Semiconductor thermopile precise temperature control liquid cooling source system

A semiconductor, liquid cooling source technology, applied in cooling/ventilation/heating renovation, electrical components, electrical equipment structural parts, etc. The effect of convenient hot switching and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with the accompanying drawings, the present invention will be further described through embodiments.

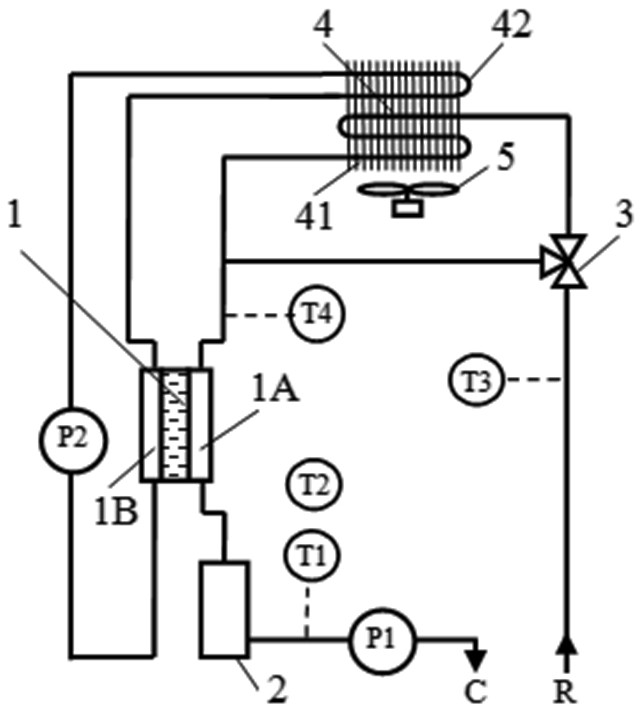

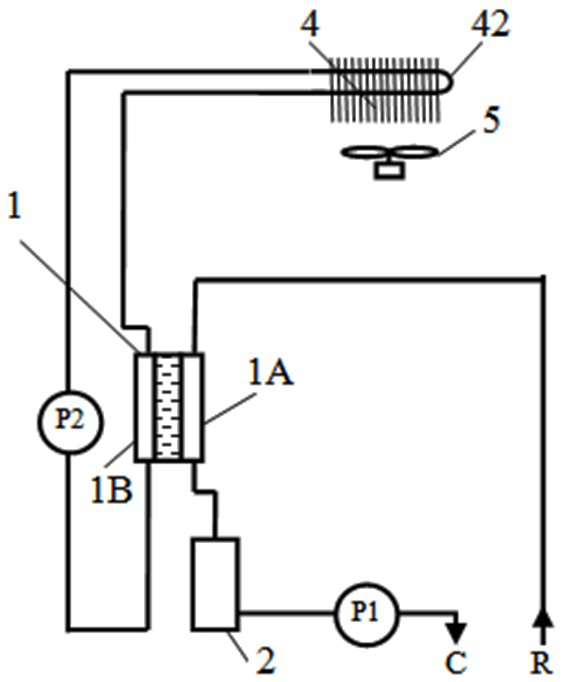

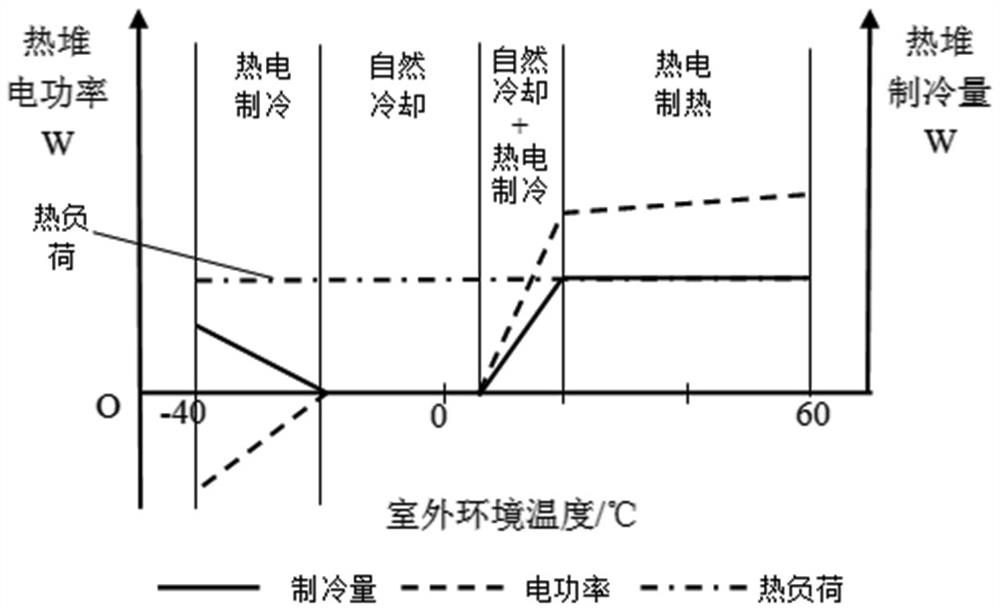

[0032] see figure 1 , a semiconductor thermopile precision temperature control liquid cold source system includes a semiconductor thermopile 1, a liquid reservoir 2, a three-way valve 3, an air heat exchanger 4, a fan 5, a first liquid pump P1 and a second liquid pump P2, The improvement lies in: using the semiconductor thermal stack 1 as the cold and heat source, the first heat exchange pipeline 41 with the three-way valve 3 and the air heat exchanger 4 constitutes a natural cooling branch (compared with figure 2 ), its function is to release the heat load of the controlled object directly to the outdoor air by using the natural temperature difference between the first circulating fluid and the outdoor low-temperature air by using the outdoor air as the natural cooling source when the outdoor temperature is low, that is, to realize natural coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com