A selvage print pressing device for fabric processing

A technology of pressing and forming and using cloth, which is applied in the direction of printing devices, printing, printing machines, etc., can solve the problems of poor effect, inability to guarantee the embossing quality of cloth lace, and low efficiency, so as to avoid falling off, ensure embossing effect, and improve Effect of Imprint Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

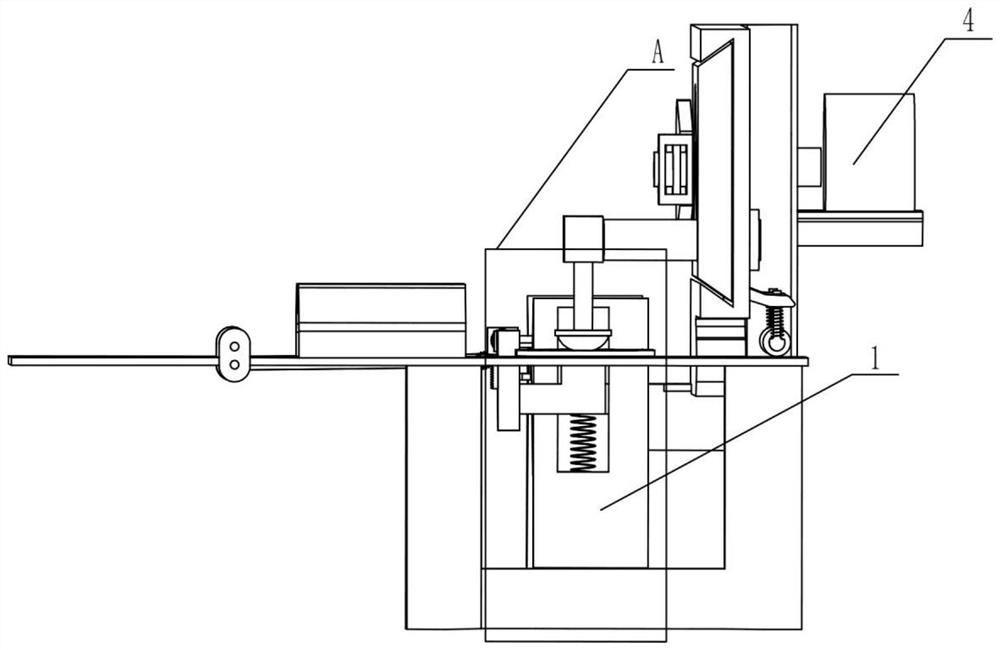

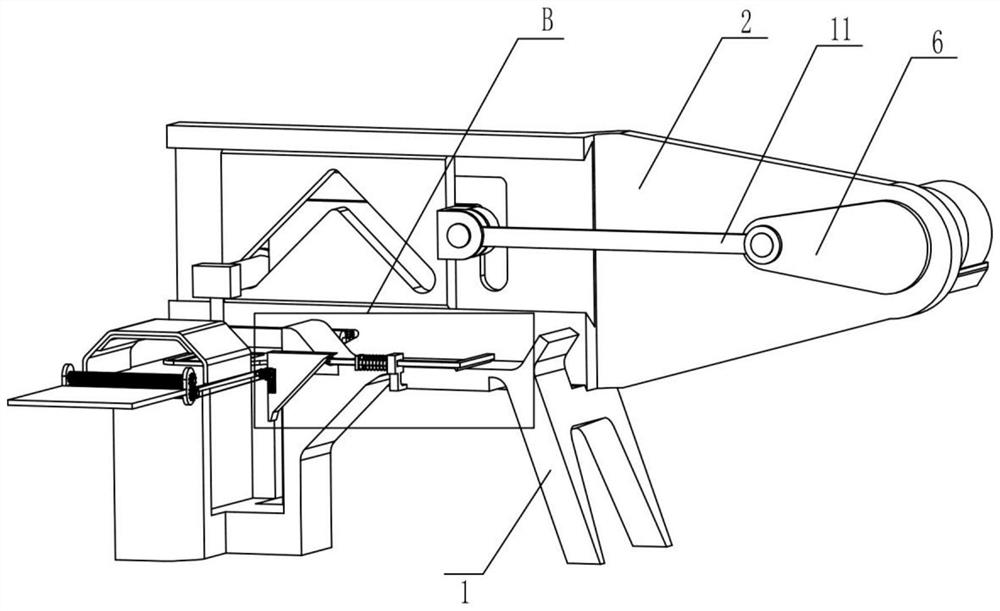

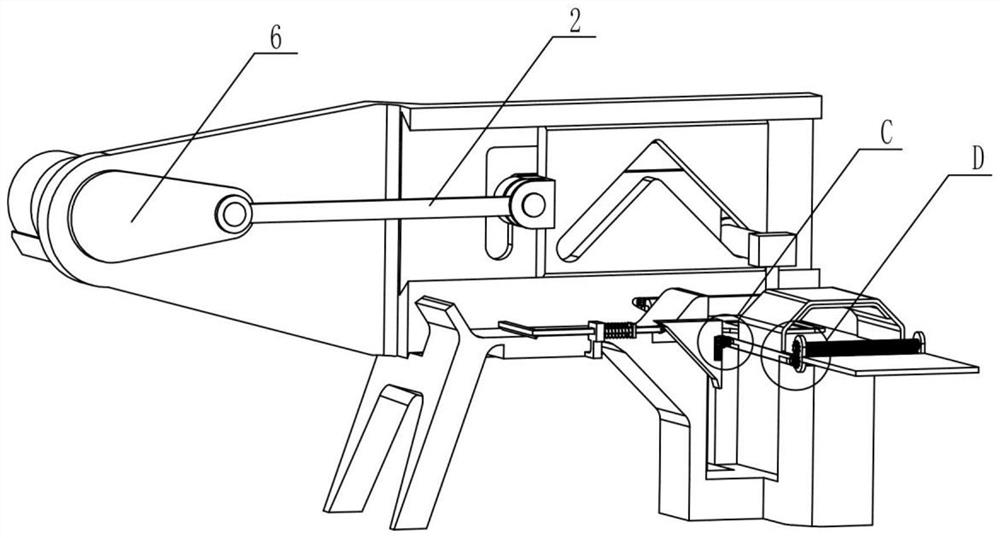

[0027] A kind of fabric processing is used for selvage flower printing pressing molding device, such as Figure 1-11 As shown, it includes base 1, chute plate 1, supporting plate 3, power mechanism, chute plate 2 7, moving rod 8, rubber pressing block 9, fixed seat 10, connecting rod 11, machine table 12, spring 1 13. Sliding block 14, template table 15, inclined push block 16, oven body 17, heating plate 18 and wiper mechanism, the chute plate-2 is fixedly installed on the base 1 provided with a semicircular groove, so The supporting plate 3 is fixedly installed on the rear side of the chute plate one 2, the driving power mechanism is installed on the chute plate one 2, and the chute plate two 7 is slidably installed on the chute plate one 2 and Away from the supporting plate 3, the moving rod 8 is slidably installed on the first chute plate 2 and the second chute 7 and is located above the base 1. The rubber that can evenly dip the paint and emboss the lace pattern on the cl...

Embodiment 2

[0032] On the basis of Example 1, such as Figure 1-11 As shown, the wiper mechanism capable of flattening the paint dipped by the rubber press block 9 includes a ferrule 19, a push rod 20, a push plate 21, a push block 22, a spring 23 and a rotating wheel 24, The ferrule 19 is fixedly mounted on the front side of the base 1, the pushing rod 20 is set in the ferrule 19 and is close to the base 1, and the pushing plate 21 used for smoothing paint is fixedly mounted on the push rod 20. The left end of the rod 20 is in contact with the base 1, the push block 22 is fixedly mounted on the push rod 20 and is close to the ferrule 19, the left end of the spring two 23 which plays a reset role is fixedly connected with the right side of the ferrule 19, and the right end is connected with the push The left side of the block 22 is fixedly connected, and the push rod 20 passes through the second spring 23, and the rotating wheel 24 is rotatably mounted on the right end of the push rod 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com