Method for manufacturing battery transfer tray

A manufacturing method and tray technology, which are applied in the field of manufacturing trays for battery transfer, can solve the problems of strong mobility, sensitivity to temperature and humidity changes, and increased surface resistance, and achieve the effect of reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below, but the present invention is not limited to these contents.

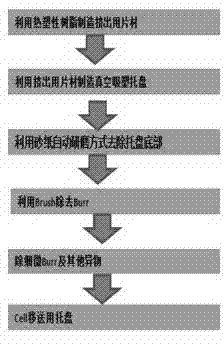

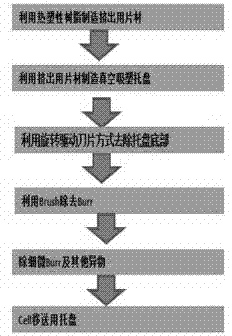

[0015] The present invention includes a step of manufacturing a thermoplastic extruded sheet from a thermoplastic resin; a step of vacuum-forming the extruded sheet to manufacture a tray for transferring batteries; and a step of removing the bottom of the tray so that batteries can pass through and be fixed.

[0016] The existing trays for battery transfer are all manufactured by injection molding. This process is to apply charges to both ends of the product before the product is shipped by using the tray to charge or perform charge and discharge tests. On the bottom of the tray Add holes so that the ends of the battery can pass through the tray. However, in the process of manufacturing trays by injection molding, different molds are made according to the type of battery, which will cause problems such as difficulty in removing foreign matter and lack o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com