Directional automatic folding device for corrugated carton gluing machines

A corrugated box and folding device technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of high cost, high labor intensity, low production efficiency, etc., and achieve precise geometric dimensions, good development prospects, and popular Large force area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

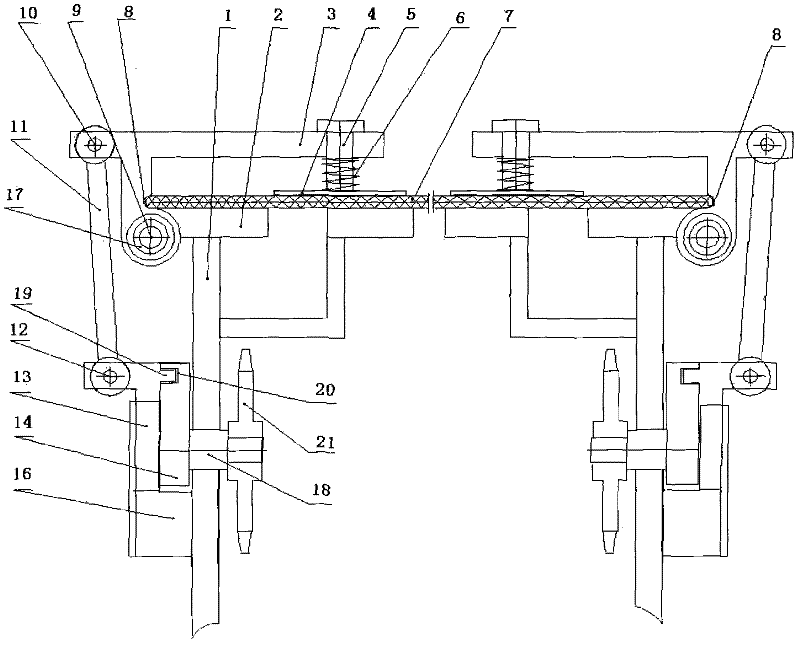

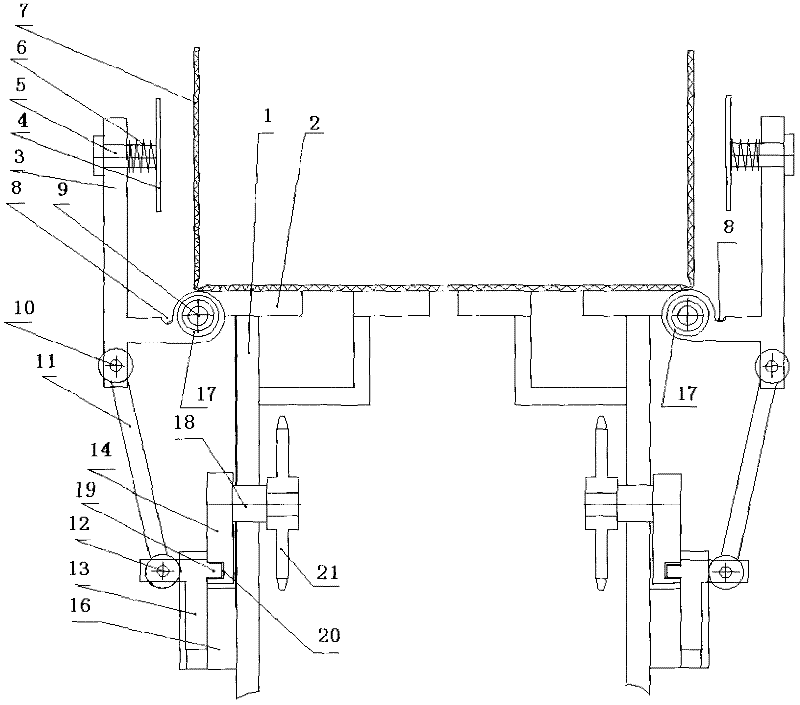

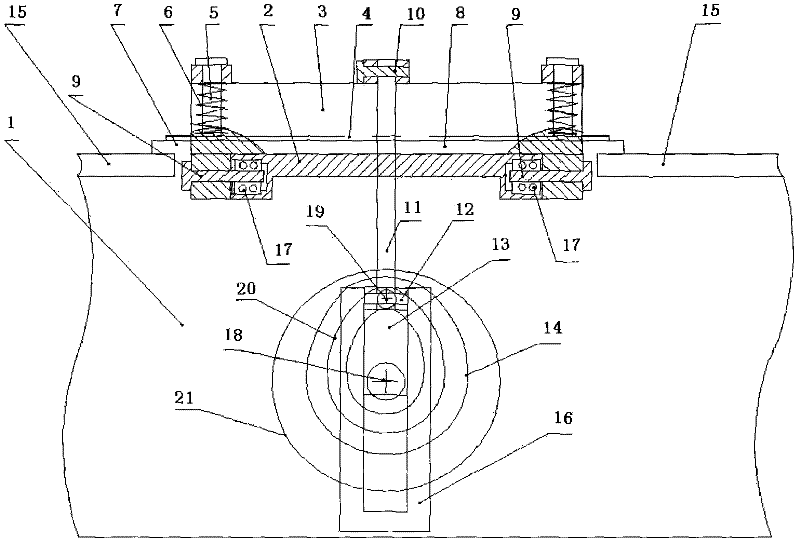

[0019]Embodiment 1: The directional automatic folding device of the corrugated box bonding machine of the present invention is symmetrically arranged on both sides of the corrugated box bonding machine, where the carton is folded from 90 degrees to 0 degrees, the folding substrate 2, the folding support Both the arm 3 and the pressing board 4 are made of stainless steel, and the surface of the board can be provided with a certain number of round holes or square holes to reduce the air resistance during movement. The sliding shaft 5 is provided with a spring 6, and the pressing board 4 is fixedly connected At the end of the sliding shaft 5, the inner surface of the positioning forming groove 8 is ground smooth so as not to grind the carton, and it should be made as long as possible to meet the needs of folding large-sized corrugated boxes. Folding in the positioning forming slot is not affected. The power source of the eccentric camshaft in this embodiment is the mechanical syn...

Embodiment 2

[0020] Embodiment 2: The power source of the eccentric camshaft described in this embodiment is the independent synchronous transmission of the servo control motor, and the servo motor is controlled and driven according to the prepared numerical control program so that it is synchronized with the directional automatic folding device. Others are the same as in Embodiment 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com