Staircase shaping support formwork

A technology for supporting formwork and stairs, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, which can solve the problem of inaccurate geometric dimensions and material utilization. Reduce and affect the construction progress and other problems, to achieve the effect of convenient and easy-to-understand construction operation, accurate geometric dimensions, and simplified construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

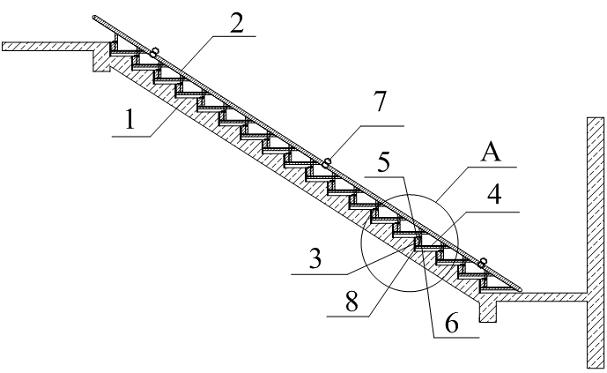

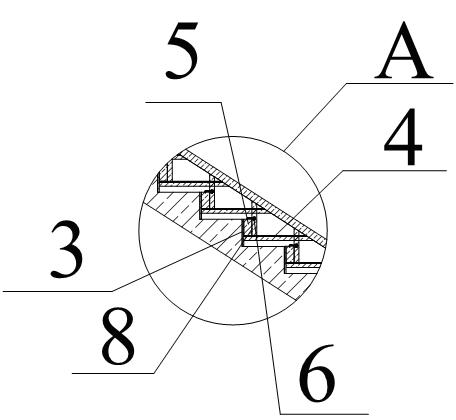

[0031] Such as figure 1 , 2 , 3 and 4, the stair-shaped formwork support is mainly composed of two support rods 2 arranged along the direction of the stair 1 and positioned above the stair 1, and several shaped boards 3 respectively leaning against the riser of the stair 1. The number of shaped boards 3 is the same as the number of risers of stairs 1 and corresponds to each other. According to the actual construction requirements and the principle of cost saving, the shaped boards 3 in this embodiment adopt laminates with a thickness of 17 mm.

[0032] The two support rods 2 are fixed together by three fastening rods 7 to form a stair shaping bracket, and the support rods 2 and the fastening rods 7 are fixed by fastening fasteners; and the bottom of each support rod 2 is provided with The horizontal ejector rod 4 corresponding to the position of the shaped plate 3, one end of the transverse ejector rod 4 is fixed on the support rod 2, and the other end thereof leans against t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com