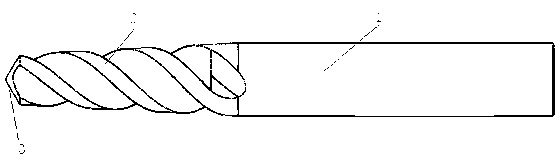

Three-edge taper twist drill

A technology of twist drills and twist drill rods, which is applied in the field of hole processing tools and can solve problems such as not being able to process taper holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] like figure 1 Shown:

[0009] The three-blade taper twist drill of this embodiment is characterized in that it has an integrally formed structure, has a cylindrical drill shank 1, and a twist drill rod 2 is connected to the front end of the drill handle, and three cutting edges 3 are evenly arranged on the drill rod. The twist drill pipe described above is a tapered drill pipe with a taper of 5°. The three-blade tapered twist drill of the present invention has a drill rod with a 5° taper, which can be applied to the processing of tapered holes, and is especially suitable for the processing of tapered threaded bottom holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com