Electronic jacquard yarn selecting unit

An electronic jacquard, integrated technology, used in jacquard machines, textiles, textiles and papermaking, etc., can solve the problems of the heddle rod affecting the service life, the large current activating the cylindrical coil, and the weaving speed, etc. Small scope, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

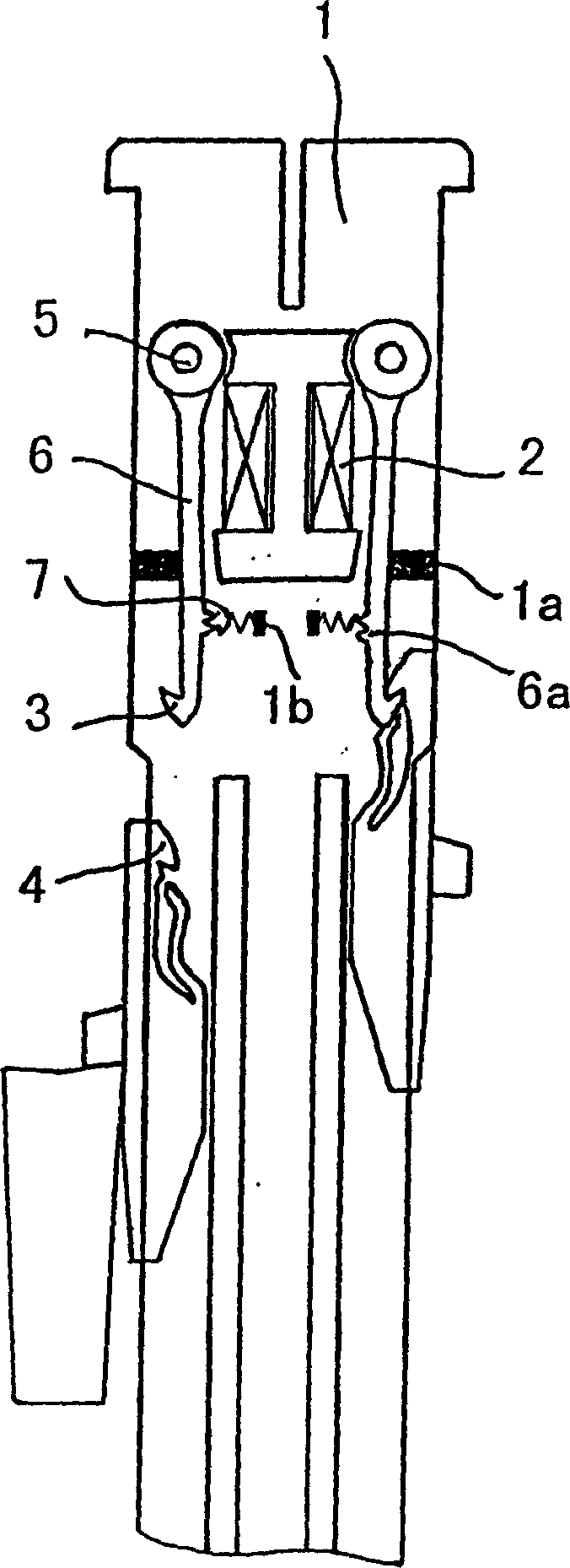

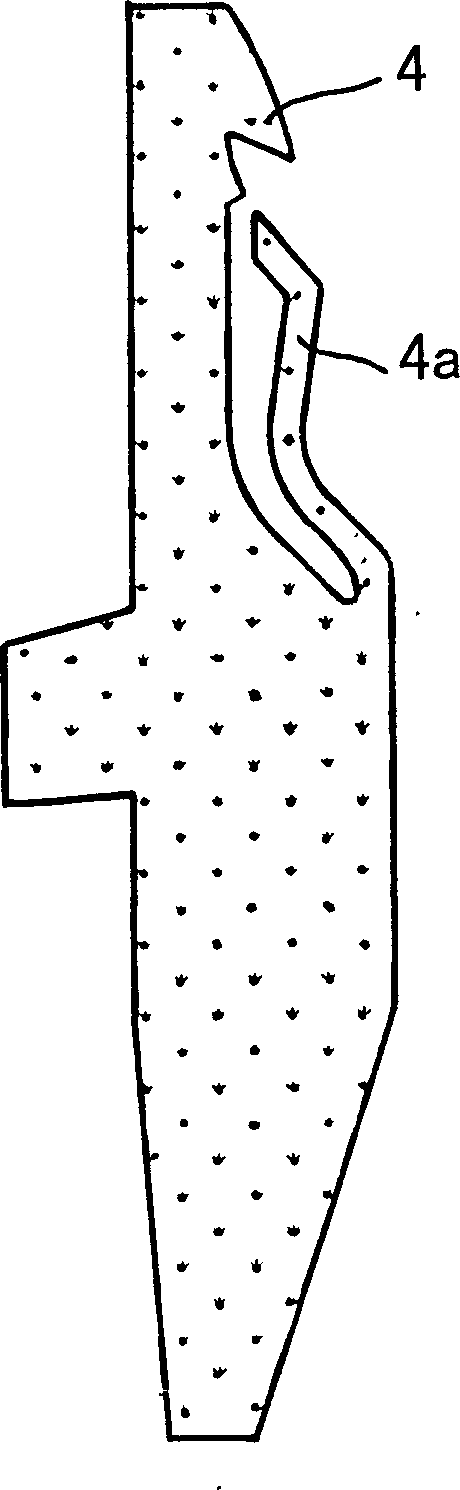

[0010] An electronic jacquard yarn selection mechanism, such as figure 1 In the structure shown, the outer boss 1a, the inner boss 1b, the pin shaft 5 and the casing 1 are injection molded into one body, the thickness of the casing 1 is 2mm, the thickness of the swing arm 6 is 1.6mm, and the number of turns of the coil is 4200 turns , the coil resistance is 645 ohms, and the energizing current is 25 mA. When installing, 8 yarn selection units are used as a group, and the thickness of each group along the combination direction is 44.8mm. The yarn selection mechanism is small in size, especially suitable for making large electronic jacquards. machine, such as the jacquard machine with 12288 needles, the number of coil turns of the traditional electronic jacquard machine is not more than 1400 turns, the coil resistance is not more than 150 ohms, and the current is 80 mA.

Embodiment 2

[0012] An electronic jacquard yarn selection mechanism, such as figure 1 In the structure shown, the outer boss 1a, the inner boss 1b, the pin shaft 5 and the casing 1 are injection molded into one body, the thickness of the casing 1 is 2mm, the thickness of the swing arm 6 is 1.6mm, and the number of turns of the coil is 4500 turns , the coil resistance is 675 ohms, and the energizing current is 25 mA. When installing, 16 yarn selection units are used as a group, and the thickness of each group along the combination direction is 89.6mm. The yarn selection mechanism is small in size, especially suitable for making large electronic jacquards. machine, such as the jacquard machine with 12288 needles, the number of coil turns of the traditional electronic jacquard machine is not more than 1400 turns, the coil resistance is not more than 150 ohms, and the current is 80 mA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com