Method of supporting large-height shear wall form

A support method and shear wall technology, applied in the processing of building materials, construction, building construction, etc., can solve the stability and safety problems of the structural system, and affect the safety of structural construction, construction period, quality, and high-height shearing There is no complete set of force wall formwork, etc., to achieve the effect of simple support structure, accurate geometric dimensions, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

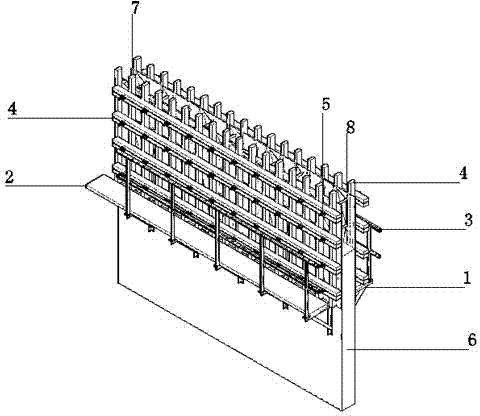

[0014] Referring to accompanying drawing, a kind of support method of large-height shear wall formwork, its specific technical scheme is as follows:

[0015] The first step: binding the steel bars within 3 meters of the lower part of the shear wall 6, supporting the formwork 7, and pouring concrete;

[0016] Step 2: After the hardness of the concrete at the lower part of the shear wall reaches 75%, remove the formwork, and install the triangular bracket 1 with high-strength bolts 1 meter below the top of the existing shear wall, with a distance of 1 meter;

[0017] The third step: place a 400*50mm scaffolding board 2 on the tripod, and then use a scaffolding steel pipe to build a 1100mm-high protective railing 3 on the plug of each tripod;

[0018] Step 4: Paste double-sided adhesive tape on the top edge of the existing shear wall, then attach the formwork to the existing shear wall, place the lower part of the formwork on the triangular bracket, place vertical wooden squares ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com