Automobile forming die anti-double-material device

A technology for automobiles and molds, which is applied in the field of anti-double-material devices for automobile forming molds, can solve the problems of inability to guarantee the double-material recognition rate, shutdown of automatic stamping production lines, and increased stress on mold inserts or mold bases, so as to achieve safe and reliable mold strength. , to ensure the effect of safety and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

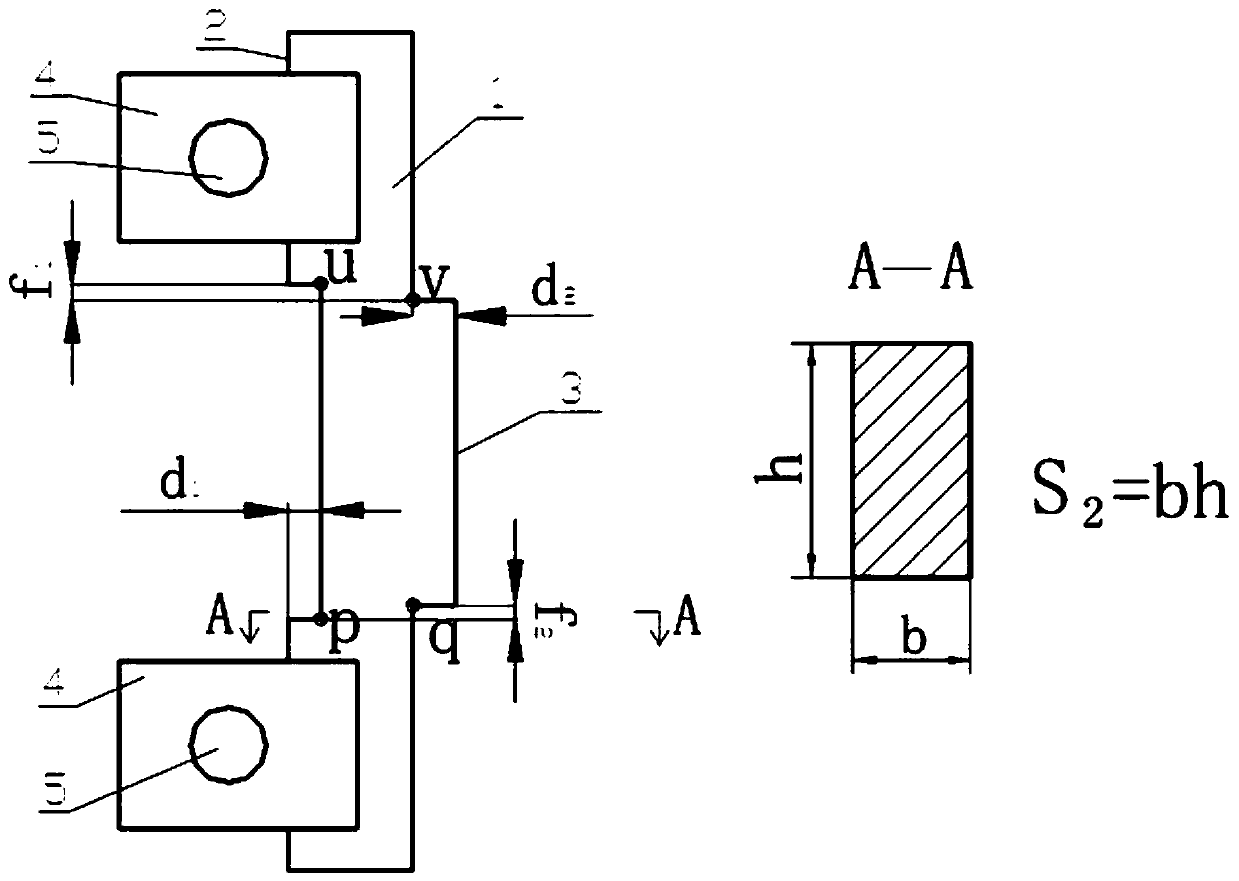

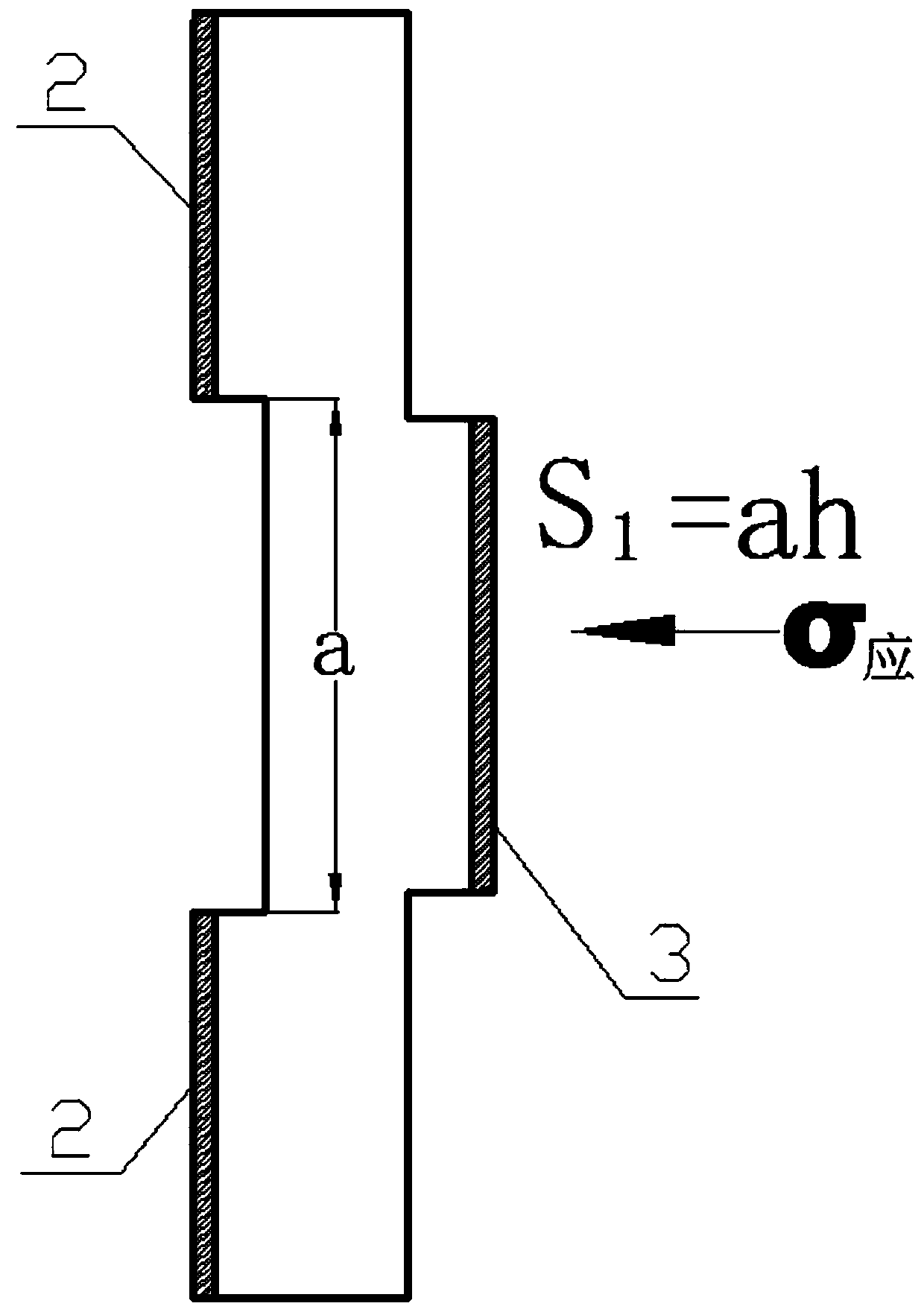

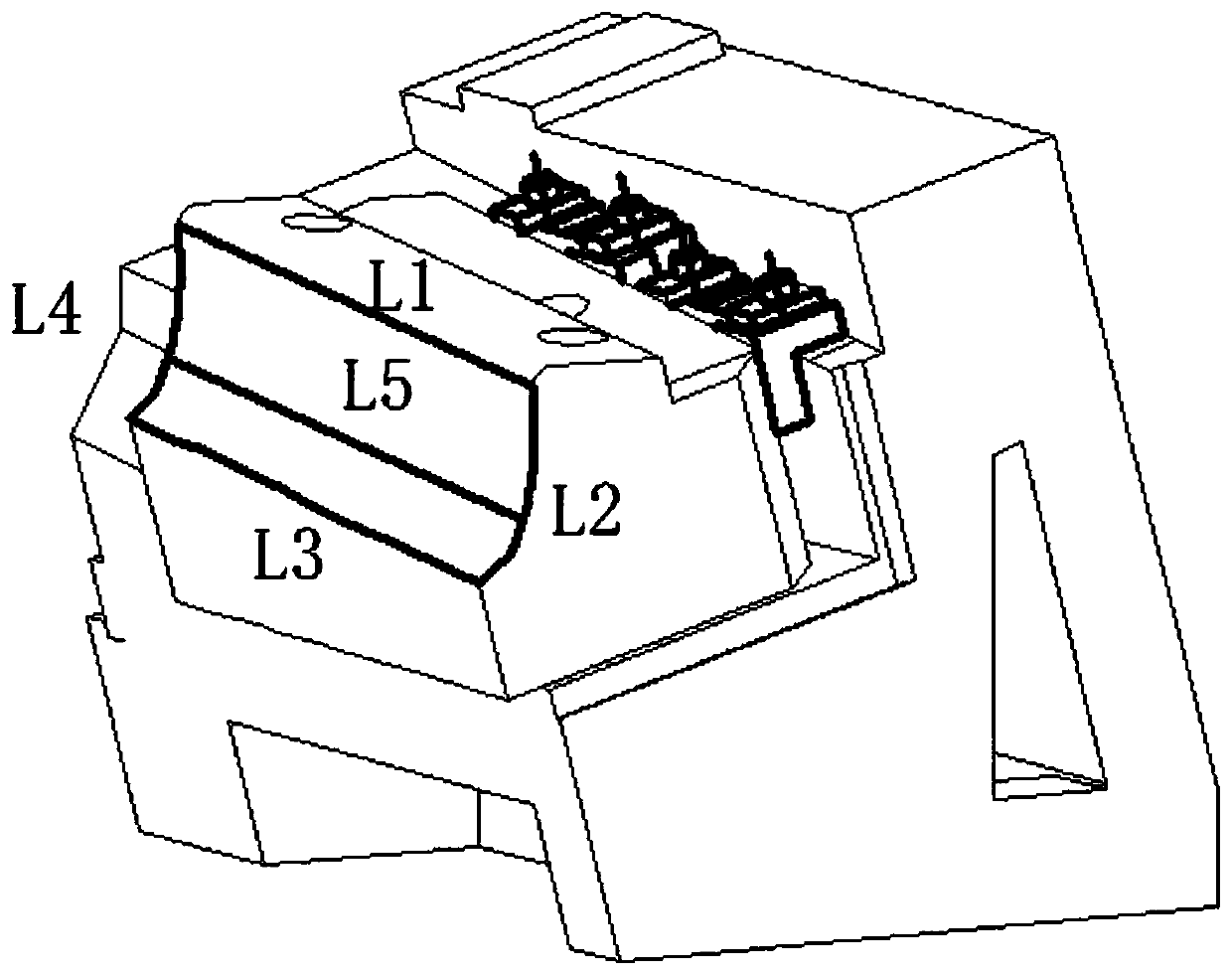

[0028] Such as figure 1 , figure 2 and Figure 5 As shown, the present invention includes a reference structural member 1, the top surface and the bottom surface of the reference structural member 1 are flat and parallel to each other, the height of the reference structural member 1 is marked as h; the front and back of the reference structural member 1 are flat, And parallel to each other; the middle part of the back of the reference structure 1 is provided with a groove, the bottom surface of the groove is a plane parallel to the back of the reference structure 1, and the depth of the groove is marked as d 1 , the groove runs through the upper and lower ends of the reference structural member 1, the width of the bottom surface of the groove is marked as a, along the length direction of the groove, the width of the bottom surface of the groove is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com