Aluminum alloy template assembling system for building

An aluminum alloy formwork and assembly system technology, which is applied to the on-site preparation of building components, construction, building construction, etc., can solve the problems of uneven stress on stair formwork, increased construction time and cost, and incompatibility of formwork technology. Achieve the effect of eliminating secondary plastering operations, improving appearance performance and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

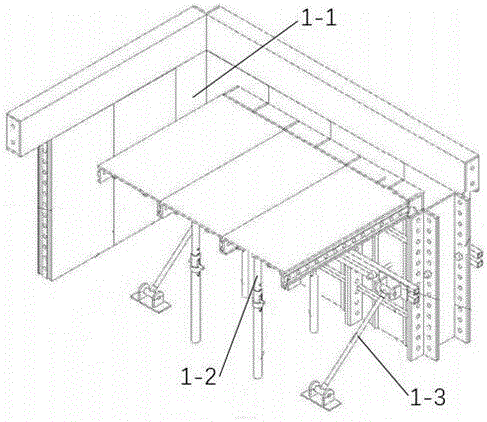

[0032] Such as figure 1 As shown, an aluminum alloy formwork assembly system for construction includes a wall pouring system 1-1 composed of aluminum alloy formwork and a panel support system 1-2, and the outer wall of the wall pouring system 1-1 is provided with a supporting structure 1 -3 for support.

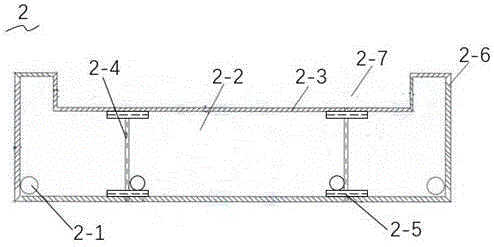

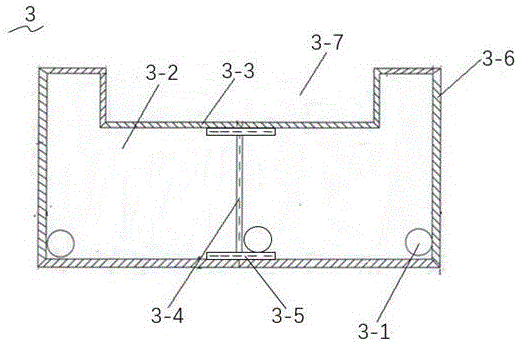

[0033] Such as figure 2 with image 3 As shown, the wall pouring system includes two connecting aluminum plates 2 and buckling aluminum plates 3 that are snap-connected to each other, and the connecting aluminum plates 2 and the buckling aluminum plates 3 are equipped with special-shaped buckling aluminum plates; Buckle aluminum plate 3 is provided with a plurality of spring pin installation holes 2-1, 3-1 respectively, and connecting aluminum plate 2 and buckle aluminum plate 3 are "concave" type hollow structures, including hollow cavities 2-2, 3-2 and The frame 2-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com