Vacuum casting process method of photoelastic model

A technology of vacuum pouring and process method, which is applied in the field of plastic model casting, which can solve the problems of human injury, affecting the optical and mechanical properties of photoelastic models, and achieve the goal of avoiding damage, improving internal mechanical and optical properties, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

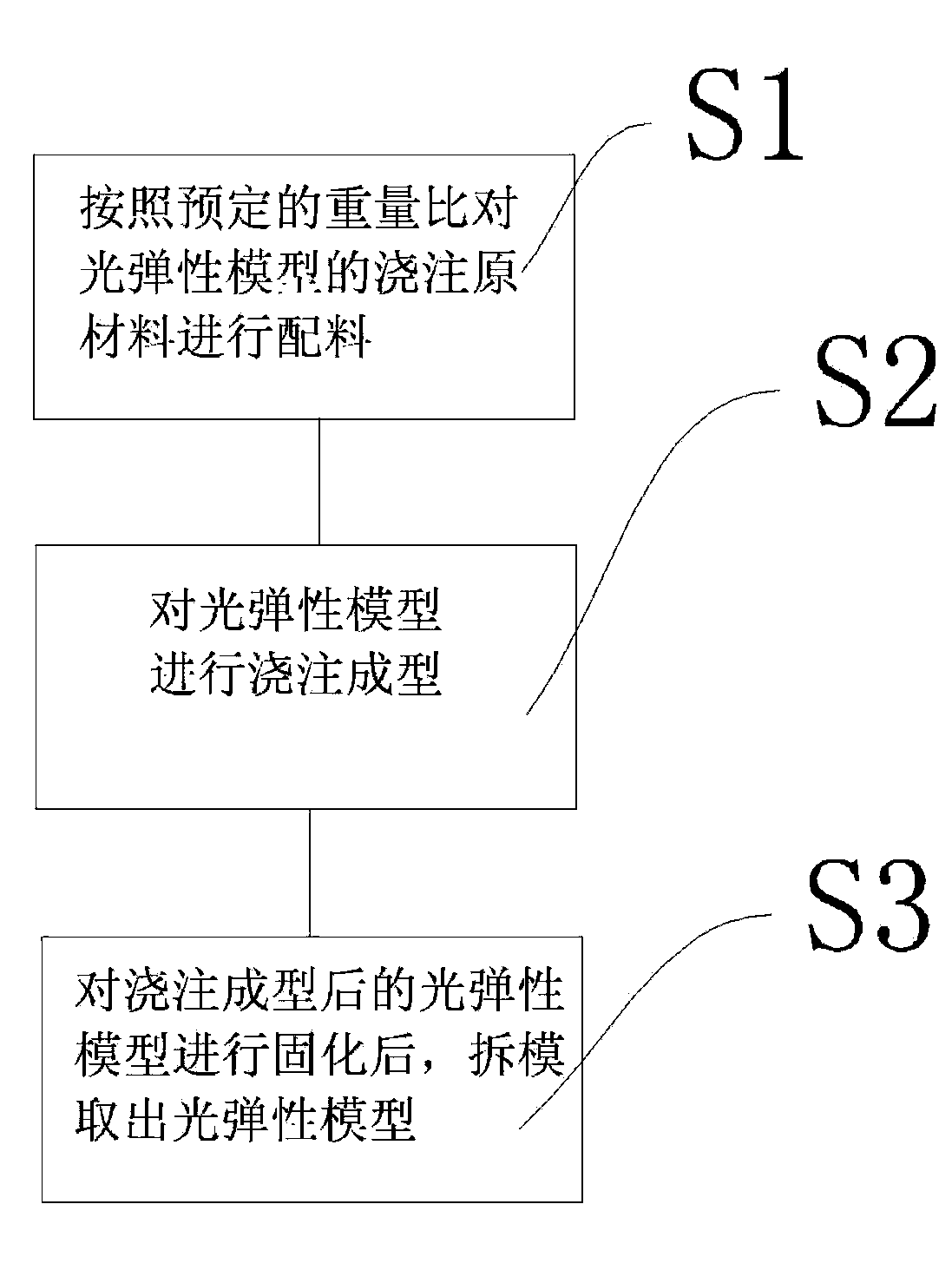

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0020] The vacuum casting process of the photoelastic model in the preferred embodiment of the present invention is carried out on a vacuum casting machine. The vacuum pouring molding machine is a vacuum casting molding machine disclosed in a Chinese patent whose announcement number is CN201501072U announced on June 9, 2010. The vacuum pouring molding machine includes a vacuum stirring control chamber, a model molding chamber and a control chamber for controlling the vacuum pouring molding machine. The model building room is also provided with a curing mold room with a lifting platform.

[0021] Before carrying out the vacuum pouring process of the photoelastic model of the present invention, the silicone rubber negative mold required for pouring m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com