Halogen-free flame-retardant conductive polypropylene composite material

A composite material, polypropylene technology, applied in the field of conductive polypropylene composite materials, can solve the problems of loss and easy injury, and achieve the effect of ensuring safety, excellent strength and reasonable selection

Inactive Publication Date: 2014-12-03

CHANGSHU KASMAIN

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the good insulation of polypropylene materials, it is easy to accumulate charges on the surface and form static electricity. After the accumulation of static electricity, it is easy to hurt people or cause other losses.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

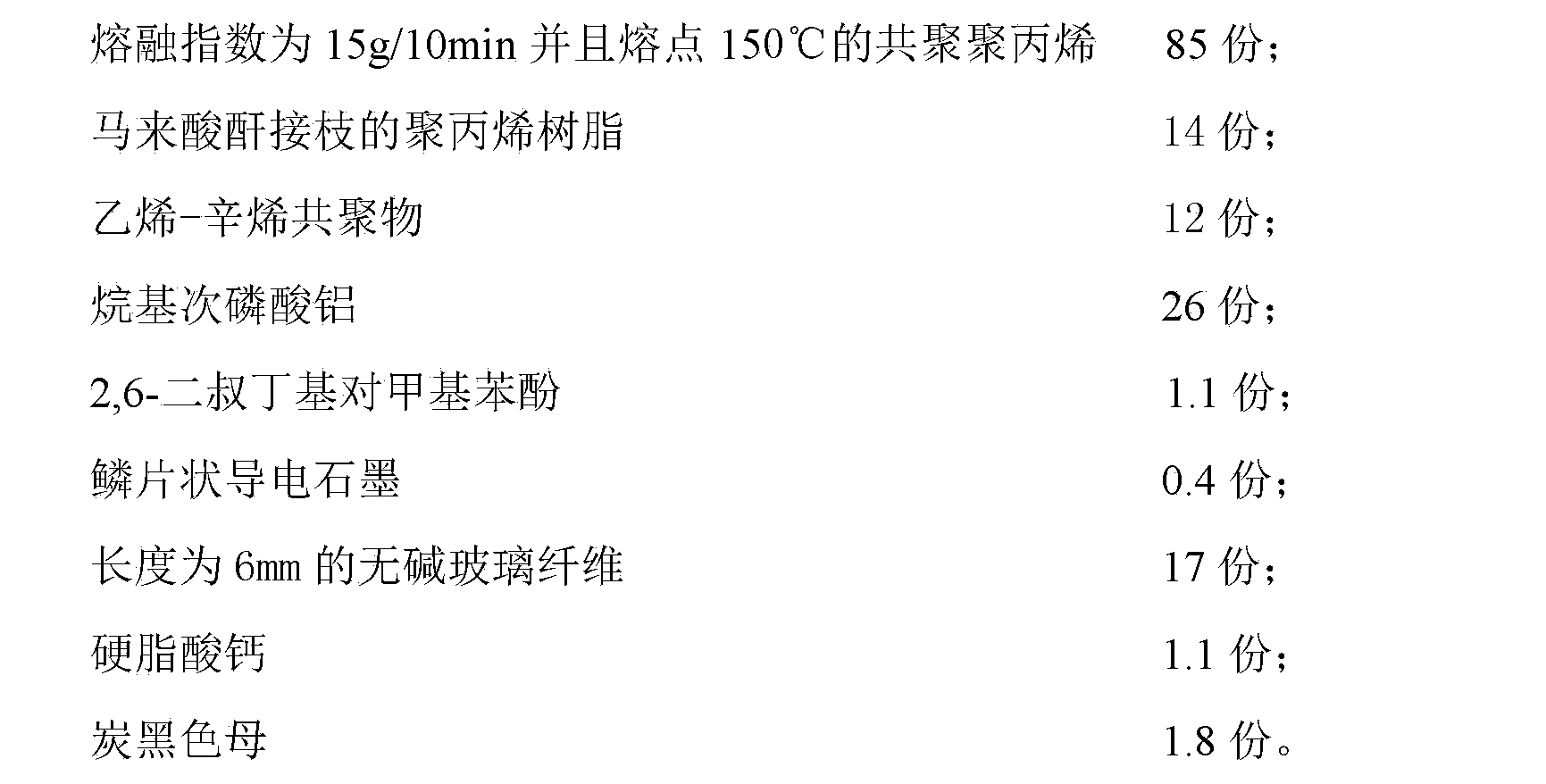

Embodiment 1

[0018]

Embodiment 2

[0020]

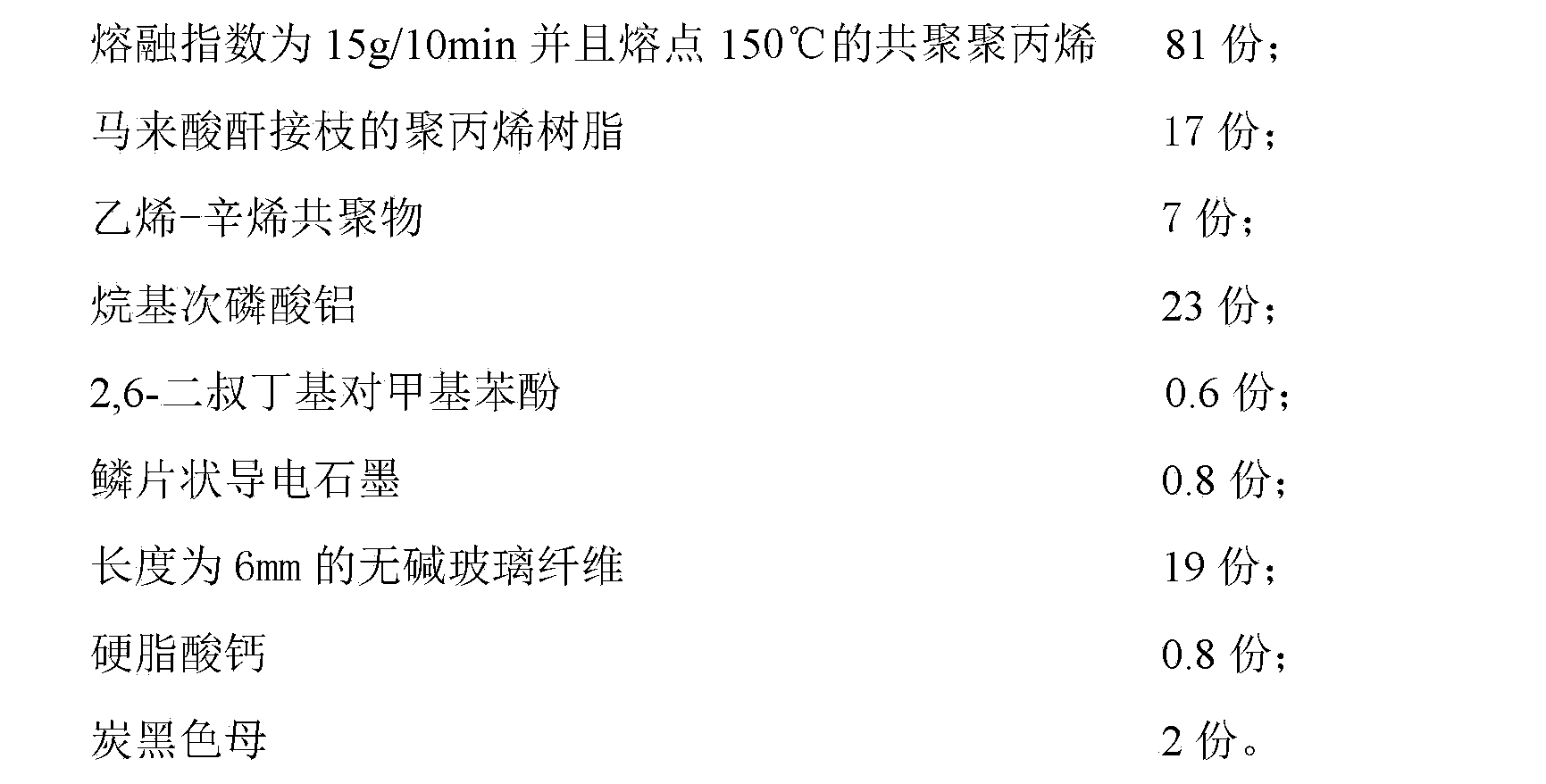

Embodiment 3

[0022]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Login to View More

Abstract

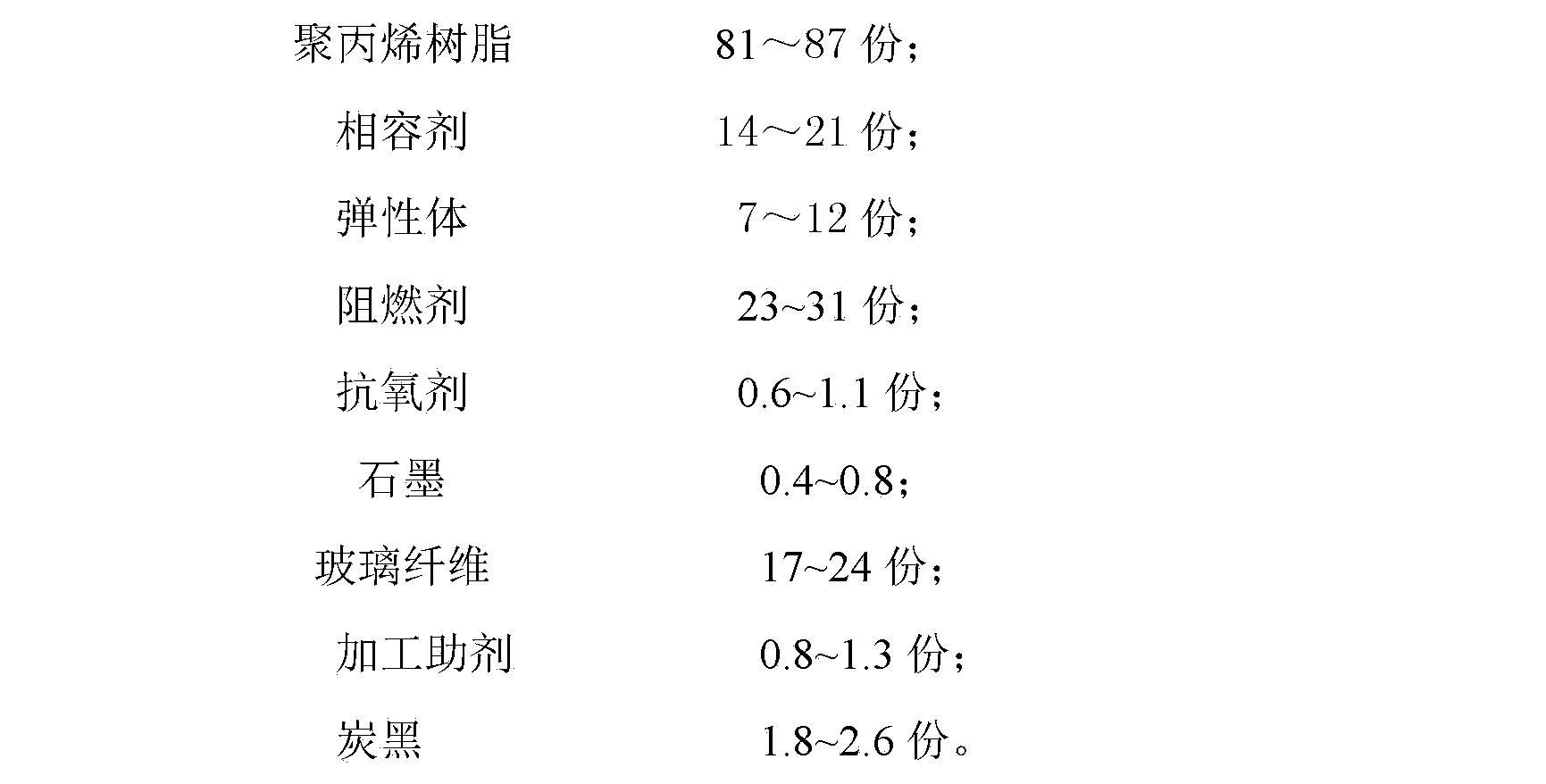

A halogen-free flame-retardant conductive polypropylene composite material belongs to the technical filed of polymer materials. The halogen-free flame-retardant conductive polypropylene composite material comprises, by weight, 81-87 parts of a polypropylene resin, 14-21 parts of a compatilizer, 7-12 parts of an elastomer, 23-31 parts of a flame retardant, 0.6-1.1 parts of an antioxidant, 0.4-0.8 parts of graphite, 17-24 parts of a glass fiber, 0.8-1.3 parts of a processing assistant and 1.8-2.6 parts of carbon black. Test results show that the halogen-free flame-retardant conductive polypropylene composite material has a bending strength of above 56-73MPa, a notch impact strength of above 12.5-15.2kj / m<2>, a thermal deformation temperature of 121-146DEG C and a flame retardation property of V-0 (UL-94-V-0-1.6mm), so the composite material has excellent strength and flame retardation property; the flame retardant is reasonably selected, so the composite material free from halogens is environmentally friendly; and the surface does not generate static electricity, so the safety is guaranteed.

Description

technical field [0001] The invention belongs to the technical field of polymer materials, and in particular relates to a halogen-free flame-retardant conductive polypropylene composite material. Background technique [0002] Polypropylene resin has excellent physical and mechanical properties and is widely used in various industries. In particular, polypropylene reinforced with glass fibers has the characteristics of light specific gravity and high strength, so it can be widely used in automobiles, construction and other fields to replace steel. However, due to the good insulation of polypropylene materials, it is easy to accumulate charges on the surface to form static electricity. After the accumulation of static electricity, it is easy to hurt people or cause other losses. Therefore, reducing the accumulated static electricity on the surface of polypropylene composite materials is a requirement of the automotive industry for interior decoration. [0003] In addition, as...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/14C08K13/04C08K3/04C08K7/14C08K5/5313

CPCC08L23/14C08K2201/001C08K2201/004C08K2201/014C08L2201/02C08L2201/04C08L2201/22C08L2203/20C08L2205/02C08L2205/03C08L51/06C08L23/0815C08K13/04C08K7/14C08K3/04C08K5/5313

Inventor 金钟文

Owner CHANGSHU KASMAIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com