Ceramic mould for carbon fiber reinforcement resin matrix composite forming and preparation method thereof

A technology for strengthening resin-based and ceramic molds, which is applied in the field of mold manufacturing, can solve the problems of strict manufacturing temperature and environmental requirements, low-strength molding process, complicated and complicated processes, and achieves reduction of post-processing procedures, high strength, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a ceramic mold for forming carbon fiber reinforced resin-based composite materials includes the following steps:

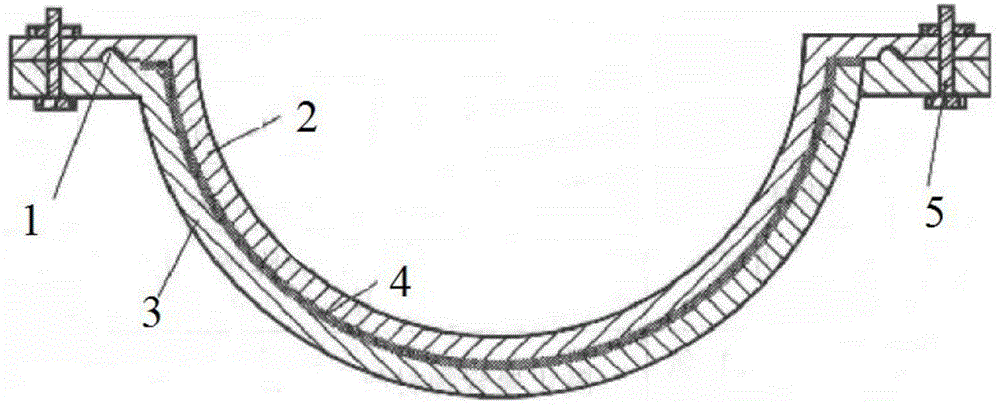

[0034] (1), design and make one as attached figure 1 The bowl-shaped prototype template; according to the adopted process, rationally design the mold structure, such as the clamping mechanism, the pouring system, the sealing system, the exhaust port design, the overflow port design, the ejection mechanism and other structures;

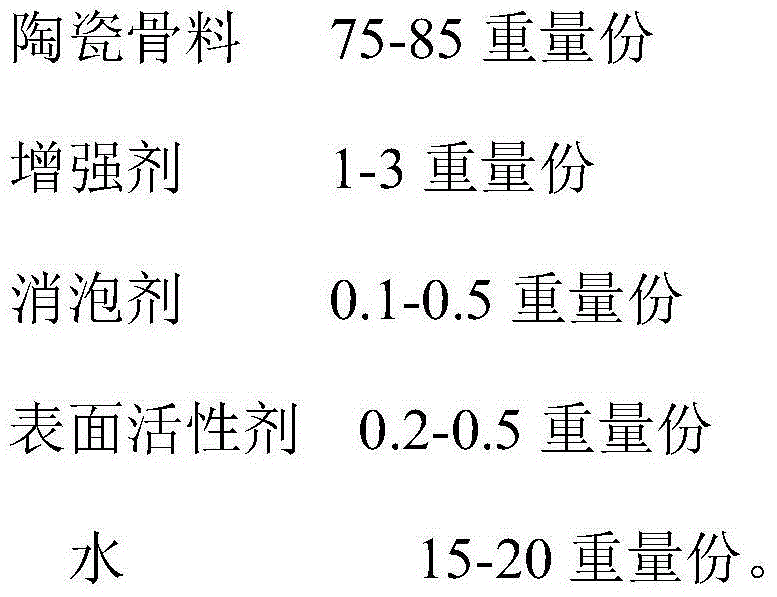

[0035] (2) Combine 45 parts by weight of porcelain powder, 30 parts by weight of alumina powder, 4 parts by weight of alumina, 2 parts by weight of 0.5mm carbon fiber reinforcement, and 0.5 parts by weight of defoamer (dimethyl silicone oil), 0.5 parts by weight of surfactant (sodium polymethacrylate) and 18 parts by weight of water are mixed uniformly to prepare a ceramic slurry;

[0036] (3) Apply the ceramic glue to the surface layer of the prototype template with a thickness of 1mm. After drying, apply the secon...

Embodiment 2

[0047] A method for preparing a ceramic mold for molding carbon fiber reinforced resin-based composite materials includes the following steps:

[0048] (1), design and make one as attached figure 1 The bowl-shaped prototype template; according to the adopted process, rationally design the mold structure, such as the clamping mechanism, the pouring system, the sealing system, the exhaust port design, the overflow port design, the ejection mechanism and other structures;

[0049] (2) Combine 40 parts by weight of porcelain powder, 35 parts by weight of silicon carbide powder, 5 parts by weight of alumina, 2 parts by weight of 0.8mm glass fiber reinforcement, and 0.3 parts by weight of defoamer (dimethyl silicone oil) , 0.2 parts by weight of surfactant (polycarboxylic acid dispersant) and 17.5 parts by weight of water are mixed uniformly to prepare ceramic slurry;

[0050] (3) Apply the ceramic glue to the surface layer of the prototype template with a thickness of 1mm. After drying, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com