Plate splicing process of laser nickel plates

A laser nickel and craft technology, applied in the direction of printing plate preparation, printing, etc., can solve the problems of poor flatness at the imposition seam, thick imposition seam, affecting the quality of laser anti-counterfeiting materials, etc., to achieve good flatness, strong operability, The effect of improving imposition quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

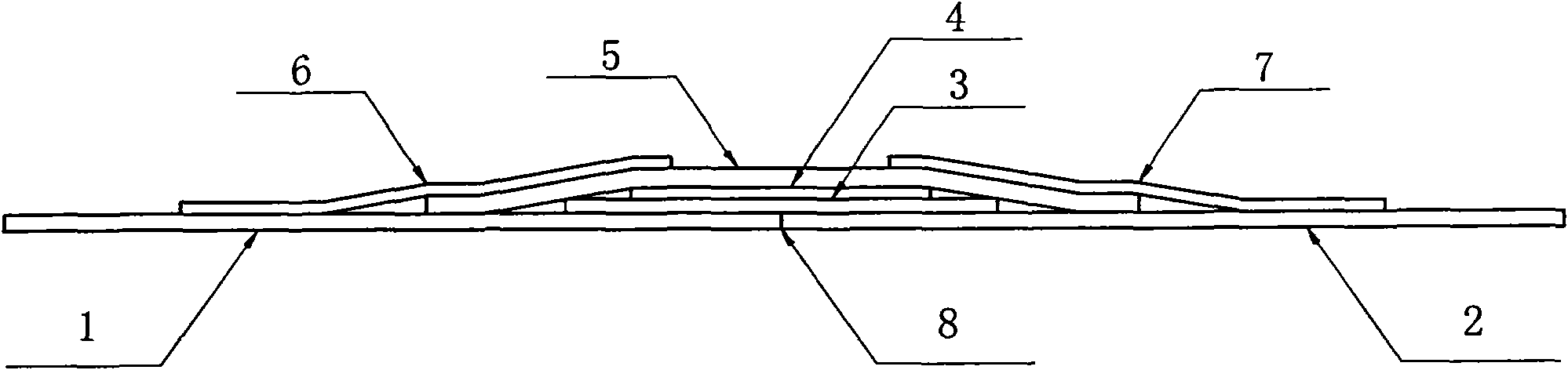

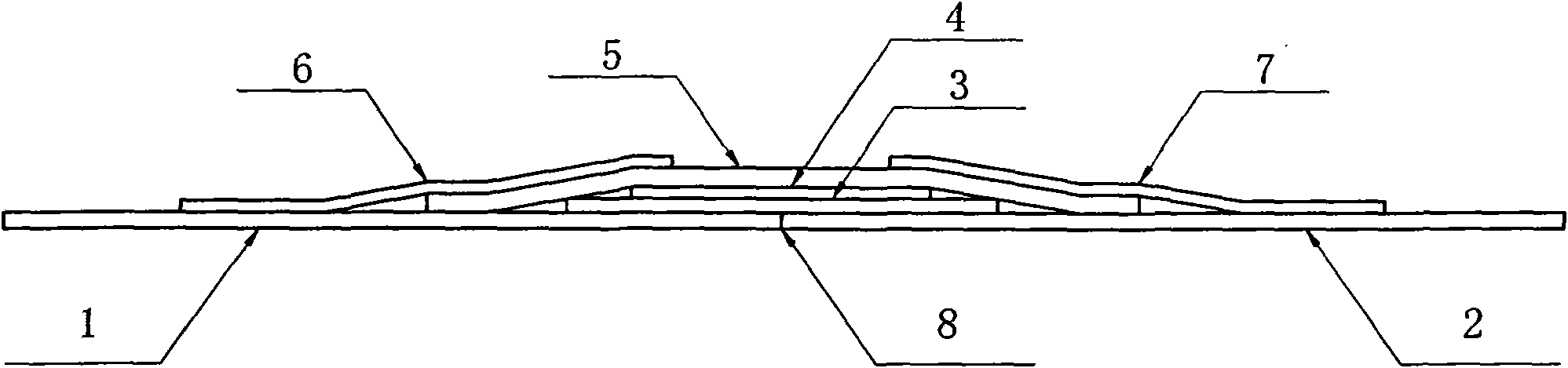

[0029] Please refer to Fig. 1 as shown in the schematic diagram of imposition structure of the present invention, a kind of imposition process of laser nickel plate, it is characterized in that comprising the following steps:

[0030] The first step: cutting the laser nickel plate with a thickness of 20-30 μm, and the cutting edge is straight and burr-free;

[0031] Pre-bonding: face up two laser nickel plates 1 and 2 with the same thickness, splice their straight and burr-free cutting edges relative to each other, and temporarily bond them together with adhesive tape;

[0032] Step 2: Put a magnetic rubber plate on a flat table, put a layer of copy paper on the magnetic rubber plate, turn the two pre-bonded laser nickel plates 1 and 2 over, and cover the magnetic rubber plate with the front facing down On the copy paper, splice the straight and burr-free cutting sides together, and the 8 seams are closely attached to each other;

[0033] Correction: Grind, smooth, and clean ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com