Modified plate pipe manufacturing reeling machine

A rolling machine, an improved technology, applied in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of uneven force on rectangular plates, high manufacturing costs, and long idling time of equipment, achieving the possibility of Improve and reduce the scrap rate, reduce the effect of the use of external force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

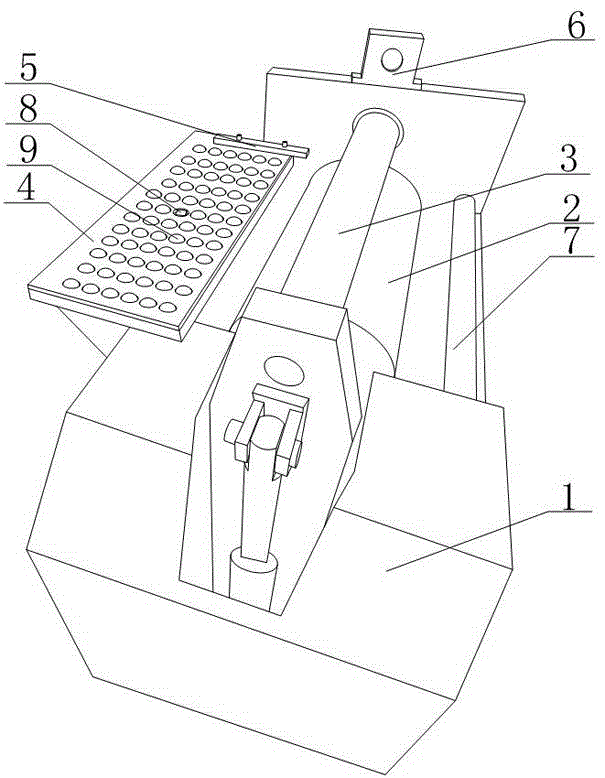

[0020] Such as figure 1 As shown, an improved plate tube rolling machine of the present invention includes a frame 1, on which a lifting lug 6 is also provided, and an active roller 2 is installed on the frame 1. 2 is also provided with a driven roller 3 above, and a protective roller 7 is also installed on the frame 1, the axis of the protective roller 7 is parallel to the axis of the driving roller 2, and a feeding table 4 is also installed on the frame 1. The feeding table 4 is facing the gap between the driving roller 2 and the driven roller 3. An alignment strip 5 is installed on the feeding table 4, and a concave hole is provided on the feeding table 4, and a concave hole is provided in the concave hole. Photoelectric switch 8. The photoelectric switch is connected to the driving mechanism of the active roller, and the output signal of the photoelectric switch is used as a signal for driving and switching of the driving mechanism. The driving mechanism of this embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com