A surface marking positioning spraying device for noodles

A surface marking and spraying device technology, which is applied in the direction of dough processing, dough embossing machine, baking, etc., can solve the problems of low efficiency and manpower consumption, and achieve the effect of high degree of automation, improved efficiency and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

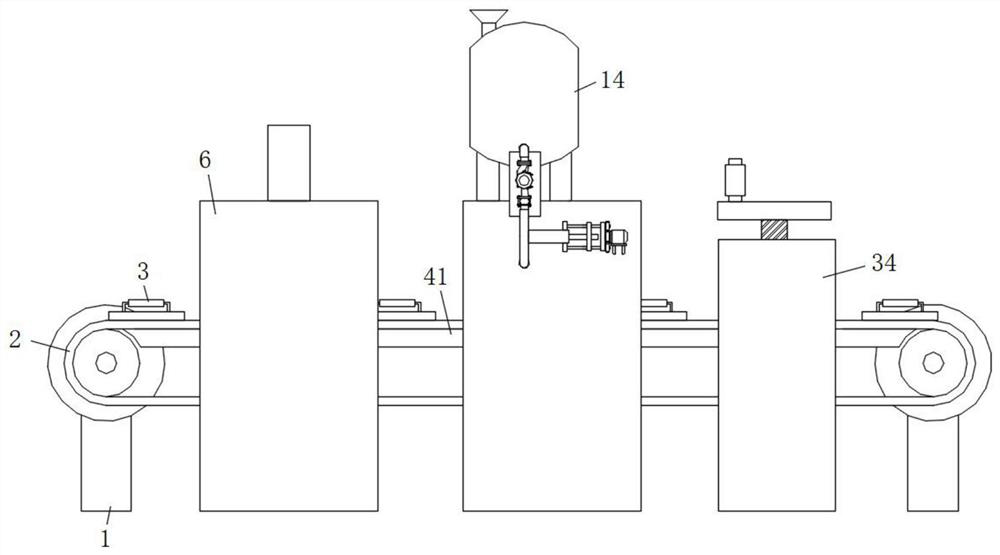

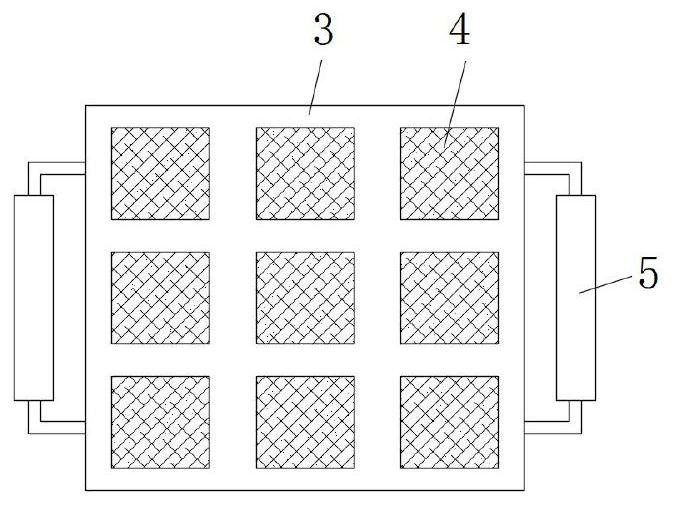

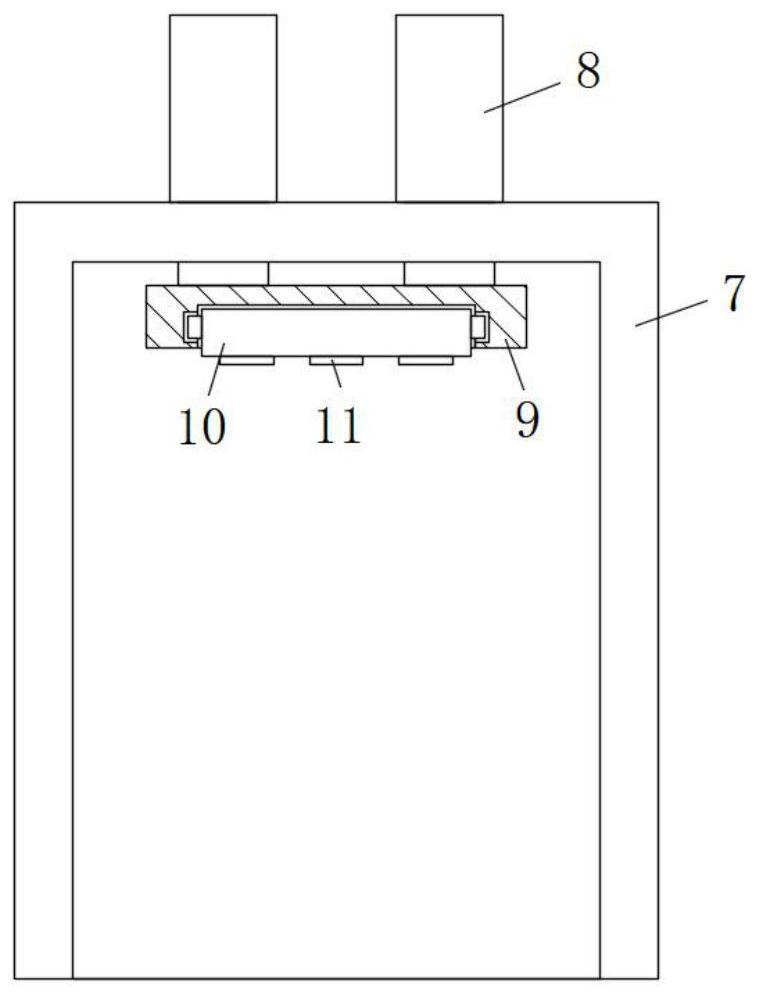

[0036] refer to Figure 1-8 , a surface mark positioning spraying device for noodles, including a mounting base 1, a conveyor belt 2 is installed on the upper end of the mounting base 1, and a limiter mold is fixed on the belt surface of the conveyor belt 2, and a plurality of limiter molds are arranged and evenly distributed on the conveyor belt 2 belt On the upper surface, a feeding tray 3 is placed on the belt surface of the conveyor belt 2, and a rectangular hole is opened through the top surface of the feeding tray 3. The inner wall of the rectangular hole is fixed with a partition net 4, and the front and rear sides of the feeding tray 3 are also fixed with lifters. Handle 5, conveyer belt 2 side is provided with marking mechanism 6, and marking mechanism 6 comprises work frame-7, and work frame-7 outer top front and rear sides are all connected with electric telescopic rod 8 by screw, and the output end of electric telescopic rod 8 wears The top surface of the working f...

Embodiment 2

[0039] Such as figure 1 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the lower side of the upper belt surface of the conveyor belt 2 is also provided with an abutment plate 41, and the top surface of the abutment plate 41 is attached to the bottom of the upper belt surface of the conveyor belt 2, and the front and back of the abutment plate 41 Sides are all fixed on the inner wall of work frame one 7, work frame two 15 and work frame three 35 by screws.

[0040] In this embodiment, when in use, the lower side of the upper belt surface of the conveyor belt 2 is also provided with a support plate 41, thereby playing the effect of supporting the feeding tray 3, and then making the embossing and oiling operations of the pasta more stable and easy. It ensures the stability of the device operation.

Embodiment 3

[0042] Such as figure 1 and 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, there are multiple feeding trays 3 that are evenly distributed on the top of the belt surface of the conveyor belt 2, and there are four mounting seats 1 that are fixed on the working surface in a rectangular shape. On the top, there are multiple partitions 4 and they are distributed in a matrix on the top surface of the feeding tray 3 .

[0043] In this embodiment, a plurality of feeding trays 3 are evenly arranged on the conveyor belt 2, so as to realize the continuous production of pasta.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com