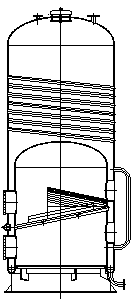

Boiler cylinder body pipe hole face mold and manufacturing method thereof

A technology of scribing template and production method, applied in manufacturing tools, workshop equipment, etc., can solve the problems of large amount of welding filling, poor appearance quality, easy to read wrong size, etc., and achieve uniform assembly gap and improved welding appearance quality. , The effect of accurate hole size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

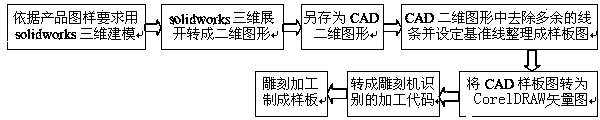

[0022] The steps of the present invention are described in detail below in conjunction with specific examples:

[0023] 1. For a certain type of boiler produced, first use the computer and Solidworks program to establish a three-dimensional graphic corresponding to the boiler shell in the computer according to the design requirements of the boiler shell tube hole;

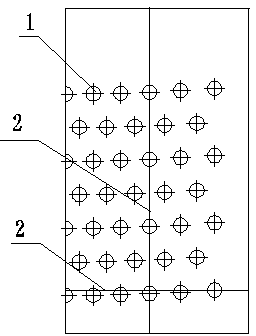

[0024] 2. Expand the three-dimensional graphics into two-dimensional graphics, and divide them into blocks according to the distribution of tube holes. The example diagram is divided into four areas, as shown in the attached figure 2 shown;

[0025] 3. Save the unfolding solidworks two-dimensional graphics as CAD format drawings;

[0026] 4. Trim the two-dimensional CAD graphics, delete the redundant lines that appear after the graphics are expanded, and determine the baseline of each block model;

[0027] 5. Convert CAD format drawings into CorelDRAW vector graphics format, and then edit and convert them into e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com