in the direction of machine/engine, coolant flow control, engine components, etc. Inability to respond quickly and other problems to achieve the effect of improving fuel economy, less pumping, and reducing pumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

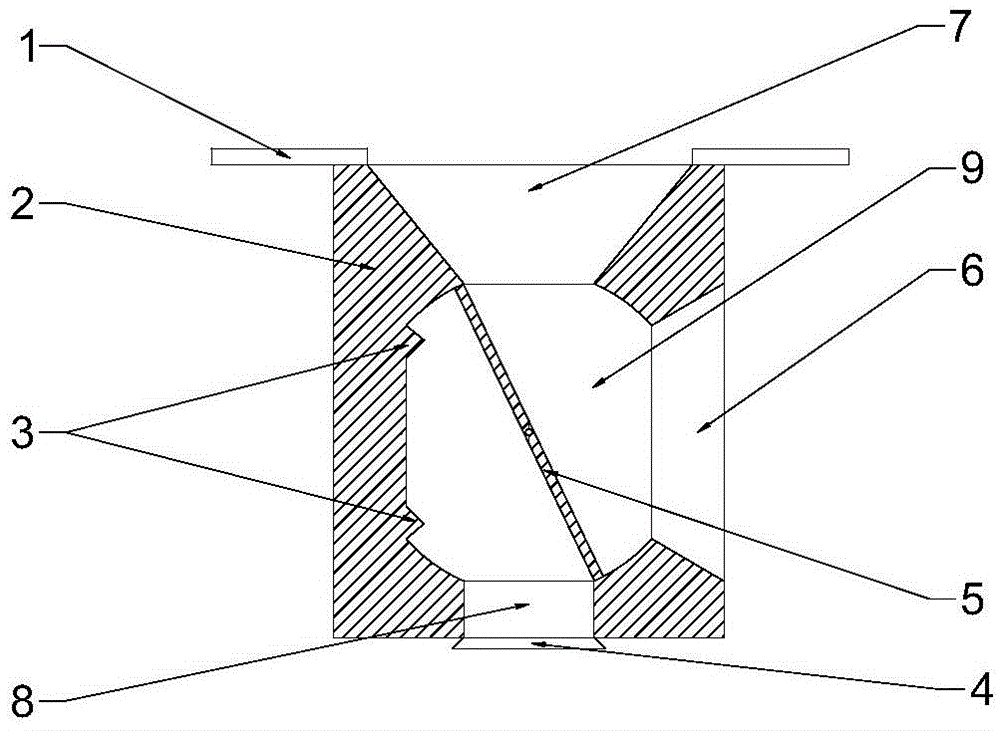

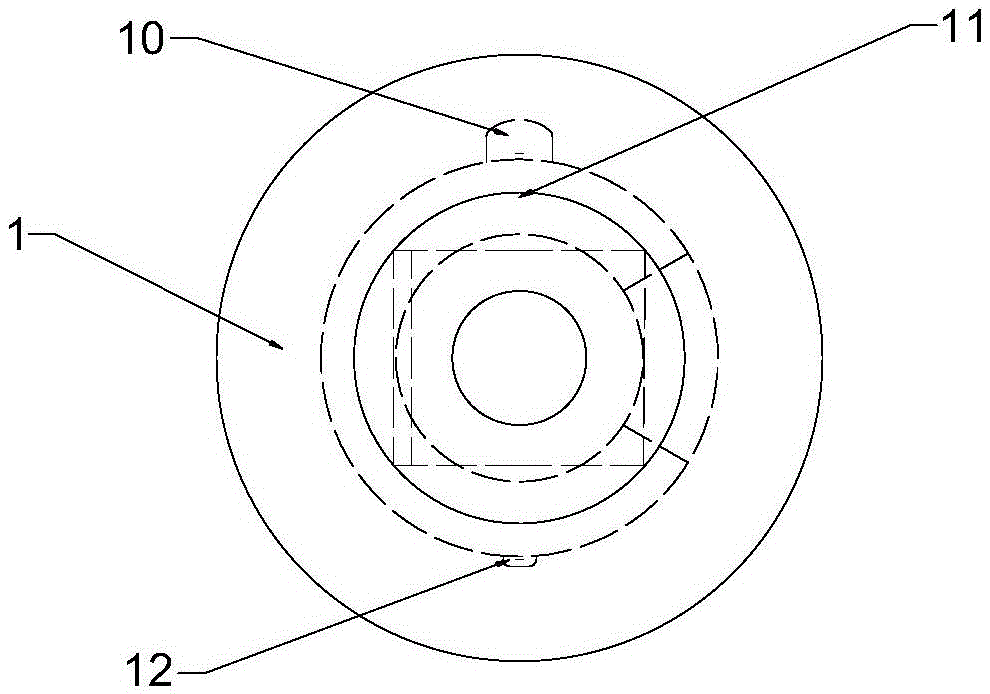

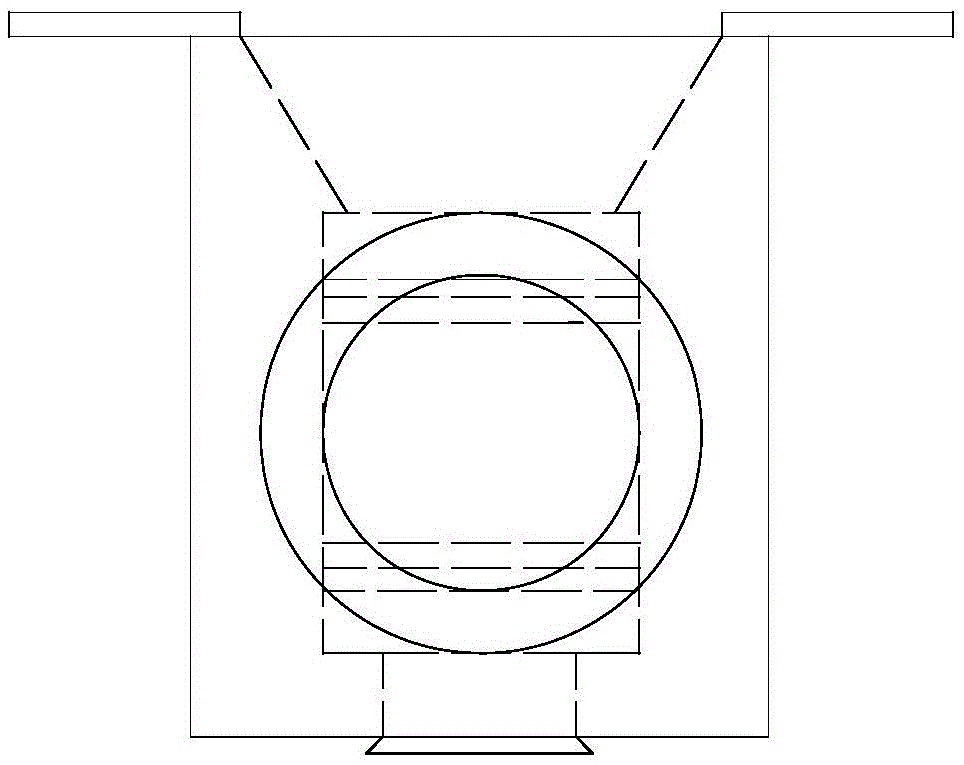

[0046] Such as Figure 1-7 As shown, the invention provides a thermostat, comprising:

[0047] The valve body assembly includes the valve body 2, the fixed positioning buckle 1 arranged above the valve body 2, the water inlet 6 connected with the water outlet pipe 13 arranged on the valve body 2, and the water inlet 6 arranged on the valve body 2. The first outlet 8 connected to the water pump water supply pipe 14 on the body, the second output port 7 connected to the radiator water supply pipe 15, the sealing ring 4, and the rear cover 12 of the rotating shaft.

[0048] The variable channel assembly includes a variable channel baffle plate 5 arranged in the inner cavity, a limit pin 3 arranged inside the valve body 2, an internal cavity 9, a rotating shaft 11, and a motor 10 for driving the baffle.

[0049] The control unit consists of a temperature sensor and a controller.

[0050] The motor works according to the controller signal, and drives the variable flow channel baf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com