Polyurethane sponge preparation and processing technology

A polyurethane sponge and processing technology, which is used in metal processing, coiling strips, thin material processing, etc., can solve the problem that the clamping of the cylindrical sponge is not stable enough, the cylindrical sponge is prone to tilt and detachment, and the cylindrical sponge cannot be changed. The thickness of slitting and other issues can avoid offset, avoid fracture and improve stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

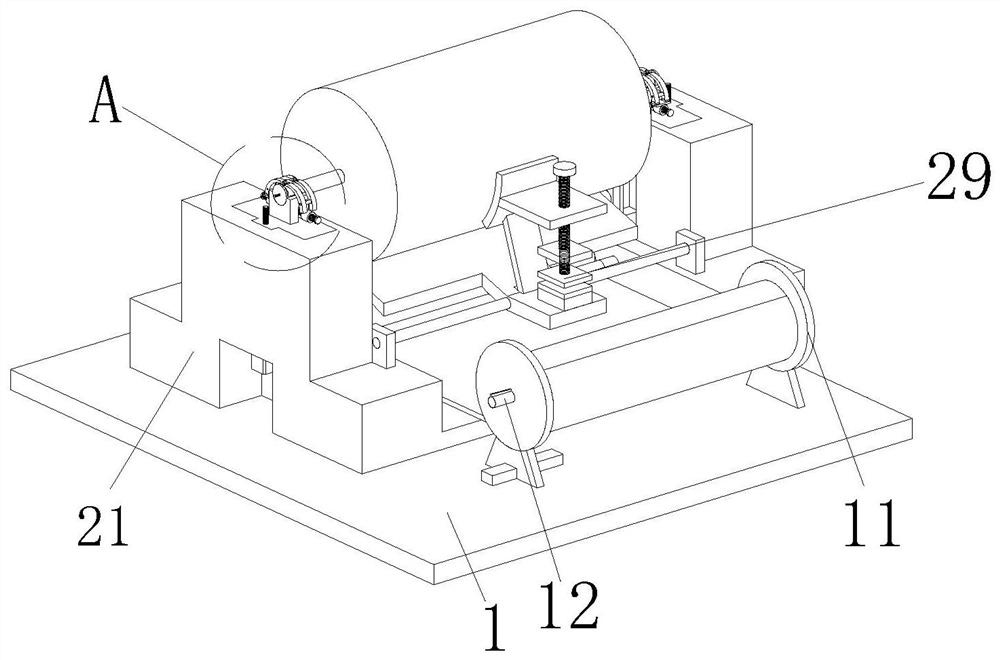

[0039] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

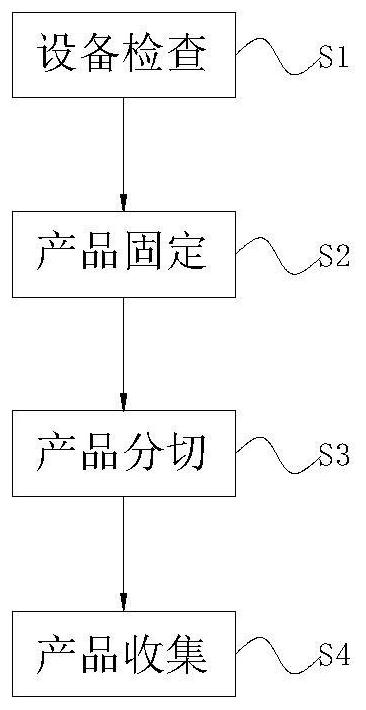

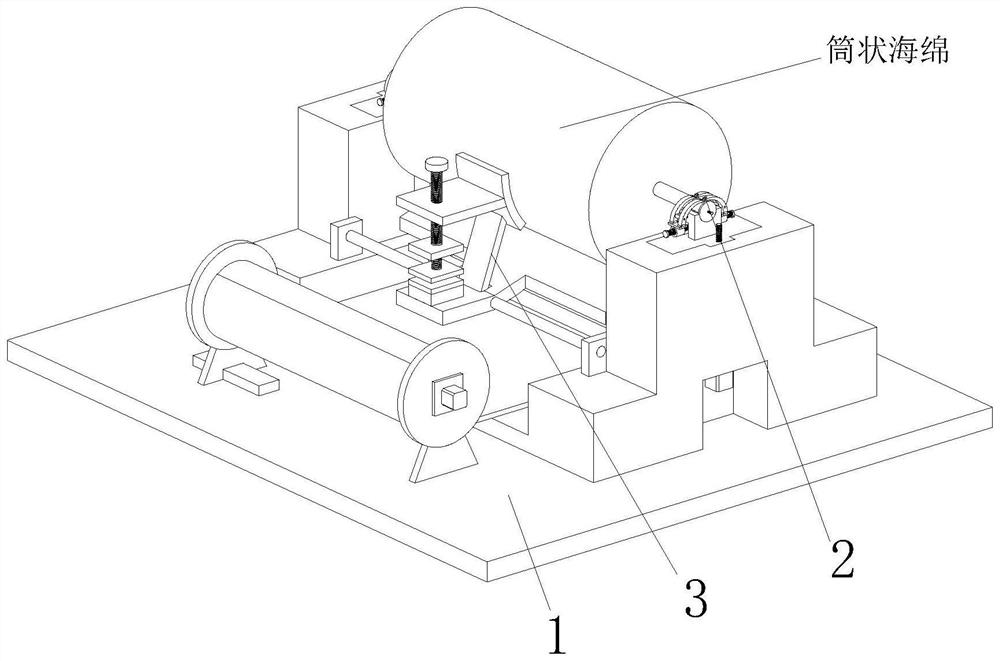

[0040] Such as Figure 1 to Figure 9As shown, a polyurethane sponge preparation and processing technology, the polyurethane sponge preparation and processing technology adopts the following polyurethane sponge preparation and processing equipment, the equipment includes a base plate 1, a clamping device 2 and a cutting device 3, and a clip The clamping device 2 is provided with a cutting device 3; during specific work, the operator first places the tubular sponge interspersed with the rotating shaft on the clamping device 2 for clamping and limiting, ensuring that the tubular sponge can Rotate on the spot, cut the tubular sponge at equal intervals by the cutting device 3, cut a whole piece of tubular sponge into thin polyurethane sponges as required...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com