Forming method of high-precision thin-wall ceramic tube

A molding method and ceramic tube technology are applied in the field of high-precision thin-walled ceramic tube molding, which can solve the problems of low precision, difficult control of the inner wall geometry of the ceramic tube, poor straightness of the ceramic tube, etc., and achieve high production efficiency and superiority. Plasticity and fluidity, good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

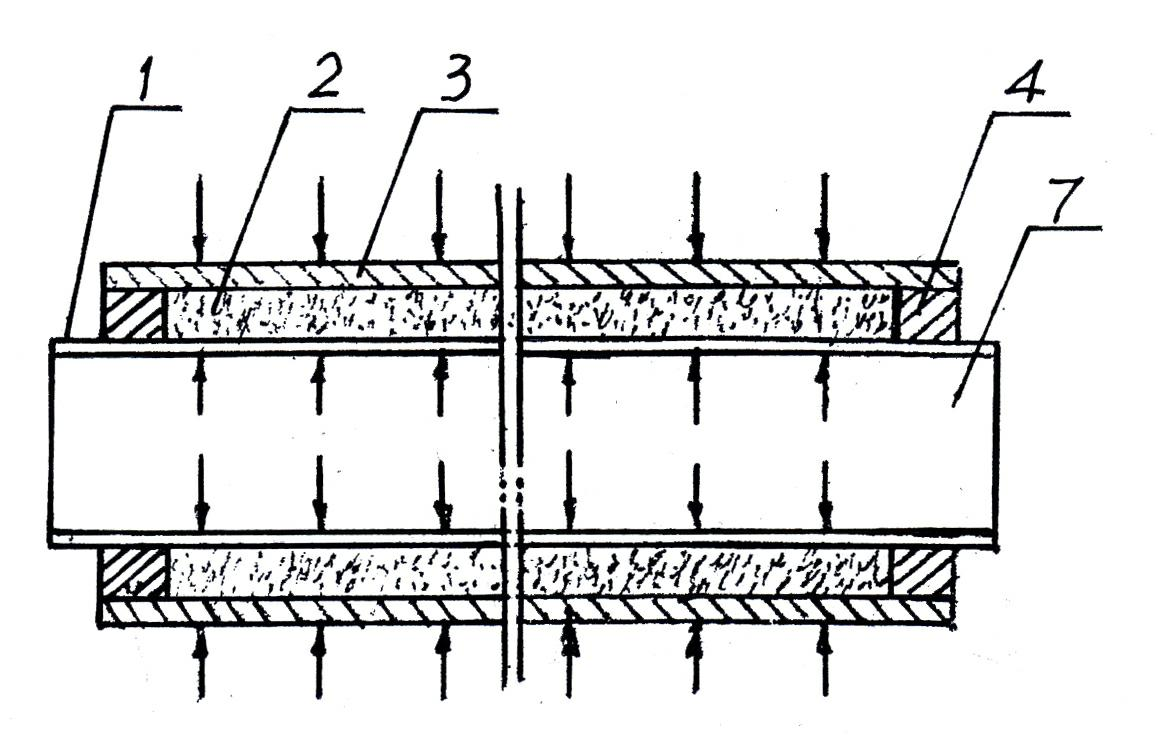

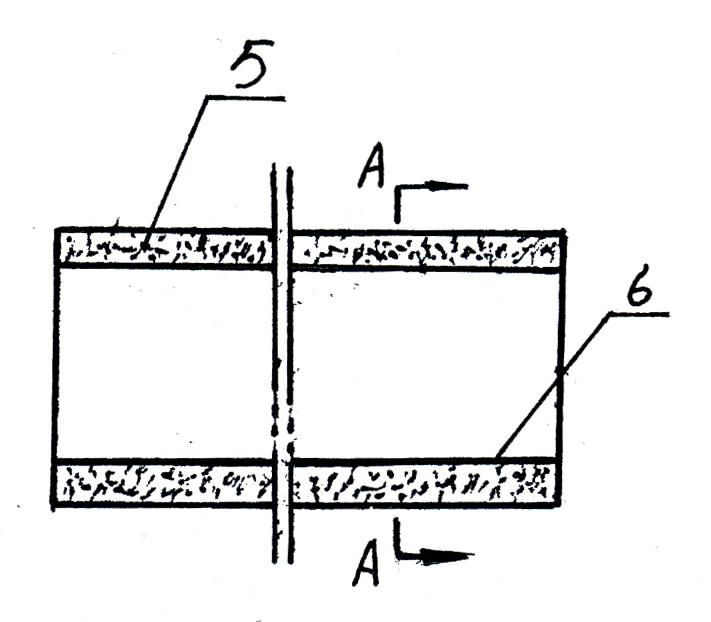

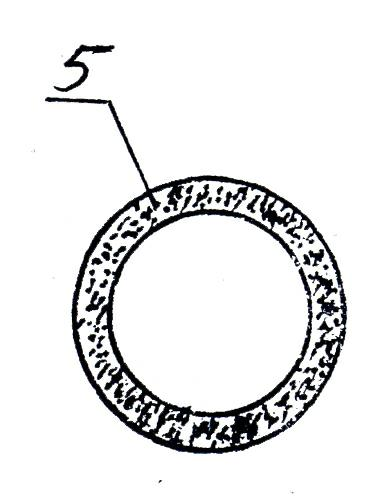

[0035] see figure 1 — image 3 As shown, the present invention manufactures high-precision thin-walled ceramic tubes by bidirectional isostatic pressing. The outer dimensions of the high-precision thin-walled ceramic tube body 5 are: length 5000 mm, inner hole diameter Ф50 mm, wall thickness 5 mm; The outer diameter of the inner mold tube 1 is Φ50mm, the wall thickness is 1mm, and the length is 5500mm.

[0036] The method steps of manufacturing this high-precision thin-walled ceramic tube are:

[0037] (1) Put the formula raw materials (calculated by weight percentage) 15-20% of alumina, 30-40% of corundum sand, and 30-40% of clay into a ball mill, add water equal to the weight of the formula raw materials, and ball mill for 2 hours , the obtained slurry is iron-removed, sieved, and press-filtered to form a mud cake, and then through vacuum mud refining, the obtained mud is stale for use;

[0038] (2) When the water content of the mud is 13-14%, add 1% methyl cellulose powd...

Embodiment 2

[0044] see figure 1 — image 3 As shown, the outer dimensions of the high-precision thin-walled ceramic tube body 5 of this embodiment are: the length is 3000 mm, the inner hole diameter is Φ20 mm, and the wall thickness is 1 mm; the outer diameter of the metal inner mold tube 1 is Ф20 mm, and the wall thickness is 0.6mm, length 3200mm. The formula mud is the same as the embodiment, the amount of methyl cellulose powder added is 2% of the weight of the mud, the water content of the mud after stale is 13%, the pressure of bidirectional isostatic pressing is 50MPa, and the pressure is held for 15 seconds. The method steps are the same as in Example 1. After two-way isostatic pressing, the diameter of the inner hole of the thin-walled ceramic tube body 5 is Ф20mm, the wall thickness is 0.8mm, and the inner wall 6 of the hole is smooth and clean, as bright as a mirror.

Embodiment 3

[0046] see Figure 4 — Image 6 As shown, the outer dimensions of the high-precision thin-walled ceramic tube blank 15 of this embodiment are: the length is 2000mm, the inner hole size is a square of 25mm×25mm, and the wall thickness is 1.5mm; the outer dimensions of the metal inner mold tube 11 are A square of 25mm×25mm, with a wall thickness of 0.5mm and a length of 2200mm. The formula mud is the same as in Example 1, the amount of methyl cellulose powder added is 3% of the weight of the mud, the water content of the mud is 14% after being stale, the two-way isostatic pressing molding pressure is 150MPa, and the holding pressure is 18 seconds. Process step is identical with embodiment 1. After two-way isostatic pressing, the inner hole of the thin-walled ceramic tube body 15 is a square with a size of 25mm×25mm, the wall thickness is 1.2mm, and the inner wall 16 of the square hole is smooth and clean, as bright as a mirror.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com