Leather conveying traveling automatic deviation correcting device and method

An automatic deviation correction device and leather technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of reducing production efficiency and wasting manpower, and achieve the effect of easy rotation angle and precise control of rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

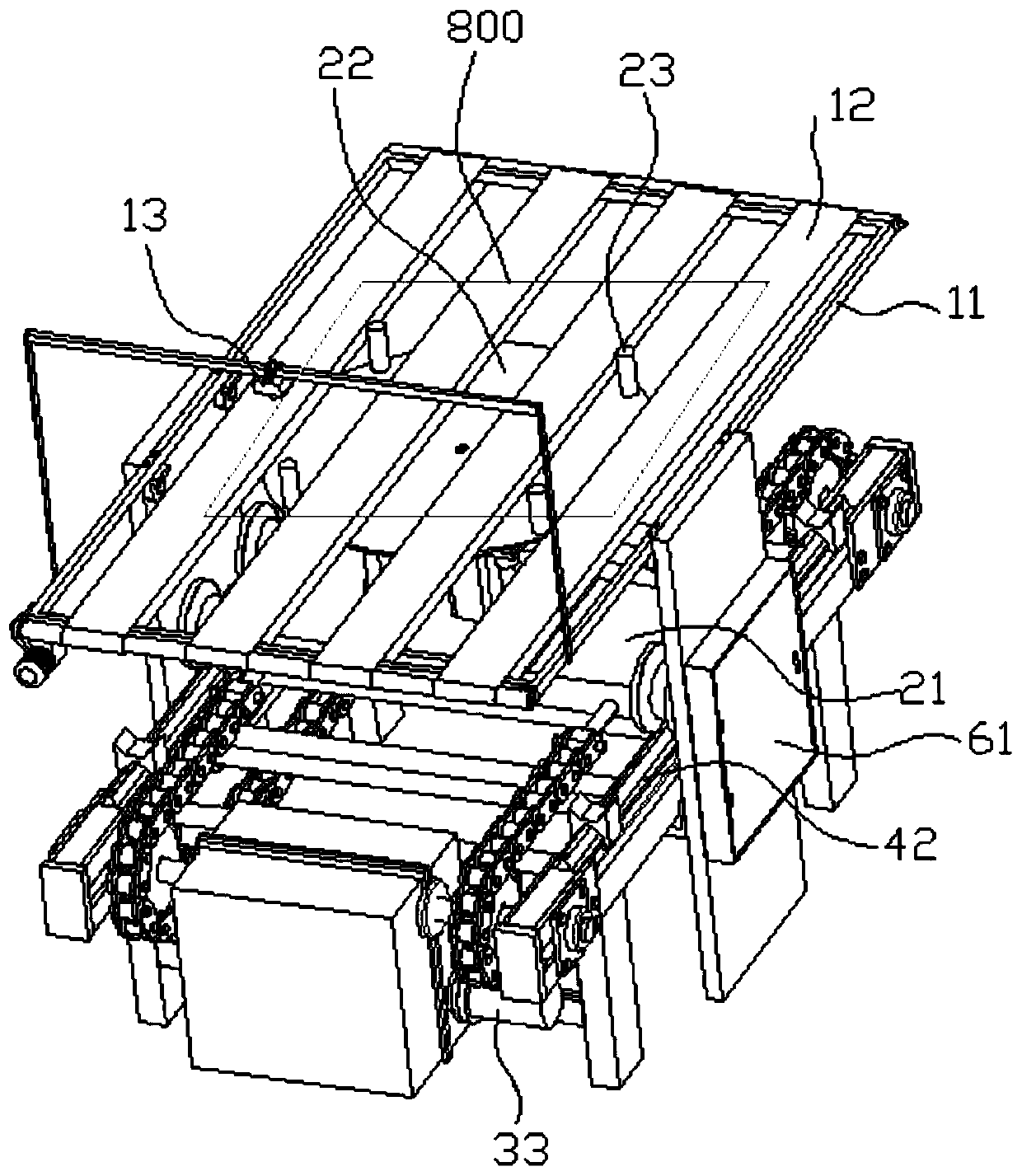

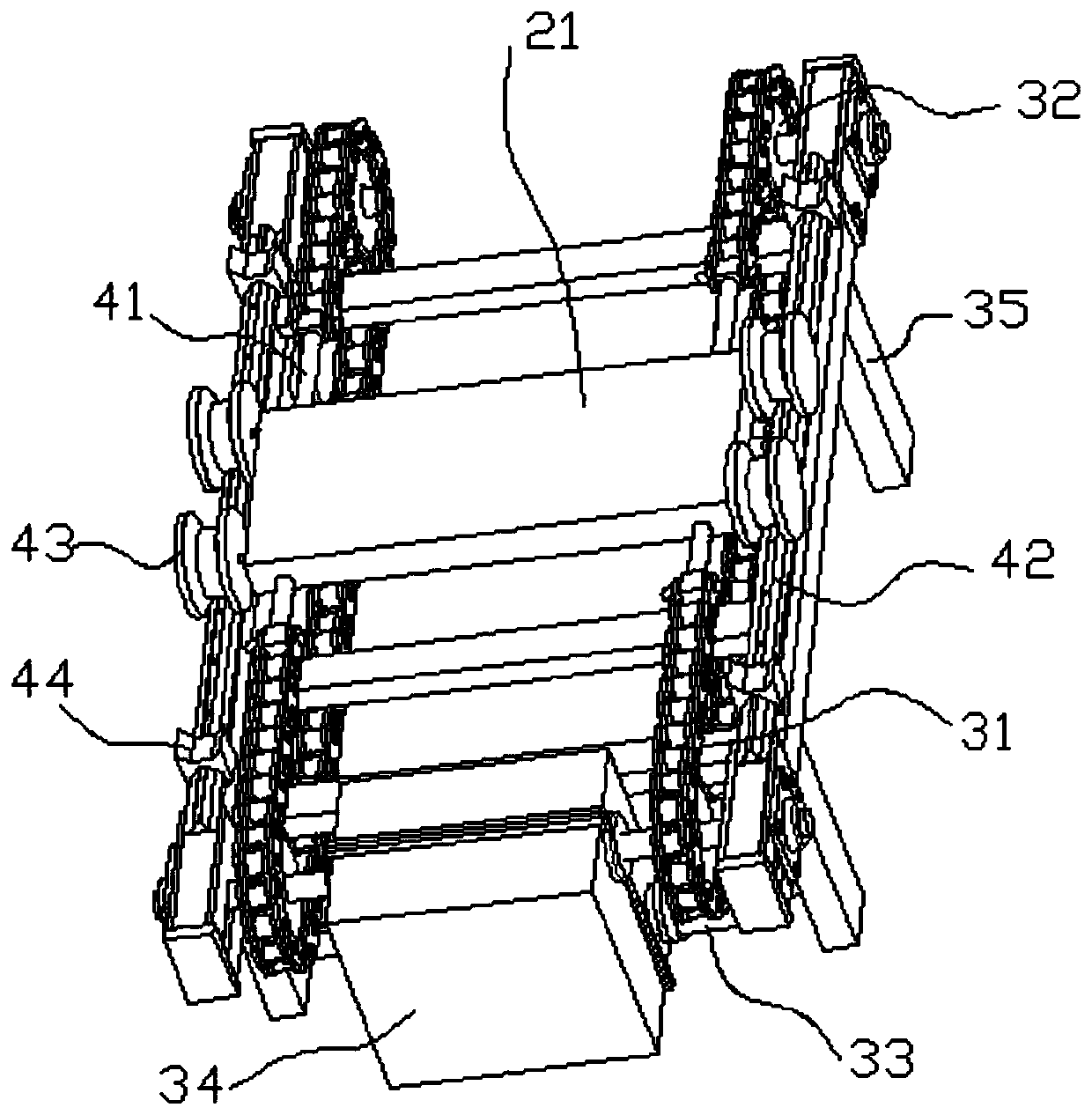

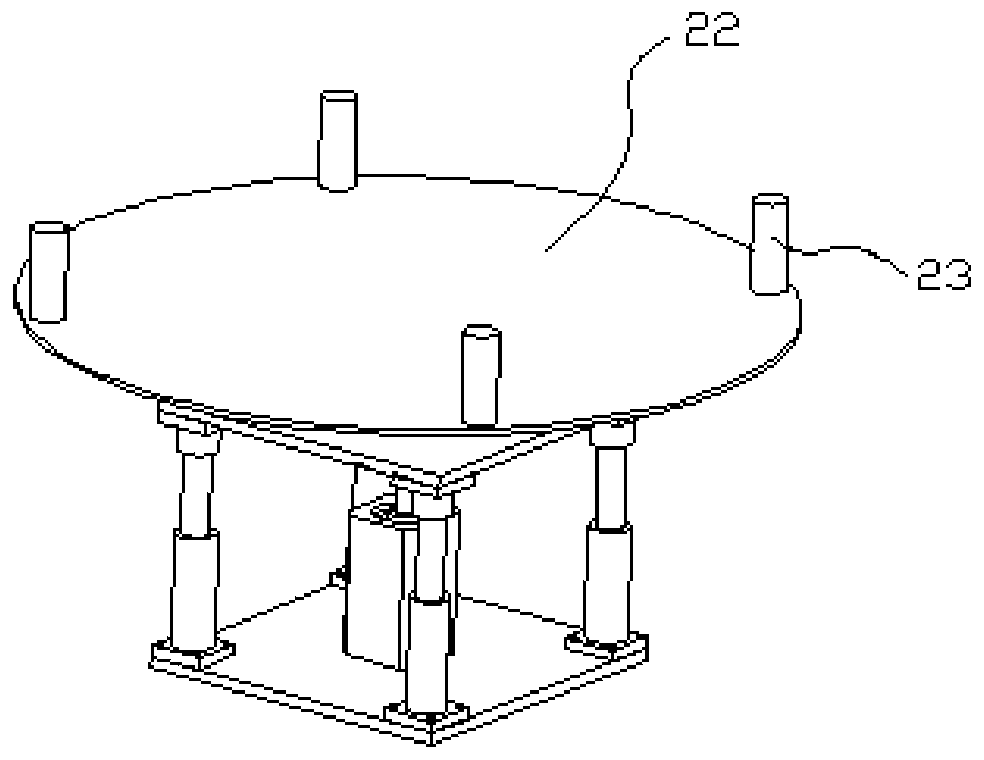

[0027] like Figure 1 to Figure 5 , an accompanying automatic deviation correction device for leather conveying according to the present invention, comprising a bed 11, a conveyor belt 12, a camera 13, an accompanying platform 21, a transplanting platform 22 and a transplanting pole 23, and the four conveyor belts 12 are separated by a certain gap and parallel to each other. Rotationally connected on the bed 11, the camera 13 is arranged above the conveyor belt 12, the accompanying platform 21 is placed below the conveyor belt 12 and can move along the direction of the conveyor belt 12, and the transplanting platform 22 can rotate and vertically move Be arranged on the accompanying platform 21, fix four transplanting bars 23 on the transplanting platform 22, the four transplanting bars 23 are divided into two groups in half and symmetrically arranged on both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com