Method for preparing flowerlike bismuth tungstate by hydrothermal process

A technology of bismuth tungstate and hydrothermal method, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of reducing the specific surface area, poor dispersibility, and high energy of materials, achieving good reproducibility, low cost, The effect of good degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

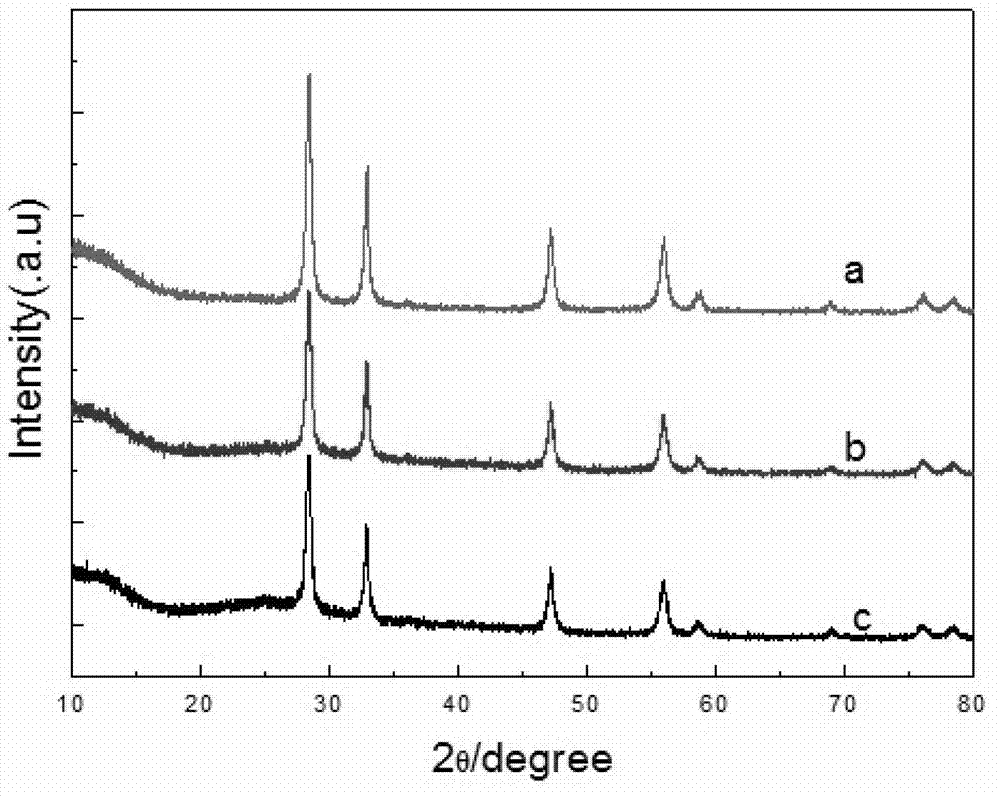

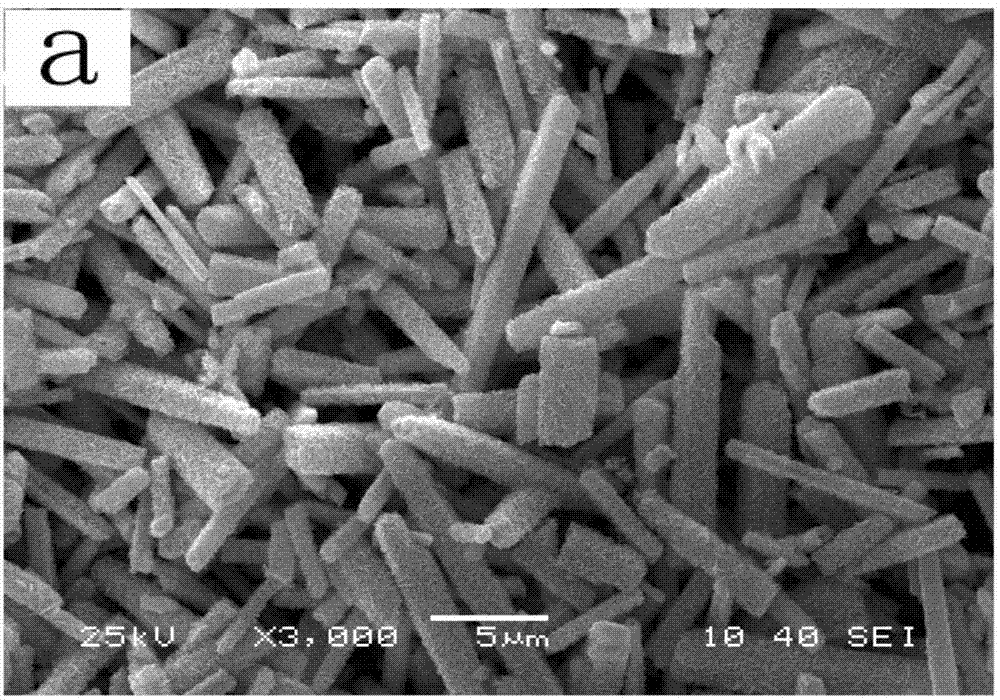

Embodiment 1

[0028] Step 1, 1mmol of Bi(NO 3 ) 3 Dissolve in 20ml of deionized water, and form a milky white solution after ultrasonic treatment;

[0029] Step two, the Na of 0.5mmol 2 WO 4 Dissolve in 20ml of deionized water, and after ultrasonic treatment, the solution is mixed evenly, and then the uniformly mixed solution is gradually added dropwise to the milky white solution in step 1, and fully stirred;

[0030] Step 3, use a NaOH solution with a concentration of 1mol / L and dilute H 2 SO 4 Adjust the pH value of the solution obtained in step 2 so that the pH of the solution=1;

[0031] Step 4, add 0.010mol of K in the reaction solution of step 3 2 SO 4 , dissolve and disperse evenly; transfer the reaction system to a 50mL polytetrafluoroethylene-lined reactor, keep it at a constant temperature for 24 hours at 180°C, and then cool naturally to room temperature to obtain a hydrothermal product;

[0032] Step 5: Centrifuge the hydrothermal product obtained in Step 4, wash with a...

Embodiment 2

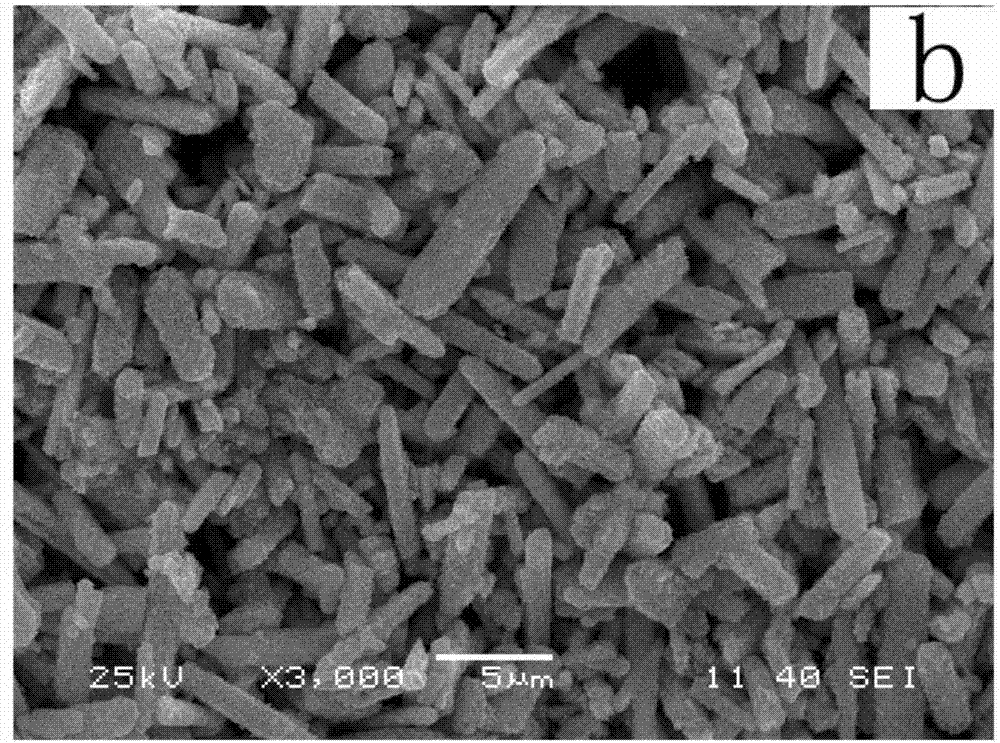

[0039] The preparation method in the present embodiment is the same as that in Example 1, the difference is only that the conditions in the preparation process are different, the pH=3 of the solution is adjusted in the step 3 of the present embodiment, and 0.030mol potassium sulfate is taken in the step 4 and the reaction temperature is 200 °C, and the rest of the conditions remain unchanged.

[0040] Get the Bi prepared by 0.1g this embodiment 2 WO 6 The photocatalytic degradation test of tetracycline was carried out in the photochemical reaction instrument, and the degradation rate of the tetracycline antibiotic by the photocatalyst was measured to reach 68% within 60 minutes.

Embodiment 3

[0042] The preparation method in this example is the same as that in Example 1, the only difference being that the conditions in the preparation process are different. In step 4, 0.030 mol of potassium sulfate is taken and the reaction temperature is 200° C., and the rest of the conditions remain unchanged.

[0043] Get the Bi prepared by 0.1g this embodiment 2 WO 6 The photocatalytic degradation test of tetracycline was carried out in the photochemical reaction instrument, and the degradation rate of the tetracycline antibiotic by the photocatalyst was measured to reach 70% within 60 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com