Film pressing device and film pressing method thereof

A film pressing and film sticking technology, which is applied in the field of medical devices, can solve the problems of affecting the appearance, the film cannot be flattened, and the lamination efficiency is low, so as to achieve the effect of improving the appearance quality, improving the use function, and improving the film sticking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

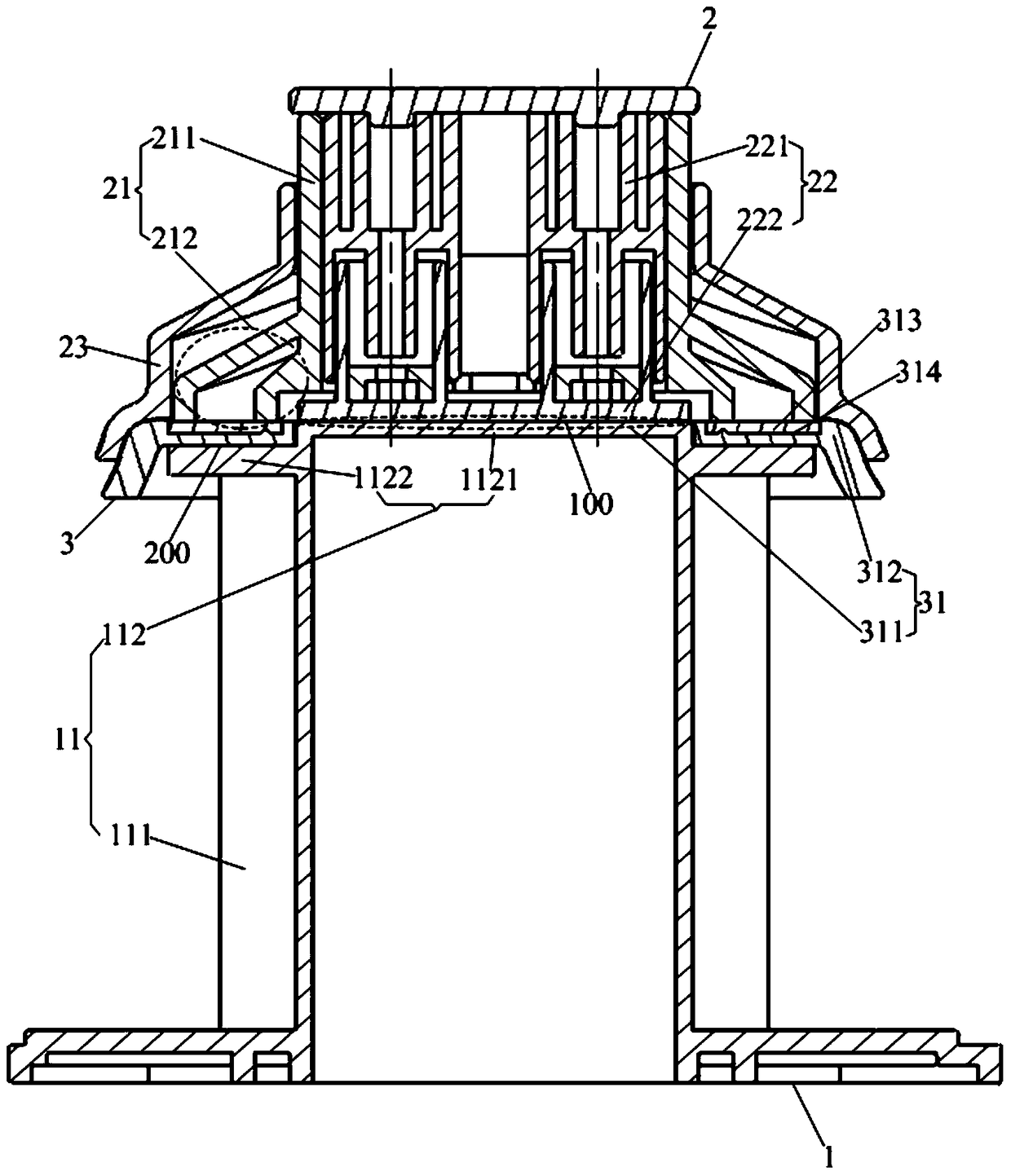

[0044] This embodiment provides a film pressing device, which is used to crimp the film onto the film window of the film frame, such as figure 1 As shown, it includes a supporting mechanism 1 and a pressing mechanism 2. The pressing mechanism 2 is located above the supporting mechanism 1, and the pressing mechanism 2 corresponds to the position of the supporting mechanism 1; the supporting mechanism 1 is used to support the film frame 3; The closing mechanism 2 is used to press the film onto the film window 311 of the film frame 3 correspondingly.

[0045] The film lamination device is provided with a support mechanism 1 and a pressing mechanism 2, so that the film crimped on the film window 311 of the film application frame 3 can be fully tightened and flattened without wrinkles, thereby not only improving the film application of the film application frame 3 The final appearance quality is improved, and the use function of the film-sticking frame 3 after film-sticking is impr...

Embodiment 2

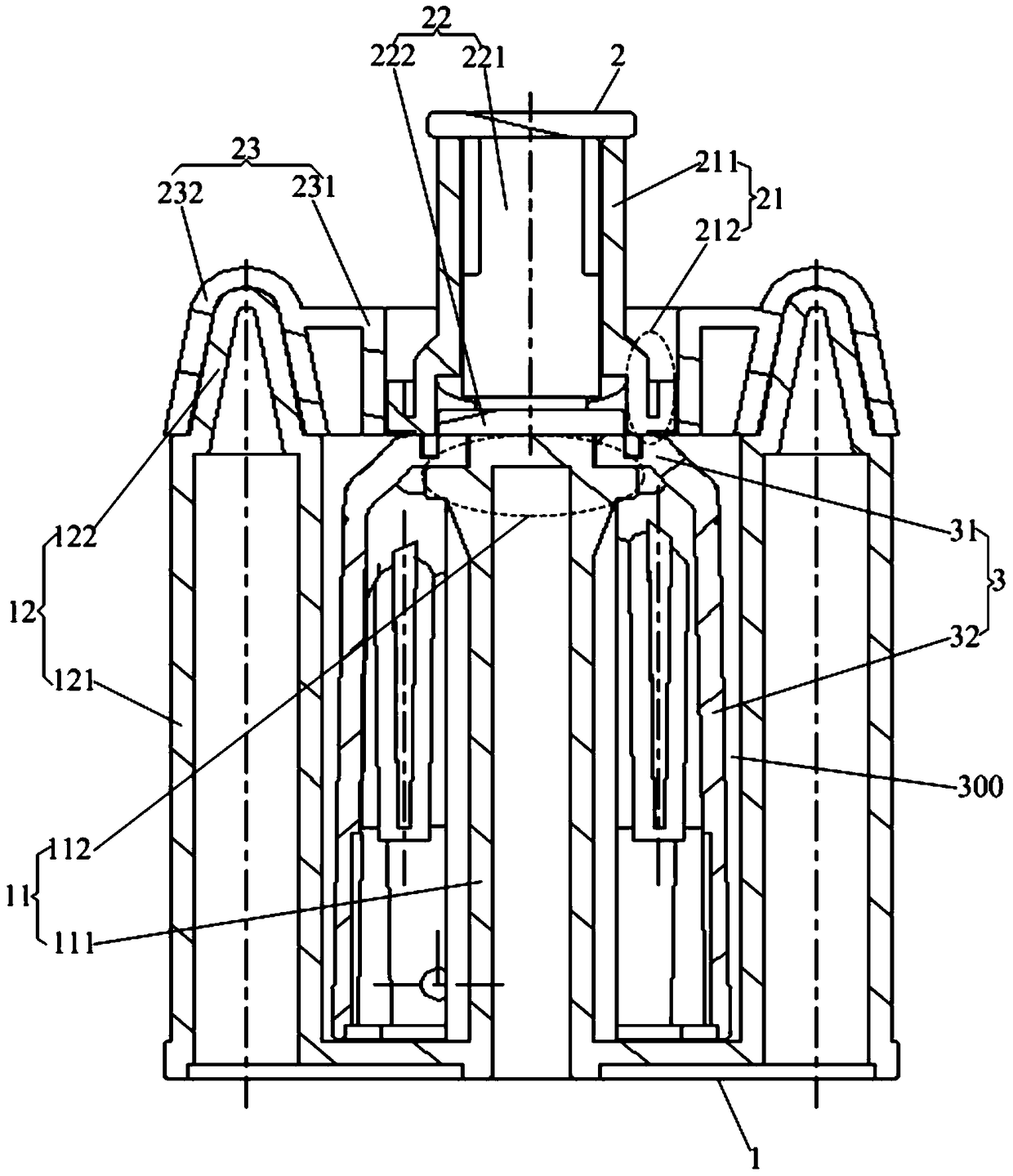

[0071] This embodiment provides a laminating device, which is different from Embodiment 1, such as figure 2 As shown, the pressing mechanism 2 further includes a positioning part 23 for positioning the film pressing part 21 , the flat film part 22 and the film during film pressing. The support mechanism 1 also includes a positioning support seat 12, the positioning support seat 12 is surrounded by the periphery of the film support seat 11, and is connected with the film support seat 11; The shape and size are matched, and the positioning part 23 can be buckled correspondingly with the top of the positioning support seat 12 .

[0072] That is, the positioning part 23 in this embodiment is provided independently, and has no connection relationship with the lamination part 21 . As long as the positioning part 23 in this embodiment is engaged with the top of the positioning support seat 12 of the support mechanism 1, the frame and restriction of the pressing film part 21, the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com