Spring clamp progressive die

A technology for feeding molds and mold bases, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of large size deviation, low yield, time-consuming and labor-intensive, etc., and achieve the effect of precise size and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

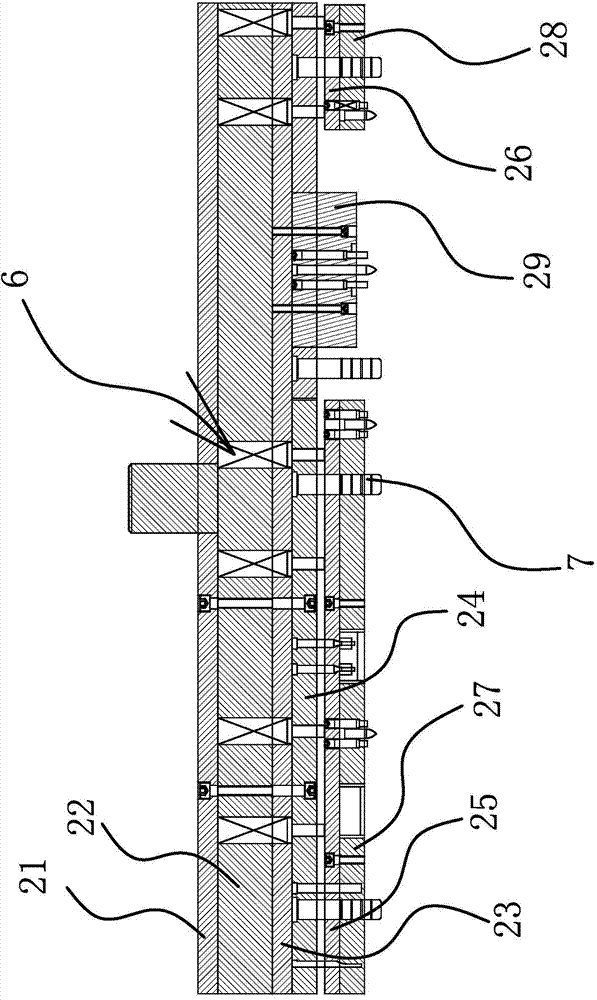

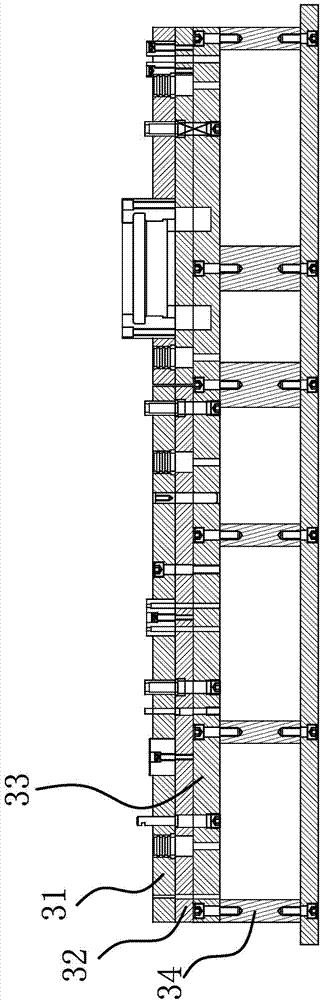

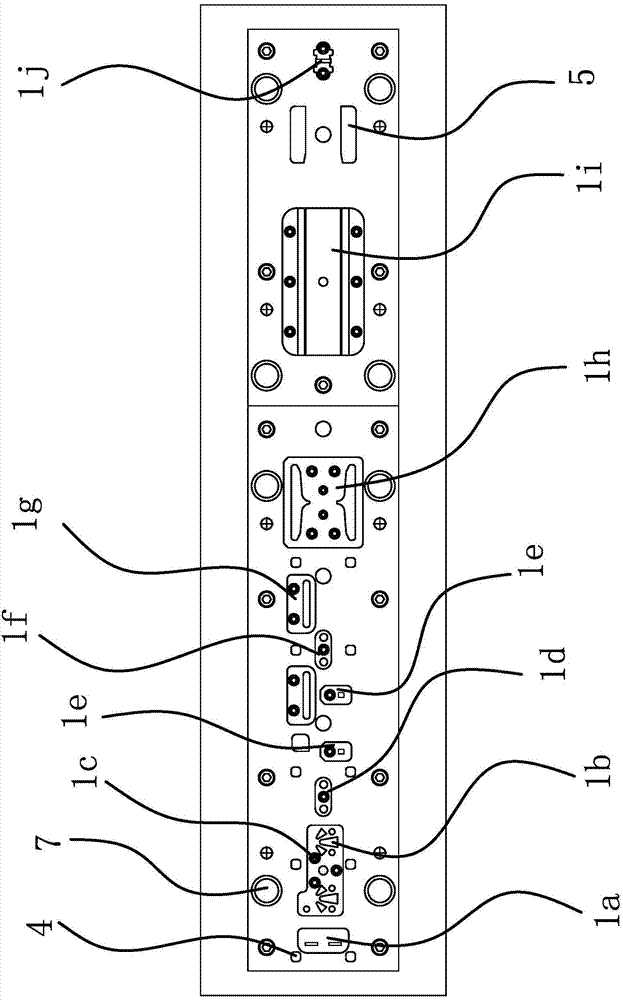

[0032] Such as figure 1 , figure 2 with image 3 As shown, a spring clamp progressive die includes an upper die base 22, a lower base plate 33, and a plurality of guide posts 7 arranged on the upper die base 22. The lower base plate 33 is sequentially provided with corner cutting inserts 1a and One bump insert 1b, punch insert 1c, first stretch insert 1d, second bump insert 1e, second stretch insert 1f, first waste insert 1g, second waste insert 1h , Bending molding insert 1i and cutting insert 1j, the upper mold base 22 is sequentially provided with a first elastic plate 27, a forming protrusion 29 and a second elastic plate 28, the first elastic plate 27 and the corner cutting insert 1a , The first bump insert 1b, the punch inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com