Brick reverse modeling auxiliary refractory material management method

A reverse modeling and brick technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems that cannot be realized, can only be used in the stage of material in and out of storage, and the brick model cannot be drawn, etc. To achieve the effect of precise matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

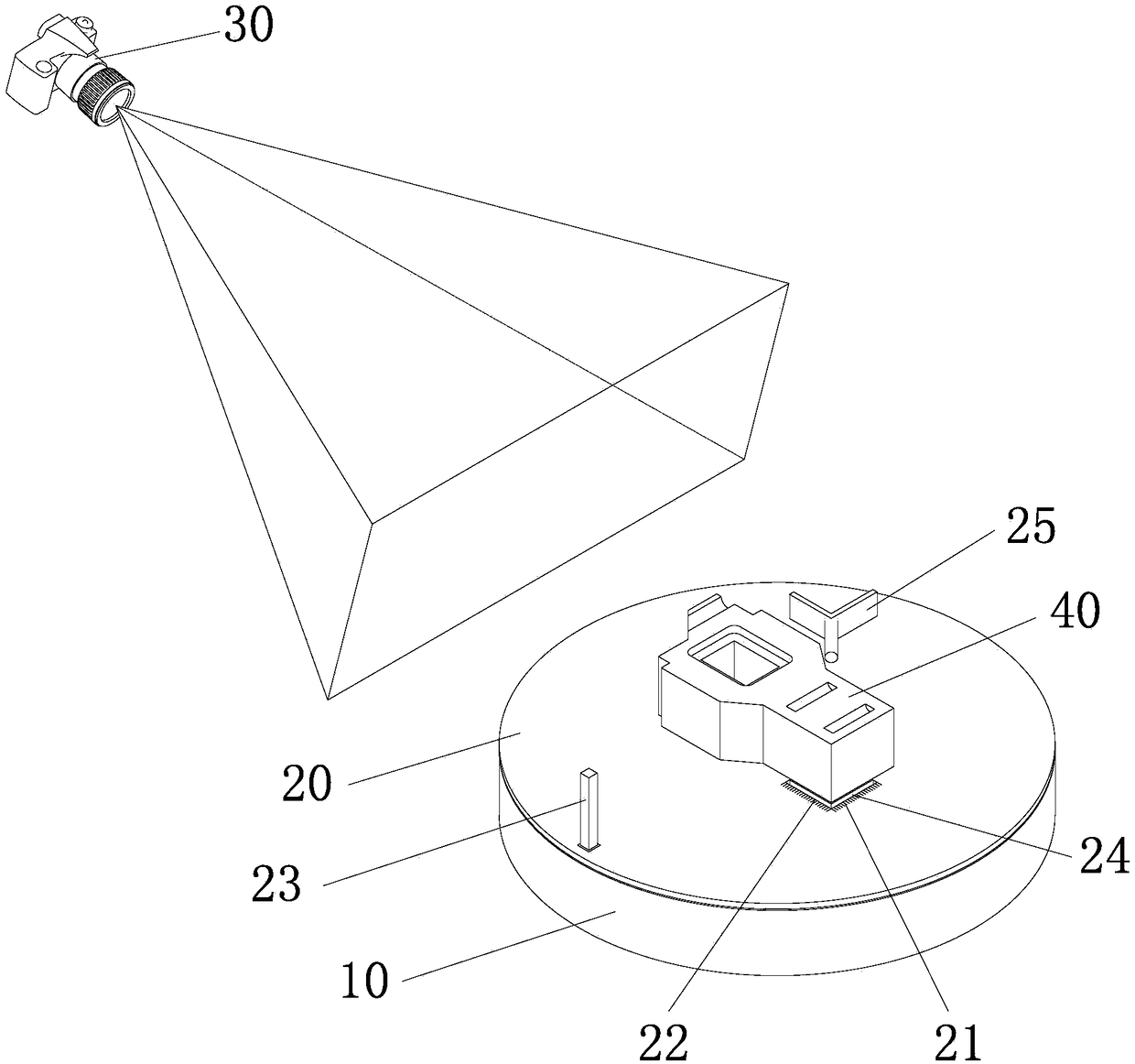

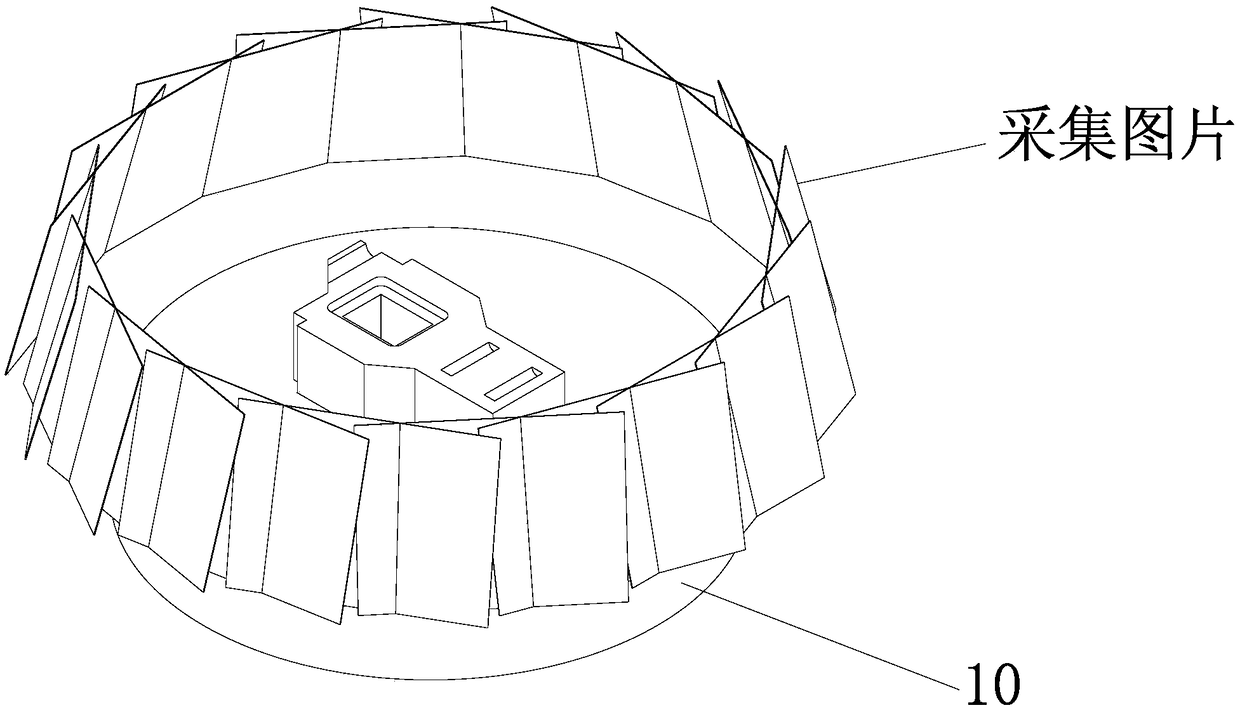

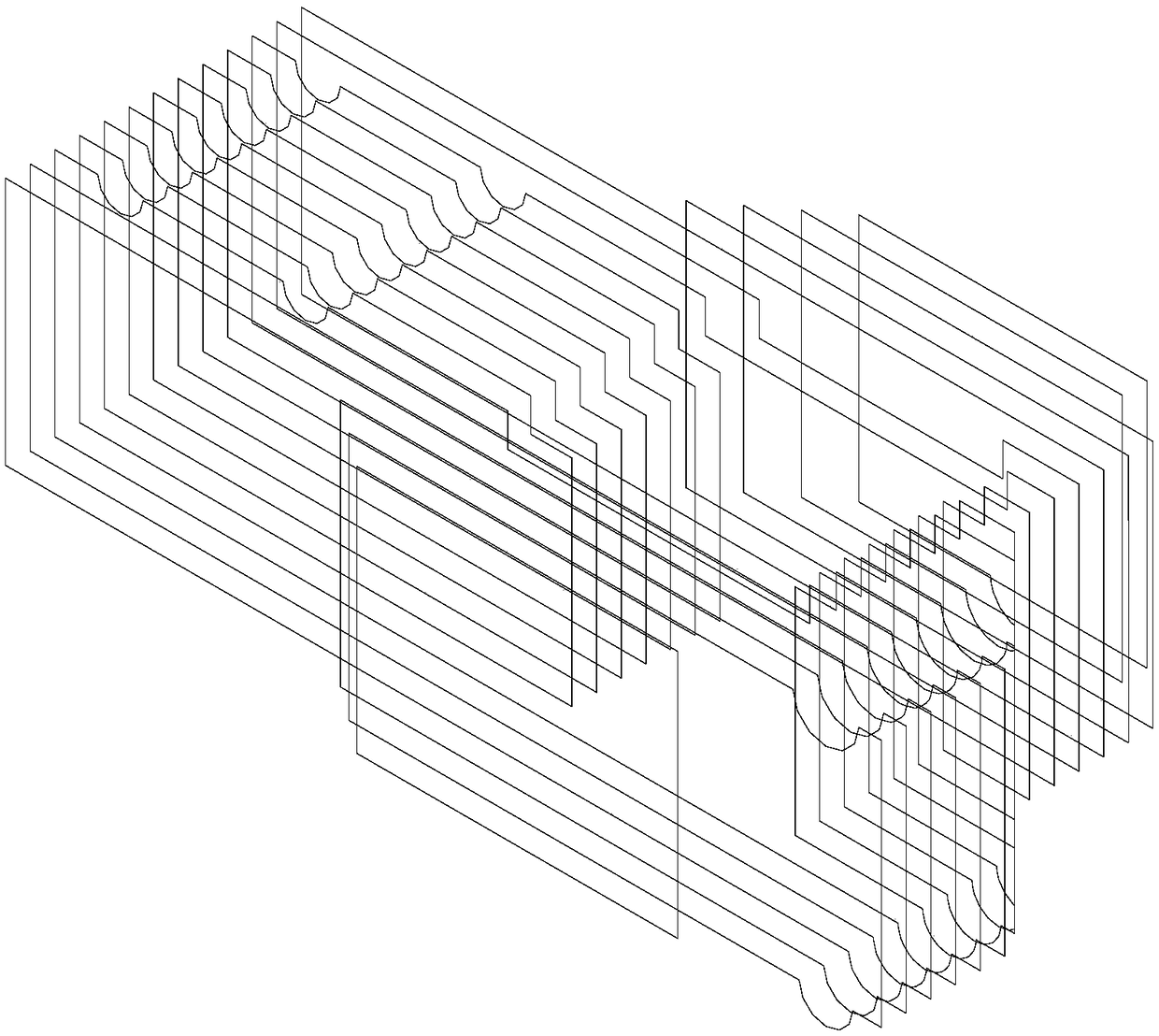

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0030] Such as Figure 1-6 As shown, the method of brick reverse modeling assisted refractory management proposed by the present invention is based on reverse modeling technology. First, the bricks are sequentially formed into a real scene model according to the used parts, and then the real scene model with dense grid surfaces is output as The obj format is imported into 3ds Max, the model is sectioned, and the section is generated as a two-dimensional graphic, that is, the three-view of the model reconstruction. Create brick family files through three-view, and load them into the project for combination, complete the construction of the model of each part of the coke oven masonry, plan the coke oven masonry according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com