Patents

Literature

56results about How to "Wrinkles won't happen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

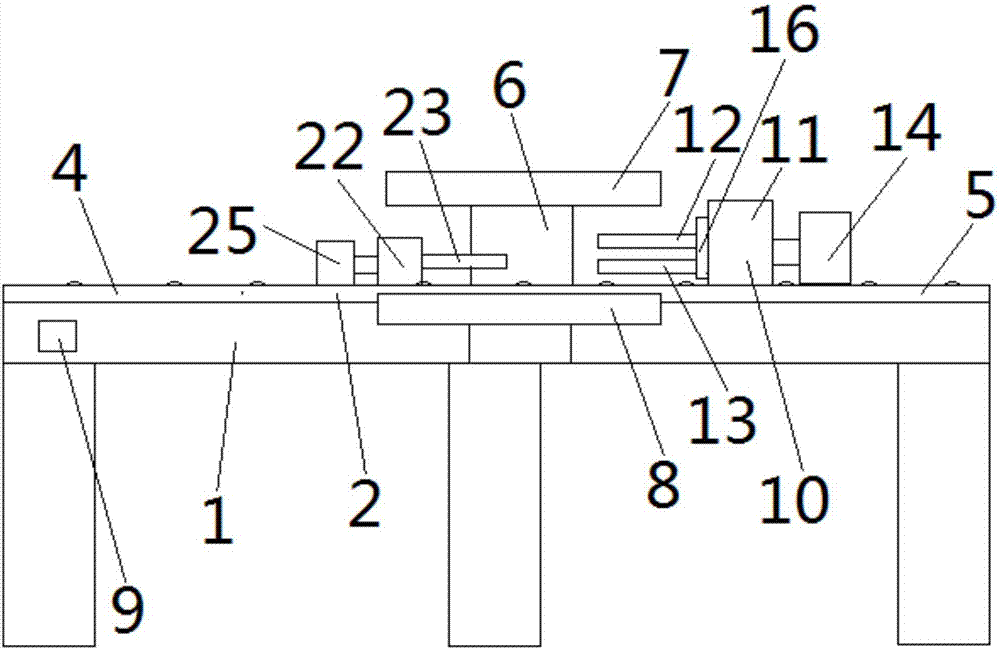

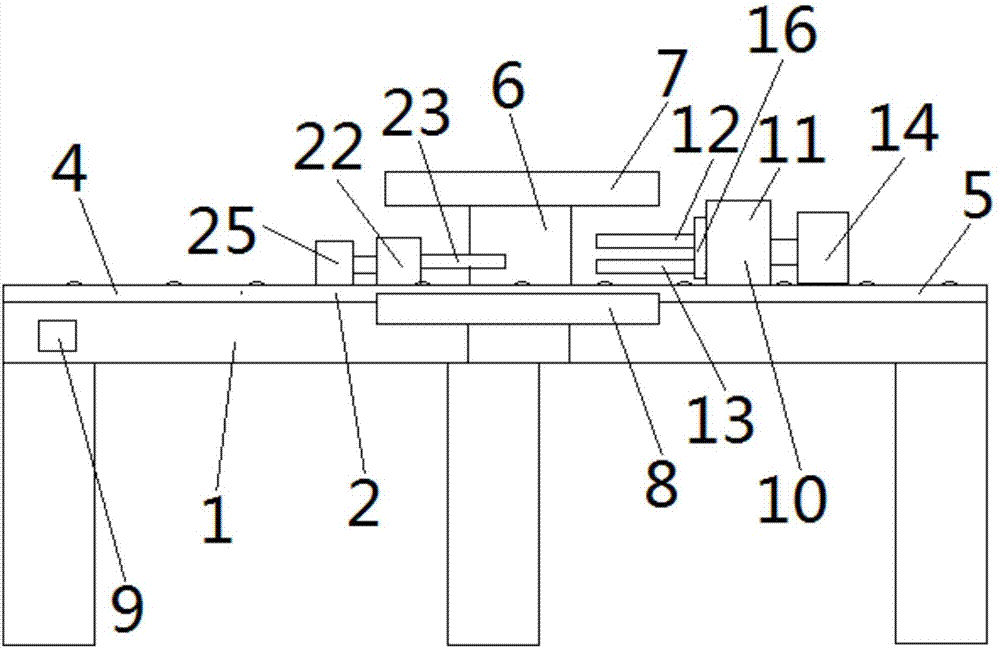

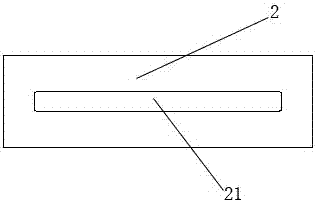

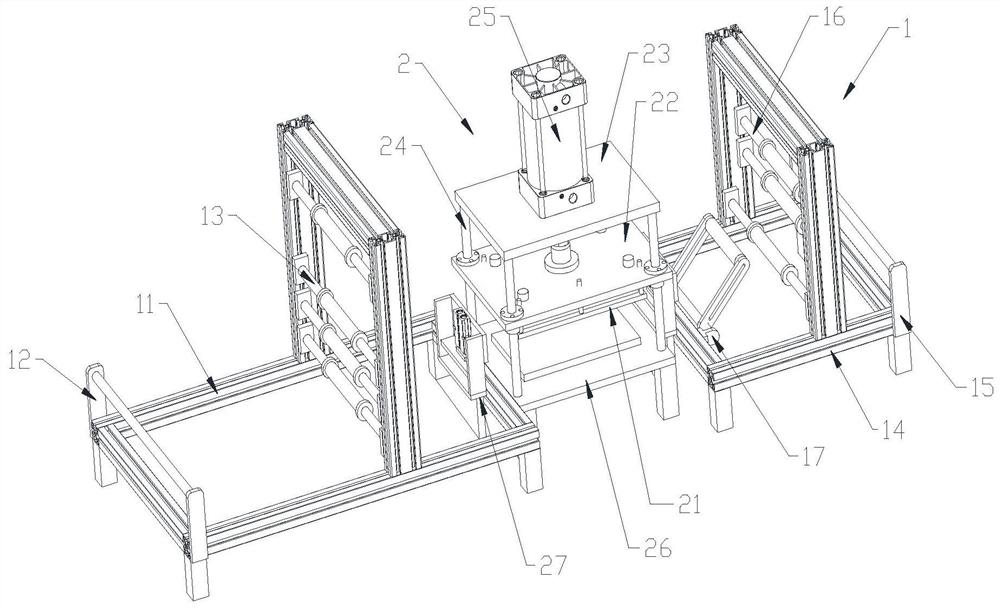

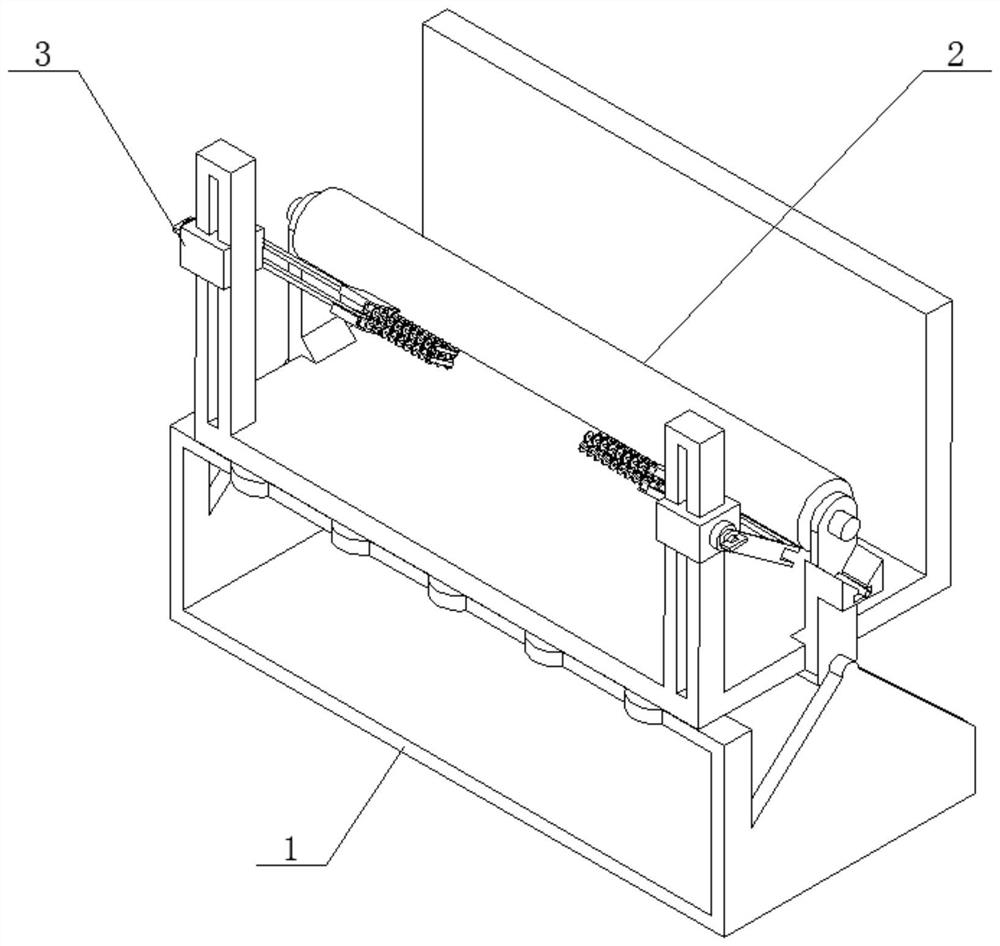

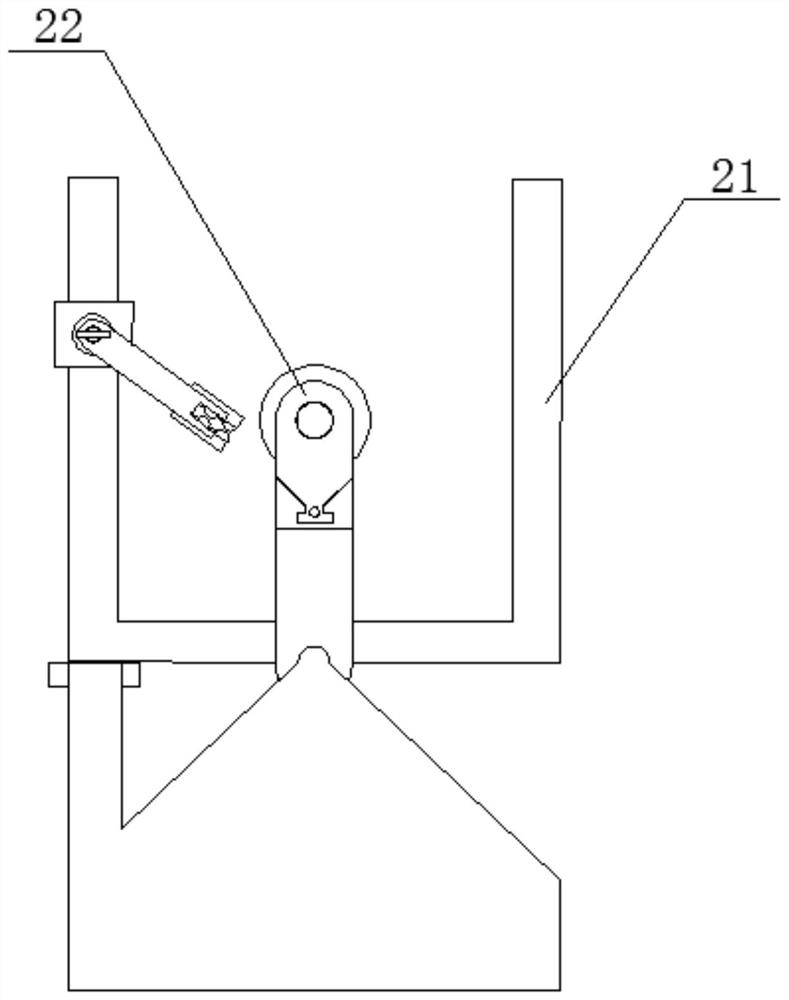

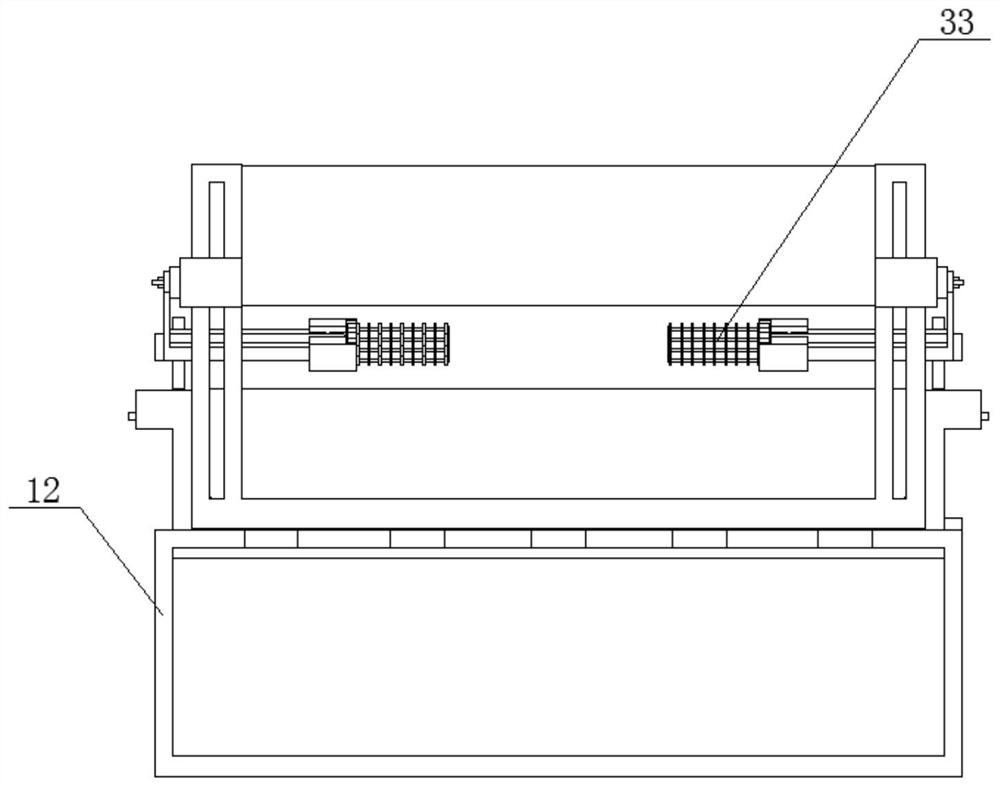

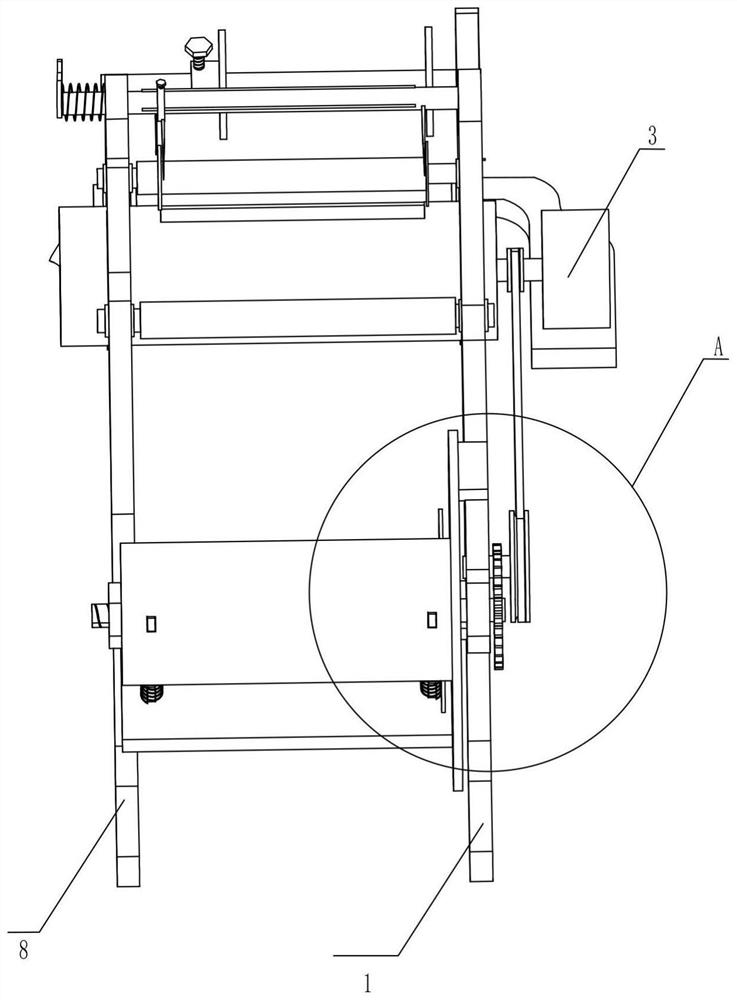

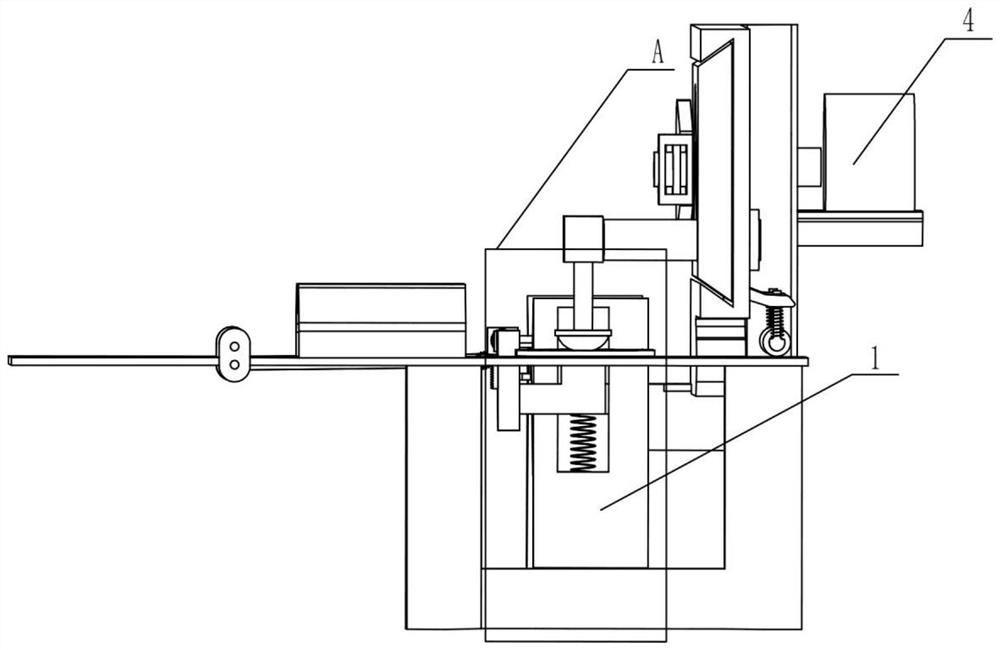

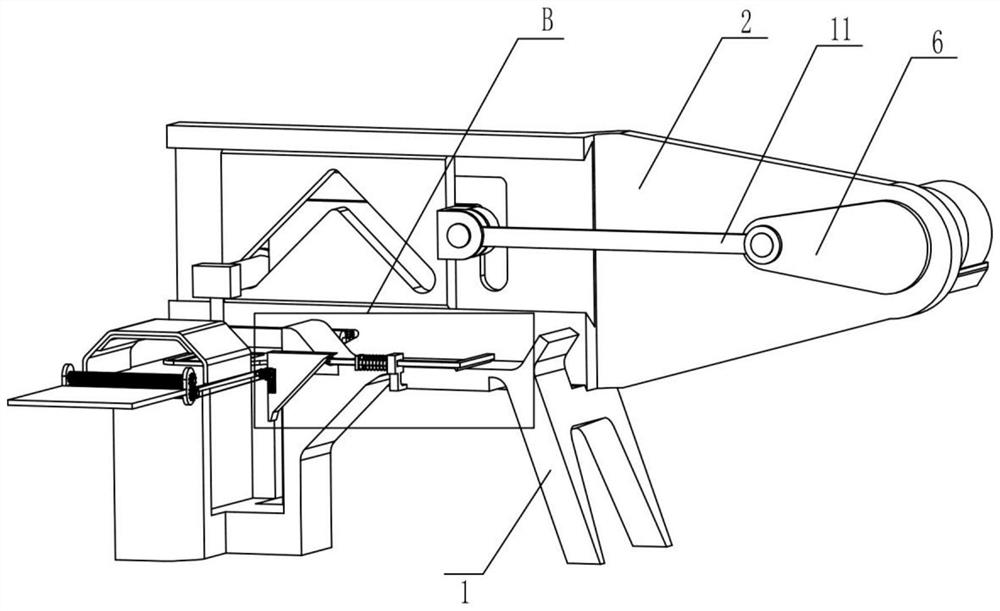

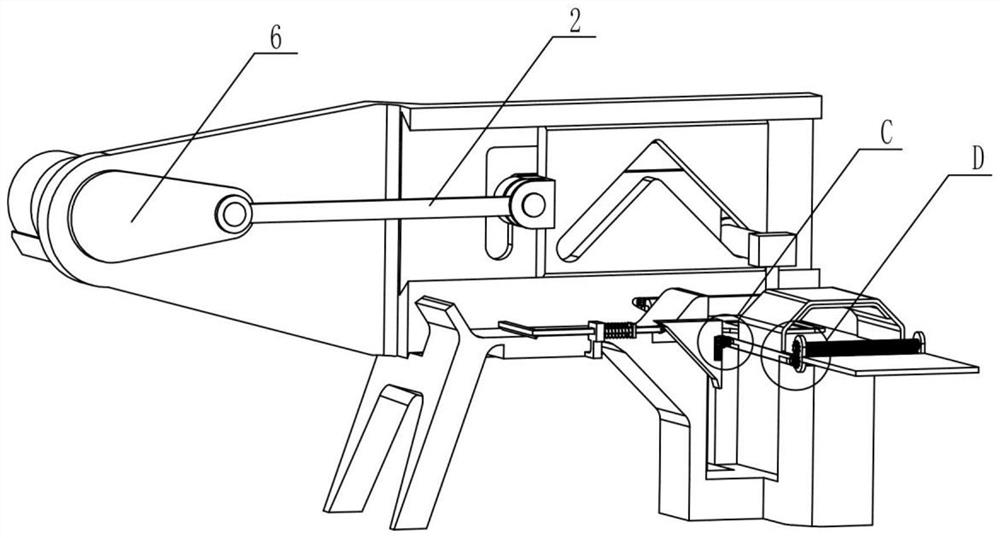

Composite fabric cutoff deviation rectifying device

PendingCN108858450ANo offsetWrinkles won't happenSevering textilesMetal working apparatusEngineeringMechanical engineering

Owner:JIANGSU HONGHUA SPECIAL EQUIP CO LTD

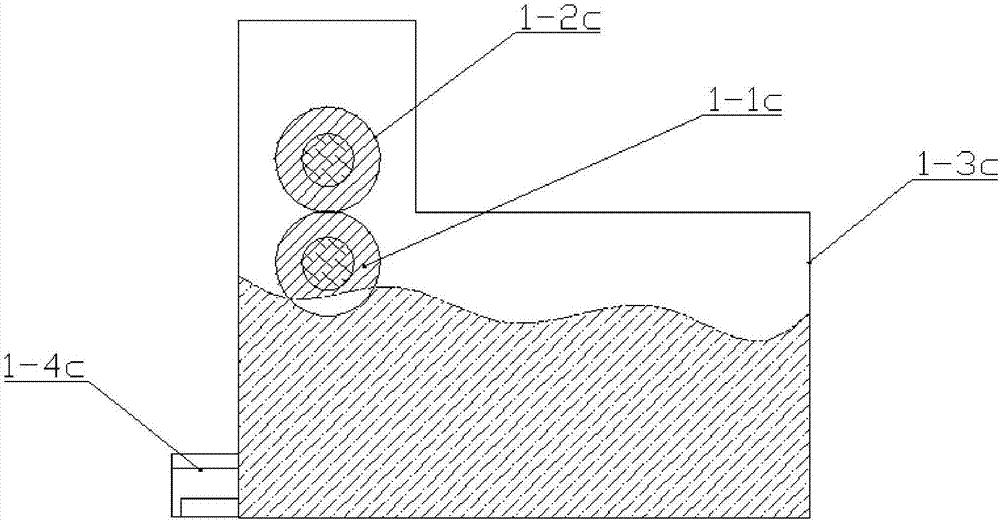

Crease-resist cloth rolling machine

The invention discloses a crease-resist cloth rolling machine. According to the invention, a cloth leveler, capable of generating a negative pressure on one side of the cloth, is arranged before the cloth is rolled on a cloth roll through cloth guide rollers, the cloth surface is tensioned through a plurality of auxiliary cloth guide rollers and the effect of the negative pressure, so that generation of drapes is prevented, and the drapes are eliminated.

Owner:JIANGSU ZHONGXIN RESOURCES GRP

Processing device of PE rolled-up film

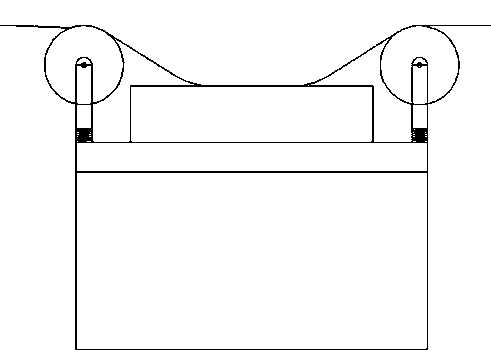

The invention discloses a processing device of a PE rolled-up film. The processing device comprises a base, a chain, a feeding support and a material collecting frame, the feeding support is symmetrically arranged on the left side of the front end of the base in an up-down mode, and a motor cover is arranged at the portion, at the lower end, of the side wall of the feeding support. According to the processing device of the PE rolled-up film, the design is reasonable in structure, an anti-wrinkling mechanism is arranged, the rolled-up film which moves on the upper end of a supporting table islimited through a support, and the rolled-up film is prevented from shifting; a movable frame is elastically connected through springs, the middle part of the movable frame is connected with an elastic roller through a first rotating shaft, the elastic roller is pressed on the rolled-up film so that wrinkles cannot be generated in the rolling process of the rolled-up PE film; sliding rails are arranged on the two sides of the support, sliding wheels are arranged at the ends of the first rotating shaft, the sliding wheels are connected with the sliding rails in a rolling mode, the whole structure is fixed, and the upper-down resistance of the movable frame during elastic movement is avoided; and a tensioning mechanism is arranged, the rolled-up film is tensioned through the action between rotating rollers and a moving roller, so that the phenomenon that the rolled-up film is loosened is avoided, and the tension of the rolled-up film is reduced.

Owner:田帅

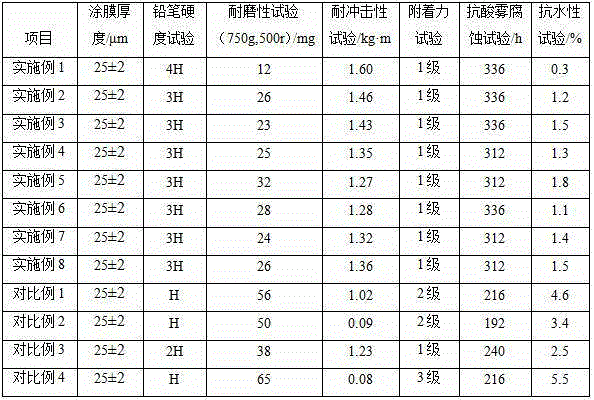

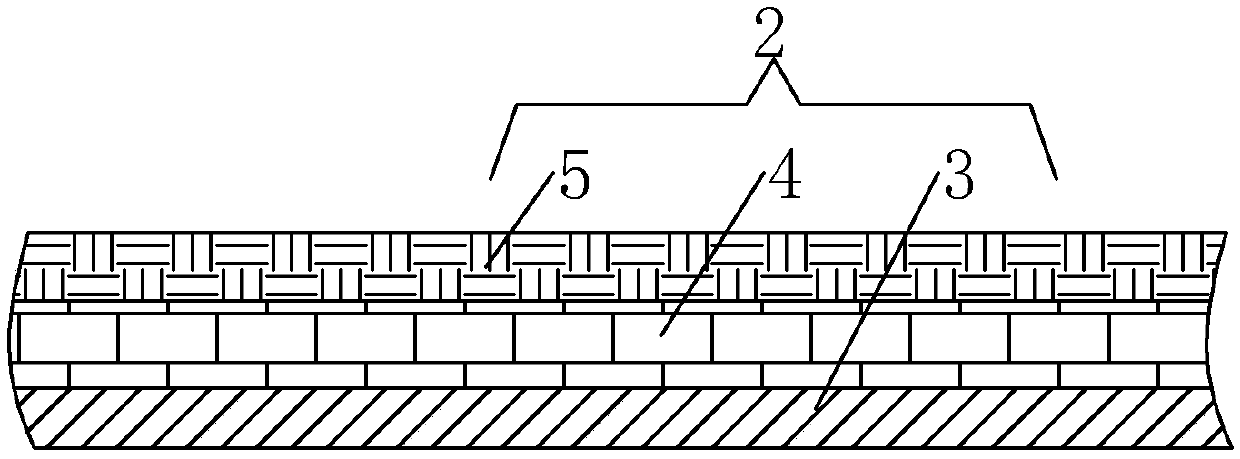

Preparation method for coating film capable of enhancing hardness and toughness of soft package lithium battery

ActiveCN105111903ALow costEasy to operateAnti-corrosive paintsEpoxy resin coatingsEpoxyPoly ether ether ketone

The invention belongs to the technical field of batteries, and particularly discloses a preparation method for a coating film capable of enhancing the hardness and toughness of a soft package lithium battery. The preparation method comprises the following steps that 1 coating film solution preparing, wherein solvent is stirred at high speed, then a composition of alkyd resin, epoxy resin and polyether ether ketone is added, the mixture is stirred, then an antifoaming agent and a flatting agent are added, the solvent is continuously added to regulate the system viscosity, and the mixture is stirred for 10-30 min to obtain coating film solutions; 2 coating film preparing, wherein the coating film solutions obtained in the step 1 are evenly sprayed on the surface of the soft package lithium battery through a spray gun and stood at room temperature or baked at high temperature in a vacuum state and stood until the coating film solutions are dry, and then the coating film is formed on the surface of the soft package lithium battery. The preparation method is simple and stable in technology; the prepared coating film can effectively improve the hardness and toughness of the soft package lithium battery, has the excellent corrosion resistance and is good in water resistance and capable of preventing dampness, effectively protecting the soft package lithium batter and prolonging the service life of the soft package lithium battery.

Owner:深圳电丰电子有限公司

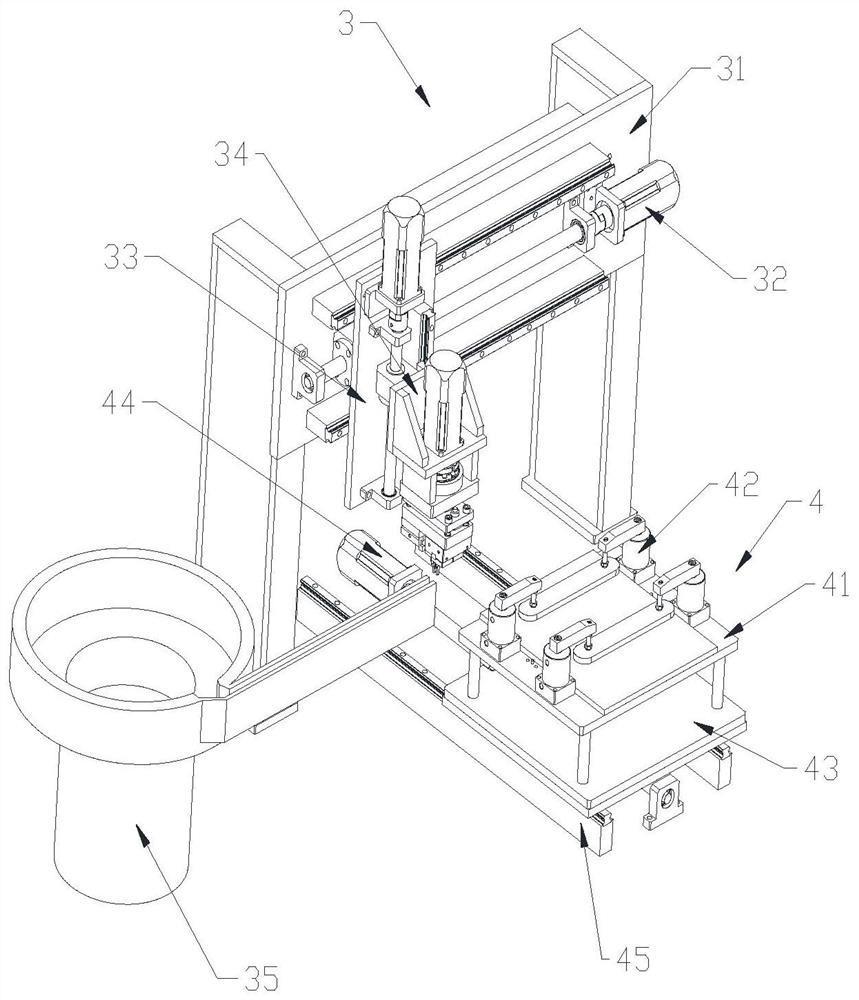

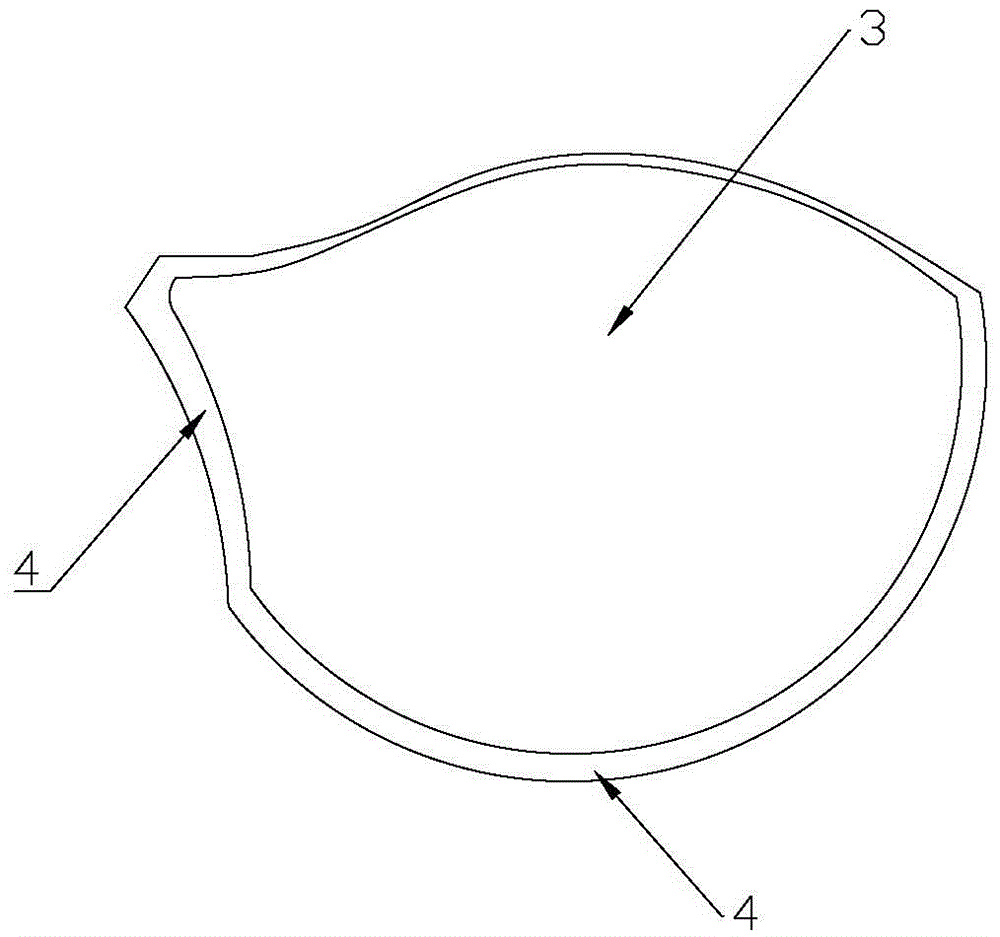

Multi-purpose child growth type furniture

PendingCN108294554ALong sustainable use timeWide range of usesGymnastic exercisingBenchesEngineeringInfancy stage

The invention belongs to the technical field of furniture, and discloses multi-purpose child growth type furniture. The multi-purpose child growth type furniture is placed on the ground to provide a user with functions of sitting, lying, sleeping and exercising, and comprises two supporting frames arranged symmetrically, the supporting frames are connected with each other through a plurality of connecting rods, the connecting rods and the supporting frames are detachably connected, the peripheral region of each supporting frame is formed by the joint of a plurality of arcs, the outer peripheral surface, near the ground, of each supporting frame is a curved structure with a projecting middle part and two curled-up ends, and the part, opposite to the curved structure, of the outer peripheralsurface is a cambered structure in accordance with human engineering characteristics. The growth type furniture has the advantages that the multi-purpose child growth type furniture can be transformed into different furniture used in each stage of a person from infancy stage to old age, and the utilization rate is high; the connecting rods can be reasonably disassembled and assembled, the designof the curled-up surface structure and the cambered structure on the supporting frame is combined, The growth type furniture can be used as a crib, a child rocking chair, sit-up exercise equipment, aleisure rocking chair, and the like, and cushions of different thicknesses can be set on the connecting rods to enhance the comfort of use.

Owner:HUNAN UNIV OF TECH

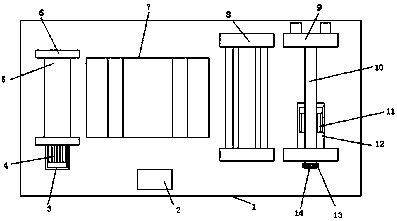

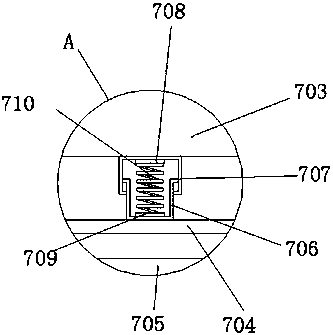

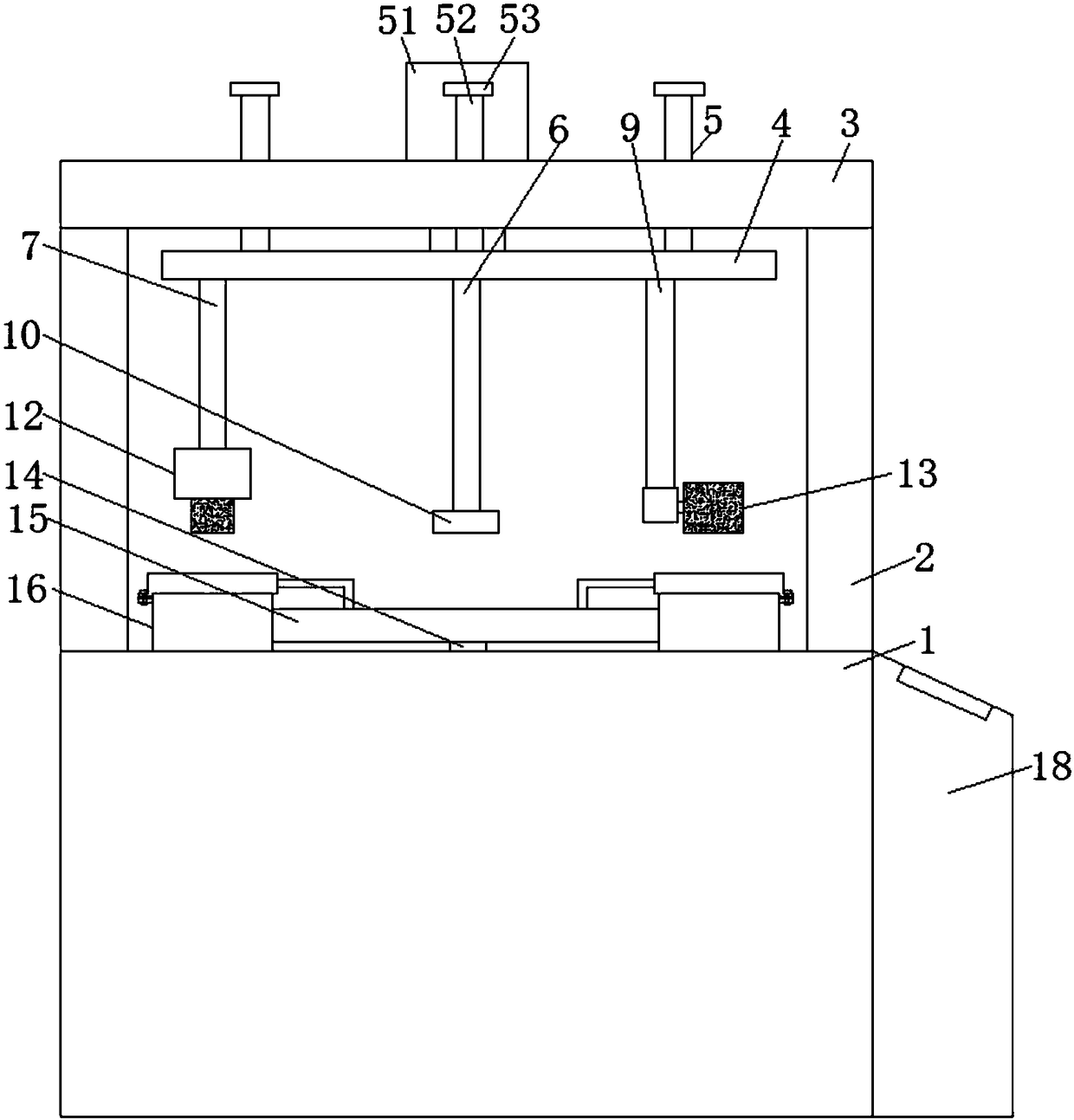

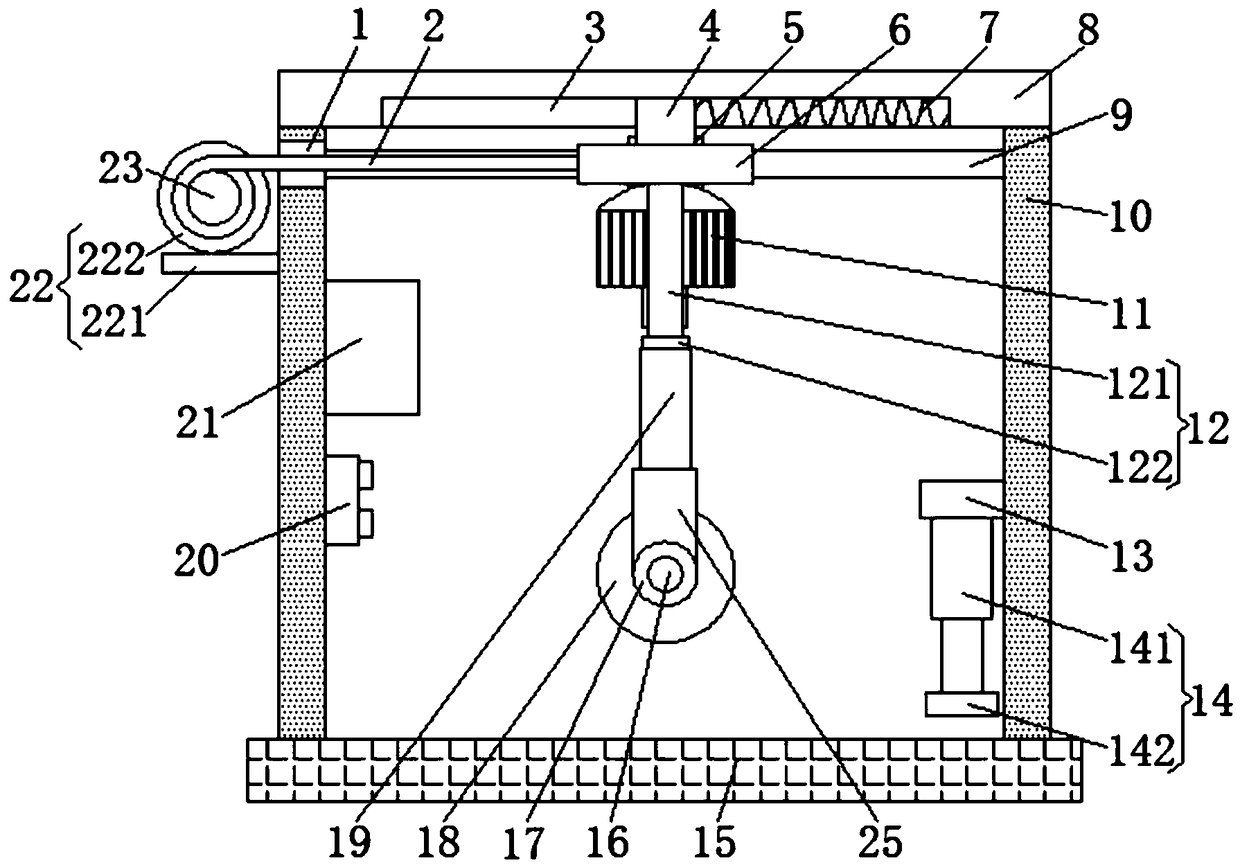

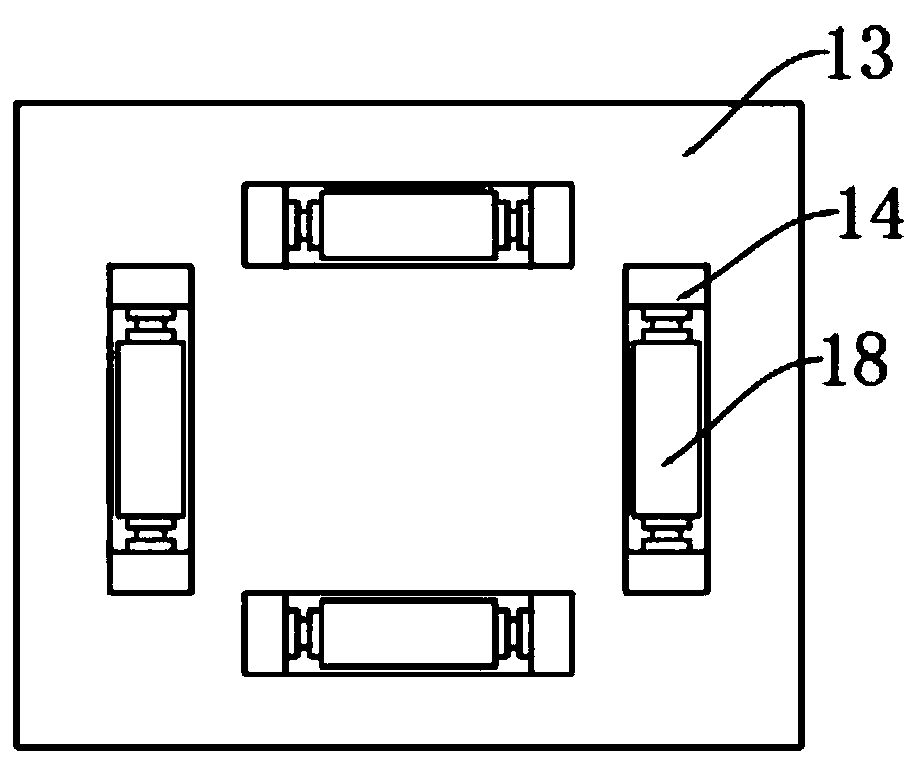

Abrasion resistant detection device of leather product

InactiveCN108225957AReliable test resultsEasy to fixInvestigating abrasion/wear resistanceWear patternWear resistance

The invention discloses an abrasion resistant detection device of a leather product. The abrasion resistant detection device comprises a detection table, wherein four groups of support rods are vertically arranged on the detection table; one ends, far away from the detection table, of the four groups of support rods are provided with a top plate; a lifting plate is arranged at one side, near the detection table, of the top plate; a lifting device is arranged between the lifting plate and the top plate; the lifting plate is vertically provided with a first hanging rod, a second hanging rod, a third hanging rod and a fourth hanging rod in a way of far away from the lifting device; one ends, far away from the lifting plate, of the first hanging rod and the third hanging rod are respectively provided with a first detection probe and a second detection probe. The abrasion resistant detection device has the advantages that the structure is simple; the design is novel; the leather sample piece fixation is firm and reliable; two groups of leather sample pieces can be sequentially subjected to abrasion tests in two grinding modes; the detection results, tested in the two grinding mode, of the leather sample pieces are more accurate; meanwhile, the abrasion mode with greater abrasion degree on the leather sample piece can also be judged; the comprehensive judgement on the abrasion resistance of the leather sample piece is facilitated.

Owner:苏州朦井纺织科技有限公司

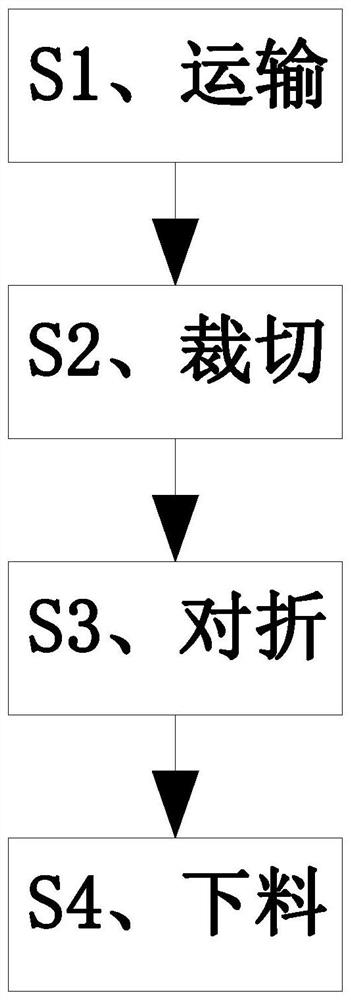

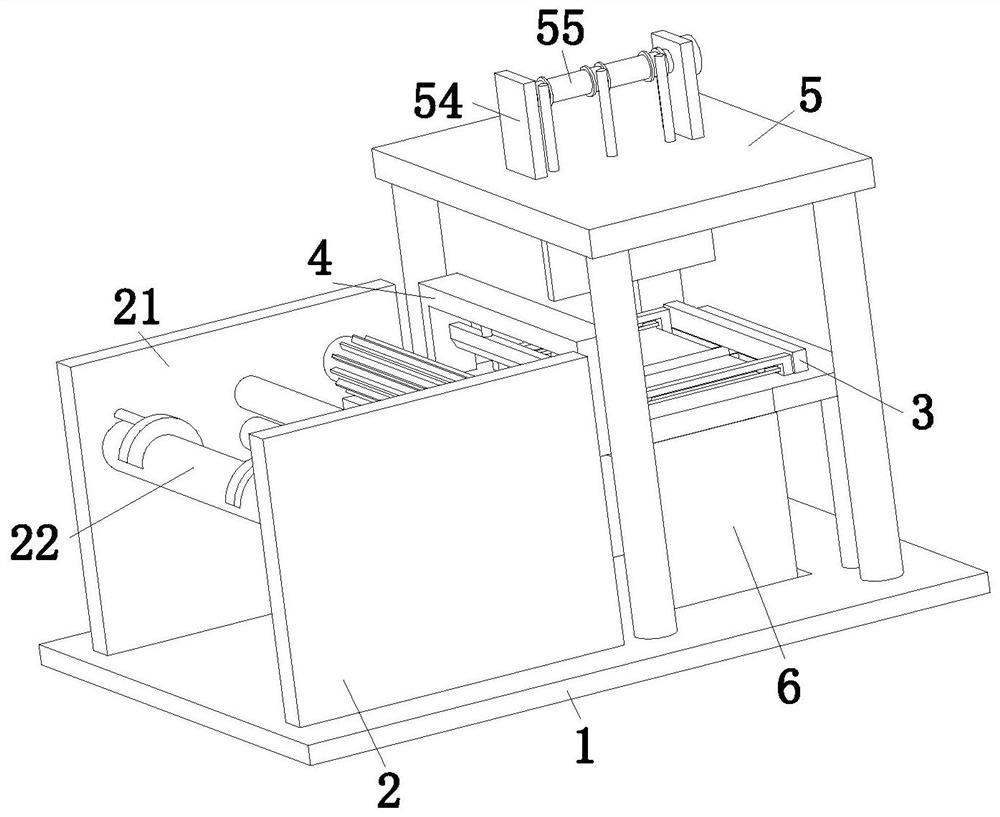

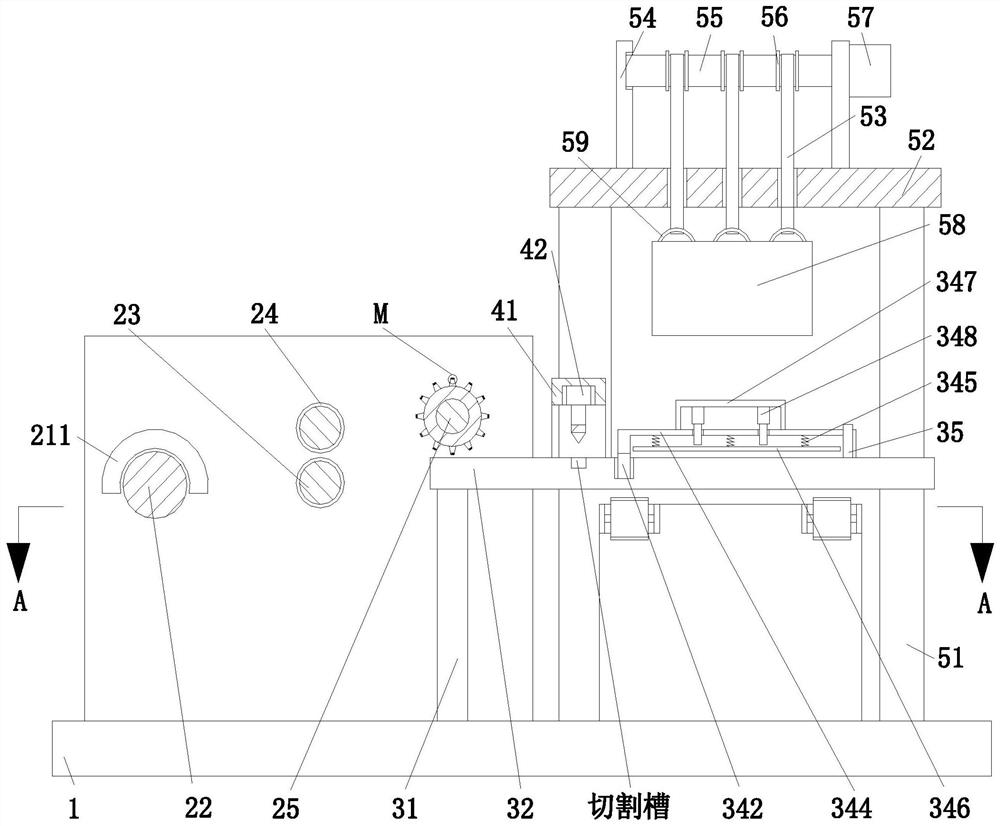

Manufacturing and processing method for aluminum foil packaging bag

InactiveCN112976686AImprove applicabilityImprove pass rateBag making operationsPaper-makingManufacturing engineeringMechanical engineering

The invention relates to a manufacturing and processing method for an aluminum foil packaging bag. The manufacturing and processing method comprises a workbench, a winding device, a fixing device, a cutting device, a moving device and a pressing device, wherein the fixing device comprises a supporting rod, a fixing structure plate, a first rectangular through groove, a moving frame and a limiting plate. According to the manufacturing and processing method, the workbench, the winding device, the fixing device, the cutting device, the moving device and the pressing device are arranged to cooperate with one another, firstly, the aluminum foil packaging bag needing to be manufactured and processed is placed on the winding device, the aluminum foil packaging bag is transported to the fixing device through the winding device, at the moment, the aluminum foil packaging bag is cut into a proper size through the cutting device, so that the applicability of the machine is improved; and at the moment, the aluminum foil packaging bag is rapidly folded in half through the moving device, so that the percent of pass of the machine is improved, the aluminum foil packaging bag is rapidly pressed through the pressing device while being folded in half, so that the working efficiency of the machine during pressing is improved.

Owner:梁星胜

Machine facilitating cloth pressing for printing machine

The invention discloses a machine facilitating cloth pressing for a printing machine. The machine comprises a bottom plate. Two side plates are fixedly connected to the upper surface of the bottom plate. The opposite surfaces of the two side plates are fixedly connected with the left and right sides of a top plate correspondingly. The lower surface of the top plate is provided with a sliding chuteinternally provided with a slide block. A spring is fixedly connected to the right lateral side of the slide block. According to the machine facilitating cloth pressing for the printing machine, cloth is placed onto the bottom plate by arranging a first motor, a threaded column, a threaded cap, a spring, a pressure roller, a first sliding rod, a second sliding rod, the top plate, a rope reel anda second motor, and an electric push rod is controlled to extend, so that a pressing plate moves downwards to press one end of the cloth; and an output shaft of the first motor is controlled to rotateforwards, so that the threaded column rotates to drive the threaded cap to move downwards, workers do not need to use tools to press the cloth, time and physical strength of the workers are saved, the pressing effect is better, the printing effect is not affected, and the product quality is improved.

Owner:周立新

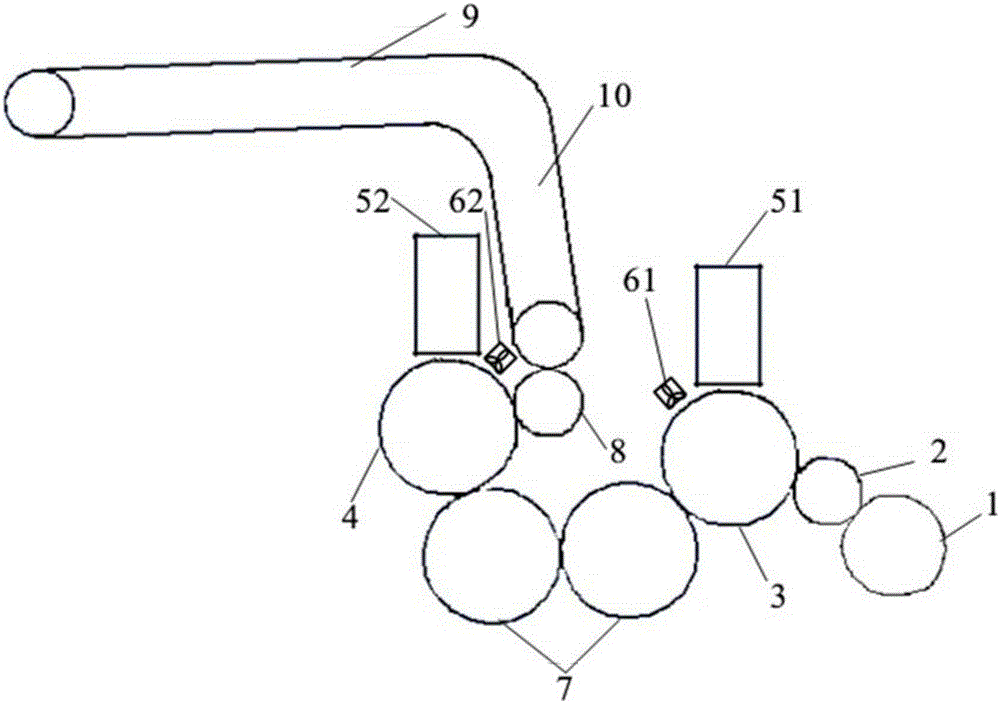

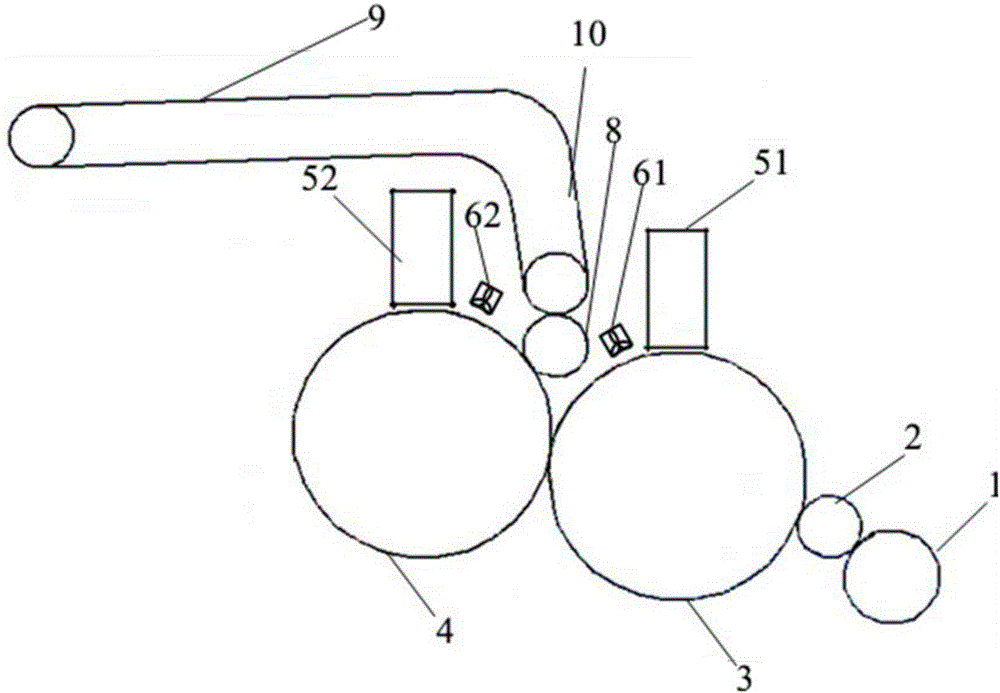

Two-sided ink-jet printer

The invention discloses a two-sided ink-jet printer, comprising a paper supply unit, a printing unit, and a paper collection unit. The paper supply unit comprises a paper feed mechanism and a paper feed roller, and is used to transmit paper to the printing unit to print. The printing unit comprises a front-surface printing roller, a paper transport unit, a back-surface printing roller, an ink jet head, and a drying device. The paper transport unit is arranged below the front-surface printing roller and the back-surface printing roller. The paper transport unit comprises a plurality of paper transport rollers. The paper transport rollers are used to transmit the paper which has been printed on the front surfaces to the back-surface printing roller to print on the back surfaces. The paper collection unit comprises a paper collection roller, a paper collection component, and a transmission portion. The paper collection roller is one a side of the back-surface printing roller, close to the front-surface printing roller. The paper collection roller transmits the paper which completes two-sided printing to the paper collection component. The printer is simple in structure, low in cost, small in space occupation, and accurate in printing, and the printer can protect paper.

Owner:江苏昌昇集团股份有限公司

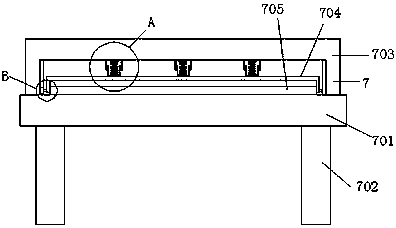

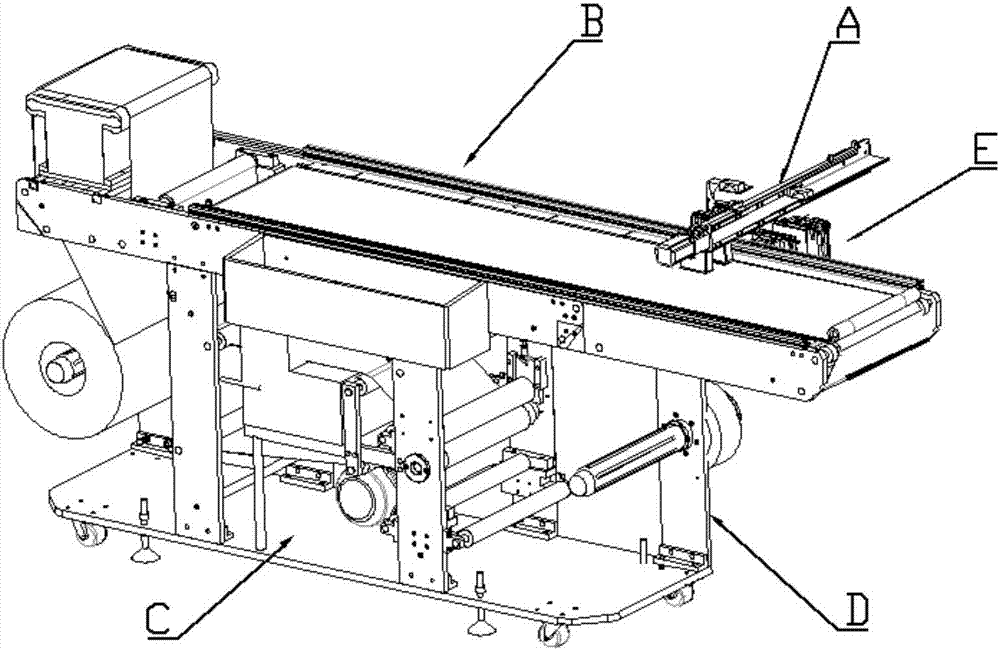

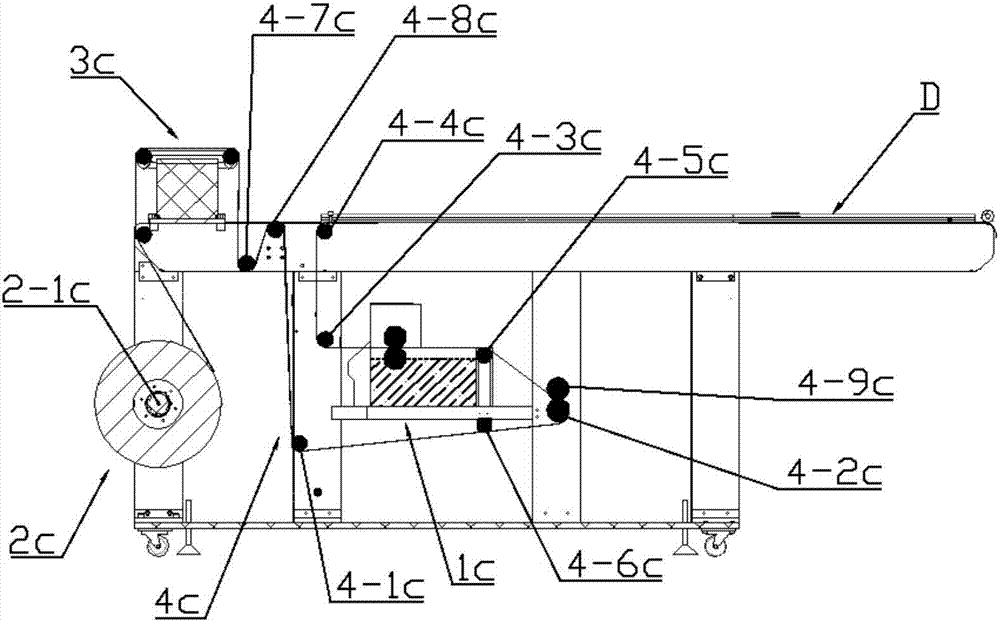

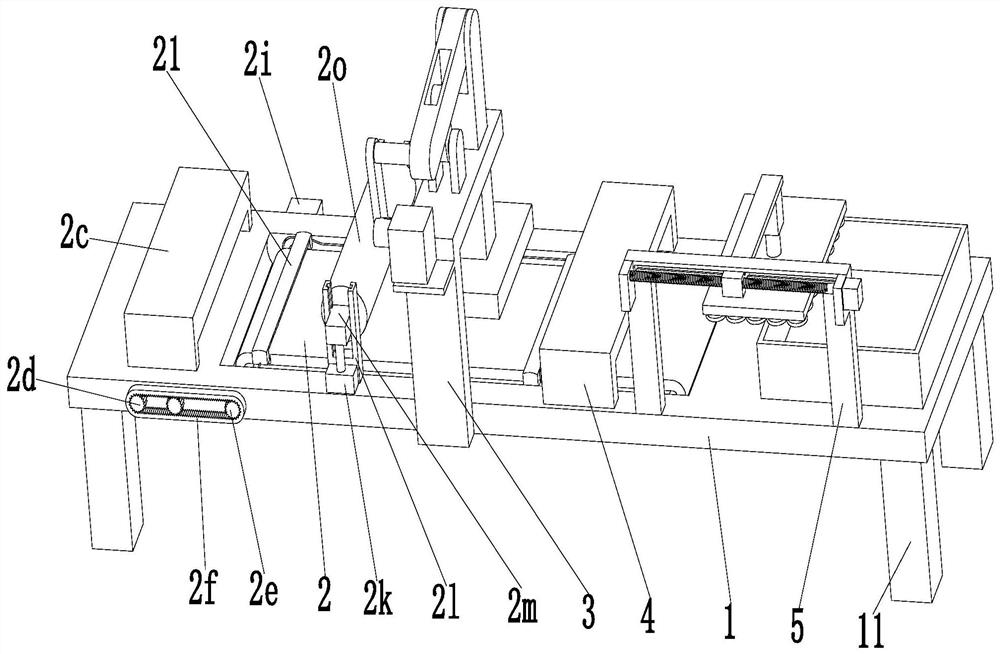

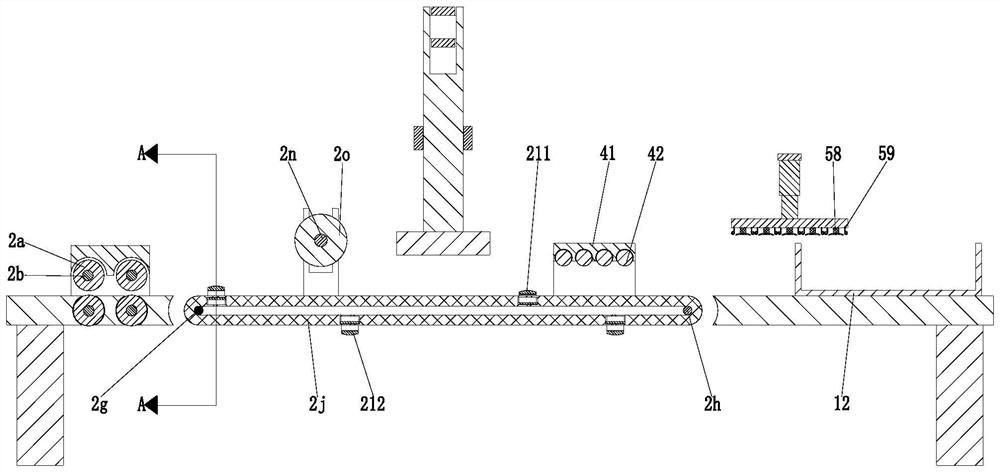

Electronic ticket front segment processing equipment

ActiveCN107010449AEasy to pasteReasonable structureConveyor partsWebs handlingComputer moduleMechanical engineering

The invention discloses electronic ticket front segment processing equipment which comprises a paper containing rack, a gluing module, a conveying module and an electronic tag automatic feeding device. The gluing module, the conveying module and the electronic tag automatic feeding device are arranged on the paper containing rack. The gluing module comprises a paper tape storage mechanism, a deviation rectifier, a paper tape conveying mechanism and a gluing mechanism which are arranged on the paper containing rack. The electronic tag automatic feeding device comprises a carrying module and a storage module. The carrying module comprises a connecting plate, an electronic tag absorbing mechanism and a transverse driving mechanism. The storage module comprises an electronic tag storage box, an electronic tag supporting plate and a supporting plate vertical driving mechanism for driving the electronic tag supporting plate to vertically move. The electronic ticket front segment processing equipment can achieve gluing and conveying of paper tape and electronic tag placing, and is simple in structure and high in work efficiency.

Owner:GUANGZHOU MINGSEN TECH CO LTD

Paper feeding device capable of intelligently separating paper, avoiding paper jamming and achieving smooth conveying

The invention relates to the technical field of network equipment, and discloses a paper feeding device capable of intelligently separating paper, avoiding paper jamming and achieving smooth conveying. The paper feeding device comprises a rack, wherein an air bin is formed in the rack, an air pump is fixedly connected to the center of the air bin, and a sliding plate is slidably connected to the interior of the air bin; a pressure switch is fixedly connected to the side wall, close to the sliding plate, of the air bin, a spring air bag is fixedly connected to the side face of the air bin, a metal feeler lever is fixedly connected into the spring air bag, a movable block is slidably connected to the side face, close to the spring air bag, of the rack, and a rotating shaft is rotatably connected into the movable block. The side surface of the elastic cavity is connected with the adsorption head through the hose, and the end of the adsorption head is fixedly connected to the side surface of the paper twisting roller, so that the adsorption head can adsorb the paper, and the effects that higher adhesive force can be provided for the printing paper when the paper is conveyed, the paper cannot be wrinkled in the conveying process, and conveying is smoother are achieved.

Owner:南京诺赋商贸有限公司

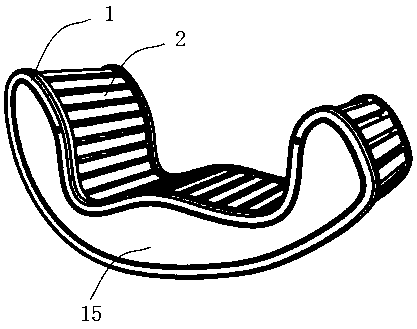

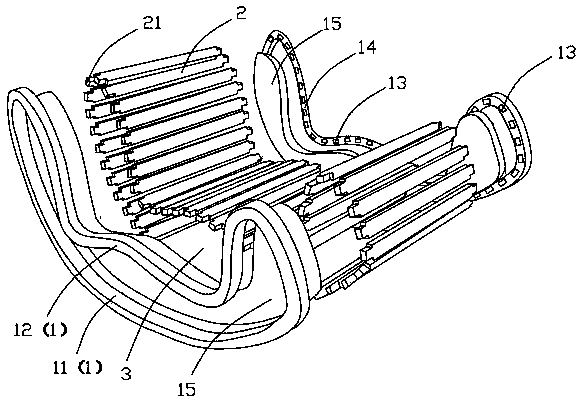

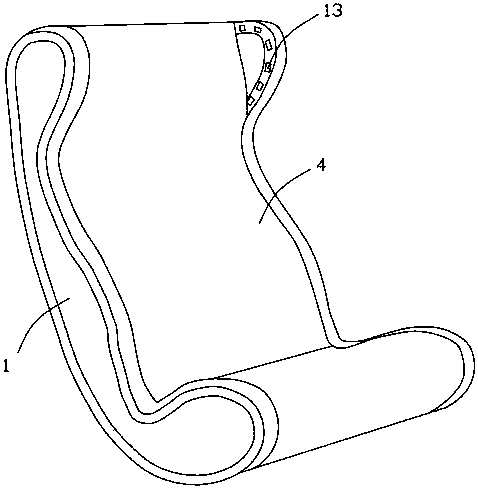

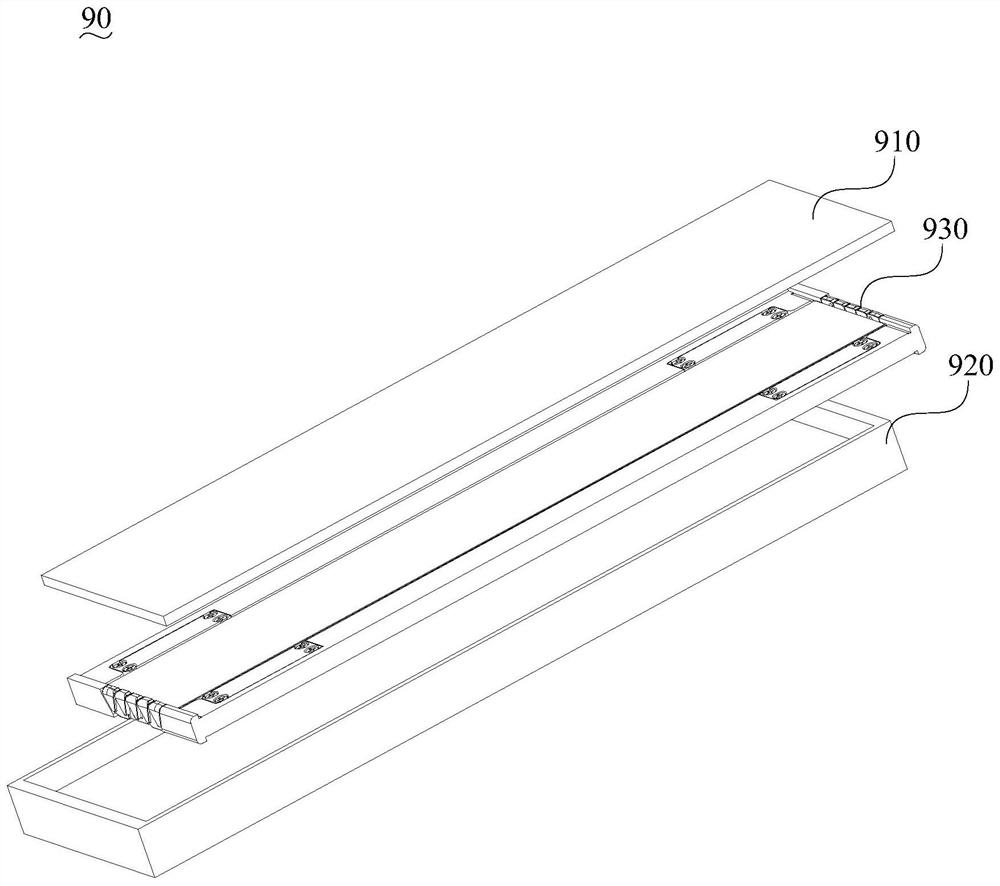

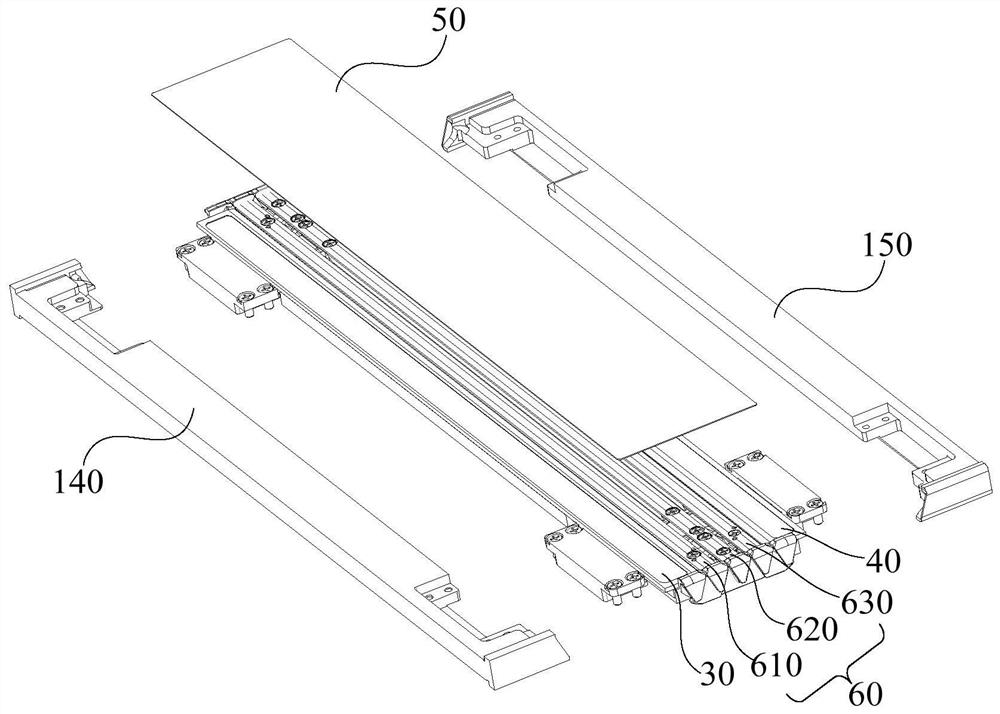

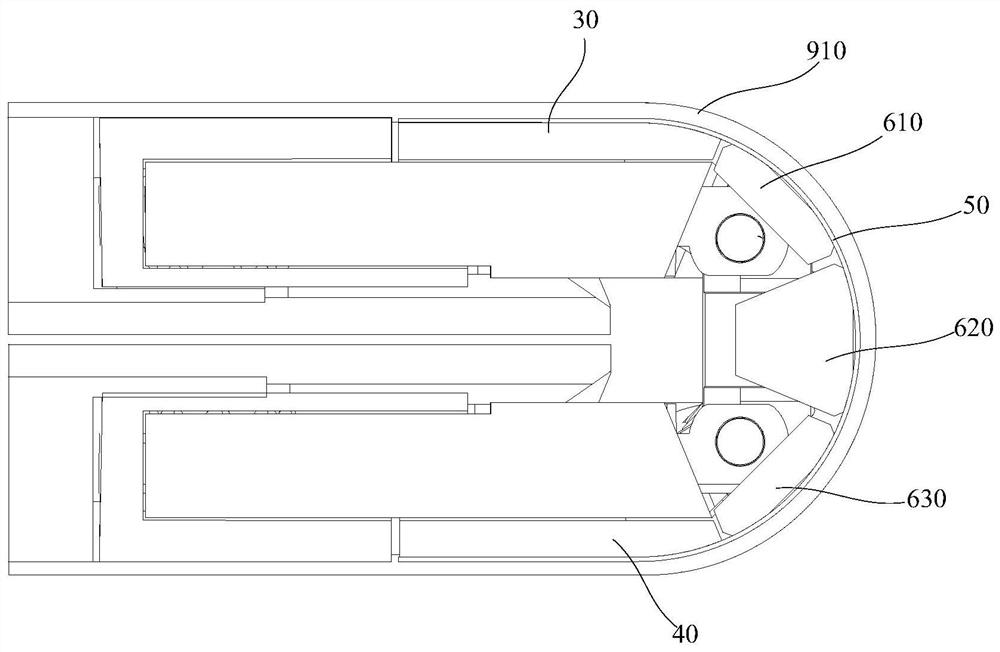

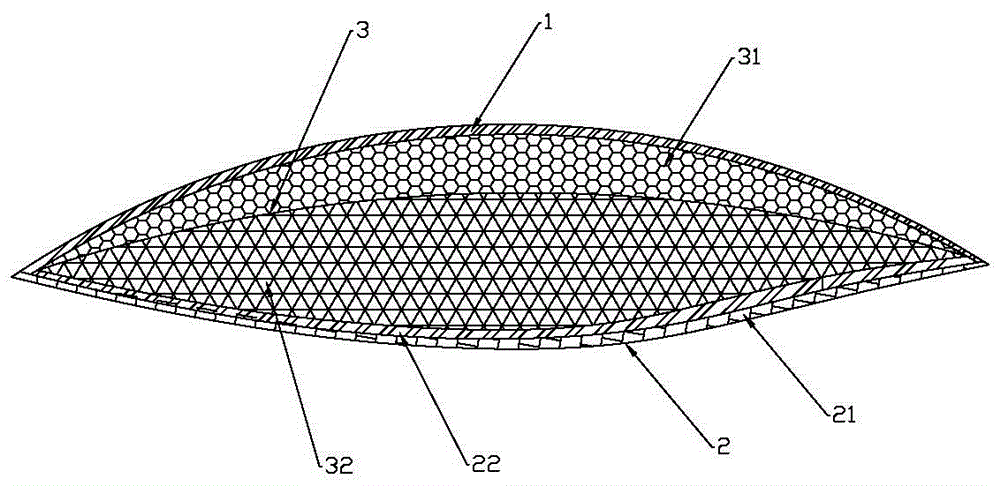

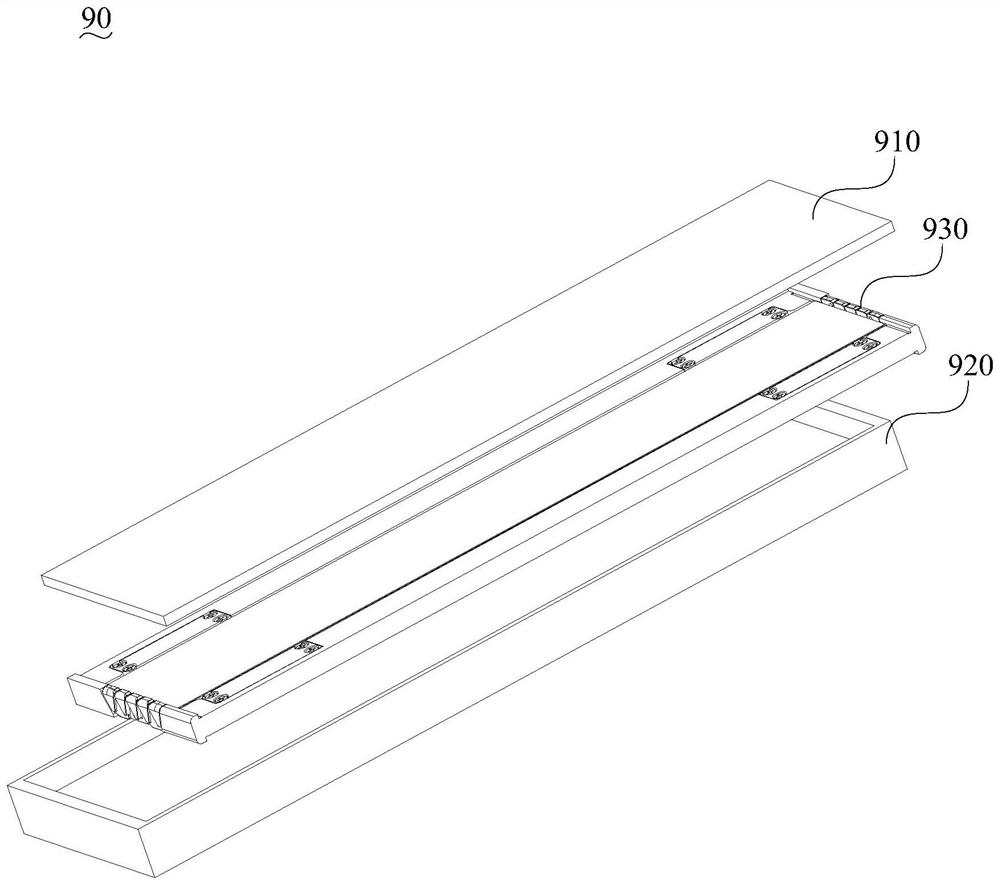

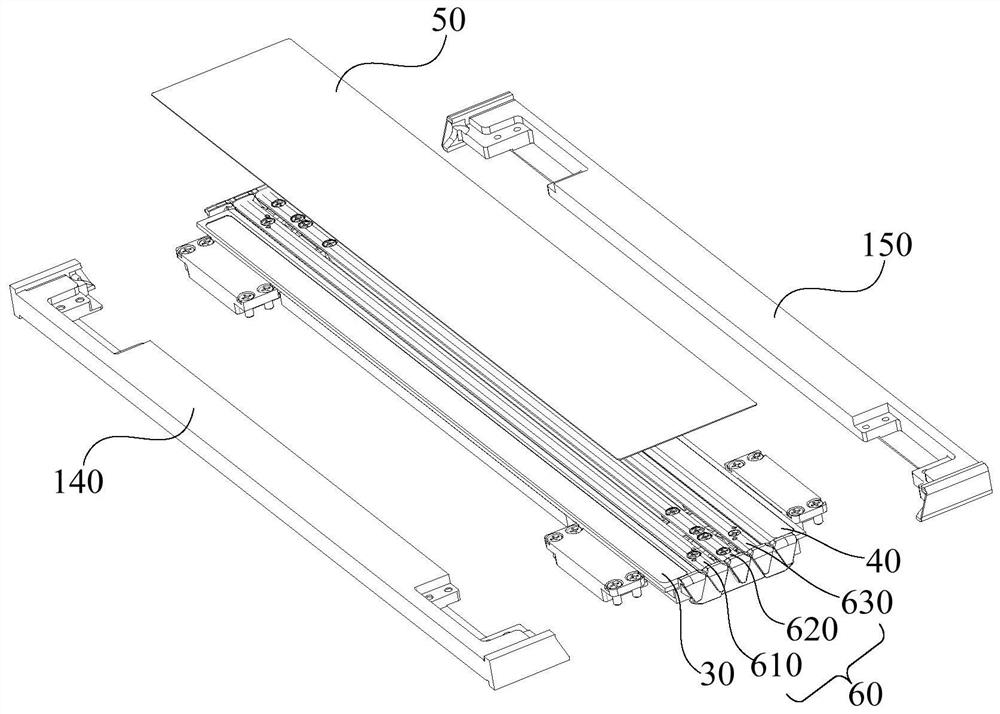

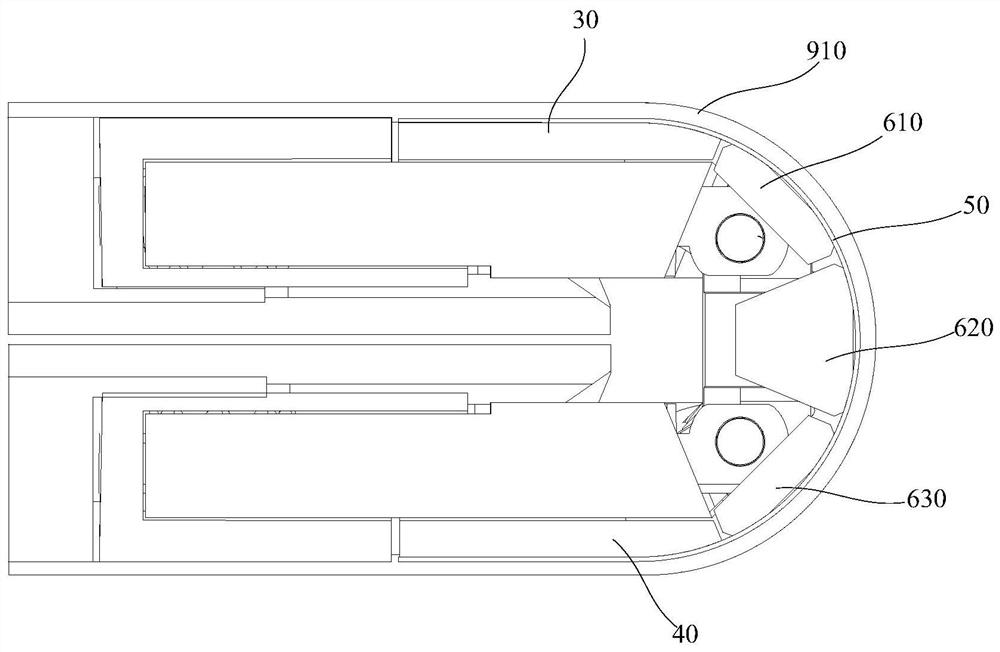

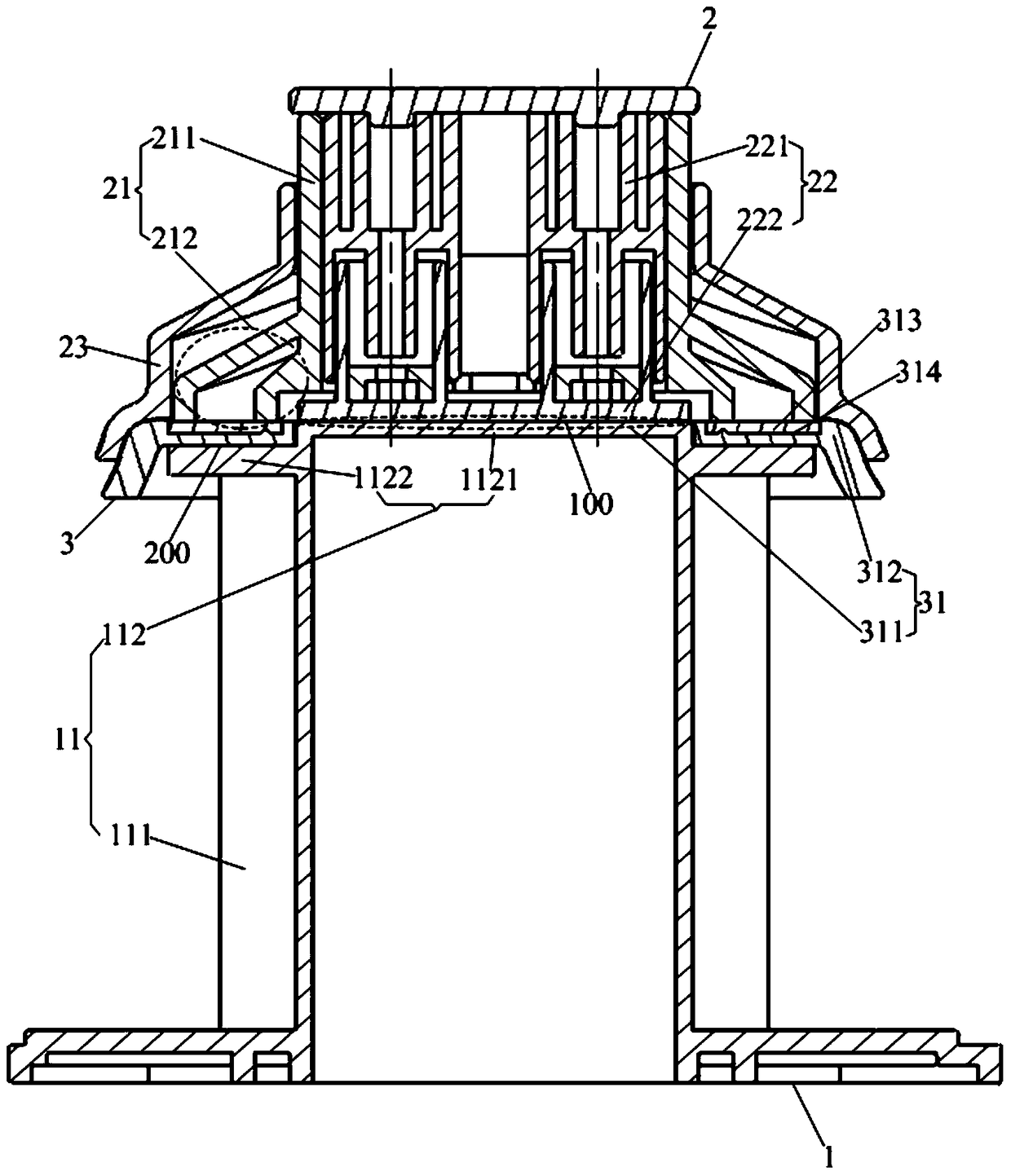

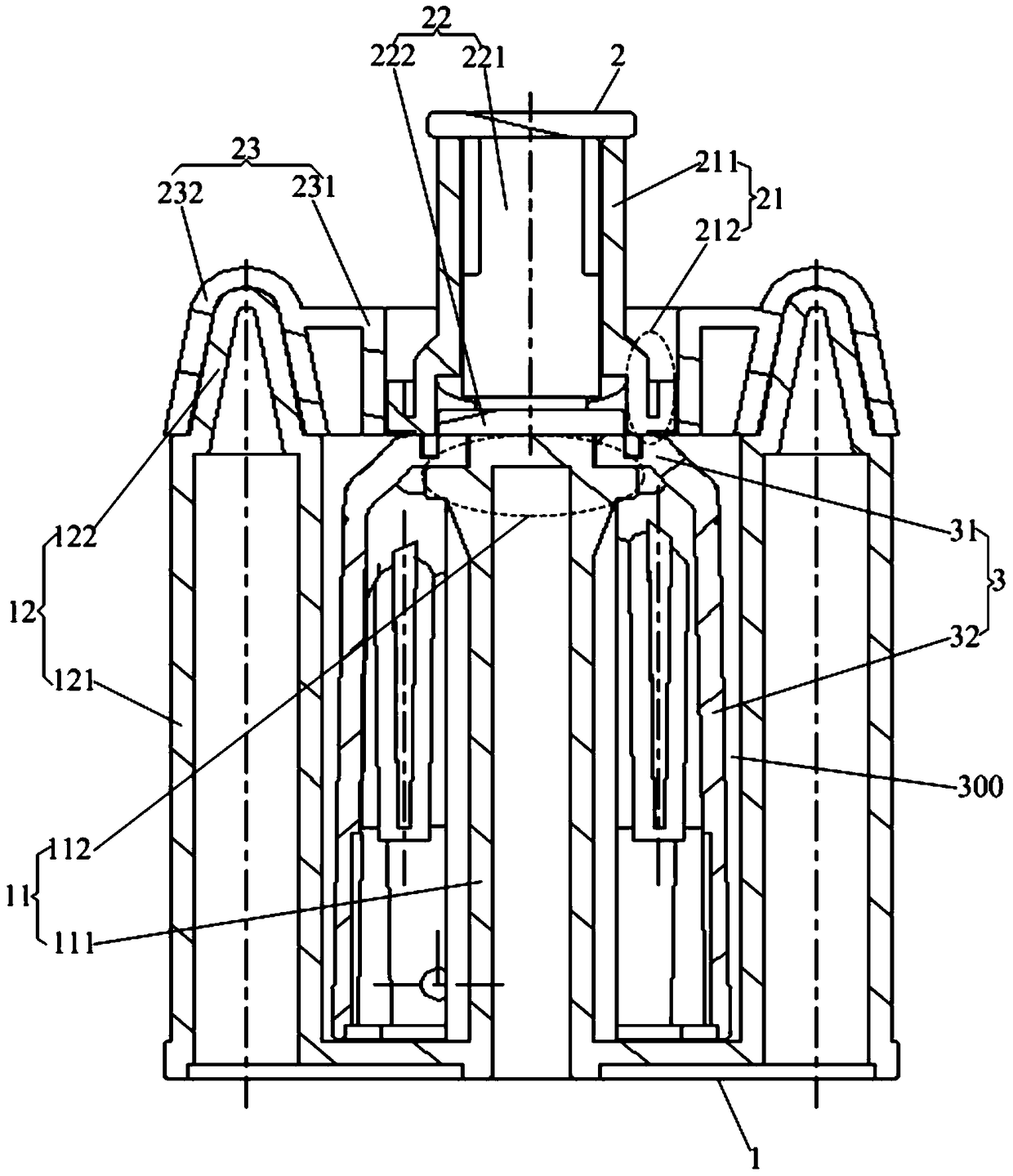

Outer folding flexible screen supporting device and electronic equipment

The invention discloses an outer folding flexible screen supporting device and electronic equipment. The outer folding flexible screen supporting device comprises a supporting frame assembly, at leastone elastic piece, a first shell, a second shell and a supporting assembly, the supporting frame assembly comprises a supporting frame and at least one supporting rib connected with the supporting frame, and the supporting frame is provided with at least one accommodating groove; the elastic piece is arranged in the accommodating groove; the first shell and the second shell are arranged on a first matching piece and a second matching piece in a sleeving mode respectively and abut against the elastic piece respectively; and the two ends of the supporting assembly are connected with the first shell and the second shell correspondingly and laid on the supporting ribs, the flexible screen is connected with the supporting assembly, the flexible screen can be driven by the supporting ribs and the supporting frame to change between a horizontal state and a bent state, and the elastic piece abuts against the first shell and the second shell to make the flexible screen in a stretched state allthe time in the horizontal state and the bent state. The flexible screen is always in a stretched state in a horizontal state and a bent state.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

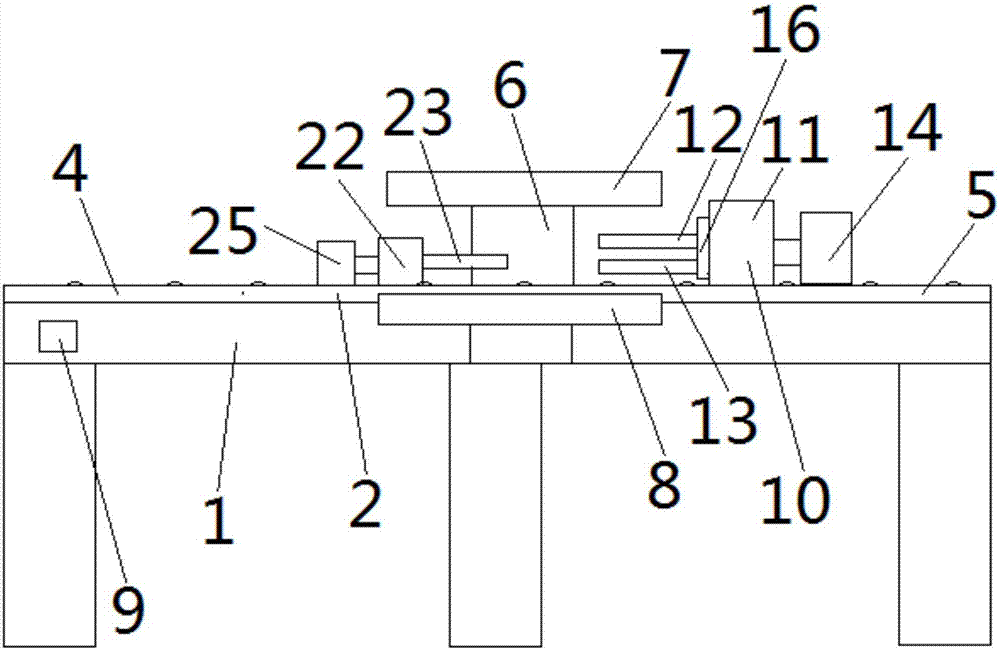

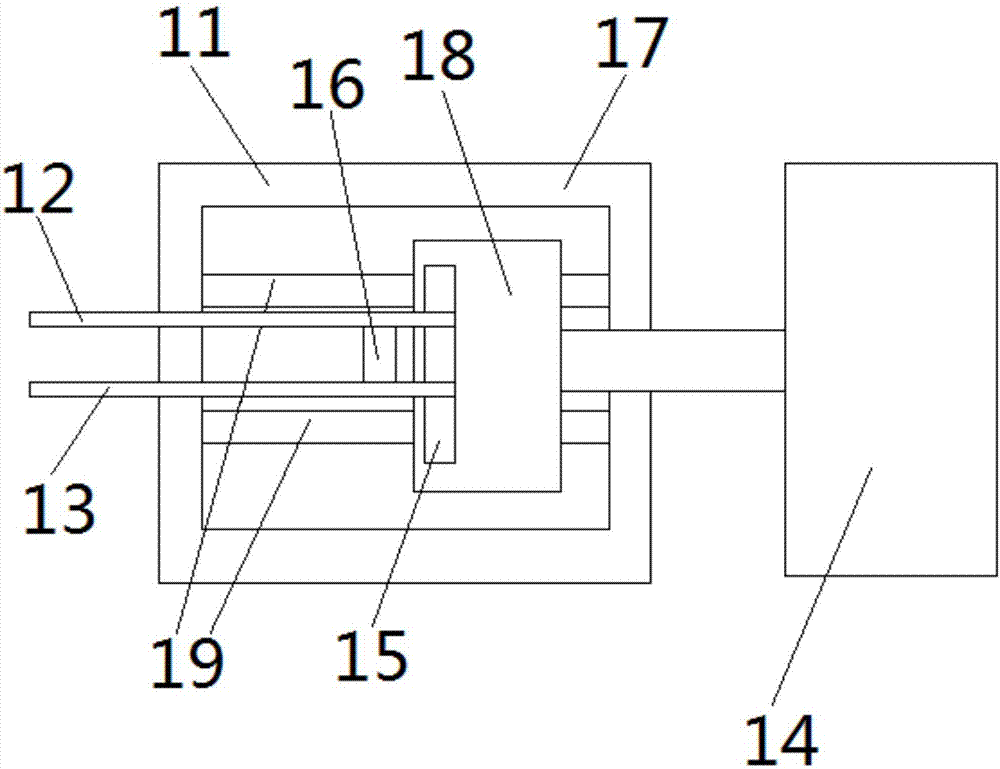

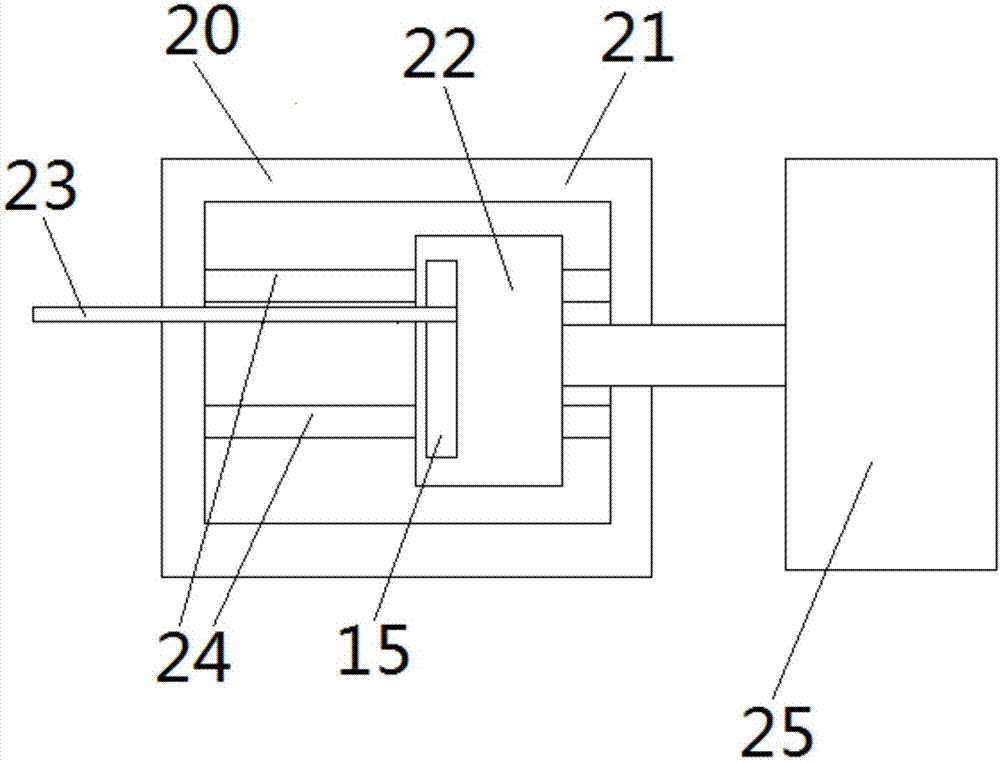

Cement packaging bag opening part automatic processing device

InactiveCN107973170AFold separatelyWrinkles won't happenFolding thin materialsAutomatic processingEngineering

The invention provides a cement packaging bag opening part automatic processing device applied to the technical field of cement packaging bag production equipment. An upper absorbing component (7) ofthe cement packaging bag opening part automatic processing device absorbs and upwards pulls a packaging bag upper layer skin opening part (27), a control component (9) is arranged to be capable of controlling a control air cylinder I (14) to stretch out, the structure that an overturning component body (11) is moved to the absorbing component (7) is pushed, when the overturning component body (11)moves to the absorbing component, and an upper overturning plate piece (12) on the overturning component body (11) is arranged to be the structure capable of overturning the edge part of the packaging bag upper layer skin opening part (27) to the inner side portion. By means of the cement packaging bag opening part automatic processing device, automatic treatment of the edge overturning and folding processes of a cement packaging bag opening part can be conveniently and quickly achieved, folds are avoided when edge overturning and folding are carried out, the labor intensity of operators is reduced, and the edge overturning and folding quality can be improved.

Owner:WUHU HENGNAITE TRANSMISSION EQUIP

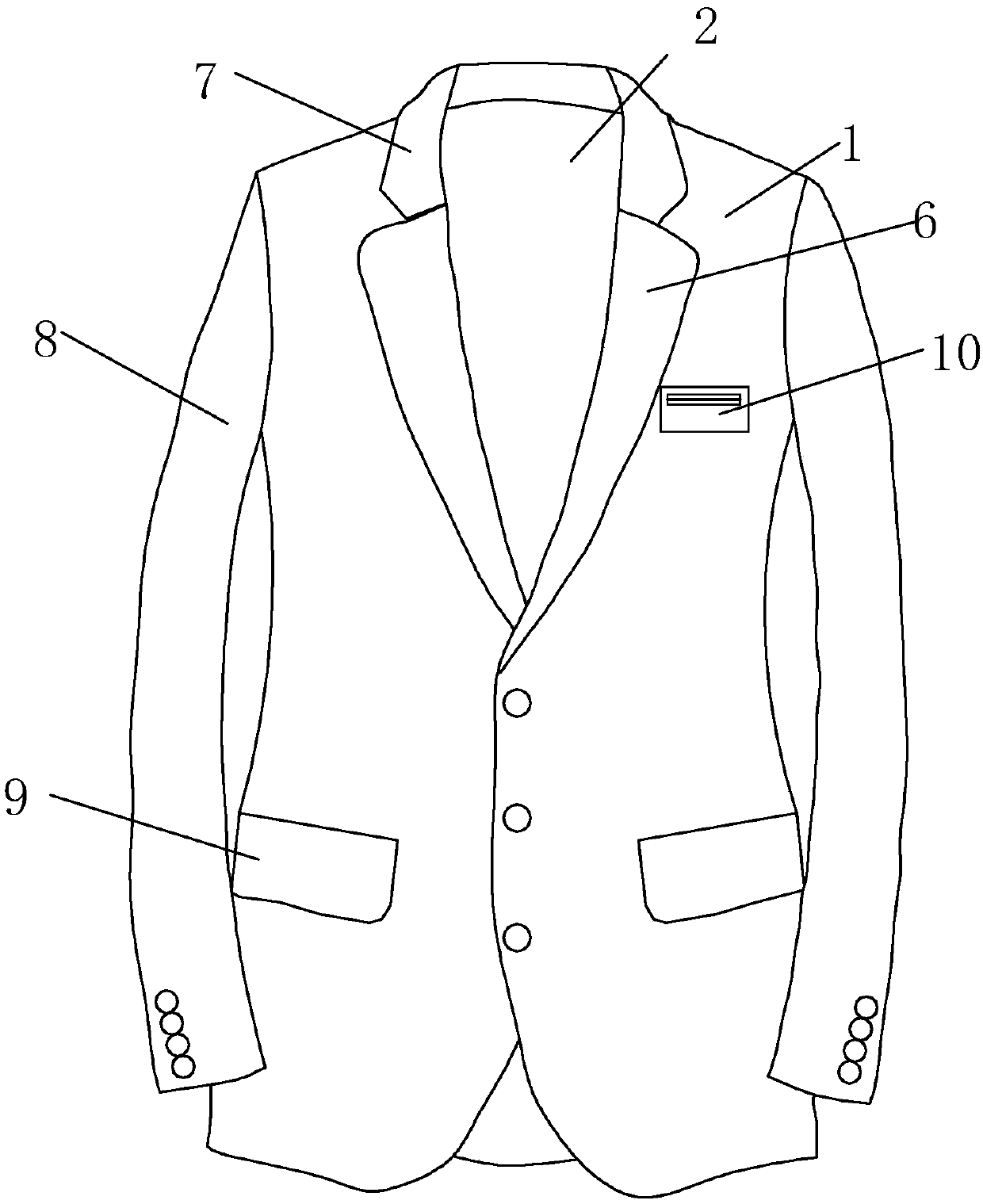

Close-fitting suit

InactiveCN109527667AEasy to fold for storageGuaranteed Slim SensualityGarment special featuresElectroconductive/antistatic filament manufactureEngineering

The invention relates to the technical field of close-fitting suits, in particular to a close-fitting suit. The suit comprises an outer suit layer, wherein an inner suit layer is sewn on the inner side of the outer suit layer, a connecting collar is sewn at the upper end of the outer suit layer, the lower end of the connecting collar is connected with a neckline, sleeves are sewn on both sides ofthe upper end of the outer suit layer, both the sleeves and the outer suit layer are made of elastic cloth, and pockets are sewn at the two ends of the lower side of the outer suit layer. The suit hasthe advantages that the elasticity of the suit is enhanced, the suit is prevented from being creased, the comfort during wearing is improved, and it is ensured that the suit closely fits the human body and attractive.

Owner:ZHEJIANG JODOLL GARMENTS

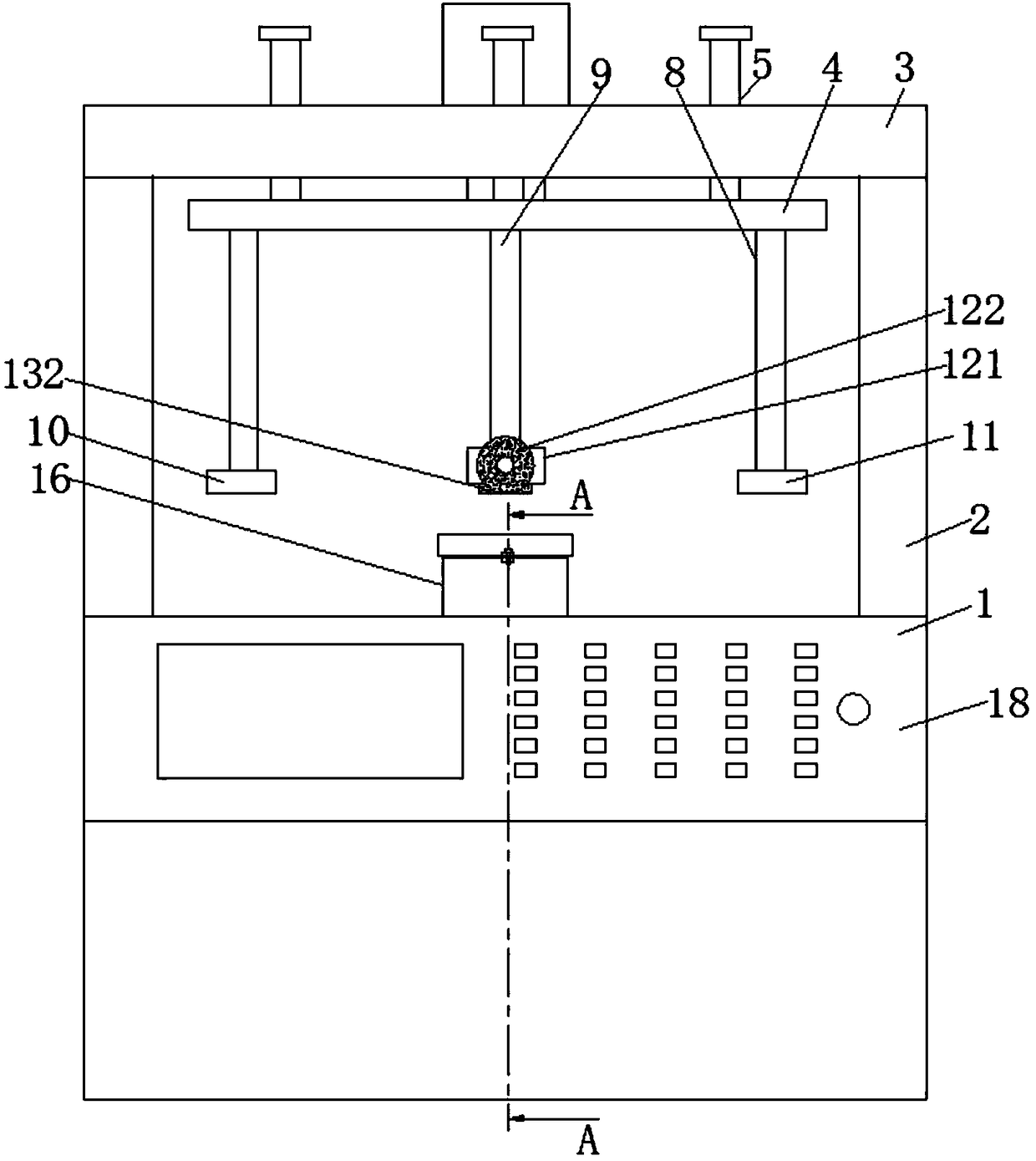

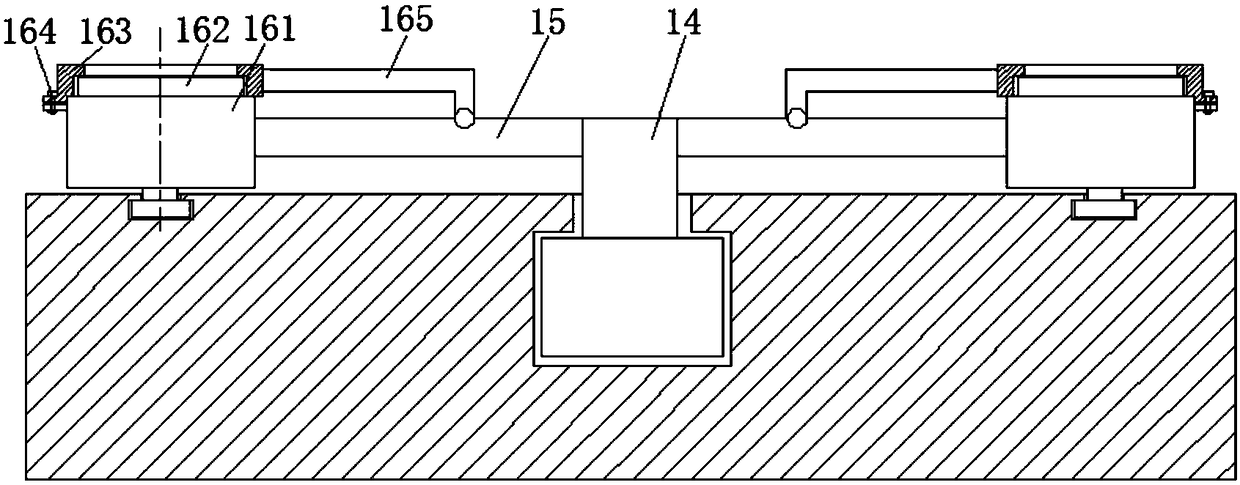

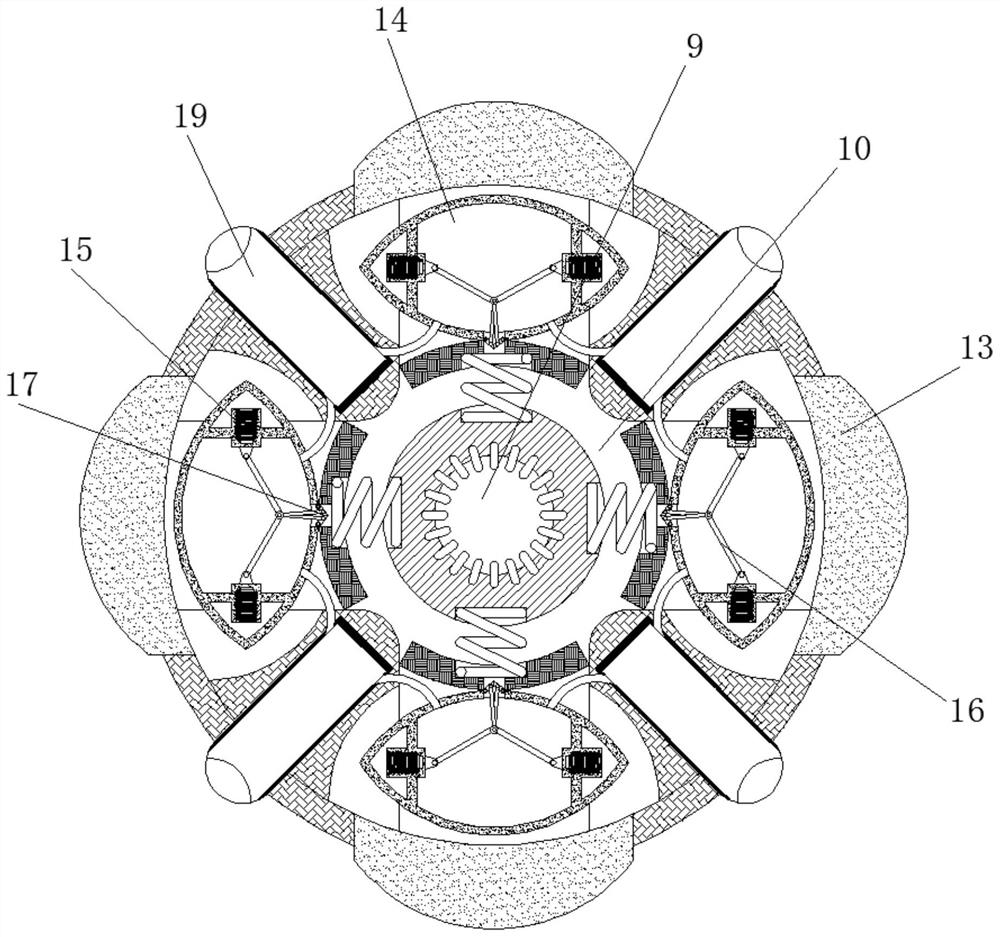

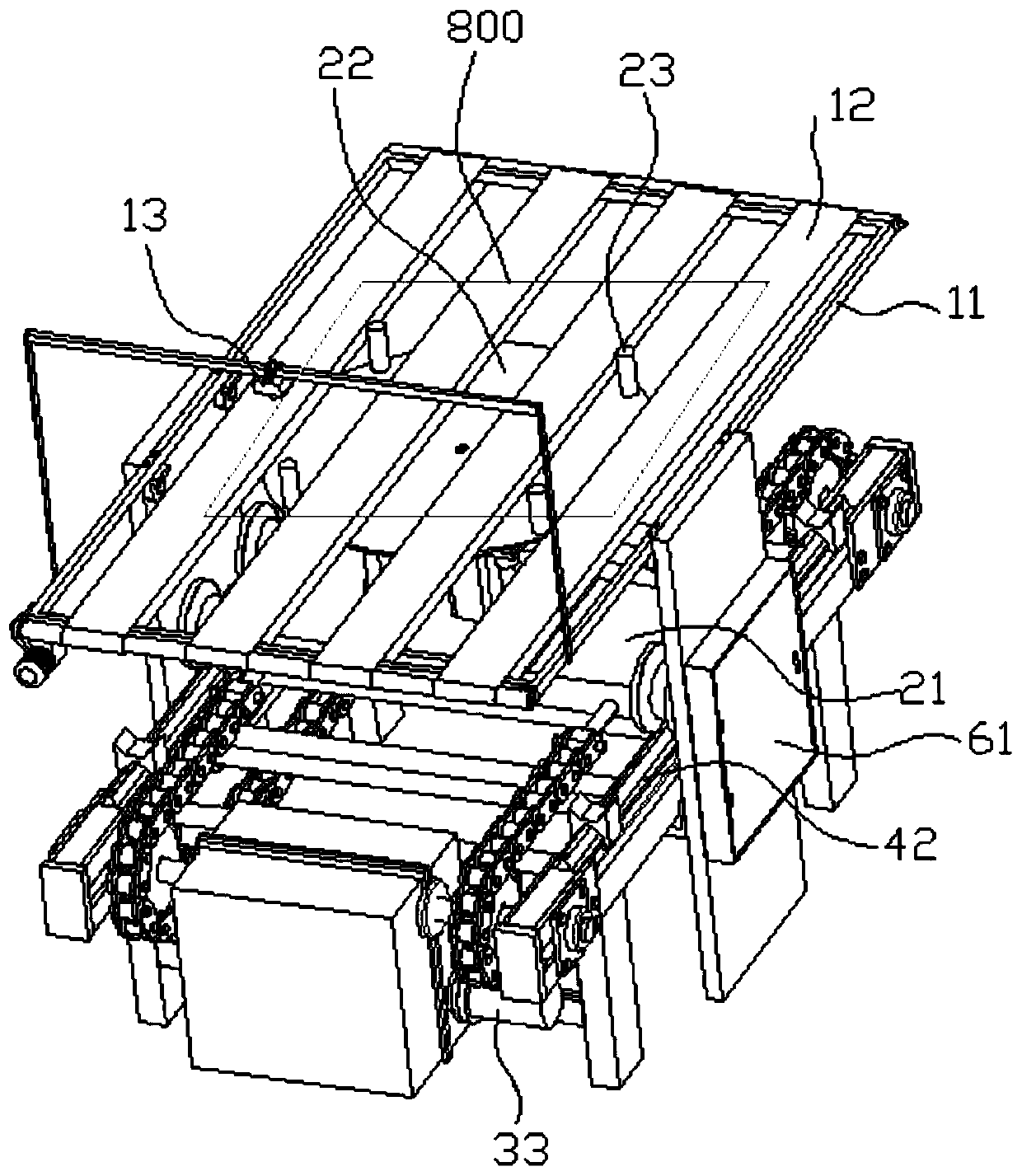

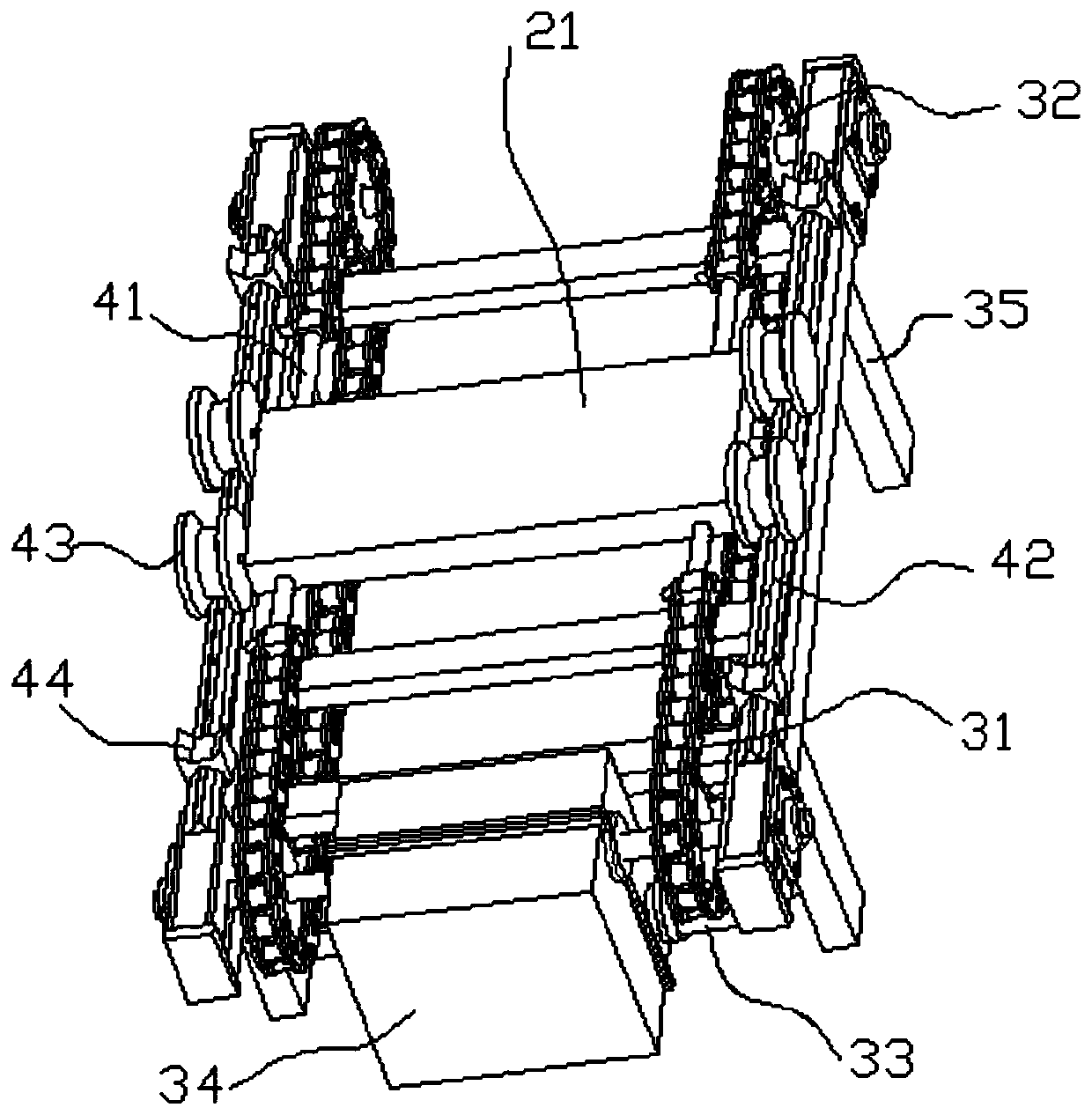

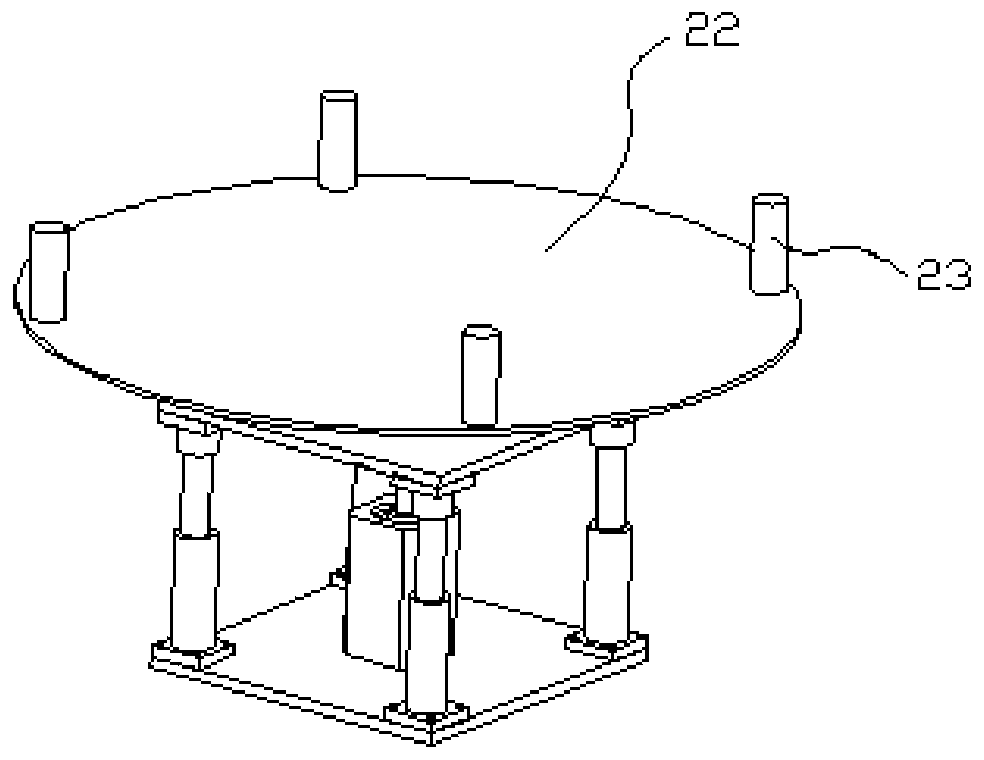

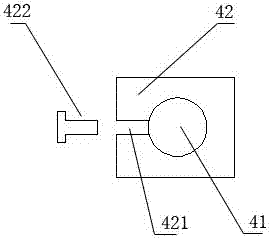

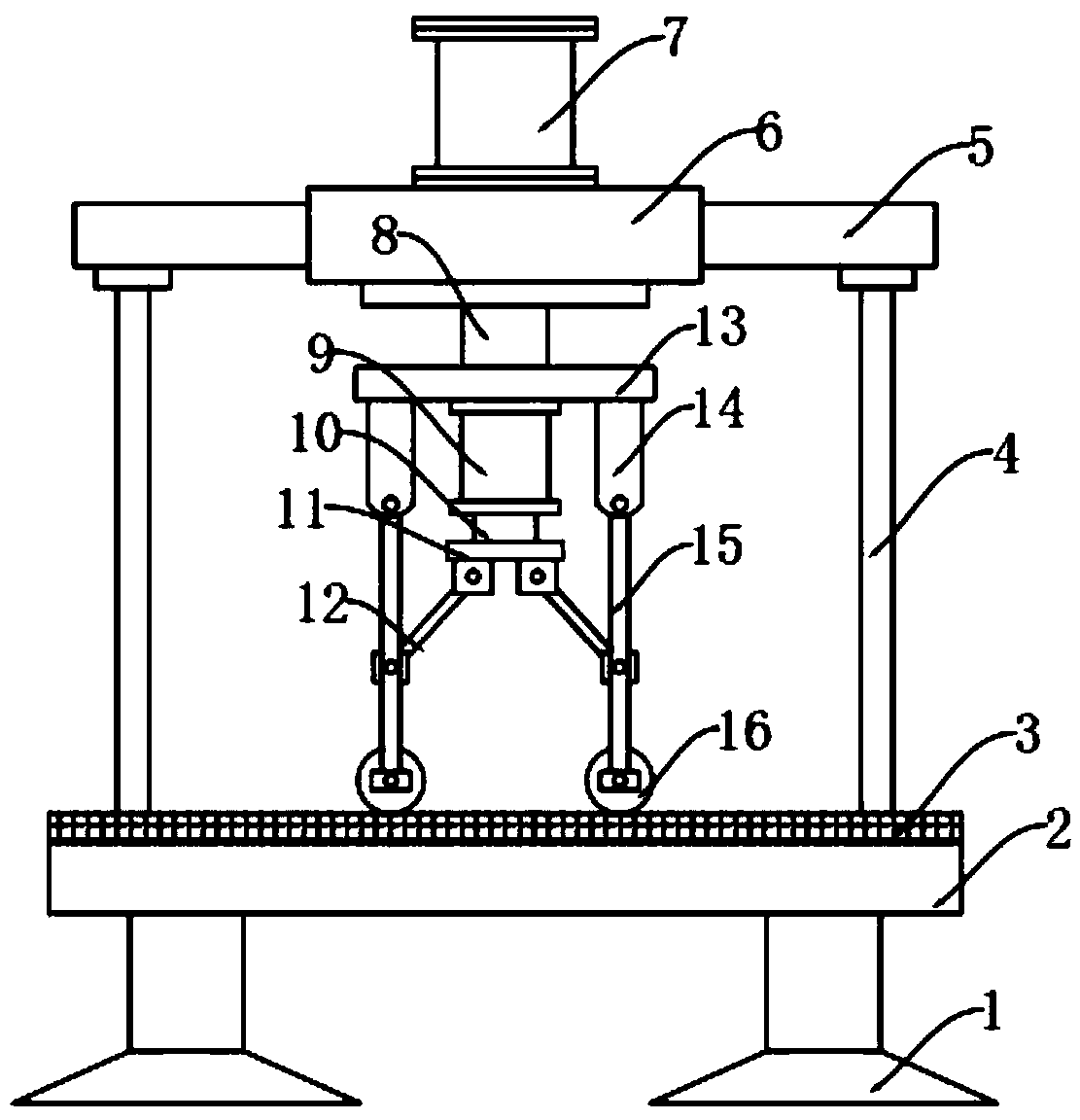

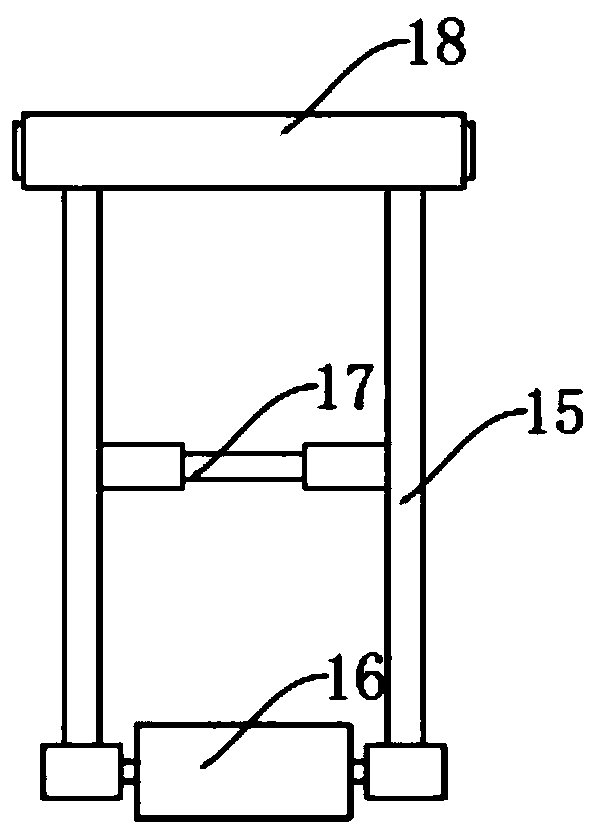

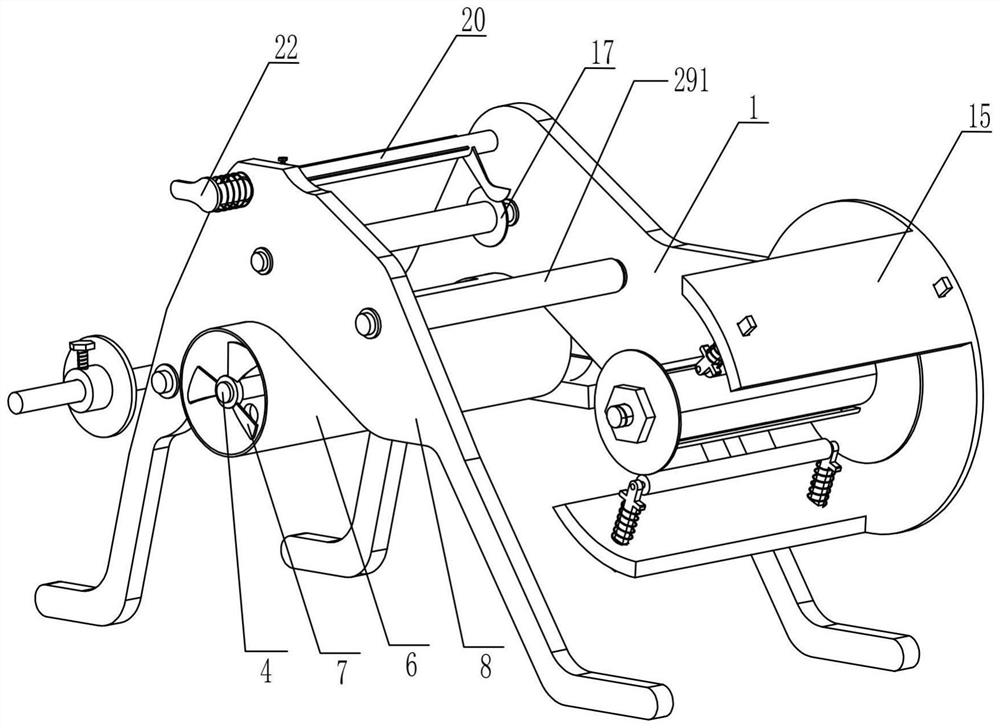

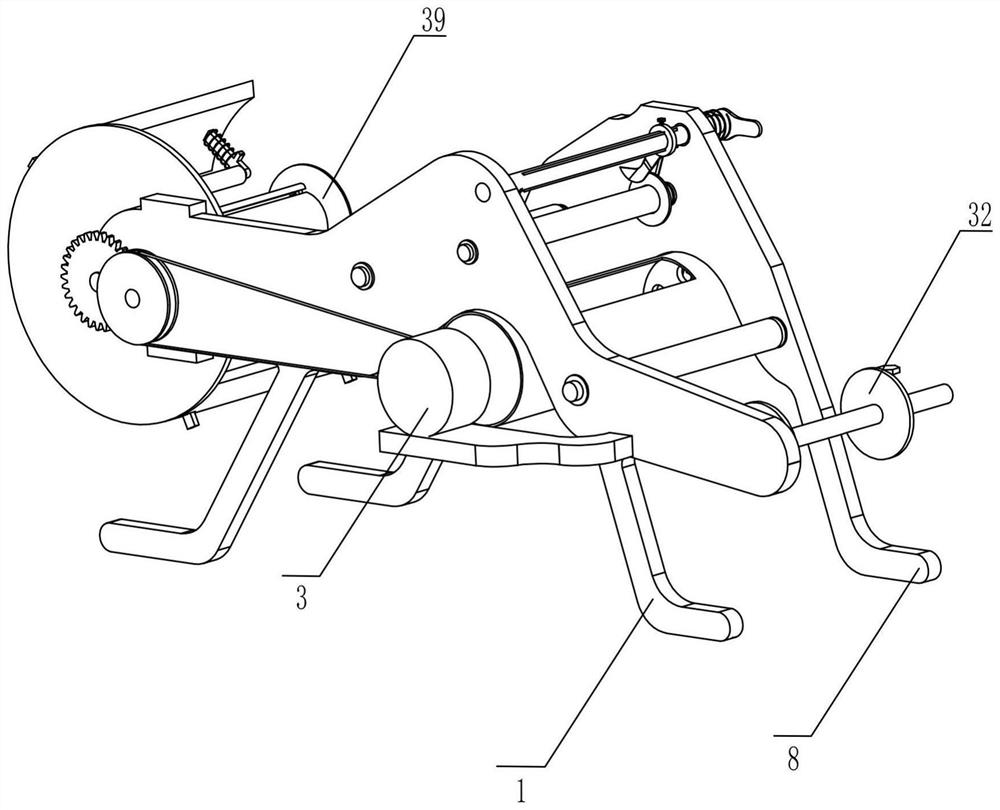

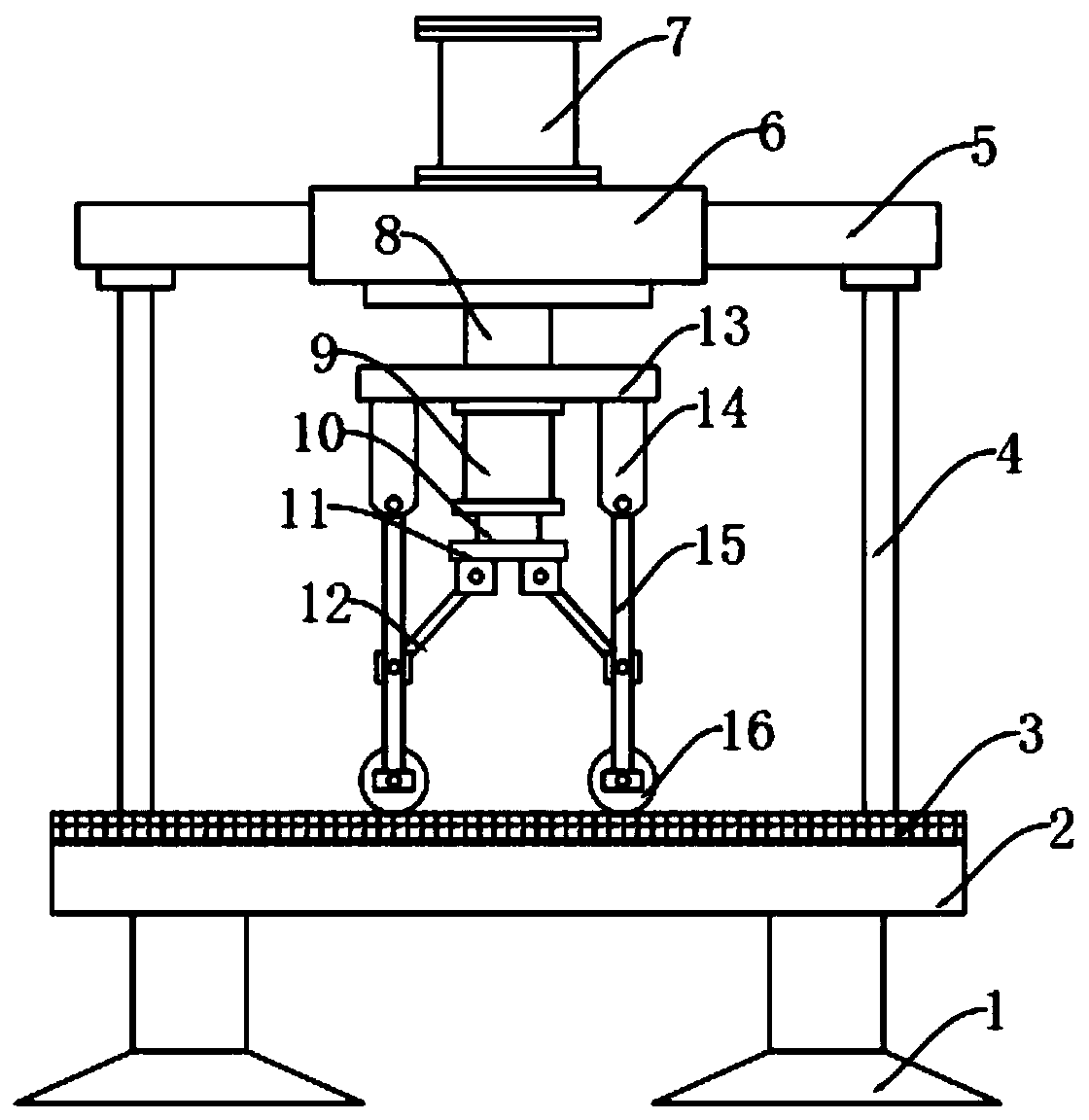

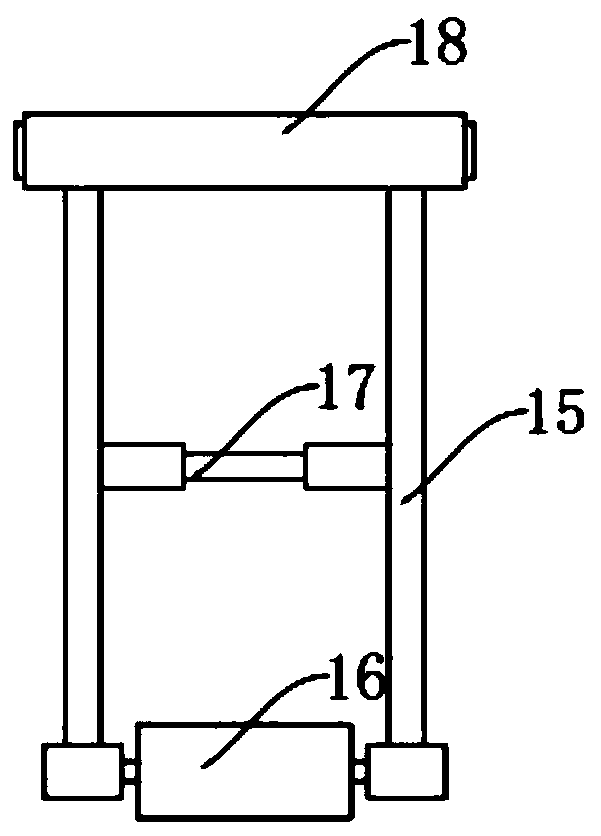

Leather conveying traveling automatic deviation correcting device and method

ActiveCN111268357AWrinkles won't happenPrecisely control the rotation angleConveyorsControl devices for conveyorsControl theoryConveyor belt

The invention discloses a leather conveying traveling automatic deviation correcting device and method. A camera collects the image information of leather on a conveyor belt and transmits the image information to a middle console; the middle console identifies and judges whether the leather deviates through the image, works out the deviation direction and angle, and gives a command; a traveling platform accelerates to move right below the leather and moves along with the conveyor belt at the same speed; and at the same time, a transplanting platform is started to jack up the leather to be separated from the conveyor belt, reversely rotates by a corresponding angle relative to the original deviation direction, and returns the leather after deviation correction onto the conveyor belt, so that traveling automatic deviation correction of leather conveying is realized. The leather conveying traveling automatic deviation correcting device ensures in-order leather conveying, avoids the phenomenon that the processing effect is not ideal due to deviation of the leather, greatly reduces the time from the former procedure to the latter procedure and improves the processing efficiency.

Owner:NANTONG UNIVERSITY

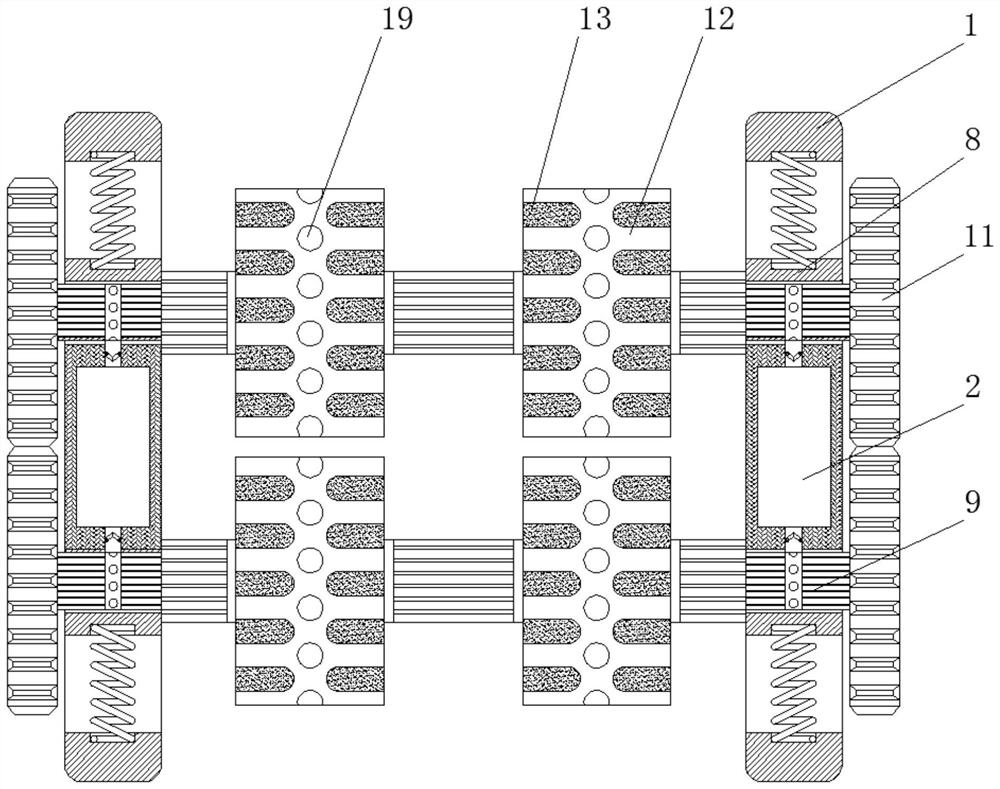

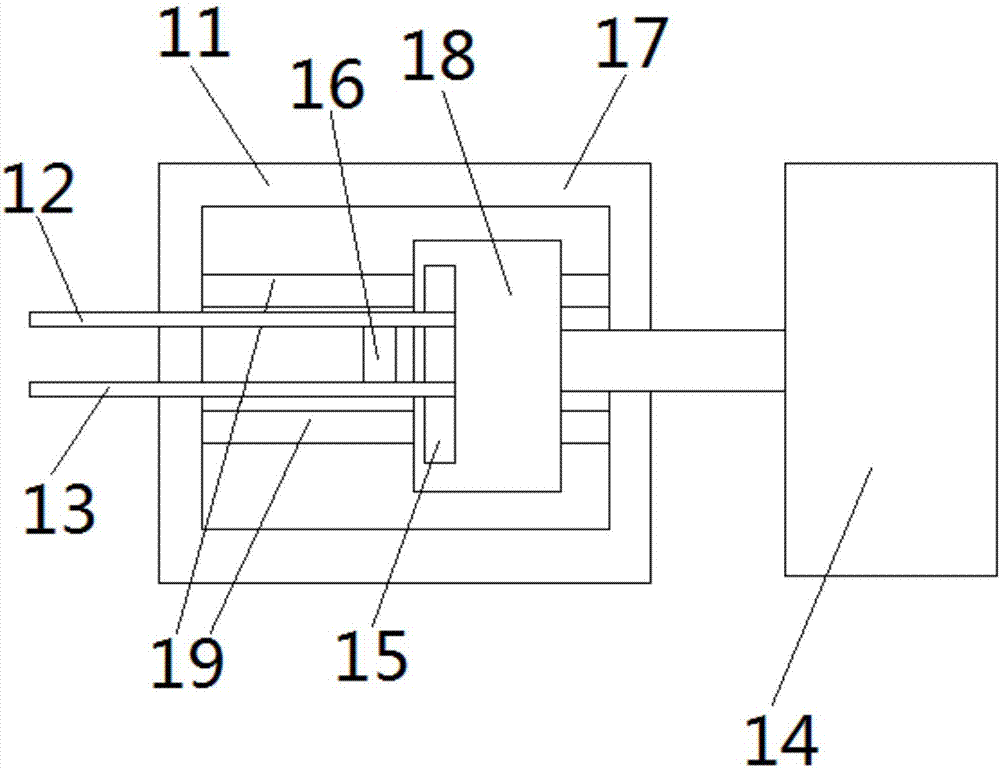

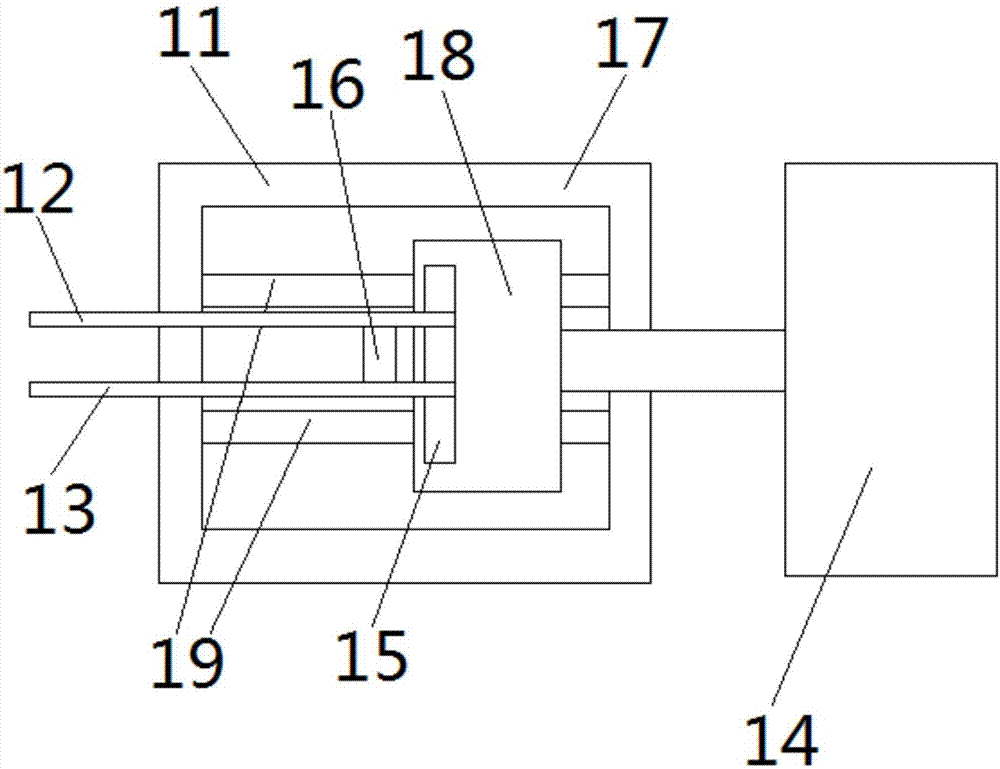

Automatic flanging and folding device for cement packaging bag

InactiveCN107962814AFold separatelyWrinkles won't happenBag making operationsPaper-makingFlangingEngineering

The invention provides an automatic flanging and folding device for a cement packaging bag. The automatic flanging and folding device for the cement packaging bag is applied to the technical field ofproduction equipment for cement packaging bags. A flanging and folding component body (11) of a front side flanging and folding component (10) of the automatic flanging and folding device for the cement packaging bag is connected with a control cylinder I (14). A control cylinder II (16) is arranged between an upper flanging and folding plate (12) and a lower flanging and folding plate (13). An installation rod I (19) is arranged on a body frame (17) of the flanging and folding component body (11). A connecting block (18) is movably arranged on the installation rod I (19) in a sleeving mode. The rear end of the connecting block (18) is connected with the control cylinder I (14). The upper flanging and folding plate (12) and the lower flanging and folding plate (13) are connected with hingepins (15) correspondingly. The automatic flanging and folding device for the cement packaging bag is simple in structure, an opening part of the cement packaging bag can be conveniently and rapidly flanged and folded automatically, it is ensured that wrinkles are avoided when the opening part of the packaging bag is flanged and folded, the flanging and folding quality is improved, and reworking is avoided.

Owner:WUHU HENGNAITE TRANSMISSION EQUIP

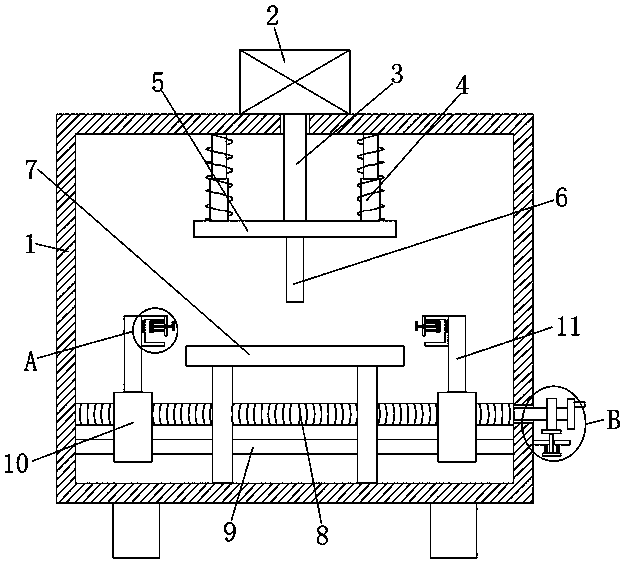

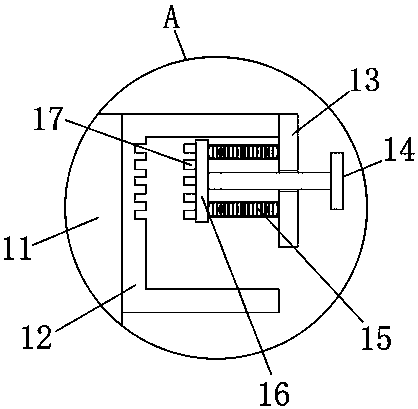

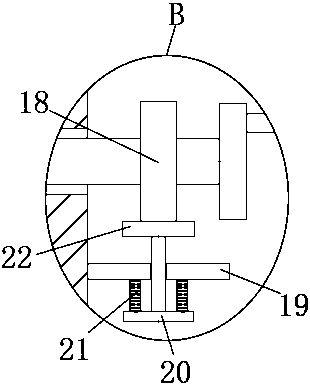

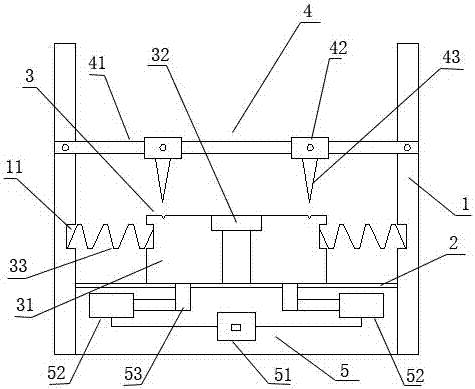

Clamping block adjusting type cutting device for cutting double-layer fabric

ActiveCN107881628AWrinkles won't happenGuaranteed accuracyPile-fabric loomsEngineeringMechanical engineering

The invention discloses a clamping block adjusting type cutting device for cutting a double-layer fabric. The clamping block adjusting type cutting device includes a machine frame, a fixed plate, a cutting carrier and a cutting mechanism. The machine frame is of a U-shaped structure. The fixed plate is mounted at the bottom of the machine frame. The cutting carrier is mounted on the fixed plate. The cutting carrier includes two supporting blocks, two springs and a plurality of clamping blocks. The lengths of the plurality of clamping blocks are different. The supporting blocks are provided with cutting V grooves. The two supporting blocks are oppositely mounted on the fixed plate. The springs are mounted between the opposite outer sides of the two supporting blocks and the machine frame, the opposite inner sides of the two supporting blocks are provided with step-shaped groove bodies respectively, and the clamping blocks are mounted between the step-shaped groove bodies. The upper endfaces of the clamping blocks and the upper end faces of the supporting blocks are located on the same horizontal plane. The cutting mechanism is mounted above the supporting blocks. According to the clamping block adjusting type cutting device, cutting intervals are adjustable.

Owner:JIANGSU LAINADUO INTELLIGENT EQUIP CO LTD

A cloth spreading device for garment making

ActiveCN108891990AWrinkles won't happenEasy to processUnfolding thin materialsWrinkle skinHydraulic cylinder

A cloth spreading device for garment making including workbench and No. 2 hydraulic cylinder, A heat layer is arranged on the workbench, the piston column on the No. 1 hydraulic cylinder is fixedly connected with a transverse plate, Four rotating clamps are symmetrically arranged on the transverse plate, the rotating clamp is rotatably connected with a first rotating shaft sleeve through a shaft,two rotating arms are fixed on the No. 1 rotating shaft sleeve, the lower end of the rotating arm is provided with a rolling press wheel, A stationary shaft is arrange between that rotating arm, the fixed shaft is inserted into the second rotating shaft sleeve, The second rotating shaft sleeve is fixed on both ends of the rotating plate, and the second rotating shaft sleeve on the rotating plate which is far away from the fixed shaft is rotatably connected with the connecting block through the shaft, the connecting block is fixed on the bottom surface of the pressing plate, the pressing plateis fixed on the end of the piston rod, and the piston rod is installed on the second hydraulic cylinder. The invention can spread and tile the cloth in four directions, and the tiling of the cloth isgood and not easy to generate wrinkles.

Owner:JIXI YUANDAO AGRI IND TECH

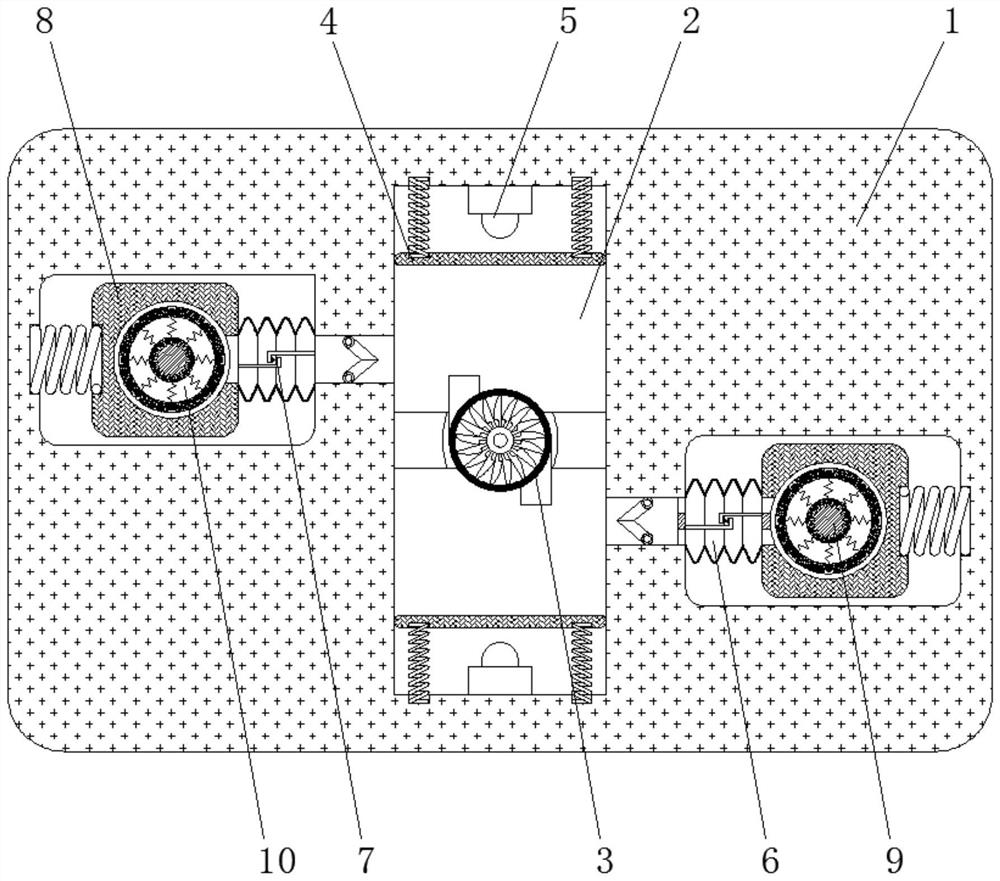

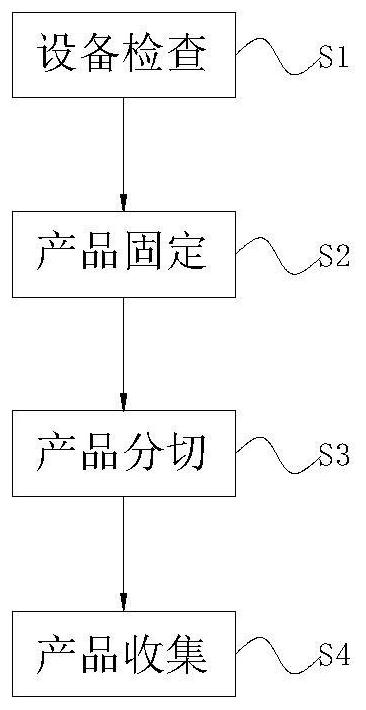

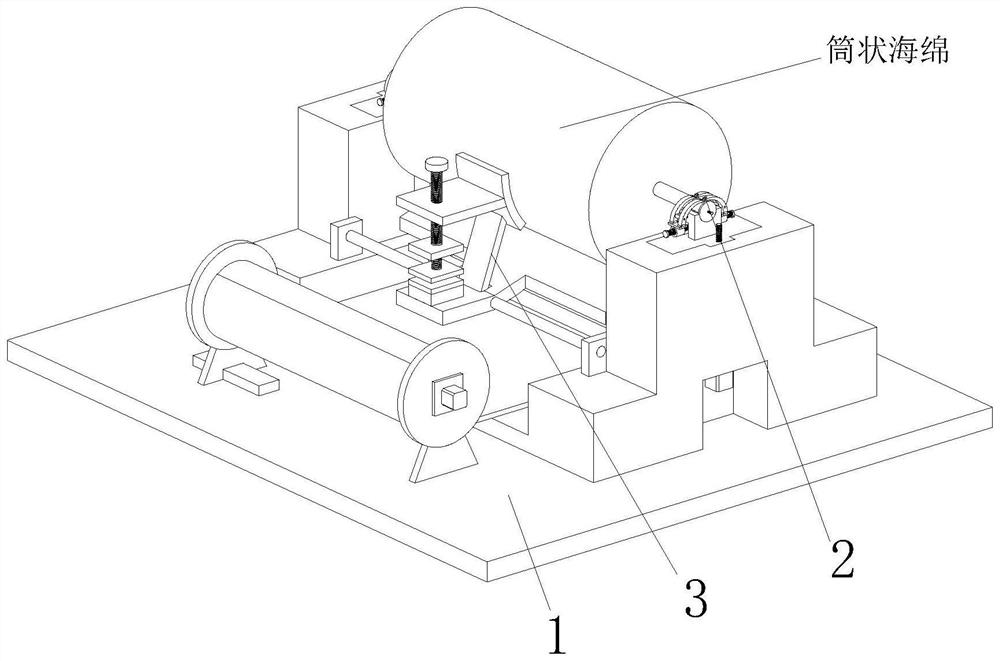

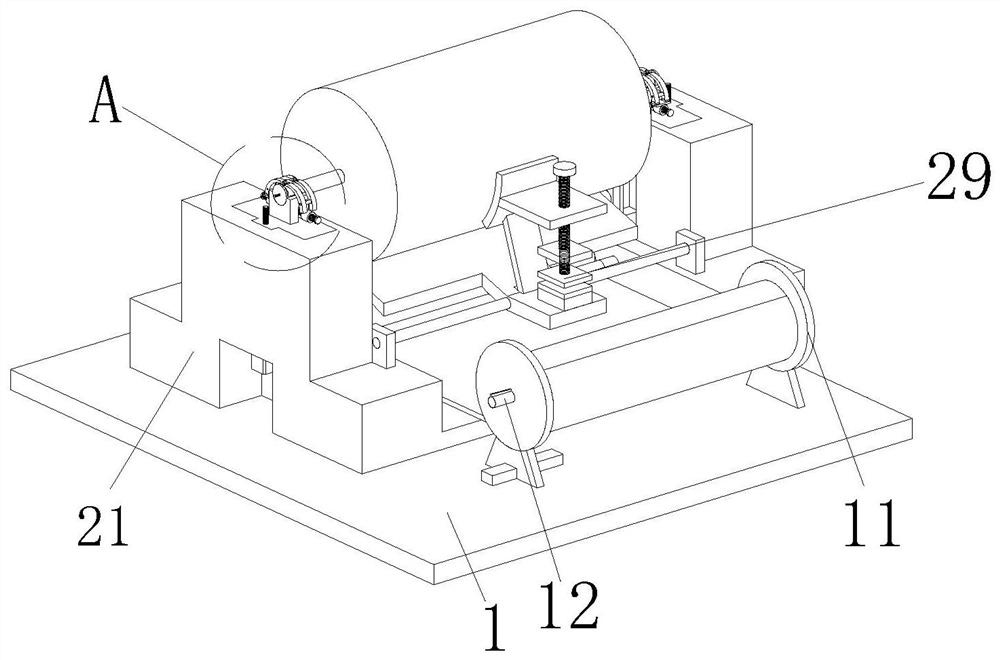

Polyurethane sponge preparation and processing technology

InactiveCN113547548AAdjustable thicknessImprove efficiencyMetal working apparatusWebs handlingPolymer sciencePolymer chemistry

The invention provides a polyurethane sponge preparation and processing technology, and relates to the technical field of polyurethane sponge preparation and processing. The polyurethane sponge preparation and processing technology comprises a bottom plate, a clamping device and a slitting device, wherein the clamping device is fixedly installed on the bottom plate, and the slitting device is arranged on the clamping device. The polyurethane sponge preparation and processing technology can solve the following problems that a, an existing polyurethane sponge preparation and processing technology is not stable enough to clamp the cylindrical sponge, and the cylindrical sponge is easy to incline and separate during rotation; and b, the existing polyurethane sponge preparation and processing technology cannot change the slitting thickness when the cylindrical sponge is slit, and only can slit the polyurethane sponge with one thickness.

Owner:蔡洋

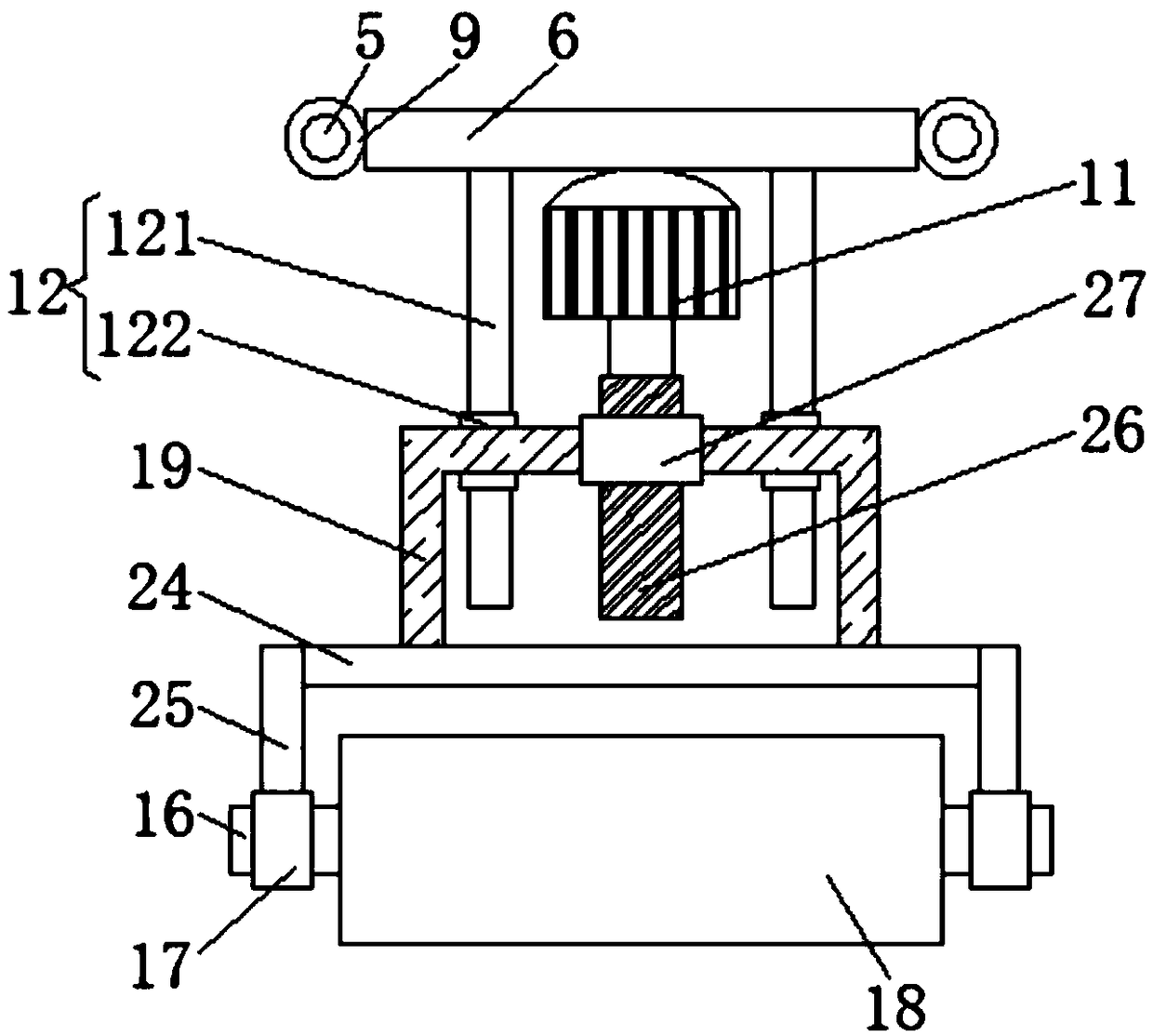

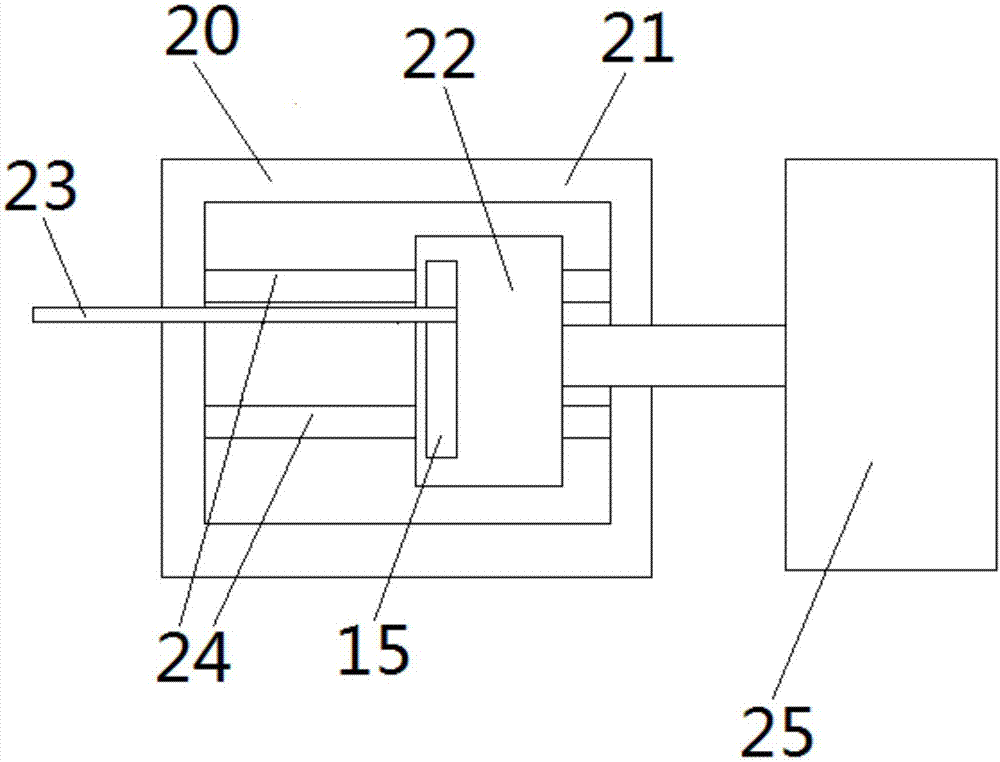

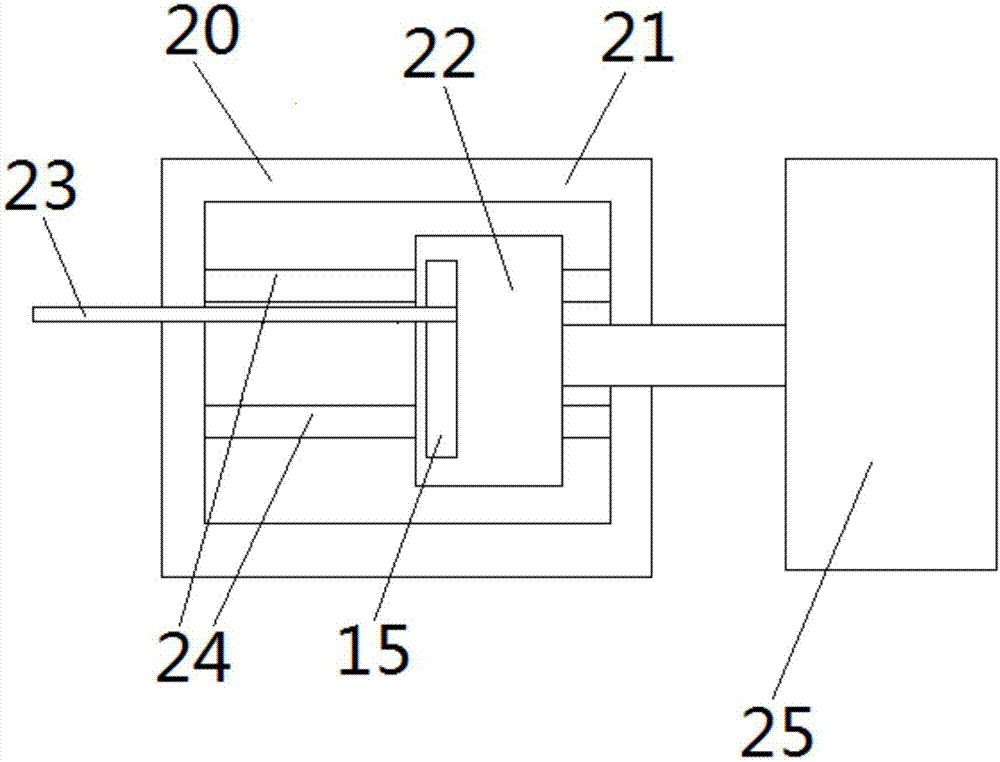

Cement packaging bag processing device

InactiveCN107963504AWrinkles won't happenNo creases appearFolding thin materialsFlangingBiomedical engineering

The invention provides a cement packaging bag processing device applied to the technical field of cement packaging bag production equipment. An upper adsorption component body (7) and a lower adsorption component body (8) of a packaging bag open portion adsorption component (6) of the cement packaging bag processing device are connected with a control component (9). A front face flanging and folding component (10) comprises a flanging and folding component body (11), an upper flanging and folding plate part (12) and a lower flanging and folding plate part (13). The flanging and folding component body (11) is connected with a control air cylinder I (14). The control air cylinder I (14) is arranged to be of a structure capable of driving the flanging and folding component body (11) to move close to or away from the lower adsorption component body (8). The cement packaging bag processing device is simple in structure; automated treatment of the flanging and folding procedure of a cement packaging bag open portion can be achieved conveniently and rapidly; it is guaranteed that the cement packaging bag open portion cannot have folds when being flanged and folded; labor intensity of operators is lowered; flanging and folding quality is improved; and rework treatment is avoided.

Owner:WUHU HENGNAITE TRANSMISSION EQUIP

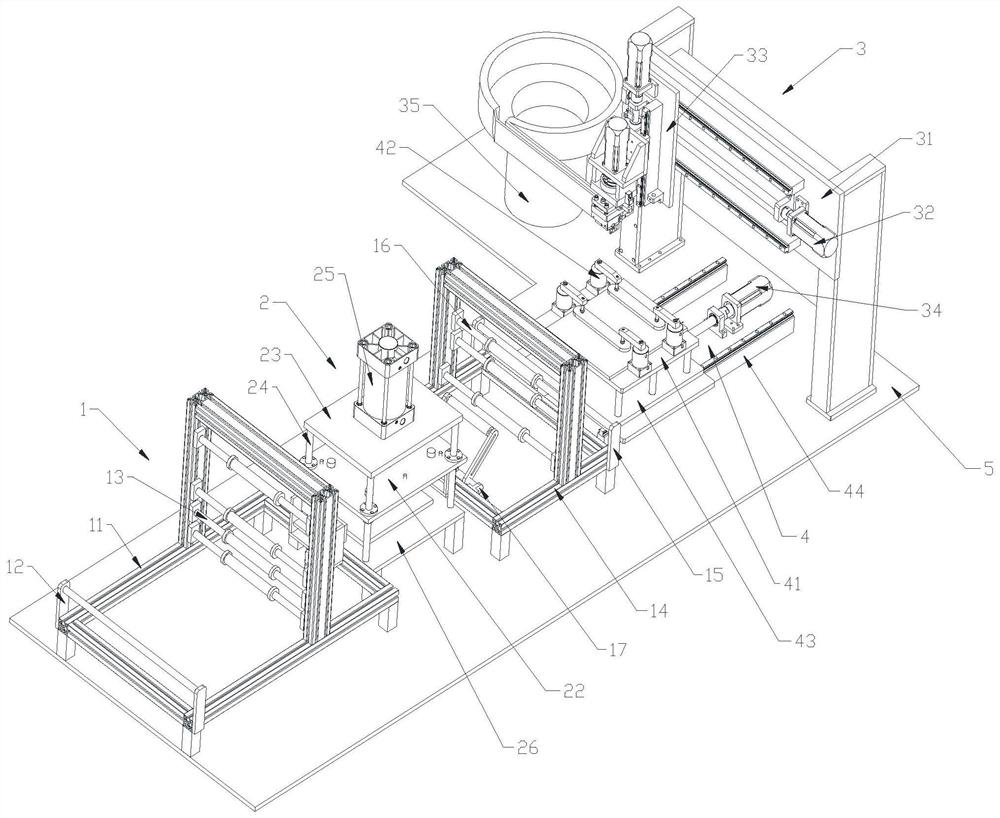

Automatic ironing and hot-pressing button set-in machine

ActiveCN111676639AEasy to operateReduce difficultyTextile shapingClothes making applicancesStructural engineeringMechanical engineering

The invention discloses an automatic ironing and hot-pressing button set-in machine. The automatic ironing and hot-pressing button set-in machine comprises a tensioning mechanism. The tensioning mechanism is fixed to an equipment platform, a hot-pressing mechanism is arranged on the equipment platform, a button set-in mechanism is arranged on one side of the equipment platform, and a flattening mechanism is arranged on one side of the button set-in mechanism. The tensioning mechanism comprises a first tensioning frame and a second tensioning frame. First tensioning fixed plates are arranged onthe first tensioning frame in a mirror image manner, a first tensioning rod is arranged between the first tensioning fixed plates, and a first movable tensioning rod support is arranged on the firsttensioning frame. First movable tensioning rod sliding blocks are arranged on the first movable tensioning rod support in an array mode, and a first movable tensioning rod is arranged between every two first movable tensioning rod sliding blocks. According to the automatic ironing and hot-pressing button set-in machine, operation is convenient, the button set-in difficulty is reduced, the button set-in efficiency is high, the production efficiency is improved, cloth is flattened through hot pressing before button set-in, the cloth does not wrinkle during button set-in, the button set-in quality is improved, and the product quality is further improved.

Owner:合肥英士博户外用品科技有限公司

A breathable and environmentally friendly bra

ActiveCN104720133BImprove breathabilityGood water permeabilityBrassieresHandkerchiefsSkin contactBiomedical engineering

Owner:HONGJI UNDERWEAR CO LTD

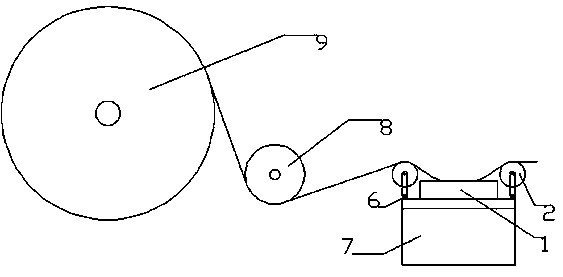

Winding equipment for plastic woven bag processing

PendingCN114655756AWrinkles won't happenEasy to removeArticle deliveryWebs handlingStructural engineeringMechanical engineering

The invention discloses a plastic woven bag processing winding device which comprises a mounting seat, a winding frame and a guide mechanism, the mounting seat comprises a stabilizing frame and a supporting frame, the supporting frame is vertically mounted on the upper end face of the stabilizing frame and fixedly connected with the stabilizing frame, and the winding frame is mounted at the upper end of the stabilizing frame and fixedly connected with the stabilizing frame. The winding frame is symmetrically arranged in the middle of the stable frame and rotationally connected with the stable frame, the guide mechanisms are symmetrically arranged in the middle of the winding frame, and the guide mechanisms are longitudinally and slidably connected with the winding frame, so that a user can stably fix the winding frame through a bent plate when needing to use the winding frame. According to the plastic woven bag winding device, it is guaranteed that a user can wind a plastic woven bag in real time through the winding roller, when the plastic woven bag made of hard materials is wound, the user can install the angle rod on the lifting base, then the machine type of the plastic woven bag is guided through the angle plate, and a guide frame does not need to be installed for use.

Owner:ANHUI YINGSHANG COUNTY TIANCHENG PRINTING PACKAGING CO LTD

External folding flexible screen support device and electronic equipment

The present application discloses an outer folding flexible screen supporting device and electronic equipment. The outer folding flexible screen supporting device includes: a supporting frame assembly, at least one elastic member, a first housing, a second housing and a supporting assembly. The supporting frame assembly includes The support frame and at least one support rib connected with the support frame are provided with at least one accommodating groove; the elastic member is arranged in the accommodating groove; The matching piece and the second matching piece are in contact with the elastic piece respectively; the two ends of the support assembly are respectively connected with the first shell and the second shell and laid on the support ribs, the flexible screen is connected with the support assembly, and the flexible screen Driven by the support ribs and the support frame, it can change from the horizontal state to the bent state, and the elastic member abuts the first shell and the second shell so that the flexible screen is always in a stretched state in the horizontal state and the bent state . The beneficial effect is that the flexible screen is always in a stretched state in a horizontal state and a bent state.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Rewinding edge thread head shearing machinery for processing

ActiveCN111703932ACut evenlyGuaranteed stable workSevering textilesMetal working apparatusEngineeringLeather belt

The invention provides rewinding edge thread head shearing machinery for processing. The rewinding edge thread head shearing machinery comprises a first supporting seat, a support plate, a motor, a first rotating shaft, a first belt wheel, an air suction barrel, fan blades, a second supporting seat, a second rotating shaft, a second belt wheel, a belt, a first gear, a third rotating shaft, a second gear, an installation plate and a shearing mechanism, wherein the motor is fixedly installed on the support plate, and one end of the first rotating shaft is fixedly connected with the output end ofthe motor. According to the rewinding edge thread head shearing machinery for the processing, by means of the arrangements of a clamping ring, a moving ring and a nut, a second sliding clamping discand a third sliding clamping disc can be adjusted, the two ends of roll cloth and the roll cloth in rewinding are compressed, the cloth thread head shearing and rewinding work is performed smoothly, and the position of a cutter can be adjusted through the moving ring, the cutter can shear cloth thread heads, and the thread head shearing work of the cloth of different widths is met; and by means ofthe arrangements of a second idler wheel, a first idler wheel, a fourth idler wheel and a compressing mechanism, the cloth is compressed in the cloth pulling and rewinding process by a third idler wheel to make the cloth not generate wrinkles, and the cloth thread head and rewinding work is finished smoothly.

Owner:SHISHI FANYUAN CLOTHING CO LTD

A selvage print pressing device for fabric processing

ActiveCN111976271BImproving imprinting efficiencyMeet the requirements of imprintingRotary pressesOther printing apparatusPrinting pressMechanical engineering

The invention relates to the technical field of cloth processing, in particular to a cloth edge pattern pressing and forming device for cloth processing. The technical problem to be solved is: to provide a lace embossing device for cloth processing which can automatically and uniformly emboss the lace pattern on the cloth, improve the efficiency of the lace embossing, and ensure the embossing quality of the cloth. A selvage pattern press forming device for cloth processing, including a base, a chute plate 1, a supporting plate, a power mechanism, a chute plate 2, a moving rod, a rubber pressing block, a fixing seat, a connecting rod, a machine table, and a spring 1. Sliding blocks, etc.; the first chute plate is fixedly installed on the base, the supporting plate is fixedly installed on one side of the chute plate, and the power mechanism is installed on the first chute plate. The power mechanism provided by the invention can make the rubber pressing block automatically dip into the paint and emboss the lace pattern on the cloth, thereby improving the embossing efficiency of the lace pattern.

Owner:桐乡市米伽家纺有限公司

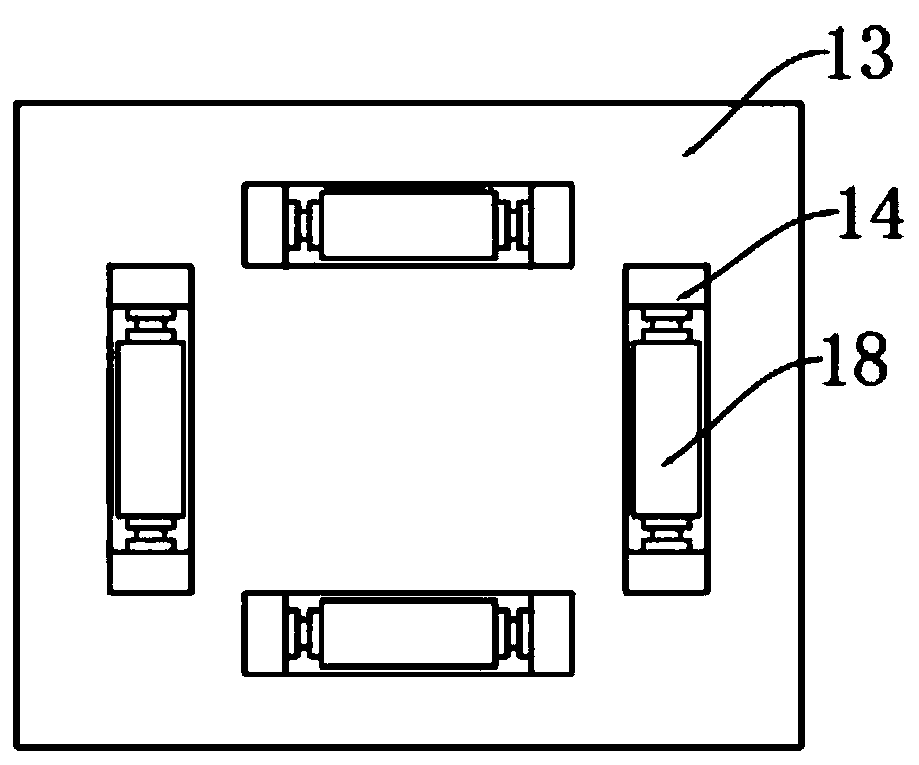

Film pressing device and film pressing method thereof

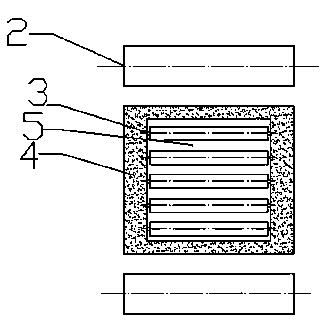

ActiveCN106926546BImprove appearance qualityIncrease the use of functionsLaminationLamination apparatusWrinkle skinEngineering

The invention provides a film pressing device and a film pressing method thereof. The laminating device is used to crimp the film onto the film window of the film frame, including a support mechanism and a pressing mechanism, the pressing mechanism is located above the supporting mechanism, and the pressing mechanism corresponds to the position of the supporting mechanism; the supporting mechanism is used for The film frame is supported; the pressing mechanism is used to press the film correspondingly to the film window of the film frame. The laminating device is equipped with a supporting mechanism and a pressing mechanism, so that the film crimped on the film window of the film frame can be fully tightened and flattened without wrinkles, which not only improves the appearance quality of the film frame after filming, Moreover, the use function of the film-sticking frame after film-sticking is improved; at the same time, the film pressing device also improves the film-sticking efficiency, thereby improving the production efficiency of the film-sticking frame.

Owner:RONGHAI SUPERSONIC MEDICINE EN

A cloth spreading device for clothing

ActiveCN108891990BWrinkles won't happenEasy to processUnfolding thin materialsHydraulic cylinderWorkbench

Owner:JIXI YUANDAO AGRI IND TECH

Spray bottle vacuumizing, bagging, sealing, isolating, stabilizing and storing method

InactiveCN112265693AThe preservation method is scientific and reasonableGuaranteed tightnessDetection of fluid at leakage pointPackaging by pressurising/gasifyingSpray bottlePumping vacuum

The invention discloses a spray bottle vacuumizing, bagging, sealing, isolating, stabilizing and storing method. The method comprises the steps of forming holes in an inner packaging bag, constructingan adsorption area and an open end edge, placing a spray bottle, vacuumizing, packaging the inner packaging bag, packaging an outer packaging bag and detecting sealing performance. According to the method, the inner packaging bag and the outer packaging bag are adopted for packaging, so that double-layer vacuum packaging is achieved; the inner packaging bag and the outer packaging bag are arranged in a matched mode, so that packaging is not prone to being damaged by transportation or weather or people; and meanwhile, influences such as cold and hot temperatures easily generated in the transportation process can be adapted, so that the sealing performance and the antibacterial performance of spray bottle packaging can be well guaranteed. According to the method, before the inner packagingbag is packaged, multiple adsorption surface areas and single open end edge can be constructed, and can be vacuumized at the same time, so that the surface of the inner packaging bag cannot be wrinkled after vacuumizing, attractiveness of the packaged product is guaranteed, the vacuumizing operation speed can be increased, and thus, packaging efficiency is improved.

Owner:山西中基美联科技有限公司

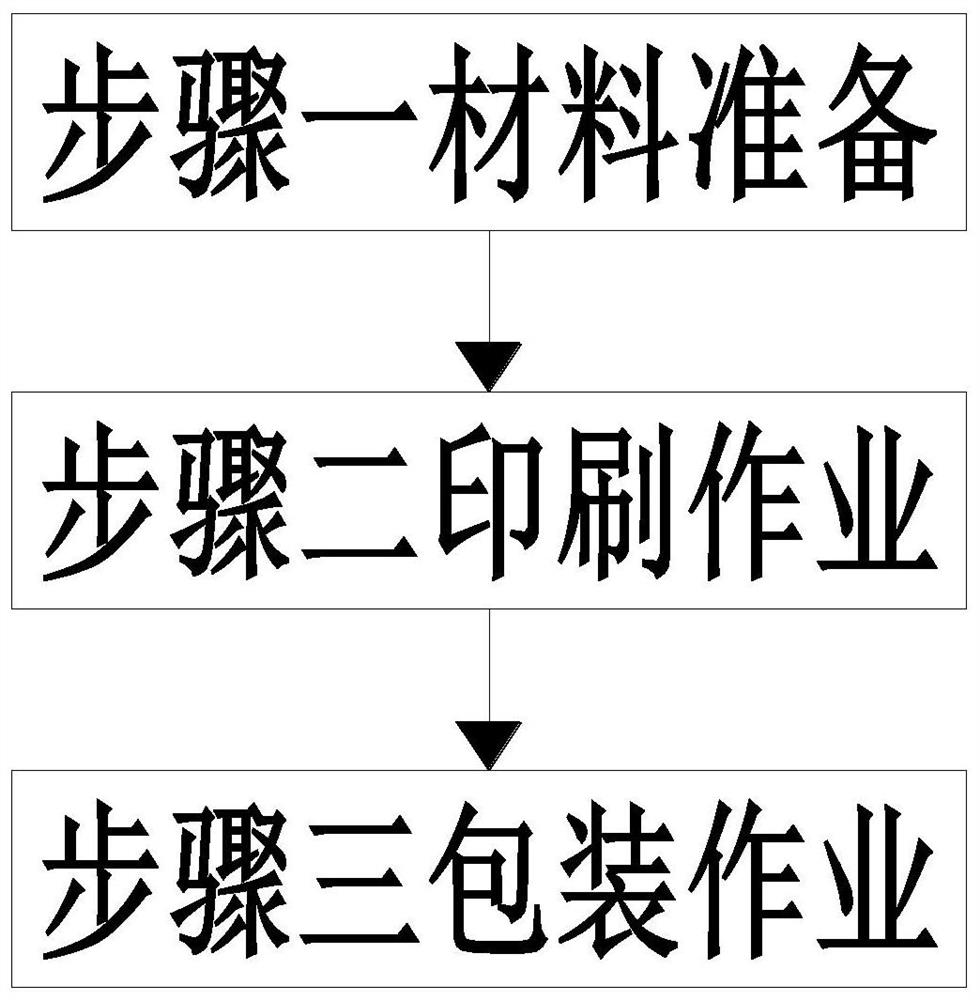

Woven packaging bag surface printing process

ActiveCN111689284AImprove printing efficiencyImprove printing effectOther printing apparatusArticle deliveryMechanical engineeringComposite material

The invention relates to a woven packaging bag surface printing process. The woven packaging bag surface printing process mainly includes the following steps of material preparation, printing operation, packaging operation and other multiple procedures. Used packaging bag printing and stacking equipment comprises a bottom plate, a conveying device, a printing device, a drying device and a stackingdevice. The problems that a, when woven packaging bags are printed traditionally, as the woven packaging bags are not positioned and clamped, the woven packaging bags can deviate, printed patterns are likely to be wrinkled, and the effect is not good; and b, the woven packaging bags cannot be stably stacked after the woven packaging bags are printed in the prior art, the woven packaging bags needto be manually collected and stacked, labor force is wasted, the woven packaging bags easily deviate in the conveying process, and the woven bags are easily wrinkled when stacked existing in existingwoven packaging bag printing and stacking can be solved, and the printing efficiency and effect of the woven packaging bags are improved.

Owner:苏州吾壹整体包装科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com