Preparation method of rare earth-doped sodium gadolinium tetrafluoride nanomaterial

A technology of sodium gadolinium tetrafluoride and nanomaterials, which is applied in the fields of chemical instruments and methods, luminescent materials, etc., and can solve the problems of the preparation and subsequent application of rare earth fluoride up-conversion luminescent nanomaterials, the large size of rare earth fluoride nanoparticles, three To solve the problems of high toxicity of fluoroacetate and achieve the effect of easy promotion, simple and novel process, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

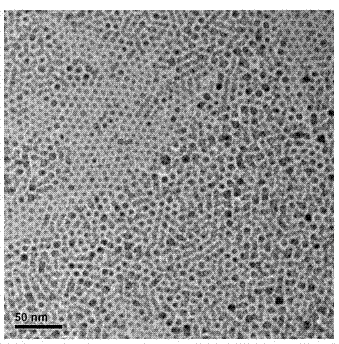

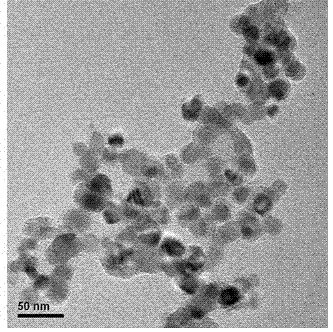

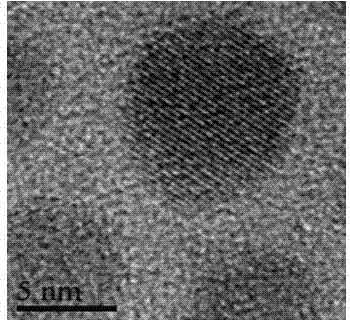

Image

Examples

Embodiment 1

[0031] (a) 20mmol of solid RECl 3 ·6H 2 O (RE=Gd, Yb, Er) and 60mmol of sodium oleate were dissolved in 30mL of distilled water, 40mL of absolute ethanol and 70mL of n-hexane and refluxed for 4 hours, then poured into a pear-shaped separatory funnel for separation, leaving The upper organic phase was washed with 35 mL of distilled water, repeated three times, and vacuum-dried to prepare a rare earth oleic acid complex;

[0032] (b) Take 1 mmol of rare earth oleic acid complex and 1 mmol of sodium oleate, add 3 mL of oleic acid, and raise the temperature to about 140 ° C under the protection of nitrogen to dissolve all of them to prepare a rare earth oleic acid precursor solution;

[0033] (c) Take out the rare earth oleic acid precursor solution prepared in the second step, add it into the polytetrafluoroethylene liner of the hydrothermal reaction kettle, and then add 15mL of butylmethylimidazolium tetrafluoroborate ionic liquid (BmimBF 4 );

[0034] (d) Put the hydrotherma...

Embodiment 2

[0036] (a) 10mmol of solid GdCl 3 ·6H 2 O and 30mmol of sodium oleate were dissolved in 15mL of distilled water, 20mL of absolute ethanol and 35mL of normal hexane and were refluxed for 4 hours, then poured into a pear-shaped separating funnel for liquid separation, leaving the upper organic phase, adding 15mL of distilled water for washing, Repeat three times, carry out vacuum drying, make rare earth oleic acid complex;

[0037] (b) Take 0.5 mmol of rare earth oleic acid complex and 0.5 mmol of sodium oleate, add 3 mL of oleic acid, and heat up to about 140 °C under the protection of nitrogen to dissolve all of them to prepare a rare earth oleic acid precursor solution;

[0038] (c) Take out the rare earth oleic acid precursor solution prepared in the second step, add it to the polytetrafluoroethylene liner of the hydrothermal reaction kettle, and then add 5 mL of butylmethylimidazolium tetrafluoroborate ionic liquid (BmimBF 4 ), finally add 20mL of methanol solution;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com